Abstract

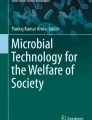

For several decades, the role of light-emitting diodes (LEDs) in plant growth has been recognized and studied with substantial depth. However, with the advancement of the technology, reaping devices with greater luminous output and greater diversity of peak wavelengths, LEDs have found more applications within the food industry, particularly in the areas of postharvest and microbiological quality. This chapter covers recent developments in the use of LEDs in the postharvest stage of agricultural outputs such as fruits and vegetables, examining their effects on the nutritional content of foods kept in cold storage, as well as the maturity and rate of ripening of foods, and their role in preventing fungal infections. Furthermore, the chapter presents recent studies exploring the use of LEDs and ultraviolet (UV) LEDs without additives, or together with photosensitizers or photocatalysts, to inactivate pathogenic bacteria in food. These methods are worth adopting by the food industry as they could provide a nonthermal means of keeping food safe without the use of chemical sanitizers or additives and may prevent the development of bacterial resistance.

Access provided by CONRICYT-eBooks. Download chapter PDF

Similar content being viewed by others

Keywords

9.1 Introduction

Light-emitting diodes (LEDs) may be correctly described as being ‘ubiquitous’ nowadays, yet one may not be fully conscious of the extent of its presence and function in the food industry. Previous chapters of this book have already discussed their relevance in floriculture, horticulture, in vitro plant morphogenesis, in preventing insect infestation, and in food production applications. LEDs have also been recognized as containing characteristics that render it suitable for various niche applications such as in space agriculture, high-technology farming, aquaculture, and other forms of food production (Yeh et al. 2015). The subsequent stages to food production, to describe it succinctly, encompass the storage, distribution, and consumption of nutritious and safe food. It is counterproductive to neglect the quality of food during these postharvest stages as it would ultimately lead to unwanted food losses or deterioration of value along the supply chain. As much as one-third of the world’s produced food is wasted, with a significant proportion being lost during the postharvest stages (FAO 2011). In developing countries, the main reasons include the lack of technological infrastructure and facilities to further process food or to allow for an efficient cold-chain system. In industrialized nations, excess food produced is eventually not consumed and is instead disposed of. Unsafe food caused by poor handling or hygiene standards may also result in food wastage; hence, there still exists a pressing need to develop technologies that extend the shelf life of foods while keeping them safe for consumption (FAO 2011). This chapter aims to address these problems, in reference to the opportunities that LEDs offer.

It is an intuitive notion that light is necessary for healthy plant growth, hence light is intimately associated with the idea of food production. Yet it is not readily apparent how light is involved in other aspects of the food supply chain. In recent years, the importance of light in retaining the postharvest status in certain foods, particularly in leafy vegetables, has been increasingly receiving the attention of researchers. It has been known for long that light is able to mitigate senescence in growing plants, and that different quality of light was able to result in varying nutritional quality of foods (Noodén and Schneider 2004). Since there is still residual biological activity during the postharvest stage, light can still have a similar biological effect and therefore reduce the degradation of the food quality through senescence, or through nutrient loss (Zhan et al. 2012b). Furthermore, light is an integral component of photodynamic inactivation (PDI), a phenomenon which causes microbial inactivation through a combination of light, a photosensitizing agent, and oxygen (Luksiene and Brovko 2013). A major advantage of this technique is that it is considered nonthermal due to the small increase in temperature to the system being treated, compared to traditional thermal methods. As such, the technique is a possible means of treating heat-sensitive food products such as minimally processed fruits and vegetables, or even various food surfaces. The technique is also promising as an alternative novel method to deal with the proliferation of antibiotic resistance in pathogens (Hamblin and Hasan 2004). Since light is central in the above applications, it is necessary to select a suitable light technology.

The most critical requirements for such a lighting technology include the ability to adjust the spectral composition of emitted light with ease and flexibility, as well as the exclusion of heating effects through radiation. This is because plant tissues contain various components that respond to different parts of the light spectrum and thereafter activate biological responses that result in desirable effects. Similarly, unique photoactive molecules which pose a threat to pathogenic bacteria also operate most effectively under certain wavelengths of light. Since thermal treatments can result in unwanted quality changes in foods, the availability of a lighting technology that reduces thermal heating to a minimum is also desirable. For these reasons, LEDs are well suited in the application of light for postharvest preservation and microbiological inactivation (D’Souza et al. 2015). The current availability of a great number of studies that have investigated the effectiveness of utilizing LEDs in the areas of postharvest preservation and food safety gives a clearer picture to their industrial, commercial, or potentially even personal application in homes, such as in the household refrigerator. This chapter highlights the relevant studies which have shown how LEDs perform this function of keeping food safe for as long as possible, in the period after it has left the ‘farm.’

It must be noted that the relevant studies in the literature have been slightly limited in their scope. For example, postharvest studies are often conducted on fruits and vegetables; very few studies have investigated their effect on meat yet. In terms of food safety , this chapter focuses primarily on microbiological food safety in line with the current trend of such LED-related studies. The food types studied in this application are more varied, from fruits and vegetables, to beverages and even chicken. Even so, there is a rich amount of knowledge that can be gleaned from these studies, and the documentation of these studies will hopefully motivate the transferal of such knowledge to other related applications in the near future. Henceforth, the proceeding chapters will delve into the unique application of LEDs in postharvest preservation and microbiological food safety.

9.2 Brief Recapitulation of LED Technology and the Measurement of Light

Previous chapters have discussed in depth the properties and features of LED devices (see Chaps. 1 and 2 for more details). This section recapitulates these points in order to relate them to their application in postharvest and food safety techniques. Briefly, LEDs are semiconductor diodes which produce light through the process of electroluminescence. Depending on the material of the semiconductor, light of distinct color is produced (Dutta Gupta and Jatothu 2013). For example, LEDs fabricated using gallium arsenide emit red light, whereas with gallium nitride and silicon carbide, blue light is emitted (Yeh et al. 2015). Due to the narrow bandwidth of wavelengths, light emitted from LEDs is said to be almost monochromatic. LEDs can also produce monochromatic light which is in the ultraviolet (UV) or infrared (IR) range. Furthermore, broad-spectrum white light can also be produced from LEDs, either by mixing light from individual red, blue, and green LEDs (DenBaars et al. 2013), or by combining a UV LED and a tricolor phosphor coating, or a blue LED with a yellow phosphor coating (Park et al. 2014). In other words, LEDs confer great flexibility over the spectral composition of light, or what is referred to as ‘light quality.’

The above properties are important for several reasons. Firstly, by producing high quantities of light of the wavelengths that are desired, less energy is consumed in producing light of wavelengths that are unwanted. This is especially important in photobiological interactions in plants, which involve interactions between light and plant pigments and photoreceptors. Chlorophylls, the photosynthetic pigment which is familiar even to the layman, possess absorption peaks typically in the blue and red regions; the reason they appear green is because green light is mostly reflected away (Zhu et al. 2008). Based on this, early studies exploring the potential of using LEDs for horticulture and plant growth achieved satisfactory results using red and blue LEDs only (Massa et al. 2008). Apart from chlorophylls, a variety of other photoreceptors or pigments are responsible for sensing or absorbing energy from different regions of the light spectrum, including limited regions of the UV and IR range (Pinho et al. 2012). For example, light in the blue region is absorbed mainly by photoreceptors such as cryptochromes, phototropins, as well as pigments such as lycopene, β-carotene, and xanthophylls, whereas green light is absorbed by pigments such as certain flavonoids and betalanins. Phytochrome is well known for sensing the ratio of red to far-red radiation present in light, thereafter triggering a variety of other photomorphological processes. Although cryptochrome is known to absorb in the UV range (at around 320–400 nm), more research is required to fully understand the mechanism behind UV perception at lower wavelengths of UV radiation (Carvalho et al. 2011). With this knowledge, monochromatic LEDs can be used to study phenomena relevant to these photoreceptors and pigments, or various LEDs can be combined to produce a light of a desired spectral composition for other purposes. Similarly, when LEDs are used in inactivating pathogenic or spoilage microorganisms through direct exposure to high-intensity light, or with a photoactive molecule which is excited at particular wavelengths, the monochromatic nature of LEDs is an advantage. In contrast, broad-spectrum lighting technologies have lower photon efficiency compared to LEDs, which produce relatively lower quantities of light of the desired wavelength at the same power consumption (Nelson and Bugbee 2014).

Secondly, monochromatic light is useful in limiting the propagation of radiant heat. The production of radiant heat from broad-spectrum light is a problem, and lighting sources such as high-intensity discharge lamps produce substantial amounts of IR radiation. This may therefore cause surface heating on plants or exposed surfaces, causing unwanted effects. Since only a narrow bandwidth of wavelengths is emitted from LEDs, IR radiation is typically absent, hence less surface heating and other associated detrimental effects are caused (Morrow 2008; Mitchell et al. 2012). However, substantial heating occurs in the p-n junctions of LEDs, which is the site of electroluminescence. Higher temperatures tend to reduce luminous efficacy, hence resulting in less light being produced. This can be prevented by using devices such as heat sinks and cooling fans. For this reason, LEDs are suitable for use in cold, temperature-controlled environments such as refrigerators and hence would be appropriate for using in cold-chain storage or in transport vehicles due to their added resistance to damage from vibration and mechanical forces (US Department of Energy 2012).

There are various other advantages that LEDs possess which are superior to other forms of lighting such as high-intensity discharge lighting, fluorescent lights, and others (D’Souza et al. 2015). Other notable features include LEDs having a unique ability of reaching full output almost immediately after being switched on, with little restrike delay, and hence can be used for high-frequency pulsing and dimming to further save energy (Yeh and Chung 2009; Branas et al. 2013; US Department of Energy 2013). LEDs also have a longer life expectancy ranging from 50,000 to 100,000 h, compared to fluorescent or high-pressure sodium lamps, which range from about 10,000 to 17,000 h (Dutta Gupta and Jatothu 2013).

Finally, while the concept of light quality has already been covered, light quantity requires some discussion. The photon flux is the most commonly encountered unit of measurement of light quantity (typically in the form of µmol m−2 s−1). It describes the number of moles of photons received per unit area per second, regardless of the wavelength or energy carried by the photons. Therefore, it is only useful in quantifying light when conceived of in the ‘particle form of light,’ which is more applicable to photochemical or photobiological reactions in plants (Pinho et al. 2012). Another metric commonly used in studies related to food safety is termed ‘irradiance,’ which is the power of light energy received per unit area (W m−2). Since photons of different wavelengths possess different amounts of energy, irradiance varies with the spectral composition of light. As an illustration, although a treatment of 100 µmol m−2 s−1 of blue light is equivalent to 100 µmol m−2 s−1 of red light in terms of photon flux, the blue light treatment will have a higher irradiance (in terms of W m−2) than red light since blue photons possess more energy than red photons. A related but outdated unit is the ‘Einstein,’ denoted by ‘E’ (e.g., µE m−2 s−1), but its usage is discouraged due to its ambiguity: it can be interpreted either as photon flux, or as irradiance (Thimijan and Heins 1983). However, it has still been used in several recent studies (Braidot et al. 2014; Dhakal and Baek 2014a, b). Irradiance is commonly used in food safety studies as the peak wavelength of monochromatic light is usually fixed according to the photoactive molecule being used (i.e., the photosensitizer), or within the blue to near-UV region. Hence, spectral composition is not relevant. Measuring in terms of energy is also useful as microbial inactivation usually depends on the dosage (J cm−2), which is the product of time and irradiance.

In short, LEDs are useful in postharvest and food safety applications because they are energy-efficient, reduce unwanted heating of foods, are suitable for cold storage and transport, have long-lasting life times, and are mechanically robust and compact in size and shape. Most importantly, the quality of light emitted is easily customizable, especially due to its monochromatic nature. In the next section, the effects of various light qualities and quantities will be shown to have many beneficial effects on the postharvest quality of foods, especially of fruits and vegetables.

9.3 LEDs in Postharvest Quality Preservation of Fruits and Vegetables

The factors that affect postharvest quality are very broad. In general, postharvest techniques aim to prevent the visual, textural, and nutritional deterioration of a food that occurs rapidly after harvesting. Furthermore, it aims to keep the levels of harmful or spoilage-related microorganisms to a minimum, as well as to control the rate of ripening so as to optimize the commercial value of an edible fruit. In short, it aims to ensure that harvested produce is in an optimal state for consumption after being transported and distributed. Critical conditions for preserving postharvest quality include using the optimal combination of temperature and relative humidity, as well as concentrations of oxygen, carbon dioxide, and ethylene (Kader and Rolle 2004).

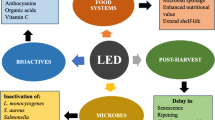

The effect of light on the postharvest quality of leafy vegetables and fruits, in particular, has been receiving more attention in recent years. It has been generally accepted that the postharvest quality of certain leafy vegetables that are exposed to small quantities of light is better than when stored in the dark (Braidot et al. 2014). Earlier postharvest studies on vegetables focused on the use of fluorescent lights mainly, showing that light can even increase the postharvest concentration of nutrients such as ascorbic acid, phenolic compounds, sugars, carotenoids, and other bioactive compounds in vegetables like spinach (Toledo et al. 2003; Lester et al. 2010; Glowacz et al. 2015), broccoli (Zhan et al. 2012a), and romaine lettuce (Zhan et al. 2012b). However, several studies utilizing LEDs as a light source have emerged recently. In general, LEDs have been used to delay senescence in perishable fruits and vegetables, in modifying nutritional content, in manipulating the rate of ripening of fruits, and in preventing fungal infections on foods to reduce food spoilage. Table 9.1 provides a summary of the different postharvest-related functions in which LEDs have successfully been shown to impart a beneficial effect.

9.3.1 Delay of Senescence in Vegetables Through LEDs

Senescence is a genetically controlled process that maximizes the survival of individual plants. Senescence allows for the conservation of available macromolecules and nutrients within the plant, by relocating them from aging plant tissue to new or developing tissue. Although it is beneficial to living and growing plants, it leads to unwanted loss of quality in harvested fruits and vegetables, which may have been detached from the rest of the plant. This in turn interrupts the transport of materials between tissues. Senescence in the postharvest stage is generally gauged in terms of characteristics which represent the marketable quality of the food; hence, this could broadly include general characteristics such as color and degree of wilting, or more specific indicators such as chlorophyll content. Based on these factors, there is notable evidence that light treatment can delay senescence in detached leaves, stems, and flowers (Pogson and Morris 2004), but light must be delivered appropriately, according to the optimal intensity, spectral composition, duration or photoperiod considerations, to the target fruit or vegetable (Noodén and Schneider 2004).

Too much light could lead to excessive photooxidative stress , which results in lower postharvest quality (Glowacz et al. 2015). Hence, selecting the correct light intensity is important. In order to determine the correct amount of light for a successful treatment, the light compensation point , which is the amount of light that results in equal rates of photosynthesis and respiration in a plant tissue, could be considered as a benchmark. Light administered in quantities below the light compensation point results in a net loss of sugars, which accelerates senescence (Noodén and Schneider 2004). However, light quality must be considered as well. A study by Costa et al. (2013) found that subjecting basil leaves (Ocimum basilicum L.) to pulsed white fluorescent light treatment at a photon flux below the compensation point effectively retarded senescence. The effect from the above treatment was comparable to pulsed red light produced using a white light and red filter. However, when a far-red filter was used, quality indicators suggested that senescence was proceeding, thereby indicating the involvement of phytochrome of senescence. Therefore, in the case of basil leaves, light quality was more influential than light quantity.

Conventionally, postharvest application of light in studies related to leafy vegetables did not exceed 30 µmol m−2 s−1 (Noichinda et al. 2007; Lester et al. 2010), and several studies have even used various forms of pulsed lighting (Costa et al. 2013; Gergoff-Grozeff et al. 2013). LEDs are well-equipped to provide such quantities of light and are far more effective than other lighting technologies at providing pulsed light. However, only a few studies which use white LED irradiation exist. In one such study, an LED produced pulses of warm white light on lamb’s lettuce, at a very low average photon flux of approximately 1.4 µEm−2 s−1 for 8 h in total (Braidot et al. 2014). Two different pulse treatments were used: specifically, 8 cycles of 1-h pulses or 16 cycles of 0.5-h square-wave pulses. Both treatments resulted in an increase in the chlorophyll a/b ratio above the initial ratio, and slower reduction in pheophytin levels, thus suggesting a delay in senescence. Furthermore, less potential oxidative damage was observed based on the pro-oxidant capacity of lipophilic extracts. However, the treatment of 16 cycles of 0.5-h pulses slowed down the degradation of chlorophylls a and b and helped retain carotenoid levels. Glucose content in light-treated or control samples was measured to be less than the initial glucose content, suggesting that pulsed light in low doses might be insufficient for photosynthesis to occur effectively. Hence, despite a net loss of glucose, there was still a limited amount chlorophyll and carotenoids produced.

Hasperué et al. (2016) investigated the rate of postharvest senescence in broccoli (Brassica oleracea var. Italica cv. Legacy) when treated with 20 µmol m−2 s−1 of a combination of white and blue LEDs. LED-treated samples showed the least amount of yellowing, and a corresponding retention of chlorophylls a and b compared to the dark control samples. Retention of glucose, fructose, and sucrose was also observed. Moreover, sucrose was increased by LED irradiation after 35 days when stored in 5 °C. All quality indicators for senescence were better for samples irradiated by LEDs than those stored in the dark even up to 42 days when stored at 5 °C. Therefore, in general, using low quantities of light from LEDs is a good means of preventing senescence from proceeding, hence keeping produce as fresh as possible, and in good marketable condition.

9.3.2 Enhancement of Nutritional Status of Vegetables and Fruits Through LEDs

The previous cases have shown that white LEDs can help to retain, or slow down the degradation of certain nutrients such as ascorbate, chlorophylls, carotenoids, and sugars. However, they can also be used to increase the nutrient content of foods. Investigations into the effects of various types of light treatments involving either monochromatic lighting regimes using LEDs, or the use of LEDs supplementing traditional light sources, have been shown to produce crops with superior nutritional quality (Bian et al. 2015). For example, Lee et al. (2014) investigated the effect of white, blue (436 nm), green (524 nm), and red (665 nm) LED treatments on the nutrient content of cabbages. It was found that after 18 days, chlorophyll content was highest for samples treated with green and white LEDs, followed by red and blue LEDs. In contrast, vitamin C and total phenolic content were increased by blue and white LED treatments. Although the results demonstrated that LED treatments generally improved the nutritional quality of vegetables stored in a refrigerator, the quantity of light received by the cabbages was not specified.

Outside of the visible range, UV and IR LEDs avail more interesting potential applications in terms of nutritional enhancement. For instance, watercress and garden pea sprouts were exposed to 33 µmol m−2 s−1 of UV-A radiation from an LED (375 nm) for a duration of 160 min daily over 3 days and then stored in darkness (Kanazawa et al. 2012). The quercetin-glycoside content of the vegetables was found to be significantly greater than those stored in the dark after 6 days from the beginning of the treatment. Hence, the study suggested that such UV LEDs could stimulate flavonoid and phenylpropanoid production in vegetables.

Near infrared (NIR) LEDs were used to investigate the effects of NIR radiation on transpiration rates and reactive oxygen species (ROS) accumulation in ‘Notip’ and ‘Cisco’ lettuce (Lactuca sativa L. Crispa Group) after harvesting (Kozuki et al. 2015). The 850-nm LED produced optimal results, leading to the lowest relative transpiration rates among all the irradiated as well as the non-irradiated control samples, for irradiation durations as low as 1 min. This was attributed to stomatal closing caused by increased ROS production in response to NIR irradiation, resulting in firmer and more visually appealing samples. Although the study measured a 20% increase in ROS production in guard cells, no further study was conducted to ascertain whether there was a corresponding increase in nutrients such as antioxidants, hence such an investigation might be worth pursuing in future studies.

Other than the leaves of vegetables, other edible plant parts respond differently to different LED treatments. Red LED treatment of broccoli (Brassica oleracea L. var. italica) at 50 µmol m−2 s−1 for 4 days caused a slower rate of ethylene production, slower degradation of ascorbate content, and less yellowness of the treated samples compared to the blue LED treatment and dark control (Ma et al. 2014). In contrast, the study by Hasperué et al. (2016) reported that the antioxidant levels, total phenolic content, and ascorbic acid levels in treated samples were mostly equal to or less than the samples stored in the dark. However, yellowing was similarly suppressed and carotenoid content increased significantly under this treatment. The lower photon flux of 20 µmol m−2 s−1 was not strong enough to induce the production of antioxidants.

To account for the biological response of such foods to light, several studies have investigated the relationship between exposure to LED light and biomolecular responses in terms of gene expression. In this regards, fruits have been studied in great detail. Blue LEDs were found to effectively increase total carotenoids in the peels and pulp of two cultivars of peaches ( Prunus persica ‘Hujing’ and ‘Jinli’), and the necessary gene expression contributing to the increases was investigated by Cao et al. (2017). Blue (440 nm) and red (660 nm) LED treatments at 80 µmol m−2 s−1 increased the content of stilbenes in grape berries ( Vitis labruscana Bailey) by appropriately regulating gene expression of key enzymes in the phenylpropanoid and stilbene biosynthesis pathways (Ahn et al. 2015). Shi et al. (2016) also showed evidence that blue LED (470 nm) irradiation at 40 µmol m−2 s−1 increased glucose and fructose while maintaining sucrose levels in Chinese bayberries (Myrica rubra Sieb. and Zucc. cv. Biqi), by upregulating genes involved in sugar metabolism such as sucrose phosphate synthase, acid invertase, glucose sensor, and cryptochrome genes.

Furthermore, citrus fruits have been extensively studied in this manner. Ma et al. (2011) outlined the effectiveness of red LED compared to blue LED irradiation on the regulation of gene expression that gave rise to an increase in β-cryptoxanthin in the flavedo of Satsuma mandarins. This effect was even greater in the flavedo of fruits treated to a combination of red LED and exogenous ethylene exposure (Ma et al. 2015). In contrast, Zhang et al. (2012) showed that blue LED treatment was more effective at increasing total carotenoids in the juice sacs of Satsuma mandarins, Valencia oranges ( Citrus sinensis Osbeck), and Lisbon lemons ( Citrus limon Burm. f. ), and they studied the regulation of similar genes. A later study showed that blue LED treatment caused greater upregulation of gene expression for ascorbic acid biosynthetic and regeneration genes, and two types of reduced glutathione-producing genes, than did red LEDs, for the same citrus cultivars (Zhang et al. 2015). From the above studies, different LEDs would induce different biochemical responses (and hence nutritional changes) in different species of fruits. Within similar species, different LEDs may have different effects depending on the location on the fruit.

9.3.3 Accelerating or Delaying the Ripening of Fruits Using LEDs

To reduce postharvest losses of fruits that are being transported over long distances or stored for long durations, manipulating the rate of ripening is a strategy that can be used. For example, the application of blue light prior to storage in the dark extended the ripening time of tomatoes (Dhakal and Baek 2014a, b). Mature green tomatoes had a slower rate of color change and were firmer when irradiated with blue light (440–450 nm) for a period of 7 days, compared to those stored in darkness or irradiated with red light (650–660 nm). Correspondingly, lycopene accumulation was reduced in response to blue light irradiation. Therefore, blue LED treatment was shown to be a convenient way of delaying the ripening of tomatoes, thereby extending their postharvest commercial value.

In contrast, blue LED light (470 nm) accelerated respiration, ethylene production, and the development of red color in strawberries (Xu et al. 2014a, b). Yet, green (525 nm) and red (630 nm) LED irradiations were also able to accelerate the increase in anthocyanins in immature strawberries to a smaller extent than blue LEDs (470 nm), suggesting that secondary ripening processes can be hastened by other LEDs if blue LEDs are unavailable (Kim et al. 2011). In a similar vein, the effect of monochromatic LED light of various wavelengths should be studied on various other climacteric fruits as this would be of immense commercial value.

9.3.4 Preventing Fungal Spoilage Through LEDs

Decay by fungi such as gray mold (Botrytis cineria) causes a significant amount of food loss (Kader and Rolle 2004). Recently it has been shown that blue LED light can help to attenuate fungal infections in citrus fruits. Soft rot area, mycelial growth, and sporulation of Penicillium digitatum , Penicillium italicum, and Phomopsis citri on the surface of tangerines were reduced when treated with blue light at 40 µmol m−2 s−1 over 5–7 d, compared to white light LED at a similar photon flux, and dark control (Alferez et al. 2012; Liao et al. 2013). This treatment was shown through real-time qRT-PCR analysis to increase the expression of phospholipase A2 (PLA2), an enzyme involved in the production of lysophosphatidylcholine which increases resistance to fungal infection and growth. In contrast, red light treatment led to the down-regulation of phospholipase D (PLD), which also provides antifungal defense (Alferez et al. 2012). Other than the above phospholipases, octanal, which possesses antifungal properties as well, increased in concentration in the flavedo of ‘Fallglo’ tangerines and sweet oranges upon blue LED irradiation. Polygalacturonase activity in P. digitatum, which is critical for fungal pathogenicity, was also lowered upon blue LED irradiation (Liao et al. 2013). The effectiveness of using blue LEDs in citrus fruits was replicated in a study on Satsuma mandarins (C. unshiu Marc. ‘Aoshimaunshu’), which showed that both 8 and 80 µmol m−2 s−1 of blue LED light (465 nm) were able to significantly decrease the rate of growth in the soft rot, mycelial, and sporulation zones over 6 days (Yamaga et al. 2015).

Following this, the question of whether continuous irradiation over several days is the most effective form of treatment arises. Alferez et al. (2012) found that 12-h blue LED treatments per day (followed by 12 h of darkness) were more effective at reducing mycelial growth of P. digitatum compared to continuous irradiation. However, these fruits were pre-treated for 3 d with blue LED light prior to inoculation, which may not be reflective of natural conditions in which the time of contamination or infection may not be known. Indeed, when fruits were inoculated immediately after harvesting, there were no significant differences between continuous treatments and 12-h treatments daily for 5 d, in terms of soft rot area of P. digitatum (Liao et al. 2013). However, both treatments reduced mycelial and sporulation areas to negligible after 5 d. Even so, since their effects were similar, it is worth considering using 12-h irradiation regimens for energy savings.

Further studies were performed using P. digitatum and P. italicum strains resistant to fungicides thiabendazole and imazalil, to ascertain the optimal lighting regime for inhibiting their growth in vitro. When 700 µmol m−2 s−1 of blue LED light was applied immediately after inoculation, colony growth was completely suppressed. When it was applied after 4 days, growth persisted but was severely limited. However, a lower photon flux of 120 µmol m−2 s−1 of blue LED light exerted a greater fungicidal effect when applied 4 d after inoculation. Although 700 µmol m−2 s−1 is a significantly high intensity of light, it was still possible to maintain the temperature of the experimental system at 20 °C throughout the duration of treatment (Lafuente and Alférez 2015). These studies exemplify how LED exposure is a viable alternative to common fungicides, as the risk of fungicide resistance increases.

Another strategy that can be employed in response to increasing fungicide resistance is the use of synergistic combinations of treatments. Yu and Lee (2013) tested the effectiveness of combining LED irradiation with the use of antagonistic bacteria, Bacillus amyloliquefaciens JBC36, which was applied as a biofilm to the surface of fruit. As opposed to the above studies, in vitro experiments found that the irradiation of 240 µmol m−2 s−1 of red LED light (645 nm) was more effective than other wavelengths in increasing the motility and biofilm formation of the bacteria. Furthermore, the LED treatment stimulated the production of iturin and fengycin, which are antifungal lipopeptides, thereby further contributing to the antifungal activity of the bacteria. Ramkumar et al. (2013) confirmed that red light exposure increased expression of fenA gene in Bacillus amyloliquefaciens JBC36, which is responsible for the synthesis of fengycin. The use of such a synergistic strategy might solve the problem of re-emergence of infections when LED treatment is discontinued, due to fungal growth below the surface of the fruit (Alferez et al. 2012). Further studies should be conducted to verify this.

UV LEDs can also be used to prevent fungal infection. A system consisting of UV LEDs of wavelengths of 272, 289, or 293 nm was used to irradiate strawberries purchased from a supermarket over 9 d at 20 mWm−2. The treatment prevented any mold growth for the period of 9 d, whereas significant growth of mold (suspected to be Botrytis cinerea ) was found on strawberries stored in 6 d of darkness. The UV treatment also resulted in the retention of anthocyanins and total soluble sugar levels, compared to those stored in the dark and which were found to have decreases in the above nutrients (Britz et al. 2013). LEDs with wavelength of 405 nm were also reported to prevent the growth of B. cinerea on detached tomato leaves, which are not usually consumed (Imada et al. 2014). This occurred through the interaction between light at that wavelength and the endogenous porphyrins in the mold, resulting in the production of toxic ROS. Using an LED within the visible range is preferable to UV LEDs of low wavelength as such UV radiation can harm the eyes and skin (Shama 2014).

9.3.5 Evaluation of LEDs in Postharvest Preservation

This section (i.e., Sect. 9.3) has focused on a few aspects of postharvest quality, namely the prevention of senescence, fungal infection and ripening, or the acceleration of ripening where applicable, as well as the enhancement of nutritional quality. With regard to nutritional quality, there is still currently a lack of studies showing the effect of various LEDs on leafy vegetables, which is surprising as there have been many studies conducted on leafy vegetables during the pre-harvest growth stage. Furthermore, there have been many postharvest studies conducted on leafy vegetables using broad-spectrum lighting. Granted that it is challenging to find the optimal lighting regime that is not excessive (hence risking oxidative damage), using low quantities of monochromatic light is still a possible path to take in initial studies. For example, Woltering and Seifu (2015) found that small quantities (5 µmol m−2 s−1) of red, blue, and green LED lights resulted in increased levels of glucose, fructose, and sucrose in butterhead lettuce, and marked reduction in sugars depletion in iceberg lettuce, compared to the samples stored in darkness. Moreover, since the quantity of light used was significantly below the light compensation point, it was concluded that increase in sugar levels was due to the process of gluconeogenesis, instead of photosynthesis. This seems to contradict the earlier statement by Noodén and Schneider (2004), which could be due to the fact that monochromatic light, not white light, was used in this experiment. It also means that the process of gluconeogensis could be exploited in novel ways to improve the nutritional quality of leafy vegetables using monochromatic light and hence should be investigated further.

An advantage of using low-powered LEDs is that it can potentially lead to high energy savings. Braidot et al. (2014) showed that lamb’s lettuces stored at 6 °C with pulsed lighting were not significantly different in terms of postharvest quality than samples stored in the dark at 4 °C. A higher storage temperature could be conducive for long-term energy savings. Furthermore, although Lee et al. (2014) did not specify the photon flux of the various treatments, it was stated that the input electrical power ranged from 1.0 to 1.5 W for each LED system in the refrigerators. These confirm the practicality of using LEDs in cold storage facilities.

A recurring issue with the use of light in general on vegetables is the reduction in mass due to moisture loss. This is normally due to transpiration, which is aggravated by light exposure. It is well known that blue light increases stomatal conductance and transpiration in leaves (Massa et al. 2008; Muneer et al. 2014), which results in moisture loss during the postharvest storage. Lee et al. (2014) reported a lower moisture content in cabbages that were exposed to blue, green, and white LEDs over 12 days, compared to samples treated with red LEDs or kept in the dark. Low moisture content can result in wilted and less visually appealing leaves, and therefore, a lower consumer acceptance, but perhaps this could potentially be reversed by IR radiation as previously shown by Kozuki et al. (2015). Therefore, in order to preserve moisture content in leafy vegetables exposed to light, future studies could incorporate IR LEDs to retard water loss due to transpiration, while incorporating other LEDs to bring about improvements in nutritional content.

Therefore, future studies conducted using LEDs on fruits and vegetables need to account for other quality changes that might compromise consumer acceptability, such as texture (which can be measured by a texture analyzer), color, or even flavor-active compounds.

9.4 LEDs in Food Safety

While the previous section has covered various postharvest quality attributes that may increase the shelf life of perishable foods by slowing down degradative processes within the food, or accelerating other biological processes that increase the commercial or nutritional value of the foods, another critical aspect of the postharvest quality is the microbiological safety of produce. Food safety is of prime priority in the food industry. Food contaminated with pathogenic bacteria could result in foodborne diseases and therefore must be appropriately processed. Thermal techniques, while being the most efficacious methods of eliminating pathogens, will cause the destruction of foods such as fresh produce, juices, and ready-to-eat salads. Compounded with consumers’ demand for minimally processed food free from chemical sanitizers and other additives, and an increasing risk of antimicrobial resistance in food pathogens, new forms of effective food safety technologies for food processing facilities need to be found (Capita and Alonso-Calleja 2011).

Visible light has bactericidal effects when combined with a photosensitizer and oxygen, through a phenomenon known as photodynamic inactivation (PDI). Moreover, UV radiation itself has bactericidal effects. When combined with suitable nanoparticles, UV radiation can cause bacterial death through photocatalytic oxidation . While the use of the above techniques has been researched quite widely for applications in the fields of medicine, dentistry, and water purification, recently more attention has been given to applications in food-related decontamination processes, with LEDs being widely studied as a suitable source of light. Other than the energy savings that LEDs offer, the lack of radiant heat is an attractive feature since heat can potentially accelerate the deterioration of food quality. The subsequent sections first present the foundational in vitro studies demonstrating the efficacy of using LED treatments in PDI, photocatalytic inactivation and direct UV exposure, followed by studies that have been conducted on model food systems such as beverages, or actual food matrices such as fruits and vegetables.

9.4.1 PDI Using Exogenous Photosensitizers

PDI is one of the most common modes of decontamination studied in food-related applications of LEDs (Luksiene and Brovko 2013). Essentially, PDI requires a photoactive molecule (also known as a photosensitizer), light, and oxygen. Excitation of the photosensitizer occurs during the interaction with a light photon. Subsequently, ROS are generated when the photosensitizer returns to ground state. This occurs through two pathways. Firstly, the Type I mechanism involves the transfer of energy to surrounding substrates, which then results in ROS generation of species such as superoxide anion (O •−2 ), hydrogen peroxide (H2O2), and hydroxyl radicals (•OH). In contrast, the Type II mechanism involves the transfer of energy from the photosensitizer to the stable molecular oxygen in its triplet state (3O2), causing its excitation to the singlet state (1O2). These ROS cause extensive damage to the cellular components comprising lipids, fatty acids, peptides, and other substrates such as in the cell membrane (Kiesslich et al. 2013). Since the production of the above ROS results in the indiscriminate destruction of cellular components, it is expected that resistance to PDI is more difficult to evolve. However, the treatment provided must be sufficient to completely inactivate the target pathogen; otherwise, sublethal treatments may induce stress tolerance (St. Denis et al. 2011). Even so, experiments have shown that resistance to PDI does not develop in targeted microorganisms even after 10 cycles of PDI treatment (Tavares et al. 2010; Bartolomeu et al. 2016).

The photosensitizer is the most crucial component in PDI, and the properties of various photosensitizers have been reviewed in considerable depth by other authors such as Luksiene and Brovko (2013) and Kiesslich et al. (2013). The following is a summary of the salient points. The characteristics of a functionally effective exogenous photosensitizer include possessing a high light absorption coefficient within the wavelength range of excitation, a triplet state which reaches a high quantum yield (Φ T > 0.4), high energy (E T ≥ 95 kJmol−1, and sufficiently long lifetime (τ T > 1 µs). These characteristics allow for maximum energy transfer from the photosensitizer to reactants. The lipophilicity and the ionization constant (pK a) must be considered alongside the nature of the food matrix as these affect the uptake of the molecule into the target pathogen. Finally, they should not in themselves be toxic. Most photosensitizers that have been identified and validated are confined to clinical applications and may not be suitable for application in food. However, photosensitizers that are suitable and effective in food applications, found in natural sources, or have been studied in substantial depth previously include hypericin, curcumin , alpha-terthienyl, and chlorophyllin (Luksiene and Brovko 2013). Based on the photosensitizer being used, it is crucial to select a suitable light source. Various forms of lighting can be used in PDI, including broad-spectrum and pulsed lighting that provide sufficient quantity of light in the range of absorbance of the photosensitizer. However, it is more economical to use light whose peak wavelength coincides with the absorption maximum of the selected photosensitizer, and therefore monochromatic light sources such as LEDs are the most appropriate lighting source.

Conventionally, a photosensitizer is added from an external source into the media carrying the microorganism of interest, or the food matrix in question. Hence the photosensitizer is found in the exogenous environment to the pathogen, where the lethal ROS are generated. In terms of susceptibility, in vitro studies have shown that Gram-positive bacteria are more susceptible to PDI as the photosensitizer is more easily trapped in the peptidoglycan layer of the cell wall, whereas the double cell membrane structure in Gram-negative bacteria acts as a more effective barrier to photosensitizers (Demidova and Hamblin 2004). Increasing the photosensitizer concentration, or using cationic photosensitizers or photosensitizers conjugated to positively charged polymers, has been shown to improve their uptake (Luksiene and Brovko 2013). Another potential strategy that could increase susceptibility in Gram-negative species is to conjugate photosensitizers to antimicrobial peptides which bind specifically to target cells. Eosin Y was conjugated to an antimicrobial peptide, (KLAKLAK)2, and was shown to target both Gram-positive and Gram-negative bacteria, as opposed to red blood cells or other mammalian cells (Johnson et al. 2012).

With sufficient knowledge of the mechanisms of inactivation that occur during PDI, qualitative and quantitative comparisons can be made between different forms of PDI treatment by using appropriate mathematical models, which can bring more clarity to the inactivation kinetics of a PDI treatment. Aponiene et al. (2015) found that the Logistic model was suitable for describing inactivation curves of B. cereus incubated with hypericin and exposed to a green LED of 585 nm (R 2 > 0.97). Furthermore, Dementavicius et al. (2016) compared three models, namely the Weibull, Logistic, and Geeraerd models, to find which one best described the inactivation of B. cereus and L. monocytogenes similarly incubated with hypericin and exposed to a green LED. The study concluded that of the three, the Logistic model gave the best fit in terms of the determination coefficient (R 2) and root-mean-square error (RMSE). In the Logistic model, model parameters include ‘number of cells resistant to treatment,’ ‘shoulder parameter,’ ‘population reduction suddenness,’ and ‘maximum reduction rate’. A thorough explanation of these parameters is discussed in Dementavicius et al. (2016). The study concluded that L. monocytogenes was more easily inactivated by hypericin-based PDI than B. cereus based on the comparison of the above parameters. This shows the merits of using mathematical modeling if done appropriately and rigorously. The availability of quantitative data can give objective insights into the efficacy of a treatment, or the susceptibility of a bacterial species to the treatment. It would be useful and beneficial to the food industry to conduct such studies on actual food matrices, such as the one performed on endogenous photosensitizers by Ghate et al. (2016).

9.4.2 PDI Through Endogenous Photosensitizers

Instead of applying photosensitizers to food systems from an external source, the excitation of endogenous photosensitizers located intrinsically within bacterial pathogens represents another antimicrobial strategy. Endogenous photosensitizers usually exist in the form of intracellular components like ‘porphyrins, cytochromes, flavins, and NADH’ (Lubart et al. 2011). Research in this field has been very productive in the recent years (Table 9.2), hence posing as a valid alternative to the use of exogenous photosensitizing agents.

Without the need for photosensitizing additives, the most critical conditions for ensuring successful inactivation lie in the LED wavelength and intensity. In terms of wavelength, it has long been established that blue light or near-UV radiation, typically within the band of 400–405 nm (Soret band), is the most effective at inactivating bacteria and fungi as it coincides with the absorption maximum of photoactive porphyrins within the organisms (Maclean et al. 2008, 2014; Endarko et al. 2012; Imada et al. 2014). For a variety of Gram-positive and Gram-negative foodborne pathogens irradiated with 486 J cm−2 from an LED of 405 nm peak wavelength, it was determined that the resulting reduction in populations was partly due to cellular membrane damage, but not DNA fragmentation (Kim et al. 2015, 2016a).

While the above mentioned studies demonstrated the effectiveness of LEDs with a peak wavelength of 405 nm, some studies that compared LEDs emitting red, blue, and green lights also confirmed that the maximum inactivation of Salmonella typhimurium , Escherichia coli O157:H7, Listeria monocytogenes, and Staphylococcus aureus was caused by blue LEDs of a slightly higher peak wavelength of 461 nm (Ghate et al. 2013). Another study confirmed the superior inactivation ability of blue LEDs over green and red LEDs on Porphyromonas gingivalis, S. aureus and E. coli DH5α (Kim et al. 2013). In both studies, green LEDs were also moderately effective at inactivating bacteria as light within the green region could still be absorbed by photosensitizers (Maclean et al. 2009), whereas no inactivation was observed by red LEDs. Moreover, treatment with blue LEDs resulted in the highest rate of sublethal injury to bacteria, indicating that blue light can significantly injure surviving populations of bacteria (Ghate et al. 2013). However, LEDs with peak wavelength at 405 nm were shown to be significantly more effective than LEDs at 460 nm, resulting in greater inactivation of S. aureus, Lactobacillus plantarum , and Vibrio parahaemolyticus after 7-h treatment at 4, 10, and 25 °C, despite the former generating a smaller maximum dosage at 7 h compared to the latter (Kumar et al. 2016). The effectiveness of the LED was attributed to the possibility that a significant proportion of the output spectrum fell within the UV range, hence compounding the killing effect on bacteria.

The effect of temperature of the system appears to have different effects on different bacteria. According to Ghate et al. (2013), at 20 °C, blue LED (461 nm) treatments halted bacterial growth of S. typhimurium, E. coli O157:H7, L. monocytogenes, and S. aureus; but when temperatures were lowered to 15 and 10 °C, inactivation was more pronounced such that blue LED treatments resulted in populations below detectable limits after 6–7.5 h. On the other hand, Kumar et al. (2016) reported greater inactivation of L. plantarum when illuminated by LEDs (405 nm) for 7 h at 25 °C with a dosage of approximately 600 Jcm−2 of blue LED treatment, which was similar to the treatment used by Ghate et al. (2013). In contrast, V. parahaemolyticus was more effectively inactivated at 4 and 10 °C under the same conditions. However, this apparent discrepancy in efficacy could be due to the use of phosphate-buffered saline (PBS) as a bacterial medium. Unlike other growth media such as trypticase soy broth, it lacks the nutrients required by injured bacteria to recover from an injured state. Additionally, the authors cautioned that the apparent high inactivation V. parahaemolyticus might have been due to cells being converted into the viable but non-culturable (VBNC) state, which is worth future investigation. These results suggest that different bacterial species will respond differently to varying temperatures, as determined by the adaptability of the bacteria’s membrane fluidity to temperature and/or the dependence of the bacteria’s self-repair system on temperature. While adapting to lower temperatures, the cell membranes of such bacteria may become composed of a greater proportion of unsaturated fatty acids which are more susceptible to ROS damage (Ghate et al. 2013; Kumar et al. 2016). More extensive studies will be required on different bacterial strains; but in general, inactivation was substantial at typical refrigerator temperatures of between 4 and 10 °C, and, hence, PDI inactivation of foodborne pathogens can readily be carried out in a refrigerator fitted with suitable LEDs, for example.

Bacterial susceptibility to PDI through endogenous photosensitizers varies significantly among, and within, bacterial species. For example, Campylobacter jejuni required a much lower dosage of blue light at 405 nm than Salmonella enteritidis and E. coli. This might be because C. jejuni, which is a microaerophilic species, is naturally more susceptible to damage via ROS. However, authors cautioned that this apparent susceptibility might be due to the ability of Campylobacter spp. to become VBNC (Murdoch et al. 2010), hence leading to an overestimation in its susceptibility. Further studies are therefore required to confirm this. In contrast, a study using a LED of 405 nm showed that Listeria spp. were most easily inactivated, followed by E.coli, Shigellasonnei, and S. enteritidis (Endarko et al. 2012). While several authors suggested that Gram-positive bacteria were more susceptible than Gram-negative species (Maclean et al. 2009; Birmpa et al. 2014), others observed that susceptibility was not determined by Gram nature (Ghate et al. 2013). Moreover, it was shown that there were differences in susceptibility between various strains of Campylobacter spp. isolates when exposed to the same treatment, and this example of intraspecies variation in susceptibility was thought to be due to different concentrations of endogenous porphyrin within species (Maclean et al. 2009; Haughton et al. 2012). On this note, Kumar et al. (2015) showed a correlation between the higher susceptibility of Gram-positive species of bacteria and the quantity of intracellular coproporphyrins. However, within Gram-positive species, there was no direct and strong correlation between coproporphyrin content and susceptibilities, possibly due to other components in bacterial cells that are capable of quenching ROS, such as pyocyanin in P. aeruginosa. The interactions between ROS produced by photosensitizing intracellular components and other such radical-scavenging components in cells suggest that future investigations should be orientated toward characterizing such components and studying their effect on the overall success of a PDI treatment.

One way of increasing susceptibility by increasing photosensitizing intracellular components is through the external addition of 5-aminolevulinic acid (ALA), a non-photoactive metabolic precursor in heme biosynthesis which can give rise to various endogenous photosensitizing porphyrins. The addition of ALA is suitable for food applications because ALA is colorless and tasteless, while being effective against a range of foodborne pathogens, yeasts and fungi, viruses, and even certain protozoa (Harris and Pierpoint 2012; Luksiene and Brovko 2013). It has been shown to inactivate not only vegetative S. typhimurium cells (Buchovec et al. 2009), but also Bacillus cereus spores (Luksiene et al. 2009) and L. monocytogenes biofilms on packaging surfaces (Buchovec et al. 2010) when treated with LED light at 400 nm for as little as 15 min.

As discussed earlier, mathematical models present us with a useful means of evaluating the efficacy of a photosensitizing treatment in terms of its inactivation kinetics. Several studies on the inactivation kinetics of PDI through endogenous photosensitizers exist. Ghate et al. (2013), who studied the effect of wavelength, temperature, and dosage of LED treatment on the inactivation and decimal reduction values of selected pathogens, reported that D-values for treatments using LEDs at 461 nm at 10 °C ranged from 1.19 h for L. monocytogenes to approximately 1.4–1.5 h for E. coli O157:H7, S. typhimurium, and S. aureus. Kumar et al. (2015) modeled the inactivation curves of B. cereus, E. coli O157:H7, S. aureus, S. typhimurium, L. monocytogenes, and P. aeruginosa treated with 405 nm and 520 nm LEDs at 4, 10, and 25 °C. A more recent work by Kumar et al. (2016) modeled the inactivation curves of L. plantarum, S. aureus, and V. parahaemolyticus, while other studies described the susceptibility of L. monocytogenes, B. cereus, S. aureus, S. typhimurium, and E. coli O157:H7 to 405-nm LED treatments using the Weibull model (Kim et al. 2015, 2016a). Since the above were in vitro studies, more inactivation studies should be conducted on food systems, as well as packaging and contact surfaces.

Despite the success of using LEDs directly to perform PDI, this method may not be as effective as PDI using exogenous photosensitizers. For instance, a dosage of 185 Jcm−2 was required to inactivate L. monocytogenes in vitro using a blue LED at 405 nm (Endarko et al. 2012), whereas 36 Jcm−2 was sufficient for a 7 log inactivation when treating a thermo resistant L. monocytogenes 56 Ly strain in vitro using sodium chlorophyllin (Na–Chl) as a photosensitizer (Luksiene et al. 2010). Nevertheless, PDI through endogenous photosensitizers is probably more desirable as the treatment does not require any photosensitizing additive to function properly. Furthermore, there is still very little data available on the consequence of adding photosensitizers to the acceptability of foods from the consumer’s point of view.

9.4.3 UV LEDs

UV radiation can be classified based on its wavelength range: a wavelength range of 200–280 nm is assigned UV-C; 280–315 nm is assigned UV-B, while 315–400 nm is assigned UV-A. UV radiation in general has a damaging effect on DNA replication and transcription. Direct exposure to UV-C or UV-B results in the inactivation of a variety of microorganisms, such as bacteria, viruses, fungi, protozoa, and several other pathogenic and parasitic organisms (Lui et al. 2014). Normally, mercury tube lamps are used to produce UV-C radiation for bactericidal purposes. In contrast, UV LEDs offer more preferable features compared to mercury tube lamps. UV LEDs have the ability to produce quick pulses with no warm-up time. Chips of various wavelengths can be constructed, as opposed to specifically fixed wavelengths of the mercury tube lamps, which usually have a peak of 254 nm. Most importantly, it contains no toxic mercury (Lui et al. 2014). Obviously, they also provide the common physical benefits of LEDs such as durability and space efficiency. Producing UV LEDs that match the efficiency of mercury tube lamps is technically challenging, but the technology is developing rapidly and is predicted to surpass mercury tube technology in the near future.

Even so, there are several studies investigating the effectiveness of direct exposure of UV radiation using UV LEDs. A UV-A LED system constructed by Hamamoto et al. (2007) could inactivate foodborne pathogens including V. parahaemolyticus, S. aureus, S. enteritidis, and an entero-pathogenic E. coli (EPEC) strain in vitro. The LEDs produced UV-A radiation at 70 m Wcm−2 at 25 °C and inactivated up to 5–6 log cycles of the bacteria within 150 min. The most susceptible bacteria was V. parahaemolyticus, which went through 6 log reductions to below detection levels within 20 min, whereas EPEC and S. aureus were inactivated below detection limits within 60 min. The least susceptible was S. enteritidis, which was inactivated by 5 log cycles after 150 min. Higher levels of 8-hydroxy-2′-deoxyguanosine indicated that UV-A LED treatment resulted in greater oxidative damage to DNA than did UV-C radiation from a low-pressure mercury lamp. However, lower levels of cyclobutane pyrimidine dimer indicated that UV-A LED treatment resulted in less direct DNA damage than from UV-C radiation.

UV-C radiation is most preferred in sterilizing food systems, and its bactericidal effect is well known (Shama 2014). A study showed that a 266-nm UV LED was more efficient at inactivating 3 strains each of E. coli O157:H7, S. typhimurium, and L. monocytogenes, in vitro, than a conventional mercury lamp with a peak wavelength of 254 nm, resulting in as high as 6 log reductions at dosages of 0.7 m J cm−2 (Kim et al. 2016b). According to the authors, UV lamps are point sources whereas UV LEDs have a planar configuration and hence emit light in a linear fashion toward the target area. Therefore, when both sources are activated from the same height and with the same irradiance, the target area receives a smaller intensity from UV lamps than compared to UV LEDs. Also, it must be noted that the UV lamp was covered with 52 layers of polypropylene film to reduce the intensity to match the lower intensities of the UV LEDs. This means that since UV lamps have much greater intensities, treatment times will be much lower than UV LEDs for the same magnitude of microbial inactivation, owing to the limited irradiance of UV LEDs at this current point in time. Even so, UV LEDs in the experiment were still able to cause 6 log reductions to occur, meaning that they would be practical for most sterilization situations.

UV LEDs are also capable of producing pulses of UV radiation. Pulsed UV-A LED with a maximum irradiance of 0.28 mWcm−2 and a frequency of 100 Hz reduced biofilm populations of E. coli by 99% after a 60-min treatment (Li et al. 2010). Moreover, pulsing has the added advantage of lower energy consumption. Wengraitis et al. (2013) exposed E. coli to several pulsed-light treatments from a UV-C LED, with varying duty cycles and repetition rate frequencies. Pulsed-light treatments ranging from 0.5 to 50 Hz at a 10% duty cycle were the most energy-efficient, at a power consumption of 204 mW. On the basis of log reduction per unit energy consumed, the treatments were approximately twice as efficient compared to continuous irradiation, as well as 20 times more efficient compared to pulsed Xenon light.

9.4.4 Photocatalytic Oxidation Using LEDs

While UV-C LED irradiation is a good method of decontamination, UV-A is not as potent as UV-C, but combining UV-A radiation with photoactive nanoparticles results in photocatalytic oxidation , which increases the potency of UV-A radiation (Chawengkijwanich and Hayata 2008; Othman et al. 2014). Photocatalytic oxidation occurs when radiation close to the UV range (usuallyUV-A radiation at 365 nm) is irradiated onto a photoactive inorganic nanoparticle materials such as titanium dioxide (TiO2), zinc oxide (ZnO), and other types of materials such as silver-titanium oxide hybrids (de Azeredo 2013). Irradiation with UV-A promotes an electron in the material’s valence band to the conduction band, leading to ROS generation and subsequent inactivation of surrounding microbes such as E. coli, S. aureus, P. aeruginosa, Enterococcus faecium, Salmonella Choleraesuis subsp., V. parahaemolyticus, L. monocytogenes, and various other spoilage bacteria which have been experimentally investigated using non-LED sources (Kim et al. 2003; Kühn et al. 2003; Li et al. 2009; Sung et al. 2013). The main cause of death is considered to be lipid peroxidation of polyunsaturated fatty acids in cell membranes caused by ROS attack, as well as other subsequent causes such as peptidoglycan damage, enzyme and coenzyme inactivation, and nucleic acid destruction (Dalrymple et al. 2010).

There are currently several studies using UV-A LEDs as a source of irradiation for photocatalytic oxidation, and most of such studies focus on water purification (Izadifard et al. 2013). In one study, UV-A LED irradiation on TiO2 film inactivated a UV-resistant strain of E. coli by 4 log cycles (Xiong and Hu 2013), and in another, UV-A LED irradiation on TiO2-coated surfaces reduced the concentration of micropollutants in potable water (Autin et al. 2013). There is existing evidence showing the effectiveness of using UV-A radiation together with food packaging incorporating suitable photoactive nanoparticles. Several experiments investigating the effect of irradiating lettuce enclosed in TiO2-coated packaging using UV-A lamps or fluorescent sources have shown that E. coli populations can be successfully reduced (Chawengkijwanich and Hayata 2008; Othman et al. 2014). To test the potential of using this strategy on surfaces, TiO2 paste was used to inactivate L. monocytogenes biofilms on stainless steel and glass materials using UV-A lamps (Chorianopoulos et al. 2011).

A study by Aponiene and Luksiene (2015) attempted an innovative combination of PDI and photocatalytic oxidation using a violet LED (405 nm), chlorophyllin, and ZnO nanoparticles to inactivate E. coli O157:H7 in vitro. In addition, the sequence of adding the photoactive ingredients into the bacterial suspension during the dark incubation, prior to photoirradiation, was investigated. Interestingly, it was found that adding both chlorophyllin and ZnO together into the bacterial suspension prior to irradiation was not as effective as adding ZnO first, followed by chlorophyllin. The simultaneous addition of ZnO and chlorophyllin resulted in an approximate reduction of 2.7 log CFU mL−1. In contrast, the addition of chlorophyllin for 15 min followed by ZnO (followed by further dark incubation of 15 min) resulted in a reduction of around 3 log CFU mL−1, whereas performing the addition in the reverse order (i.e., ZnO followed by chlorophyllin) resulted in the greatest reduction of around 4.5 log CFU mL−1. The reason for this was attributed to the initial electrostatic interactions of ZnO nanoparticles with the negatively charged cell membranes of the bacteria, after which negatively charged chlorophyllin bound to ZnO, hence increasing the overall interactions between the bacterial cell membrane and photoactive ingredients. The overall benefit of this method is that since PDI is less effective on Gram-negative species, a combination of PDI and photocatalytic oxidation could synergistically increase the success of inactivating such species.

9.4.5 Effect of PDI Treatments Using LEDs on Food Products

Recently, more studies using LEDs have been performed on real food matrices to understand their efficacy in inactivating bacteria inoculated on the surfaces of various types of foods. Table 9.3 shows a summary of PDI treatments using exogenous photosensitizers on foods.

In fruits and vegetables, reductions of around 2 log cycles of bacteria in an approximate time frame of up to an hour were generally reported. For example, treating apricots, plums and cauliflowers inoculated with B. cereus with hypericin as a photosensitizer, and a green LED (585 nm) light with an irradiance of 3.84 mWcm−2 led to a significant decrease of the bacterial population after only 30 min of irradiation (Aponiene et al. 2015). Similarly, treating strawberries that had been inoculated with L. monocytogenes with Na–Chl as photosensitizer combined with irradiation with a blue LED (400 nm) light at 12 mWcm−2 resulted in a decrease of the bacterial population after a 20-min treatment (Luksiene and Paskeviciute 2011b).

Meat products have also been investigated. The population of S. aureus inoculated onto chicken meat was reduced by 1.7 log cycles after illumination of blue LED (435 nm) with a curcumin-based photosensitizer (Tortik et al. 2014). Without the use of added photosensitizers, Campylobacter spp.was inactivated effectively by near-UV LED (395 nm) in vitro and on chicken meat, with as little as 0.12 Jcm−2 required (Haughton et al. 2012), as shown in Table 9.4. However, the use of blue LED light at 405 nm was significantly less effective in reducing the population of Campylobacter spp. inoculated onto chicken skin using chicken exudate (Gunther et al. 2016), requiring a higher dosage of up to approximately 180 Jcm−2. The less effectiveness was attributed to the higher optical density of chicken exudate, hence requiring a higher level of irradiation in order to penetrate more effectively.

Another study was performed on orange juice inoculated with a Salmonella cocktail, which was illuminated with blue LEDs of 460 nm (Ghate et al. 2016). The greatest reduction in bacterial populations was observed when a treatment comprising of an irradiance of 92.0 mWcm−2 for 13.58 h at 20 °C led to a 4.8 log reduction of the bacteria. However, the treatment with the lowest D-value (in terms of Jcm−2) was the one comprising of an irradiance of 92.0 mWcm−2 at 12 °C.

UV LEDs have also been tested in various food matrices. One such experiment studied the ability of UV-A LEDs (365 nm) to inactivate E. coli DH5α in beverages by using drinks with artificial colorants in varying concentrations, and commercially available orange juice. Lower concentrations of colorants in the solutions resulted in greater inactivation of the bacteria. As for the orange juice samples subjected to similar treatment, a lower rate of inactivation was reported compared to the control containing phosphate buffer solution. For one brand of juice, a log reduction of approximately 0.5 log cycles was reported, whereas a log reduction of 2.5 log cycles was reported in the second brand of juice. The large variation observed in inactivation between solutions containing different colorants and concentrations was suggested to be due to the fact that not all colorants possess an absorbance band which overlapped at 365 nm. Furthermore, colorants which possess antioxidant properties might have been able to quench ROS produced during the process, hence lowering the efficacy. Also, pigments and particles such as fiber might scatter, reflect, or absorb light, causing less UV radiation to penetrate into the drink (Lian et al. 2010). Although it would be preferable for more studies to be conducted to verify these claims, the optical properties of food matrices, as influenced by the presence of various food compounds or ingredients, as well as the possibility of quenching of ROS by food components, are worth paying attention to in future studies.

Apart from drinks, the effect of UV-A LED (365 nm) treatment on E. coli DH5α inoculated onto lettuce and cabbage leaves was studied. Irradiation of 90 min with an irradiance of 125 mWcm−2 resulted in a decrease of 3.5 log cycles, with negligible loss of vitamin C, no formation of nitrites or nitrates, and less than 5% loss in moisture content (Aihara et al. 2014). Moreover, the effect of UV-C LEDs on the inactivation of foodborne pathogens inoculated onto cheese slices was studied, showing that 3 mJ cm−2 of the 266 nm UV LEDs resulted in approximately 4.5 log reduction in E. coli O157:H7 and S. typhimurium, as well as 3.3 log reduction in L. monocytogenes (Kim et al. 2016b).

As detailed in the previous sections, LED treatments during the postharvest stages of fruits and vegetables may activate certain biological processes that could either lead to further nutritional degradation, or increase in nutrient value. Apricots, plums, and cauliflower treated with hypericin and green LED light were found to have no significant differences with the control samples in terms of antioxidant activity and color (Aponiene et al. 2015). The short illumination time of 30 min was negligible compared to the much longer hours typically used in postharvest applications, hence the duration could have been insufficient to cause the degradation or stimulation of antioxidant compounds. In contrast, an increase in total antioxidant capacity was reported in strawberries treated with Na–Chl and LEDs, although anthocyanin and total soluble phenolics content did not increase (Luksiene and Paskeviciute 2011b). In this case, it is not certain whether the increase in antioxidant capacity was due to LED illumination, as the concentration of photosensitizer used in the study by Luksiene and Paskeviciute (2011b) was almost 100 times greater compared to that used by Aponiene et al. (2015). Furthermore, Na–Chl, which was the photosensitizer used by Luksiene and Paskeviciute (2011b), possesses high antioxidant capacity (Luksiene and Paskeviciute 2011a). Hence, the increase in antioxidant activity was more likely due to the addition of Na–Chl as opposed to being a biological response to LED light. However, the addition of a photosensitizer which is high in nutritional value is also an attractive idea, as it provides the benefits of increased safety as well as a more nutritious product. In contrast, Zhang et al. (2015) showed that pulsed blue LED lighting set at a period of 400 µs and a duty of 50%, with intensity of 100 µmol m−2 s−1, resulted in a substantially larger increase in the ascorbate content of citrus fruit after 4 weeks of irradiation compared to storing in the dark. Although the objective of the research was to study nutritional changes, it showed that since pulsed lighting using LEDs was also a viable means of photoirradiation, the nutritional quality of food can be simultaneously improved while being kept safe.

Due to the minimal radiant heat emitted, LEDs cause minimal increase in temperature on the surface or the interior of foods. This prevents the degradation of nutrients and organoleptic properties of such foods, as well as preventing the thermal degradation of nutrients. In milk, Srimagal et al. (2016) reported small increases in temperature ranging from 1 to 2 °C when illuminated by various LEDs (405, 430, and 460 nm) over 60 min at initial temperatures of 5, 10, and 15 °C. Similarly, the surface temperature of various fruits and vegetables was increased from 20 °C to a maximum of 25 °C after up to 30 min of illumination, which was observed in apricots, plums, and cauliflowers (Aponiene et al. 2015) as well as strawberries (Luksiene and Paskeviciute 2011b). A dose of 4.2 Jcm−2 from a near-UV LED (395 nm) caused the surface temperature of skinless chicken fillet to increase from approximately 25–30 °C (Haughton et al. 2012). Hence, it is confirmed that LED treatments are considered nonthermal due to the minimal increase in temperature from such treatments.

9.4.6 PDI in Decontamination of Food Surface Through Packaging Materials Using LEDs

Photosensitizers can also be incorporated onto the surfaces of packaging materials or food contact surfaces. Irradiation of chlorophyllin-based photosensitizers incorporated onto polyolefin packaging materials using LEDs with wavelength of 405 nm for 15 min at an irradiance of 20 mWcm−2 inactivated L. monocytogenes (Luksiene et al. 2010) and B. cereus (Luksiene and Paskeviciute 2011a) by approximately 4 log cycles. Table 9.5 summarizes similar findings, where PDI was used to decontaminate food surfaces through packaging materials using LEDs.

Several studies also attempted to sterilize the contaminated surface of food contact materials using LEDs without adding exogenous photosensitizers (Table 9.6).

Apart from incorporating photosensitizers onto food contact surfaces or packaging materials, Luksiene and Brovko (2013) suggested exploring the incorporation of photosensitizers such as chlorophyllin onto various polymer-based films and coatings that are commonly used on foods like meat and poultry. Upon irradiation, PDI would be initiated on the surface of the food to ensure its microbial safety. A chlorophyllin-chitosan complex was used to coat strawberries and was then subjected to irradiation by LED with wavelength of 405 nm to test the efficacy of the treatment on inoculated S. typhimurium and yeasts and molds. The population count of S. typhimurium fell from around 5.4 to 3.2 log CFU g−1, while the number of yeasts and mold fell from 4.0 to 2.6 log CFU g−1. Yet the appearance of strawberries was less moldy after the experimental period. As strawberries tend to spoil quickly, this method could be a potential way to lengthen the commercial viability of strawberries in the market (Buchovec et al. 2016).

A previous study by López-Carballo et al. (2008), who used a quartz/halogen lamp instead of LEDs to provide light for photoirradiation of cooked frankfurters containing chlorophyllin-coated gelatin film or coating, reported a small reduction in the populations of S. aureus and L. monocytogenes by approximately 1.5 log cycles each. In spite of the low efficacy of the method, it is worth exploring the use of such coatings in conjunction with LED illumination to further inhibit the growth of low microbial loads of pathogens on meats kept in cold storage. However, more studies are needed to understand the effect of such films and coatings on the organoleptic properties and acceptability of such foods.

9.4.7 Evaluation of Role of LEDs in Microbiological Food Safety

It has been sufficiently shown that inactivation methods employing LEDs possess several useful advantages, including preventing the formation of resistant strains, the absence of toxic mercury, and the ability to design a compact source of radiation, compared to conventional and bulky low-pressure mercury lamps. Pulsing can also bring about energy savings. However, one obvious and major shortfall of radiation in the visible or UV range is the low penetration depth into food, which might limit decontamination to only the surface of vegetables, fruits and some meats, or non-opaque liquid food products (D’Souza et al. 2015). Even so, LEDs can effectively be used as a component in the hurdle technology framework for those types of food which are detrimentally affected by thermal processes.

A noteworthy observation from the study by Ghate et al. (2016) on the inactivation behavior in orange juice was that a photobiological response was not independent of treatment duration and irradiance, and similar dosages won’t result in a similar photobiological response. In other words, at the same temperature and dosage of blue LED light treatment, a 92.0 mWcm−2 treatment resulted in greater inactivation than a 254.7 mWcm−2 treatment, although it would be expected to be similar. This could be due to the mechanism of action that applied stress through PDI, or through extrinsic factors present in the orange juice matrix. It highlights the importance of conducting proper studies on food matrices as their variety and complexity can lead to unexpected deviations from the trend. Few studies have tested the law of reciprocity within food-related studies and hence would be useful for future research.