Abstract

A proper load-transfer (or t-z) model describing the pile and surrounding soil interaction is important for accurately predicting the behavior of piles. This paper presents a nonlinear prediction approach of load-displacement response for vertically loaded single pile based on a load transfer method by introducing a proposed t-z model for pile-soil interface. The proposed t-z model comprises a hardening/softening mechanism which is able to capture the hardening and softening behavior of pile-soil interactions. Combined with a linear load-displacement relationship of pile tip, a highly effective computer program has been developed for nonlinear analysis of the load-displacement behavior of a vertically loaded single pile. And also, predictions of t-z curves and load-settlement curves from the proposed approach have been compared with the measured values from two well-documented field experimental pile loading case studies. The results of the comparisons indicate that the predictions show good agreement with the measured values.

Access provided by CONRICYT-eBooks. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Pile foundation is commonly used for support loading from super structure of vertical forces because of its high capacity, small settlement, good suitability and wide applicability. The analysis of load-deformation response of single piles is an essential basis for pile foundation design. The most reliable method to determine the response of the piles is based on the results obtained from pile load tests, but it can be expensive and time-consuming. Consequently, the theoretical method for analyzing the load-settlement behavior of single piles is essential for engineering design.

A number of theoretical methods are used to predict load-settlement for single pile, including the load-transfer method (Kraft et al. 1981), the shear displacement method (Randolph and Wroth 1978; Guo and Randolph 1999), the finite-element method (Said et al. 2009), and other simplified analytical methods (Zhang and Zhang 2012). The load-transfer method has widely used for prediction of the load-deformation relationship for vertically loaded single pile due to its simplicity and capability of incorporating nonlinear soil behavior. The load-transfer (or t-z) curve is the graphical representation of the unit skin friction attributable to the vertical displacement of the pile relative to the surrounding soil in each geological stratum, and varies with depth, soil-pile interface friction angle, and type of pile installation. Numerous t-z models or functions have been proposed for the prediction of the t-z curves, including empirical functions (Colye and Reese 1966; Vijayvergiya 1969; Reese and O’Neill 1989) and theoretical functions (Randolph and Wroth 1979; Kraft et al. 1981). While the empirical functions are very site-specific and may produce error up to 100%, for example, Coyle and Reese (1966) reported that the error between the computed and actual bearing capacities of piles varies from −52% to +61% using their empirical t-z curve. The theoretical functions are more attractive because of the flexibility with which site specific strength, stress-strain behavior and stress history of soils, pile-soil interaction as well as pile installation can be readily incorporated.

To account for the nonlinearity in the stress-strain hardening response of soil, the theoretical t-z curve is usually taken to be hyperbolic function to simulate the relationship between unit skin friction and pile soil relative displacement developed along the pile-soil interface (Kondner 1963; Duncan and Chang 1970). However, laboratory and field observations suggest that skin friction softening phenomenon occurs at pile-soil interface in clay and cemented soils (Randolph and Gourvenec 2011; Zhang and Zhang 2012). The skin friction softening behavior is generally attributable to the decrease in the interface friction angle along the residual shear surface developed in the pile-soil interface (Nanda and Patra 2014). Although the empirical t-z curves included skin friction softening behavior reported by Coyle and Reese (1966) and the theoretical t-z curves by Vijayvergiya (1969) and Zhang and Zhang (2012), a few theoretical t-z models account for the skin friction softening behavior in detail.

This paper presents a nonlinear prediction approach of load-displacement response for vertically loaded single pile based on the load transfer method by introducing a proposed theoretical t-z model for pile-soil interface. The proposed theoretical t-z model comprises a hardening/softening mechanism which is able to capture the hardening and softening behavior of pile-soil interactions. Combined with a linear load-displacement relationship for pile tip, a highly effective computer program has been developed for nonlinear analysis of the load-displacement behavior of a vertically loaded single pile. The proposed t-z model can be used for all soils (clay and sand), and the proposed method can be used for homogeneous soil and inhomogeneous layered soil system. Two case studies with different soil strata are considered for validation.

2 Proposed t-z Hardening/Softening Model for Pile-Soil Interface

2.1 Pile-Soil Interaction

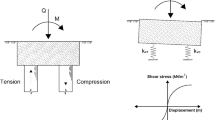

The mechanical behavior of pile-soil interaction within the interface is rather complex, which affect by pile-soil interface roughness, composition of soil, relative density, grain-size distribution, shape of soil particles, moisture content of soil, magnitude stress level, and rate of shearing (Evgin and Fakharian 1997). The relationship between shear stress and shear displacement for the pile-soil interface at a same constant normal stress (σ ni ) may be either hardening or softening, which depends on the void ratio in granular soil and on the Atterberg limits in fine soils. For example, Cao et al. (2014, 2015) conducted large-scale shear tests on sand-concrete interface shearing behavior under constant normal stress and found that shear stress mobilized rapidly in the initial shear displacement and thereafter the rate of shear stress mobilization decreases considerably with the shear displacement for relative denseness D r = 21.6% as shown in Fig. 1, Type 1. For D r = 72.5%, after an initial increase in unit skin friction, softening behavior occurred (Fig. 1, Type 2).

The variation of shear stress with shear displacement (after CAO et al. 2014, 2015)

2.2 Modified Hyperbolic t-z Hardening Model

Based on the schematic diagram shown in Fig. 1, for type 1 in the hardening regime the t-z function is assumed of hyperbolic type, it can be written as follows (Duncan and Chang 1970):

Where τ z and Δ z are the unit skin friction and pile-soil relative displacement at give depth, z, respectively; and a, b are empirical coefficients, which can be obtained in the following form:

Where, G0 is initial shear stiffness (tangent of the hyperbolic curve at the origin); τ zult is limiting unit skin friction.

The initial shear stiffness, G0, is an important parameter related to accurately predictions of the t-z curves. Several investigators have reported that the limiting initial shear stiffness value of very small strain varies from 10−6 for low plasticity to 10−5 for highly plastic clays (Likitlersuang et al. 2013). However, the conventional tests, for example, special triaxial test, obtaining the maximum initial shear stiffness only have 10−4 strain. Therefore, it clearly follows that the accurately estimation of the initial shear stiffness is really challenging by using conventional tests. Furthermore, the limitation of traditional hyperbolic t-z model is that it does not peak, yet it is obvious that a finite pile-soil relative displacement is required to mobilize maximum unit skin friction. Therefore, using these constants in computation ultimately produces no complete convergence to the experimentally observed relationship between unit skin friction and pile-soil relative displacement at failure. Consequently, an appropriate t-z function, which defines maximum unit skin friction with respect to pile-soil relative movement at failure, can be more attractive. Hence

Where, Δ zult is limiting pile-soil relative displacement at failure, in an unconfined compression test of soil sample from near the pile shaft stress level.

Assuming the relationship between initial shear stiffness and tangential shear stiffness at failure can be expressed as the following form:

Where, G is tangential shear stiffness at failure; n is constant.

Substitute Eqs. (2), (4) and (5) into Eq. (1), the modified hyperbolic t-z hardening model can be obtained in the following form:

Figure 2 shows the performance of the model by comparing it with the actual test results, the computed results from Eq. (6). The experimental databases used in Fig. 2 were taken from the results reported by Wang et al. (2012). It is observed that the proposed t-z model shows good agreement with the measured value. In addition, the advantage of the proposed t-z model is that the degree of nonlinearity of pile-soil interaction behavior can be described by the parameter n. The proposed t-z model would be degenerate to the traditional theoretical t-z model, for example perfectly plastic, liner elastic-perfectly plastic models, and the empirical models, as shown in Fig. 3.

2.3 Proposed t-z Hardening/Softening Model

As already observed in Fig. 1 in the case of type 2, the initial hardening phase with increasing value of shear displacement (Δ z ), after a peak of maximum mobilized shear stress at failure \( (\mathit{\Delta}_{z} = \mathit{\Delta}_{zmax} ,\,\tau_{z} = \tau_{zmax} ), \) evolves into shear stress softening until a final plateau corresponding to the ultimate state \( (\mathit{\Delta}_{z} = \mathit{\Delta}_{zult} ,\,\tau_{z} = \tau_{zult} ) \). Thus, the t-z model in the softening regime can be governed by the following equation:

Where, f indicates the amplitude of shaft shear stress hardening/softening. It can be observed from Eq. (7) that, when the parameter f = 0, it reflects the t-z hardening model, whereas it is the t-z softening model for f > 0. The peak of unit skin friction may occur only in high strength of soil structure, for example in overconsolidated soil or in dense sand. A parametric study of the influence of parameter f on the evolution of t-z curves is given in Fig. 4. The laboratory data used in Fig. 4 were taken from the results reported by Cao et al. (2015). It shows that the bigger the value of f, the greater the peak of parabolic curve is obtained, which corresponds eventually to the denser soil. Figure 4 also shows that for a given relation of unit skin friction and pile-soil relative displacement softening behavior, there is only a determined value of f.

Figure 5 shows t-z curves plotted from the present model is generally consistent with the measured values given by Wang et al. (2012) and the predicted results using t-z traditional softening models (Exponential model and Parabola model) proposed by Zou et al. (2011) and Vijayvergiya (1969). It is clear that the proposed t-z model shows a well good agreement between the calculated value and the measured value than the traditional t-z softening models, particularly for the pile-soil relative displacement greater than the maximum value.

3 Load Transfer Curve for Pile Tip

The accuracy of predicting the load-deformation behavior of vertically loaded single pile is not only dependent on the pile-surrounding soil interaction but also dependent on the interaction between pile tip and the bearing stratum soil.

In practical engineering, the ratio of pile length respect to its diameter of greater 20, the mobilized tip resistance at the design load may represent a small percentage of the limiting tip resistance, with the corresponding degree of mobilization typically less than 20% at twice the design load (Zhu and Chang 2002). Besides, it is difficulty in complete clearing of the bearing stratum soil of a borehole in bored pile construction, which will lead to a greater pile tip displacement when the tip resistance is fully mobilized unless the pile is short and rests directly on rocks. In addition, an excess pile tip settlement implies an excess pile head settlement that would not be permitted in practice. Therefore, a linear relationship between pile tip resistance and tip displacement is proposed, as shown in Eq. (8).

Where, Q b and Δ b are pile tip resistance and displacement, respectively; E sb and v sb are compressive modulus and Poisson’s ratio of bearing stratum soil, respectively; and D b is pile diameter at the tip.

4 Model Parameters Study

The proposed t-z hardening/softening model requires six parameters for computation: degree of nonlinearity of pile-soil interaction (n), limiting and maximum pile-soil relative displacement (Δ zult , Δ zmax ), unit skin friction at limit and maximum (τ zult , τ zmax ), and the strength of soil structure (f). These parameters have physical meaning soils can easily be determined from laboratory or field experiments. The properties of the soil sample for a laboratory test should be close to the behavior of the soil around the pile shaft in the field.

4.1 Degree of Nonlinearity (N)

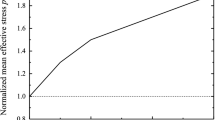

Based on the field single pile load test databases in different soils presented by the authors (Rollins et al. 2005; Zhang and Zhang 2012) are used to determine the degree of nonlinearity of pile-soil interaction (n), as shown in Fig. 6. In Fig. 6, the skin friction, τ z , is normalized by the limiting unit skin friction, τ zult , and the pile-soil relative displacement, Δ z , is normalized by the pile shaft diameter, D. It can be observed from Fig. 6 that, the value of n varies from 2 to 13, and the trend line of n is 5 of the value of coefficient of determination term, r2 = 0.977.

4.2 Maximum/Limiting Unit Skin Friction and Pile-Soil Relative Displacement (τ Zmax , Δ Zmax , τ Zult , and Δ Zult )

Based on the results of the load tests on 18 instrumented piles (Zou et al. 2011; Wang et al. 2012; Zhang and Zhang 2012) in different soils for skin friction softening behavior, the relationship between τ zult /τ zmax and Δ zult /Δ zmax is obtained, as shown in Fig. 7. It can be noted that the ratio of the limiting to the maximum unit skin friction, τ zult /τ zmax , is generally from 0.75 to 1.00 and the ratio of Δ zult /Δ zmax ranges from 1.5 to 3.0.

It is well known that the interface behavior of an actual pile at a site is affected by many complicated factors, such as construction methods, pile types, soil types, stratigraphy, and loading procedure, which may influence the magnitude of parameter Δ zult . The value of Δ zult can be determined experimentally. Generally, the values of parameter have been found to be in the range 5–25 mm for 0.7–1.1 m pile diameter in different soils (Zhang and Zhang 2012).

From above discussion, the parameter Δ zmax can be capture from the ratio of Δ zult /Δ zmax in Fig. 7, and the value of τ zult can be computed from the ratio of τ zult /τ zmax (see Fig. 7). Therefore, the maximum unit skin friction, τ zmax , must be determined firstly.

Numerous skin friction design approaches have been proposed for the load-transfer analysis. These design approaches generally fall into two main categories: (1) total stress design methods using undrained analysis (Skempton 1959), and (2) effective stress design approach using drained analysis (Burland 1973). Despite a number of significant contributions being made to the literature on the earlier category, many of these approaches have a number of inherent drawbacks, for example soil behavior is governed by effective stress and complex stress-strain changes occur during the pile installation which cannot be completely describes using the initial undrained strength profile. In an attempt to overcome many of the drawbacks associated with total stress design approaches, Burland (1973) advocated an effective stress design approach using the drained strength of soils. In Burland’s method, the evaluation of the maximum unit skin friction, τ zmax , at a given depth, z, along a vertical pile, which is controlled by the horizontal effective stress at failure σ h ′(z), and the pile-soil interface friction angle δ′, is linked to the vertical effective stress σ v ′(z) through an empirical parameter beta, β.

A particularly attractive feature of the β method is that assuming the lateral earth pressure coefficient, K f , is equal to the lateral earth pressure coefficient at rest, K0, and the pile-soil interface friction angel, δ′, is equal to the effective internal friction angle φ′ (see Eq. (10)). The range of β is from about 0.15 to 0.30 in the practical range φ′ (range of 10° to 45°). That is, almost any reasonable estimate for φ′ gives the same computed skin resistance. However, it still remains to be seen from a load test whether it is correct.

Figure 8 is a data plot from Reese and O’Neill (1988), Rollins et al. (2005) and Park et al. (2010) that was obtained from back computing more than one hundred field load tests in gravel, gravelly sand, sand and clay soil. It can be observed that very high values of β, up to 7.2, can occur at shallow depth. The values of β decrease with an increase in depth and asymptotically approach the normally consolidated (NC) range beyond a depth of approximately 20 m or so. These findings are reasonable because, in most natural soil profiles, the overconsolidation ratio (OCR) generally decreases with increasing depth. It also can be seen form the Fig. 8 that at a given depth larger values for β are expected passing from clay to gravel.

Consideration of soil property variation in depth can make a substantial difference, the suggested different depth depending β curves in different soil types are developed by the authors (Reese and O’Neill 1988; Rollins et al. 2005; and Park et al. 2010), as shown in Fig. 8. It is clear that making a load-displacement prediction that compares favorably with a load test is more a coincidence than the result of using the Eq. (10), particularly for short piles.

4.3 Strength of Soil Structure (f)

The parameter f can be determined by back-analysis of field load test results. A series of field test (Zou et al. 2011; Wang et al. 2012; Zhang and Zhang 2012) show that the values of parameter f have been found to be in the range 0.45-0.55 for different soils (e.g., mud, clay, sandy silt, silty clay).

5 Algorithm for Load-Settlement Analysis of a Vertically Loaded Single Pile

The steps involved in developing load-settlement curves are similar to the procedure discussed by Coyle and Reese (1966). Some of the steps proposed by Coyle and Reese (1966) have been modified to accommodate computer coding and faster computation. The detailed steps are given as follows:

-

(1)

Divide a single pile into m segments from the pile end to the pile head, as shown in Fig. 9.

-

(2)

Assume a small pile tip displacement, Δ b , and determine the pile tip resistance, Q b , from Eq. (8).

-

(3)

Assume the vertical moment at middle height of first pile segment, Δc1, equal to the movement of the pile tip, Δ b . Based on the proposed t-z function as given in Eq. (7), the unit skin friction of pile segment 1, τz1, developed in the interface between pile segment 1 and soil can be obtained using the assumed value of Δc1.

-

(4)

Compute load at top of pile segment 1, Q ti |i=1, by adding load found in step (3) to the known load acting at the bottom of the segment, Q b , according to the force equilibriums Eq. (11) of a pile segment (Fig. 9(c)).

$$ Q_{ti} = Q_{bi} + \pi DL_{i} \tau_{zi} $$(11) -

(5)

Assuming a linear variation of load in the pile segment, the elastic deformation at the midpoint of pile segment 1, Δ ci |i=1, can be computed by:

$$ \mathit{\Delta}_{ci} = \frac{{(Q_{ti} + 3Q_{bi} )L_{i} }}{{8E_{p} A_{p} }} $$(12) -

(6)

The new movement of the midpoint of pile segment 1, Δ ci ′ |i=1, can be written as:

$$ \mathit{\Delta}_{ci}^{{\prime }} = \mathit{\Delta}_{bi} { + }\mathit{\Delta}_{ci} $$(13) -

(7)

Compute the difference between new midpoint movement Δc1′with assumed value of Δc1 from step (3). Check if this difference is less than an acceptable specified value, e.g., 1×10−6m.

-

(8)

Repeat steps (3) through (7) until the requirement for acceptably specified value mentioned in step (10) is met.

-

(9)

Calculate the movement and load at the top of pile segment 1, Δ ti |i=1 and Q ti |i=1, respectively, using the following equations:

$$ \mathit{\Delta}_{ti} = \mathit{\Delta}_{bi} + \mathit{\Delta}_{ci}^{{\prime }} $$(14)$$ Q_{ti} = Q_{bi} + \pi DL_{i} \tau_{zi}^{{\prime }} $$(15)Where, τ zi ′ is derived from Eq. (7) and a new midpoint movement, Δ ci ′.

-

(10)

Set load at the tip of the next segment above equal to load found in step (4).

-

(11)

Consider the next segment above and assume the movement at the midpoint of this segment equal to the movement of the top of the segment next below. Repeat steps (3) through (9) for this segment.

-

(12)

Repeat step (11) until the top segment of the pile has been considered and load and settlement on the top of pile for the tip movement assumed in step (2) have been determined.

-

(13)

Repeat steps (2) through (12) until all specified pile tip movements have been considered.

6 Verification of Proposed Approach

In order to examine the validity of the proposed approach and procedure outlined in the preceding sections for the analysis of the load-settlement response of vertically loaded single pile, two instrumented pile load tests are analyzed and their results reviewed.

6.1 Case Study 1

Nabil (2001) presented the results of axial compression load tests on two concrete bored piles installed in homogeneous cemented sands on the South Surra, Kuwait. The bored cast-in-site pile of 2.25 m length and 0.1 m diameter, having an elastic modulus of 20 GPa. The cemented sand was reported to have a thickness of 4.5 m, a water content of 3.6%, a bulk density of 18.17 kN/m3, a compression modulus of 25 MPa, and a limiting pile-soil relative displacement of 25 mm. The peak strength parameter c′ and φ′ are 20 kPa and 35°, respectively, and the residual strength parameters are 0 and 34°. The input parameters for proposed t-z model can be determined by the results of drained triaxial compression tests using undisturbed samples taken from the cemented sand deposit for testing reported by Nabil (2001). The degree of nonlinearity n = 10, the ratio of limiting to maximum pile-soil relative displacement Δ zult /Δ zmax = 4.38, the ratio of unit skin friction at limit to at maximum τ zult /τ zmax = 0.71, and the strength of soil structure f = 0.70. To account for the value of β variation in depth, the value of β located at upper depth of 0.5 pile length is 4.0, and the below depth of 0.5 pile length the β = 3.6. In the analysis of the load-settlement response of a single pile, the pile is divided into 13 segments with each pile segment of 0.2 m in length, except of the pile head and end segment where the pile segment length is assumed to be 0.025 m.

Figure 10(a) shows that the load-settlement curves at the pile head plotted from the present method is generally consistent with the measured results given by Nabil (2001) and the predicted results using t-z softening models proposed by Vijayvergiya (1969) and Zou et al. (2011) at all loading levels. It can be observed that the proposed approach is generally in good agreement with field-observed behavior than the calculated results using traditional t-z softening model. In addition, the predicted limiting bearing capacity, Q u , using parabola and exponential t-z softening model is significant less than the measured value. This finding is reasonable because, when the pile-soil relative displacement greater than the maximum value, the unit skin friction quickly decreases with increasing pile-soil relative displacement, which lead to the limiting unit skin friction less than the measured value at limiting pile-soil relative displacement (see Fig. 5).

Figure 10(b) compares the variation in the axial load along the pile shaft obtained from the traditional t-z model and the present t-z model. It is clear that the axial load values obtained in the present t-z model are less than that from the traditional t-z model at the same depth. This can be also explained the reason of predicted limiting bearing capacity using parabola and exponential t-z softening model is significant less than the measured value.

6.2 Case Study 2

The response of concrete bored piles were installed in Bangkok clay located at three sites has been investigated by Promboon and Brenner (1981). The test results of the pile situated at Site A (Bank of Thailand, Tha Kasem Road) is used for examine the validity of the proposed approach and procedure outlined in the preceding sections for the analysis of the load-settlement response of vertically loaded single pile. The bored cast-in-site pile of 25.8 m length and 1.0 m diameter, and had an elastic modulus of 22GPa. The soil strata consist of soft clay, medium clay, stiff sandy clay, and sand at various locations. The soil properties and engineering characteristics have been obtained from the observations reported by Promboon & Brenner (1981). The soil strata are lightly overconsolidated, having an OCR of 2–3.5. The liquid limit, plasticity index, bulk density, and internal friction angle of soil strata vary from 70% to 50%, 40 to 30, 15.5 to 17.0 kN/m3, and 24° to 25°, respectively.

Promboon and Brenner (1981) reported skin friction softening behavior in the t-z curve at depths of 4.5–10.5 and 19.5 m–23.5 m. For other soil strata, skin friction is accord with t-z hardening curve. Based on the measured t-z curve at different depth, the details about the input parameters for proposed t-z model used for prediction are given in Table 1.

The predicted and measured load-settlement curves at the head of the single pile are shown in Fig. 11(a). The computed and measured axial load distribution along pile shaft is shown in Fig. 11(b). The evaluation as reported in Figs. 11 shows good agreement between the computed and measured values. Indirectly the validity of the proposed t-z model in Eq. (7) is verified.

7 Conclusion

An analytical approach for load-displacement response of vertically loaded single pile has been developed based on a load transfer method by introducing a proposed t-z model for pile-soil interface considering the hardening/softening behavior of skin friction. There are some meaningful conclusions in the current study which are presented as follows:

-

1.

A development of a theoretical t-z function for the pile-soil interface is being established. The function is based on a series of results and hypotheses of the previous field and laboratory investigations. The proposed function is able to describe soil nonlinear stress-strain behavior and skin friction hardening/softening mechanism and the degradation phenomenon for strong structural characteristic of soils such as dense sand and cemented soil. The six input parameters required for the proposed t-z function have physical meanings and can be easily determined from field or laboratory experiments. Case studies of bored piles in different soil strata indicate that the proposed t-z function can be describe the load transfer behavior of pile-soil interface with reasonable accuracy.

-

2.

A highly effective computer program for nonlinear analysis of the load-displacement response of a vertically loaded single pile has been developed by using the load transfer method with the proposed t-z model. The proposed approach has been validated by two cases studies using very different soil strata. The response of a single pile resulting from two traditional t-z softening models including parabola and exponential functions analyses are also compared in order to study the degradation phenomenon of skin friction. The results of the comparisons indicate that the proposed approach is generally in good agreement with field-observed behavior than the calculated results derived from traditional t-z softening models.

References

Burland, J.B.: Shaft friction of piles in clay - a simple fundamental approach. Ground Eng. 6(3), 30–42 (1973)

Coyle, H.M., Reese, L.C.: Load transfer for axially loaded piles in clay. J. Soil Mech. Found. Div. 92(2), 1–26 (1966)

Cao, W.P., Lu, Q.Y., Liang, P.: Experimental study on shear mechanical properties on dense sand-concrete interface under constant and varying normal stress. Build. Struct. 45(1), 82–86 (2015). (in Chinese)

Duncan, J.M., Chang, C.Y.: Nonlinear analysis of stress and strain in soils. Soil Mech. Found. Div. J. 96(5), 1629–1653 (1970)

Evgin, E., Fakharian, K.: Effect of stress paths on the behavior of sand steel interfaces. Can. Geotech. J. 33(6), 853–865 (1997)

Guo, W.D., Randolph, M.F.: An efficient approach for settlement prediction of pile groups. Géotechnique 49(2), 161–179 (1999)

Kraft, L.M., Ray, P.R., Kagawa, T.: Theoretical t-z curves. J. Geotech. Eng. Div. 107(11), 1543–1561 (1981)

Kondner, R.L.: Hyperbolic stress-strain response: cohesive soils. J. Soil Mech. Found. Div. 89(1), 115–143 (1963)

Likitlersuang, S., Teachavorasinskun, S., Surarak, C., et al.: Small strain stiffness and stiffness degradation curve of Bangkok Clays. Soils Found. 53(4), 498–509 (2013)

Liang, P., Cao, W.P., Lu, Q.Y.: Experimental research on shear mechanical properties on loose sand-concrete interface under constant/varying normal stress. Build. Struct. 44(8), 61–65 (2014). (in Chinese)

Nabil, F.I.: Axial load tests on bored piles and pile groups in cemented sands. J. Geotech. Geoenviron. Eng. 127(9), 766–773 (2001)

Nanda, S., Patra, N.R.: Theoretical load-transfer curves along piles considering soil nonlinearity. J. Geotech. Geoenviron. Eng. 140(1), 91–101 (2014)

Promboon, S., Brenner, R,P.: Large diameter bored piles in Bangkok clay. In: 10th International Conference on Soil Mechanics and Foundation Engineering, pp. 815–818 (1981)

Park, S., Roberts, L.A., Misra, A.: Characterization of “t-z” Parameters and their variability for auger pressure grouted piles using field load test data. In: GeoFlorida 2010: Advances in Analysis, Modeling & Design, pp. 1757–1766 (2010)

Reese, L.C.: Drilled shafts: construction procedures and design methods. Tunn. Undergr. Space Technol. 5(1), 156–157 (1989)

Randolph, M.F., Wroth, C.P.: Analysis of deformation of vertically loaded piles. J. Geotech. Eng. Div. 104(12), 1465–1488 (1978)

Randolph, M., Gourvenec, S.: Offshore Geotechnical Engineering. Spon, New York (2011)

Rollins, K.M., Clayton, R.J., Mikesell, R.C., et al.: Drilled shaft side friction in gravelly soils. J. Geotech. Geoenviron. Eng. 131(8), 987–1003 (2005)

Skempton, A.W.: Cast in-situ bored piles in London clay. Géotechnique 9(4), 153–173 (1959)

Said, I., De Gennaro, V.D., Frank, R.: Axisymmetric finite element analysis of pile loading tests. Comput. Geotech. 36(1), 6–19 (2009)

Vijayvergiya, V.N.: Load movement characteristic of piles. In: 4th Annual Symposium of the Waterway, pp. 269–284 (1969)

Wang, W.D., Li, Y.H., Wu, J.B.: Pile-soil interface shear model of super long bored pile and its FEM simulation. Rock Mech. 33(12), 3818–3824 (2012). (in Chinese)

Zhu, H., Chang, M.F.: Load transfer curves along bored piles considering modulus degradation. J. Geotech. Geoenviron. Eng. 128(9), 764–774 (2002)

Zou, J., Zhang, Z.M., Liu, J.W., et al.: A load transfer model considering strain softening of soils. Chin. J. Geotech. Eng. 32(7), 27–31 (2011). (in Chinese)

Zhang, Q.Q., Zhang, Z.M.: A simplified nonlinear approach for single pile settlement analysis. Can. Geotech. J. 49(11), 1256–1266 (2012)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2018 Springer Nature Singapore Pte Ltd. and Zhejiang University Press

About this paper

Cite this paper

Lu, Q., Luo, Q. (2018). A Load Transfer Approach for Studying the Load-Deformation Response of Vertically Loaded Single Pile. In: Chen, R., Zheng, G., Ou, C. (eds) Proceedings of the 2nd International Symposium on Asia Urban GeoEngineering. Springer Series in Geomechanics and Geoengineering. Springer, Singapore. https://doi.org/10.1007/978-981-10-6632-0_29

Download citation

DOI: https://doi.org/10.1007/978-981-10-6632-0_29

Publisher Name: Springer, Singapore

Print ISBN: 978-981-10-6631-3

Online ISBN: 978-981-10-6632-0

eBook Packages: EngineeringEngineering (R0)