Abstract

The paper presents a case study of a full top-down basement construction using Secant Pile Wall (SPW) with top down slabs as both temporary and permanent shoring system in a coastal weathered sedimentary formation in Malaysia with upper highly permeable course grained sandy alluvial deposits within the excavation depth. This full top-down excavation method and wall embedment into the hard weathered sedimentation formation have achieved a well-controlled ground deformation with minimal acceptable ground distresses and excavation seepage quantity as expected. In view of the expected high water table near to the coastal course grained alluvial deposits, design option of using drained raft with passive pumping system to handle the seepage inflow was explored and adopted to avoid the costly tension piles and thick basement slab. The secant pile wall embedded into the weathered sedimentary formation, which is not far from the lowest basement level achieved fairly satisfactory performance in reducing seepage inflow. Recharge wells were provided as mitigation measure for drawdown control during basement excavation construction and operational life time of the basement. During the investigation, there was an expectation of the inclined saline water intrusion interface with depth, which was confirmed from the increasing salinity profile of soil samples with depth. Such saline intrusion, which is not usually a focus of excavation projects near coastal areas, can cause durability and maintenance problems to the planned drained raft system and operational equipment. This paper shares the design performance data of the basement wall behaviours and seepage regime in the unusual sandy alluvial deposits in Malaysia.

Access provided by CONRICYT-eBooks. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

The case study in this paper presents the challenges in re-developing an occupied site located in the downtown of capital city of Sabah state in Malaysia. The proposed new development mainly consists of one block of 14-storey office tower with four (4) levels of basements. The maximum depth of excavation below the existing ground level is about 14.1 m to accommodate a 4-storey basement. The main geotechnical concern of this basement excavation construction is that the ground movement associated with the lowering of groundwater during temporary excavation stage and operational stage may cause potential distresses to adjacent existing structures and underground utilities surrounding the development site. Hence, to minimise the ground movement, a full top-down basement construction using Secant Pile Wall with top-down floor slabs as both temporary and permanent shoring system was adopted. On other hand, to resolve the hydrostatic uplift pressure from the high groundwater table to the basement structure during operational life time, design option of using drained raft system with passive pumping system and recharge wells to control the groundwater drawdown was adopted, instead of using costly tension piles and thick basement slab. As the development site is very close to the coast, saline water intrusion profile was also investigated in the durability assessment.

2 General Geology and Subsurface Information

Based on the published geology map, the site is underlain by Crocker formation, which is generally sedimentary rock formed during the Oligocene Epoch consisting of flysch-type sandstone, shale, siltstone with tuff, limestone breccia and agglomerate. Due to intense weathering process of tropical climate and regional tectonic actions, these sedimentary rocks have been subjected to physical and chemical weathering processes in reducing its engineering characteristic, particularly at the upper stratum.

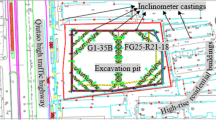

A total of 23 nos. of boreholes were sunken within the 2.2 acres site to investigate and ascertain the subsoil stratigraphy meanwhile four (4) water standpipes were installed at the selected boreholes to monitor the groundwater table regime as shown in Fig. 1. The subsoil stratigraphy for the site generally can be classified into four (4) strata according to the reduce levels: (1) Ground level at RL+2.3m down to RL0.0m: Backfill; (2) RL0.0m to RL–11.0m: Alluvial Deposits; (3) RL–11.0m to RL–19.0m: Weathered Residual Soil; and (4) RL–13.0m to RL–19.0m or deeper: Crocker Formation.

The detailed subsoil stratification interpreted from the borehole logging is illustrated in Fig. 2. Rock head is generally encountered at about RL–19.0m over the entire site, except for the south-east corner area where rock head is somehow shallow at RL–13.0m, which is only slightly deeper than the lowest basement slab level. From standpipe monitoring, the groundwater table is found to be near to ground surface, i.e. at 1 m beneath (RL+1.3m). This is understandable in view of the close proximity (about 600 m) of the site to the coast line where the mean sea level is high and also subject to tidal highs and lows.

3 Full Top-Down Construction Method with Secant Pile Wall

The site has a shape of nearly perfect square with 94 m in length (parallel to north-east direction) by 104 m in width (parallel to south-east direction) and is surrounded by busy road networks with a roundabout at the corner of site, and adjacent buildings (such as hotel, retail shops, government institution, etc.) located immediately across the roads. Without the as-built information of the foundation type and details of those nearby existing structures, the ultimate objective of the basement construction method will have to consider minimizing the potential ground movements in both ground settlement and lateral displacements due to the deep excavation and the associated groundwater drawdown. Hence, full top-down basement construction method using Secant Pile Wall with lateral supports from basement floor slabs was adopted as there was also pressing need to complete the superstructure and handover to the anchored tenant under the agreement. This development is designed with certified LEED Silver Rating Level in the energy efficient and environmental friendly design.

Secant Pile Wall is formed by installing hard cast-in-situ reinforced bored piles (secondary pile with reinforcements) by overcutting the completed soft piles (unreinforced primary piles) along the designated wall alignment. Primary piles without any reinforcing bars are installed first with secondary piles constructed in between primary piles once the latter attain concrete setting without gaining its full strength. The secondary piles are reinforced with steel cage designed to take the design ultimate bending moments and shear forces resulted from soil-structure interaction analysis of staged excavations and constructions. Typical detail of the Secant Pile Wall configuration is shown in Fig. 3.

The Secant Pile Wall was generally embedded into the weathered sedimentary rocks with rock socket length ranging from 0.5 m to 1.0 m depending on the rock head level. In some cases, which the rock head level is very deep, the maximum length of primary piles and secondary pile were 19.6 m and 24.0 m respectively. The toe of SPW are down to 10 m below the soffit the lowest basement slab unless the bedrock level is encountered at shallow depth. Two sections (Fig. 1) showing the SPW with toe levels, floor slab levels and excavation stages are shown in Figs. 4 and 5.

Full top-down construction is a method for deep excavation and basement construction in which the permanent basement floors are constructed simultaneously as the excavation progresses in stages to facilitate the basement floor slab construction. At the same time, the superstructure construction with plunge-in column supports can also commence at the ground floor up more or less simultaneously with the basement excavation in order to expedite the overall construction programme, particularly with short construction duration contractually. For this project site, the overall basement excavation and construction sequence is outlined in Table 1 below.

The top-down construction begins with basement wall installation and also load-bearing foundation carrying the building structure. In other words, the foundation piles and basement columns are constructed before any basement excavation takes place. When the basement excavation works commence, the construction of the superstructure is also started, in which the self-weight of the superstructure is supported by the plunge-in columns embedded into the foundation piles as described below. These basement columns comprise of plunged-in columns using steel stanchions embedded into the underlying foundation bored piles constructed up to the cut-off level with reasonable concrete overcasting for accommodating the upwards displacing contaminated tremie concrete. First excavation was carried out and the top basement slab was casted with proper connection to the steel plunge-in columns. After the concrete floor has gained sufficient strength for formwork removal, soil under the top basement floor was further excavated to the next designated excavated level. And the similar procedures were repeated for the next basement floor until the Final Excavation Level (FEL). The ground floor slab is usually strengthened structurally as working platform with design loading provision catered for construction machineries and temporary storage of materials. Openings were allowed at the locations of the lift shaft or access ramp areas within the ground floor slab and every basement slabs (except lowest basement) to facilitate transporting construction materials in and also removal of spoil materials. Compact earthwork machineries suitable for very tight working space were used. Figures 6 and 7 show the top-down basement construction activities for this case study. The advantages and disadvantages of top-down basement construction can be summarised in Table 2.

4 Drained Raft Conceptual Method

Hydrostatic uplift problem arises after complete sealing of the lowest basement slab and the build-up of the recovered hydrostatic groundwater head exceeds the structural capacity of the slab or the dead weight of the structure, the basement floor slab will crack or, more catastrophically, surfer upward punching shear failure at supports or flexural failure at the mid spans. These limit state damage can be resolved structurally by tension anchorage piles tying down the basement slab or/and providing significantly thick slab as counterweight. Another solution is to reduce the hydrostatic uplift action using drained raft, which is primarily a drainage solution with introducing the underlying free draining filtered granular layer beneath the basement slab and half-perforated subsoil collection pipes connecting to several sump pits. The permanent underlying subsoil drainage can only passively reduce building-up of hydrostatic uplift pressure from the recovery of groundwater regime back to the steady state groundwater regime after completion of lowest basement slab. Electrical submersible dewatering pumps with automatic on/off controls by designated triggered water levels. The typical detail of drained raft is shown in Fig. 8. As the basement slab has its own self-weight and structural strengths of the floor slabs with support reactions from the internal columns and the basement wall, the basement floor slab can still withstand fair amount of hydrostatic uplift pressure. In this case, the basement slab can handle about 10 kPa uplift pressure in serviceability limit state. For a more prudent design consideration, the floor slab design has allowed for crack induced design to release the excess uplift pressure in a control manner if the unexpected uplift pressure builds up due to failure of the subsoil drains.

The mechanism of the drained raft to reduce uplift pressure is by intercepting any seepage flow reaching the free draining filtered granular drainage layer with phreatic surface at atmospheric pressure, diverting the collected seepage water in subsoil pipes connecting to circular concrete ring deep sump pits, and lastly discharging the collected seepage water away from the basement to ground surface drainage using high capacity electrical pumps when the full storage threshold is triggered. The design requirements of the filtered granular layer and perforated subsoil pipes have to fulfil two (2) main functionality, namely the high permeable conveyance drainage capacity and the filter retention to prevent internal erosion of the foundation soils. Meanwhile, the volumetric capacity of the sump pits and electrical pumps shall be reasonably configured to more than the rate and anticipated total volume of water ingress into the basement in the seepage analysis and calculation. Given the upper layer of highly permeable course grained sandy alluvial deposits within the excavation depth as shown in Fig. 9, seepage analyses considering upper bound and lower bound soil permeability were cautiously performed and site evaluation of the measured seepage ingress rate and volume was also implemented during the excavation stages (refer to the result and discussion in Sect. 5.2). The estimated seepage rate with the two bound limits ranges from 40 m3/day to 135 m3/day.

5 Results of Instrumentation Data During Construction Stage

For any basement excavation project, it is both important and useful to implement instrumentation scheme to monitor the actual magnitude of lateral soil movement, wall deflection profile, settlement of the retained ground, seepage rate with fluctuated groundwater table regime at the retained side due to tidal fluctuation and the changing hydraulic boundary at the excavation side at various excavation stages, etc. The actual performance results with measured magnitudes have been timely reviewed and have the ground models recalibrated at all time for subsequent prediction at corresponding construction stage of analysis. The following two (2) sections will discuss the instrumentation data of wall lateral movement and seepage ingress respectively.

5.1 Actual Wall Lateral Movement Against Prediction

There were total of five (5) inclinometers installed inside the selected secondary piles of the Secant Pile Wall at the critical sections. These inclinometers in the wall were regularly monitored before and after each stage of excavation and by weekly basis during the basement excavation and shoring floor slab construction. Meanwhile, three (3) sets of threshold levels (i.e. Green, Amber and Red Zones) were established from the analytical prediction during the design stage for monitoring and determining the implementation of emergency response where necessary. Appropriate actions will be taken according to the construction specifications if the instrumentation results exceed the designated threshold levels during the review. Preparation of implementing emergency action and caution of following up the developing trend will be exercised when the results fall within Amber zone and shall implement the planned action immediately when entering into Red zone. Figure 10 shows two (2) sets of inclinometer readings (location of INC-1 and INC-4 as shown in Fig. 1) recorded throughout the construction period.

The threshold level of Red zone is equal to the maximum wall lateral displacement predicted from the soil-structure interaction analysis for the entire stage of excavation and construction works. Meanwhile, the threshold level of Amber zone is taken as about 85% of the expected maximum lateral deflection. It shall be noted that the specified threshold limit for the inclinometer reading is an absolute magnitude, not the deflection profile/trend. The measured wall deflection profile will theoretically match with cautious estimate whilst the exact magnitude of the lateral movement is harder to predict accurately. As such, it is more critical to monitor the measured value against the analytical prediction and observe the developing incremental trends.

As observed from the measured inclinometer readings in the A-axis (towards the excavation face), the wall deflection occurred in a profile where lateral displacement at the top wall level is the largest and gradually reduces with depths until the apparent fixity at the firm ground. Hence, it is surmised to deduce that the most critical wall deflection had occurred during the first stage of excavation down to a meter below Basement 1 slab in which the SBP wall was in cantilever condition with ground floor slab yet to be constructed. Thereafter, all subsequent excavation works had caused the retaining wall to deflect further inwards. The measured magnitudes of wall deflection from the above two inclinometer readings have exceeded the predicted value. When the threshold level was breached, this had prompted the site team to conduct daily inspection on the surrounding retained ground to examine the signs of distress and damages. As shown in Fig. 11, minor ground settlement at the active zone behind the wall was found on the road pavement and rectification works using cement grout to seal the cracks was carried out immediately. This ground depression in the active zone will be obvious when the wall deflects in the cantilever condition. Inclinometer INC-4 shows larger wall deflection primarily due to low stiffness floor slab support with the existence of opening voids for construction access as shown in Fig. 7.

5.2 Actual Seepage Ingress into Basement Excavation Against Prediction

There were four (4) temporary groundwater extraction wells constructed with installing 500 mm diameter and 6 mm wall thickness mild steel slotted pipe casing until about 18 m depth below ground surface. The main purpose of these temporary extraction wells was to ensure a relatively dry excavation base for the working platform. The water seeping into these open wells were extracted using submersible pumps via temporary hose piping system with flow meter to measure the off-site discharge into the nearby existing storm water drainage. The flow meter was read for recording the daily volume of water pumped out from each well. Figure 12 shows the flow meter readings for three (3) wells whilst the fourth well was not successfully monitored due to technical fault in the measurement.

It was observed that the actual volume of water pumped out for each well ranged from 0 m3/day (dry) up to 60 m3/day. Flowmeter No. 2 which was installed in the well located at the north-east side of the site recorded higher inflow of groundwater. In geographical view, the coast line is located parallel with the western boundary of the site meanwhile further east side of the site lays the inland. Generally, this augurs well with the prediction. However, it is important to realise a fact that the SPW has embedded into the hard and weathered Crocker formation and some even into the rock mass of Crocker formation. It was believed that the SPW embedment has somehow effectively cutoff the groundwater seepage regime in the alluvial layer. Figure 9 also evidences that there is a reduction of permeability with depth. If the seepage is effectively cutoff, the groundwater regime shall maintain pretty much in the initial state of ambient hydrostatic condition with phreatic line at approximately RL+1.3m. The groundwater condition beneath the excavation will be also of hydrostatic profile, but at lower piezometric head with atmospheric pressure at about RL–13.3m. Thus, there will be hydraulic difference of about 14.6 m along the seepage path of 17 m to 29 m along the SPW.

6 Saline Water Intrusion

Based on the site hydrogeological and geomorphological conditions, it is logical to expect the fresh groundwater flow regime from inland hilly catchment areas towards the coast where terrain elevation and groundwater level is at its lowest. This naturally steady flow movement of fresh water towards sea prevents denser salt water from entering fresh water coastal aquifers. Saltwater has a higher content of dissolved mineral salts, thus resulting its higher density than fresh water. The higher hydrostatic pressure of the heavier salt water, dispersion and diffusion effects form a wedge-shaped intrusion interface into coastal aquifers underlain the fresh water flow body. The salt water and fresh water meet in a transition zone where mixing occurs through dispersion and diffusion.

The distance between the project site and the coastal shoreline is very near, i.e. about 600 m only. Therefore, there would be saline water intrusion occurred within the subsurface region. Based on Ghyben-Herzberg relation by Verrjuit (1968), the saline water intrusion interface can be approximated as shown in Fig. 13. Sampling and laboratory testing of groundwater collected from the site were also conducted to confirm the hypothesis of this salt-water interface. In this case study, the groundwater samples were collected from the recovery of groundwater at the base of casing during performing rising head permeability tests after two times pumping-out of borehole water. However, it is suggested that more appropriate sampling method is to extract the pore water from undisturbed soil samples in order to better preserve the chemical content.

As presented in Table 3, it is evident that there is increasing salinity profile of groundwater samples with depth. With the 14 m difference in the piezometric head between the ambient groundwater regime outside the basement and the passive drained raft design inside the basement with wall embedment into formation with higher salinity, the collected water seepage at the drained raft can be of some degree of salinity. Therefore, corrosion of the pumping system and any metallic components along the pipe network can be of shorter life span due to some corrosion. The potential solution is to use less metallic components to lengthen the entire pressure relief system.

7 Conclusion

This paper presents the case study of full top-down basement construction work using Secant Pile Wall (SPW) with permanent top-down slabs as shoring system in coastal weathered sedimentary Crocker formation in the capital city of Sabah, Kota Kinabalu. The actual wall deflection performance as measured by inclinometers in the SPW was slightly more than the prediction established from soil-structure analysis during the design stage. Besides that, drained raft system was successfully constructed as attractive alternative of the costly tension pile option or/and the thick basement slab, to cater for the high hydrostatic uplift pressure. From the measurement of the water quantity pumped out from the collection wells, the actual volume of water ingress was somehow less than the prediction based on steady state seepage analysis during the design stage. The effective cut-off by SPW to maintain the hydrostatic groundwater profile in the highly permeable sandy alluvial layer was observed. The seepage collected at the Basement 4 subsoil drains is likely another groundwater regime in the jointed rock mass of Crocker formation, which can be differentiated from perched groundwater regime in the over burden alluvial deposit and weathered residual soils derived from Crocker formation. It is also interesting to note that saline water intrusion was detected at this site as expected due to the close proximity to the sea shore as evidenced in the groundwater samples collected from the rising head permeability tests. Saline water can cause corrosion of steel elements and thus affect the durability of all reinforced concrete structures. Therefore, caution advice had been highlighted to the asset operator on the need for necessary maintenance or replacement of any corroded components in the pumping system.

Reference

Verrjuit, A.: A note on the Ghyben-Herzberg formula. Bull. Int. Assoc. Sci. Hydrol. 13(4), 43–46 (1968). Technological University, Delft, Netherlands. Accessed 21 Mar 2009

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2018 Springer Nature Singapore Pte Ltd. and Zhejiang University Press

About this paper

Cite this paper

Liew, SS., Ting, DI. (2018). Design of Full Top-Down Basement Construction with Drain Raft Concept Over Coastal Weathered Sedimentary Formation in Malaysia. In: Chen, R., Zheng, G., Ou, C. (eds) Proceedings of the 2nd International Symposium on Asia Urban GeoEngineering. Springer Series in Geomechanics and Geoengineering. Springer, Singapore. https://doi.org/10.1007/978-981-10-6632-0_48

Download citation

DOI: https://doi.org/10.1007/978-981-10-6632-0_48

Publisher Name: Springer, Singapore

Print ISBN: 978-981-10-6631-3

Online ISBN: 978-981-10-6632-0

eBook Packages: EngineeringEngineering (R0)