Abstract

Multi-step catalytic processes are generally required in chemoselective conversion of biomass derivatives into chemical products. Integration of different types of transformations into a single catalytic system with a bifunctional catalyst can be used to improve reaction efficiency, enhance product selectivity and to promote specific reaction pathways. In this chapter, the fundamentals of bifunctional catalysis are introduced to understand some of the specific roles in designing catalytic materials for biomass transformations. Acid-mediated hydrolysis of polysaccharides to mono- and oligosaccharides in combination with successive isomerization is one of the effective strategies for valorization of sugar-containing solutions, wherein the type of acid catalyst (i.e., Lewis and Brønsted acids) can be used to control product distribution. Catalytic production and upgrading of furanic compounds (e.g., 5-hydroxymethylfurfural, 2,5-furandicarboxylic acid, and 2,5-dimethylfuran) with bifunctional materials via corresponding tandem reaction pathways is another effective strategy. Emphasis can be placed on the synthesis of organic acids (e.g., levulinic acid and lactic acid) from carbohydrates through either anaerobic or aerobic oxidation, integrated with preprocessing reactions. This chapter provides an overview of bifunctional catalytic systems and a perspective outlook on bifunctional catalytic pathways for biomass transformations.

Access provided by CONRICYT-eBooks. Download chapter PDF

Similar content being viewed by others

Keywords

1 Bifunctional Catalysis

In comparison with monofunctional catalytic systems, bifunctional catalysts with Brønsted/Lewis acid, acid-base, or metal-containing acid/base sites have been demonstrated to exhibit remarkably high performance in both gas-phase (e.g., syn-gas to hydrocarbons or alcohols) and liquid-phase (e.g., aqueous-organic) conversions [1,2,3,4,5,6,7]. Bifunctional catalysis may be in use, more commonly than is generally recognized, because a certain number of monofunctional catalysts are most likely bifunctional in nature [8]. For instance, the surfaces of transition metal oxides (e.g., MoO2 and Cr2O3) have been found to possess both types of hydrogenation-dehydrogenation and acidic sites, implying that the apparently single-site catalysts possibly have bifunctional activities, in spite of their relatively lower activity than their tailor-designed two-site counterparts [8].

To mimic enzymatic catalysts, materials can be designed with functionalities (e.g., metal centers, basic and acidic sites, nucleophiles, hydrogen bond donors/accepter groups) that are spartially organized around active sites to promote efficient transformations [9]. Some reported heterogeneous catalysts have unprecedented performance unattainable with homogeneous catalysts [9]. Typically, the cooperation between the active sites or groups (T1/T2 as in Fig. 1.1) of a bifunctional material surface in catalyzing a reaction with two substrates (S1/S2 as in Fig. 1.1) can be divided into four different modes (Fig. 1.1) that possibly include dual activation (A), sequential activation (B), self activation (C), and multiple point transition state stabilization (D) [9, 10]. All of these strategies have been adopted as references for the design of synthetic catalysts that are able to take full advantage of multifunctional cooperation in catalytic processes [9].

Cooperative modes between active sites or groups (T1/T2) of a bifunctional catalyst in the activation of two substrates (S1/S2) (Adapted with permission from Ref. [9], Copyright © 2008 Royal Society of Chemistry) (A) Dual activation, (B) Sequential activation, (C) Self activation, (D) Multiple point transition state stabilization

From the point of view of organic chemistry, bifunctional catalysis is defined as both nucleo- and electrophilic substrates being separately activated by discrete active sites present on a single catalytic material (Fig. 1.2a) [11]. In line with bifunctional catalysis, both cascade and double activation catalysis may be present, wherein two or more catalysts activate the identical substrate sequentially or in a concerted manner, respectively (Fig. 1.2 b–c). On the contrary, the nucleo- and electrophilic substrates may be concurrently activated by two or multiple separate catalysts such that synergistic catalysis occurs (Fig. 1.2d). In this chapter, acid-participated bifunctional catalytic hydrolysis of polysaccharides to mono- and oligosaccharides will be introduced. The key step of glucose isomerization involved in the valorization of sugar-containing solutions mediated by dual functional groups is depicted. Further, discussion is made on application of the techniques to the production of biofuranic platform molecules (e.g., 5-hydroxymethylfurfural and furfural) and the upgrading of these compounds to oxygenated and hydrogenated furans (e.g., 2,5-furandicarboxylic acid and 2,5-dimethylfuran) tandem reaction pathways. Finally, the synthesis of organic acids (e.g., levulinic acid and lactic acid) from carbohydrates is introduced through either anaerobic or aerobic oxidation via bifunctional catalysis.

Schematic representation of bifunctional catalysis (Adapted with permission from Ref. [11], Copyright © 2014 Royal Society of Chemistry) (A) Bifunctional catalysis, (B) Cascade catalysis, (C) Double activation catalysis, (D) Synergistic catalysis

2 Hydrolysis of Oligo- and Polysaccharides

Simple sugars hydrolyzed from biomass over chemical and enzymatic catalysts have been used to study the production of liquid/gas fuels (e.g., ethanol, butanol, hydrogen, and methane) or formation of chemical products (e.g., organic acids, furanic/aromatic compounds, and polyols), as illustrated in Fig. 1.3 [12, 13]. In the conversion of oligo- and polysaccharides (e.g., cellobiose and cellulose) into monosaccharides such as glucose via hydrolysis, homogeneous chemical catalysts generally show good activity, but they require harsh reaction conditions (> 180 °C), and have recycle and waste treatment issues especially for when mineral acids (e.g., H2SO4, H3PO4 and HNO3) are used. Enzymes, on the other hand, have good selectivity but are generally inefficient, expensive and are susceptible to impurities [14]. In this regard, the use of solid acids or supported catalysts that are stable and recoverable could address the issues inherent in both homogeneous catalysts and enzyme catalysts to promote hydrolysis reactions that are selective and efficient that can be performed at mild conditions without environmental wastes.

Schematic representation of a catalytic strategy for biomass upgrading (Adapted with permission from Ref. [12], Copyright © 2012, Elsevier)

2.1 Brønsted/Lewis Acid Bifunctional Solid Catalysts

In the organosolv process, Schwiderski et al. [15] demonstrated that a Lewis acid AlCl3 was able to catalyze both ketol-endiol-tautomerism and dehydration to produce furfural from beech wood chips, showing comparable and even superior activity to that of a Brønsted acid such as HCl [15]. For both Lewis and Brønsted acid sites, the increase in acidity was found to be favorable for the cleavage of β-1,4-glycosidic bonds in cellobiose and in cellulose, thus enhancing their hydrolysis [16]. Typically, the distribution of Brønsted and Lewis acid sites on mixed metal oxides can be adjusted by simply changing the molar ratio of metal species or calcination temperature of the catalyst. In an in-depth study on the role of WO x clusters in WO3/ZrO2 catalysts, it was observed that a high WO x loading resulted in an increase in the number of Brønsted acid sites, and prevailed over the number of Lewis acid sites of ZrO2 even at calcination temperatures greater than 700 °C [17].

One type of commercially available Brønsted/Lewis acid bifunctionalized catalysts is the H-form zeolites that show moderate activity and stability for hydrolysis of hemicellulose and cellulose. H-form zeolites forms that have relatively higher acidic (e.g., ferrierite) and hydrophobic sites with high Si/Al ratios have superior performance to others for hydrolysis of carbohydrates [18, 19]. With these types of catalysts, the polymerization of monosaccharides (e.g., glucose) to humins with zeolites is significantly inhibited, which possibly can be attributed to shape-selectivity, in comparison with other solid and homogeneous acids (e.g., sulphated zirconia and heteropoly acids) [20]. Over H-USY-15 (Si/Al = 15) in water, a moderate yield of xylose and arabinose (56%) with >90% carbon balance is obtained from hemicellulose at 170 °C in 1 h [21], while the sulfonated H-USY zeolite gives improved yields (ca. 78%) at 140 °C after 9 h [22]. These results highlight the effect of Brønsted acid sites and the importance of Lewis acid sites. Meso- and macropores created on zeolites by dealumination (e.g., treated with oxalic acid) promote the accessibility of the acid sites to the reactants, thus improving the mass transfer, with the yield of total reduced sugars increasing by tenfold [23]. Under microwave heating conditions, the hydrolysis of cellulose to glucose gives moderate yields (ca. 37%) over H-form zeolites, but only requires reaction times on the order of minutes (e.g., 8 min) [24]. The integration of bifunctional catalytic materials with auxiliaries such as microwave and ultrasound offers yet another approach to improve reaction efficiency.

As a biomass-derived polymer that has aromatic monomeric units rather than glucose monomeric units, the hydrolytic degradation of lignin into aromatic monomers can also be achieved with well-designed solid acid catalysts based on zeolites [25]. For example, H-USY affords 60% yields of monomeric aromatics from lignin at 250 °C, further demonstrating the potential of Brønsted/Lewis acid bifunctional solids (particularly zeolites) for conversion of biomass-related compounds into small components or fractions.

2.2 Base-Acid Bifunctional Solid Catalysts

The pretreatment of biomass with base (e.g., Ca(OH)2, NaOH and KOH) can be used to remove lignin at ambient to 100 °C temperatures, while the remaining polysaccharides can be hydrolyzed with acidic or enzymatic catalysts [26]. In an improved process, Chandel et al. found that crude lignocelluloses (e.g., sugarcane bagasse) consecutively pretreated with dilute H2SO4 and NaOH could surmount the structural recalcitrance of the biomass, thus enhancing subsequent cellulase accessibility and hydrolysis efficiency for ethanol production [27]. Likewise, an acid-base mixture can be employed to simplify the catalytic steps for one-pot production of cellulosic ethanol, without solid/liquid separation, neutralization and detoxification (Fig. 1.4) [28]. This process integrates acid-base catalyzed hydrolysis of cellulose and subsequent fermentation of ethanol with in situ produced cellulase into a single step. Gratifyingly, the yield of ethanol reached 70.7% from the fermentation of the whole rice straw slurry after 60 h, which was relatively higher than that (49.7% yield) obtained by simultaneous saccharification and fermentation (SSF) of washed solids of pretreated rice straw (Fig. 1.4) [28]. These results demonstrate both the advantages of an integrated process in the production of ethanol from rice straw.

Schematic pathway for integrated processing of rice straw with acid-base pretreatment/enzyme catalysis to produce ethanol (Adapted with permission from Ref. [28], Copyright © 2014 Royal Society of Chemistry)

The activation of hydrotalcite (HT) with Ca(OH)2 simultaneously increases its basicity and acidity from 0.42 and 0.21 mmol/g to 1.76 and 1.17 mmol/g, as measured by CO2- and NH3-TPD, respectively [29]. The resulting HT-OHCa catalyst shows a greatly enhanced glucose yield (39.8%) and selectivity (85.3%) in the hydrolysis of ball-milled cellulose, as compared with pristine HT (11.0% yield and 40.6% selectivity), Ca(OH)2 (10.6% yield and 39.8% selectivity) and reference experiments without a catalyst (0.4% yield and 3.5% selectivity) at 150 °C in 24 h (Table 1.1). The HT-OHCa catalyst was able to be recycled for at least four times (sequentially reused catalysts denoted as HT-OHCa2, HT-OHCa3 and HT-OHCa4), with glucose yield and selectivity slightly decreasing to 35.0% and 80.5%, respectively (Table 1.1, entries 5–7) [29]. In addition, Ba(OH)2, KOH and NaOH-activated HTs were found to show moderate glucose selectivities and yields (Table 1.1, entries 8–10), further confirming that the catalyst performance was positively correlated with the content of both acid and base sites.

3 Sugar Isomerization

Enzymes (e.g., glucose isomerase) are commonly active for the isomeric conversion of simple monosaccharides. The stability of an enzyme can be increased by immobilization onto solid supportssuch as silica or chitosan [30, 31]. Solid basic and acidic chemocatalysts that have comparable reactivity as their homogeneous counterparts and which have favorable reaction times and recycle characteristics have been proposed for the selective isomerization of sugars [32, 33]. Solid bases such as TiO2, ZrO2 and relevant hybrids normally have low catalytic activity, giving no more than 20% yields of fructose in the case of glucose isomerization [34, 35]. However, Sn-beta, which typically acts as a Lewis acid, is able to isomerize glucose to fructose with high yields of 31% in water at 110 or 140 °C in 30 min or 12 min reaction time, respectively [36]. Glucose in the pyranose form partitions into the zeolite, followed by ring-opening to the acyclic form over the Lewis acid center and isomerizes into fructose in the acyclic form, which finally proceeds to ring closure to give the furanose form of fructose (Fig. 1.5) [37].

Besides the Lewis acid center of Sn species being located in the framework of BEA zeolite, the adjacent silanol group synergistically promotes the hydride transfer in the glucose-to-fructose isomerization, and allows the single-step reaction to proceed with a low activation energy barrier while the epimerization of glucose to mannose via a Bilik-type rearrangement is impeded [38]. The proximate hydroxyl group is possibly derived from either co-adsorbed water or intrinsic silanol, and the cooperative effect of the Sn center and –OH group compensates the negative charge more effectively on the O1 atom of glucose during the rate-controlling step of a hydride shift from the C2 carbon to the C1 carbon (transition state (TS) in Fig. 1.6) [39, 40]. In the isomerization of glucose to fructose over tungstite (WO3·H2O), cooperative action of tungsten species (Lewis acid site) with a neighboring proton donor occurs [41]. The conversion of glucose increases when methanol is used as solvent instead of water, probably due to the differences in the solvation of the hydrophobic pores [42]. However, the epimerization of glucose to mannose as the dominant side reaction may take place by either two subsequent 1,2-intramolecular hydride transfer steps over Sn-Beta or one 1,2 intramolecular carbon shift step on Na-exchanged Sn-Beta in methanol [42]. Gao et al. conducted a series of glucose isomerization reactions in subcritical aqueous straight- and branched-chain alcohols, and found that primary and secondary alcohols could promote glucose conversion to fructose in high selectivity, while the increase of t-butyl alcohol concentration resulted in a decrease of both glucose conversion and fructose yield [43, 44]. In addition, the ordered mesoporosity of the Sn-containing zeolite was favorable for the isomerization of C5 and C6 sugars (e.g., xylose and glucose) because it improved mass transfer and increased reaction rate [45]. Further, even the aldose component in the disaccharide could be isomerized to ketose (e.g., lactose-lactulose and cellobiose-cellobiulose) over Sn-beta zeolites in water or subcritical aqueous ethanol [46, 47]. Unexpectedly, the beta zeolite containing Ti4+centers (Ti-beta) were found to preferentially catalyze the isomerization of glucose to sorbose through an intramolecular C5-C1 rather than C2-C1 hydride-shift [48].

By using commercially available zeolites as Brønsted-Lewis acidic catalysts, efficient isomerization of glucose to fructose is possible with remarkable yields (up to 55%) via a two-step methanol-water process that uses methanol in the initial reaction for the isomerization and etherification of glucose to a mixture of fructose and methyl fructoside at 120 °C for 1 h (step 1), and that is followed by water addition in the second step proceeding hydrolysis to regenerate fructose from methyl fructoside (step 2) as shown in Fig. 1.7 [49]. In this catalytic process, the isomerization of glucose to fructose and trapping of fructose as fructoside in the alcohol are catalyzed by Lewis and Brønsted acid sites, respectively [50]. It is found that the H-form zeolite (e.g., H-USY) promotes the glucose-to-fructose isomerization via an intramolecular hydride-shift rather than through solvent exchange [51]. Likewise, catalytic isomerization of xylose to xylulose (up to 47% yield) via the two-step methanol-water process, and erythrose to erythrulose (45% yield) in water can be realized over the commercial large-pore zeolites such as H-USY-6 (Si/Al = 6) and H-beta (Si/Al = 12.5) [52, 53]. In the presence of a single-unit-cell Sn-MFI with both Brønsted and Lewis acid sites, a maximum fructose yield of 65% is obtained from glucose via an identical two-step process in ethanol and water [54]. The coupling of Lewis and Brønsted acidity with newly developed catalytic routes allows an increase in reaction efficiency.

Reaction pathway for converting glucose to fructose in a two-step process (Step 1, in R-OH; Step 2, water addition) (Adapted with permission from Ref. [49], Copyright © 2013, American Chemical Society)

4 Synthesis of Biofuranic Compounds

In the past decade, a large number of catalytic systems and functional materials have been reported that are selective for the transformation of biomass-derived hexoses and pentoses into furans such as 5-hydroxymethylfurfural (HMF), furfural, 2,5-dimethylfuran, γ-valerolactone, 5-ethoxymethylfurfural, 2,5-diformylfuran, 2,5-furandicarboxylic acid and maleic anhydride via cascade reactions such as hydrolysis, dehydration, etherification, hydrogenation and oxidation (Fig. 1.8) [55]. These biofuranic compounds have high potential for use in industrial applications. In this section, catalytic strategies used for production of furanic products from bio-based compounds are briefly discussed.

4.1 Brønsted-Lewis Acid Bifunctional Catalysis

In the dehydration of fructose, either Lewis acid (e.g., AlCl3) or Brønsted acid (e.g., HCl, H2SO4 and H3PO4) alone promote formation of HMF with high efficiency (20 min), but in only fair yields (< 60%) at moderate reaction conditions (120 °C). However, a mixture of Lewis and Brønsted acids (e.g., AlCl3 and H3PO4) in a single catalytic system is able to achieve HMF from fructose in yields as high as 92.6% under identical reaction condtions [56]. The in situ formed fructose-phosphate-AlCl3 complex is proposed as the reason for the enhanced stability of the fructofuranose during the reaction through its shifting of the balance from fructopyranose to fructose-phosphate-AlCl3 complex (Fig. 1.9), followed by dehydration over the protonic acid to give HMF. Binder and Raines showed that glucose, cellulose and even untreated corn stover could also be converted into HMF (48–81% yields) at temperatures of 100–140 °C in a single step with CrCl3 and HCl catalysts [57].

Reaction pathway for producing HMF from fructose stabilized by a fructose-phosphate-AlCl3complex (Adapted with permission from Ref. [56], Copyright © 2014 Royal Society of Chemistry)

For producing HMF from glucose in cascade reactions using CrCl3together with HCl in aqueous media, Lewis acidic catalysts are active for the isomerization of glucose to fructose, while Brønsted acid catalysts are favorable for subsequently promoting the dehydration reaction to give HMF (Fig. 1.10) [58]. The glucose-to-fructose isomerization is inhibited by HCl which decreases the equilibrium [Cr(H2O)5OH]2+concentration, while the overall consumption rate of fructose and HMF over Lewis acid species most likely promotes side reactions. Several other studies show that both the fructose dehydration rate and HMF selectivity (up to 62% yield) are enhanced in a mixed solvent of water and tetrahydrofuran or 2-sec-butylphenol at 160–170 °C by introducing a certain amount of HCl into the Lewis acidic Al3+aqua/hydroxo complexes [59, 60]. In a similar manner, the combined use of Sn-beta with HCl [61], or metal salts (e.g., CrCl3, InCl3, CoSO4, FeCl2 and MnCl2) with SO3 H-functionalized ionic liquids [62,63,64,65,66] is able to catalyze glucose and glucose-containing saccharides (e.g., cellulose) to obtain HMF in good yields (up to >80%). The recyclability of the acidic ionic liquids coupled with metal salts can be improved by immobilizing both active species into a solid polymer that retains catalytic activity [67].

Metal oxides are typically Lewis acid catalysts, and they rarely exhibit high selectivity and reactivity in the conversion of glucose to HMF [68]. However, the introduction of Brønsted acid sites into metal oxides by treatment with mineral acids (e.g., phosphoric acid and sulfuric acid) or acidic metal species (e.g., tungsten), and the resulting Brønsted-Lewis acid bifunctional hybrids (e.g., zirconium, aluminum, titanium, tantalum and niobium phosphates, sulfated zirconia, and W-Zr or W-Sn oxide) increase the efficiency of the direct conversion of glucose to HMF as compared with pristine metal oxides [69,70,71,72,73,74,75,76]. Some other neoteric strategies have been explored for the introduction of Brønsted acid sites into metal oxides. For example, the SBA-Sn-OH Lewis and Brønsted bifunctional catalyst can be prepared by grafting of dimethyldichlorostannane onto the SBA-15 surface (SBA-Sn-Me) that is followed by calcination to transform the –CH3 into –OH groups (Fig. 1.11) [77].

Schematic route for synthesis of Lewis-Brønsted bifunctional SBA-Sn-OH (Adapted with permission from Ref. [77], Copyright © 2014 Royal Society of Chemistry)

The synthesis of heteropolyacid salts via exchange with metal ions (Cs+, Ag+and Cr3+) is an efficient way to solidify homogeneous heteropolyacids such as 12-tungstophosphoric acid and silicotungstic acid for obtaining Lewis-Brønsted dual sites and porous structure [78,79,80]. Notably, the replacement of W in 12-tungstophosphoric acid with Cr makes the resulting acid H3PW11CrO39 simultaneously bear strong Brønsted and Lewis acid centers, while the further introduction of hexadecyltrimethylammonium bromide (CTAB) forms a highly water-tolerant salt [81]. Due to the dual acidity and hydrophobicity of the catalyst, more than 90% hexose conversion has been reported for the production of HMF [81]. The framework dealumination and desilication of H-form zeolites are efficient for the extension of pore diameters and for the adjustment of Lewis-Brønsted acid sites distribution [82]. The resulting desilicated H-ZSM-5 and dealuminated H-beta zeolites display pronounced performance in the transformation of either cellulose or glucose (67–81% conversion) into HMF (up to ca. 50% yield) in water or ionic liquids [83,84,85] (Fig. 1.12).

Lewis-Brønsted bifunctional catalysts like cesium salts of 12-tungstophosphoric acid, silicoaluminophosphate, partially hydroxylated magnesium fluoride, Zr-(W,Al) mixed oxides, sulfonated carbonaceous TiO2, and H-form zeolites promote formation of furfural in moderate to good yields from pentose sugars (e.g., hemicellulose, xylan, xylose, arabinose and ribose) [21, 86,87,88,89,90,91,92,93]. The catalysts with high molar ratios of Brønsted to Lewis acid sites have selectivity towards furfural as much as 30 times higher than that for relatively higher concentrations of Lewis acid sites [93]. Notably, the transformation of hexoses (e.g., glucose) into furfural (up to 37% yield) is realized by involving a retro-aldol reaction to form pentoses over H-form zeolites (e.g., H-ZSM-5 and H-beta) in γ-valerolactone with 10 wt% water, while the strong Brønsted acid Amberlyst-70 is exclusively selective for the dehydration of glucose and fructose to HMF rather than furfural [94]. These results show that the close interplay of Lewis acid and Brønsted acid centers in the solid catalyst seems to be crucial for achieving good activity in the synthesis of either HMF or furfural from biomass-derived sugars.

4.2 Base-Acid Bifunctional Catalysis

Besides the interplay of Lewis-Brønsted dual acidic sites, the reactivity of acids in the catalytic transformation of glucose into HMF is also affected by the presence of a solid base catalyst [95]. Combination of a solid base catalyst with an acidic catalyst allows glucose to be efficiently converted into HMF through glucose-to-fructose isomerization over HT, and the subsequent dehydration is catalyzed by Amberlyst-15 under mild conditions (Fig. 1.13a) [96]. After reaction in N,N-dimethylformamide at 80 °C for 9 h, 58% selectivity towards HMF for a glucose conversion of 73% is obtained, while no HMF forms in the presence of either Amberlyst-15 or HT. These results clearly show the synergistic role of solid acid and solid base in the synthesis of HMF from glucose. The mixed catalytic systems can be further extended to disaccharides including sucrose and cellobiose for producing HMF to obtain yields of 54% and 35% at 120 °C in 3 h reaction time, respectively [96]. The formation of anhydroglucose from glucose over an acid (i.e., Amberlyst-15) is evidently limited by HT (base)-catalyzed isomerization of glucose to fructose at relatively low reaction temperatures [97]. By using this solid acid-base mixed catalyst system, xylose can be directly transformed into furfural (up to 41% yield) at 100 °C for 3 h, with the isomer xylulose as a key intermediate (Fig. 1.13b) [98, 99]. Likewise, a mixture of arabinose, rhamnose and lactose over Amberlyst-15 and HT is selectively converted to yield furfural (30.5%), HMF (29.1%) and 5-methyl-2-furaldehyde (32.2%) at 110 °C after 6 h, respectively [100]. Catalytically upgrading sugar components of crude biomass with solid base and acid mixtures is most likely to be a promising approach for one-pot synthesis of biofuranic compounds especially HMF and furfural.

TiO2, ZrO2 and their mixed oxides possess both basic and acidic sites for the conversion of glucose components to HMF via the key intermediate fructose [101]. Moreover, the use of these single catalysts greatly simplify the separation and recovery process, although hot compressed water (ca. 200–300 °C) is required to transform glucose into HMF (<20% yields) [102, 103]. The relatively low HMF yields can be ascribed to the lack of strong Brønsted acid sites. In connection to this, Qi et al. found that the acidity of ZrO2 could be significantly enhanced by impregnation with H2SO4, and the resulting sulfated ZrO2 exhibited good activity in the dehydration of fructose (93.6% conversion) to HMF (72.8% yields) under microwave heating in acetone/dimethylsulfoxide (DMSO) at 180 °C for 20 min reaction time [104]. Under mild conditions of 100 °C and 6 h, the sulfated ZrO2 catalyst could also afford HMF (<10% selectivity) but with a large portion of fructose (ca. 80% selectivity) from glucose [105]. It can be speculated that tetragonal ZrO2 (Lewis base) should be active for the isomerization of glucose to fructose via an enol intermediate, while polydentate surface SO4 2− species (Brønsted acid) acts on the subsequent dehydration of fructose to HMF, as illustrated in Fig. 1.14. Moreover, Lewis acidic Zr4+might assist the stabilization of the enolate intermediate formed during the isomerization reaction. With the aim of combining both basic and acidic centers into a single catalyst, some other protocols have been examined. For example, the post-grafting of SO3 H and NH2 groups onto mesoporous silica nanoparticles via covalent bonds [106], the assembly of lysine with 12-tungstophophoric acid [107], and the incorporation of heteroatoms (e.g., Sn, Zr, Cr and Ti) into the framework of molecular sieves make the resulting hybrids highly disperse and to have compatible dual active sites [108], which are active for producing HMF in yields of reaching >80% from hexose sugars.

Sulfated ZrO2mediated reaction mechanism for (a) glucose-to-fructose isomerisation over basic sites (O2−), and (b) fructose-to-HMF dehydration with Brønsted acid sites (−OH) (Adapted with permission from Ref. [105], Copyright © 2014 Royal Society of Chemistry)

4.3 Metal-Base Bifunctional Catalysis

Selective oxidation of biomass derivatives to carboxylic acids is an important route to petroleum-based chemicals. In particular, 2,5-furandicarboxylic acid (FDCA) has been regarded as a potential replacement for terephthalic acid to produce polyethyleneterephthalate, which can be attained by the aerobic oxidation of HMF (Fig. 1.15) [109]. In most cases, the addition of a basic additive (e.g., NaOH) is necessary to facilitate the oxidation reaction by desorption of the acid product from the metal (e.g., Pt, Pb and Au) surface, wherein the reactivity of hydroxide is generally superior to that of carbonate [110, 111]. The alcohol oxidation of 5-hydroxymethyl-2-furancarboxylic acid (HMFCA) into FDCA is found to be the rate-determining step [110, 111]. In the presence of 5 mol% NaOH, 1 wt% Au supported on TiO2 catalyzes HMF being fully oxidized to FDCA (71% yield) at 30 °C and 2.0 MPa O2 after 18 h [112]. The formation of partially oxidized intermediate HMFCA is proportional to the base dosage and O2 pressure, implying that the reaction occurs mainly through initial oxidation of the –CHO moiety to 5-formyl-2-furancarboxylic acid (FFCA) followed by oxidation of the –OH group in HMF to yield the final product FDCA (Fig. 1.15). The possible oxygenated intermediate 2,5-diformylfuran (DFF) is hardly observed during the reaction [113,114,115], which means that the reaction pathway is most likely that shown in Fig. 1.15.

To improve the recyclability of the catalyst system, porous solid base (e.g., HT) can be used as either a co-catalyst or a support [116, 117]. The combination of HT with Au/TiO2, and Au supported on HT both show excellent performance in the aerobic oxidation of HMF [116, 117], giving FDCA in maximum yield of 99% at 95 °C in water under flowing O2 (50 mL/min). By simple deposition of a relatively low-cost ruthenium salt (e.g., Ru(NO3)3 or RuCl3) onto a basic support (e.g., HT, MgO, La2O3 or spinel), supported ruthenium catalysts are active in the oxidation reaction, and Ru(OH) x with basic supports as the active center [118,119,120]. On the other hand, metal ions (e.g., Fe3+and Co2+) supported on porphyrin-based porous organic polymers exhibit good activity in the oxidation of HMF (>95% conversion) to yield FDCA (up to >90%) at 100 °C after 3–24 h using either oxygen/air or peroxide (e.g., tert-butyl hydroperoxide), wherein basic porphyrin subunits and metal ion centers are dual active species [121, 122]. Unlike catalytic systems mediated by zero-valent metal particles (e.g., Pt, Pd and Au), DFF instead of HMFCA is observed to be the key intermediate for producing FDCA from HMF over supported metal-porphyrin catalysts [122]. The reactivity of metal-base bifunctional catalytic materials is greatly enhanced by their concerted interplay, but the reaction pathways might be affected by the type of active species.

4.4 Metal-Acid Bifunctional Catalysis

Hydrogenation and hydrodeoxygenation (HDO) over metal particles accompanied by acidic species are the frequently used routes to decrease the oxygen contents of biomass components. Much attention has been placed on the selective hydrogenation of HMF to 2,5-dimethylfuran (DMF), which is deemed to be a promising alternative liquid fuel for transportation [123, 124]. A Brønsted acid (e.g., HCl and H2SO4) can be used to cleave the furanic C-O bond, and then PdAu particles stabilized on carbon support (PdAu/C) show good performance for the complete hydrogenation of HMF to DMF (up to 96% yield) at 60 °C after 12 h under an H2 atmosphere [125]. The 2-methylfurfural (5-MF) and 5-methylfurfuryl alcohol (MFA) are both observed while ring-hydrogenated products such as 2,5-dimethyltetrahydrofuran (DMTHF) and 2,5-bis(hydromethyl)tetrahydrofuran (DHTHF) do not seem to form (Fig. 1.16), indicating that the reaction proceeds through intermediates containing alcohol groups. Apart from the promotional role of negatively charged Au formed by the co-existence of Pd, HCl with strong acidity (pKa < −5) and chloride ion are necessary as co-catalyst for effective and selective production of DMF by preventing undesirable ring-hydrogenation and facilitating hydrogenolysis through nucleophilic substitution on the alcohol groups of the reactants to form an active chlorinated intermediate [125].

Bimetallic catalysts containing a Lewis acidic center (e.g., Zn2+and Co2+) and a hydriding metal component (e.g., Pd and Ru) are more recyclable and have good reactivity for forming DMF from hydrogenation of HMF. For instance, the combination of Zn2+in the form of ZnO, with Pd, Ru or Cu particles catalyzes HMF conversion to DMF with yields of >85% under 0.8–1.5 MPa H2 at 150–220 °C after 5–8 h, which were more active than ZnCl2 (no DMF observed) and a single metallic catalyst such as Pd/C and Ru/C (<30% DMF yield) [126, 127]. Likewise, the introduction of acidic CoO x species into Pt, Ru or Ni nanoparticles promotes the hydrogenation of HMF under mild conditions with reaction temperatures as low as 130 °C and no more than 1 MPa H2 pressure, producing DMF in yields of up to 98% [128,129,130]. The co-added Lewis acidic species seems to be favorable for the substrate absorption and the C-O bond cleavage. Notably, the reusability of these bimetallic hybrids is greatly enhanced by the presence of secondary metal oxides (e.g., Co3O4 and ZnO) during hydrogenolysis. On the other hand, the use of acidic solid supports (e.g., zeolite and tungsten carbide) to immobilize and disperse metal particles provides another efficient way to efficiently hydrogenate HMF to produce DMF [131, 132]. Further integration of a strong Brønsted acid (e.g., Amberlyst-15) with a solid catalyst containing metal-acid dual sites allows effective conversion of fructose to yield DMF via the intermediate of HMF in a two-step process involving fructose dehydration and subsequent hydrogenation [133]. The design of metal-acid bifunctional catalytic materials seems to be one of the most promising ways to directly valorize upstream biomass derivatives to desired products having low oxygen content.

5 Synthesis of Bio-Based Organic Acids

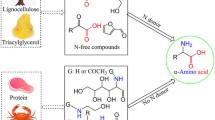

Instead of producing oxygenates (e.g., gluconic acid, glycolic acid, and acetic acid) from biomass-derived sugars under aerobic conditions, the anaerobic oxidation process leads to the formation of either levulinic acid (LA) or lactic acid (LAC), as shown in Fig. 1.17, which is closely dependent on the type of catalysts and reaction conditions. For the synthesis of LA or its ester from hexose sugars, HMF is the key intermediate, while the subsequent rehydration removes one carbon atom as formic acid [134]. However, glucose over a Brønsted acid is not converted to LA or its ester, but yields anhydroglucose in dipolar aprotic solvents (e.g., N,N-dimethyl formamide or dimethylsulfoxide) or alkyl glucopyranoside in alcohols (e.g., methanol or ethanol) as the dominant product [135]. This obstacle is overcome by the introduction of Lewis acidic species into Brønsted acid-catalyzed systems [136]. In this regard, the solid zeolitic materials seem to be one of the best options that can be used as bifunctional catalysts. Saravanamurugan and Riisager illustrate that the commerical zeolites especially large-pore H-USY(Si/Al = 6) with both Brønsted and Lewis acid sites produce methyl and ethyl levulinates (ML and EL) with yields of >40% from glucose at 160 °C after 20 h, wherein the cascade reactions including isomerization, dehydration, and rehydration take place in sequence [137]. Further doping of Lewis acidic species (e.g., Cr3+and Fe3+) onto the surface framework of Y-type faujasite zeolites results in the formation of hybrids (e.g., Cr/HY and Fe/HY) with enhanced Lewis acidity, which exhibit pronounced LA yields (ca. 62%) at 180 °C within 3 h [138, 139]. Similarly, a number of solid Brønsted-Lewis acid bifunctional catalysts such as sulfated Dowex 50 modified by cation exchange with FeCl3 [140] and sulfated or phosphorylated metal oxides (e.g., SO4/ZrO2, SO4/TiO2, and PO4/ZrO2) [141,142,143] are active for the conversion of glucose to LA, and the appropriate molar ratio of Brønsted to Lewis acid sites (ca. 1.2–2.0) play a crucial role in the enhancement of glucose conversion and LA yields.

Besides the occurrence of aldose-ketose isomerization, the presence of excess Lewis acidic sites results in the retro-aldol reaction of hexose sugars (e.g., glucose and fructose) to trioses including glyceraldehyde and dihydroxyacetone, followed by dehydration to pyruvaldehyde over Lewis acid sites, finally giving LAC or its ester via the addition of one molecule water or alcohol and succeeding the 1,2-hydride shift (Fig. 1.18) [144]. The Sn grafted carbon-silica (MCM-41) has both Lewis acidity (Sn4+) and Brønsted acidity (e.g., −OH and –COOH derived from carbon part) that can be changed by adjusting the carbon loading amount [145]. The carbon-containing Sn-Si-MCM-41 catalyst with balanced Lewis/Brønsted acidic sites greatly improves the conversion of sucrose in methanol at 155 °C after 20 h to yield methyl lactate (45%), and is superior to SnCl4·5H2O (26%) and carbon-free Sn-Si-MCM-41 (18%) [145]. Zeolitic materials with both Lewis acidic Sn and Brønsted acidic Al centers exhibit a faster formation of ethyl lactate (>100 h−1) from dihydroxyacetone in comparison with Al-free Sn-beta (72 h−1), which is possibly due to the dehydration reaction being promoted by Brønsted acid sites [146]. When cellobiose or even cellulose is employed as substrate, the hydrolysis step integrated with retro-aldol, dehydration and hydration reactions is able to be accelerated by the coexistence of strong Brønsted acidity and weak or medium Lewis acidity [16], thus directly giving the desired lactic acid product in moderate yields (e.g., 18–27% over AlW and ZrW) in water under hydrothermal conditions (e.g., at 190 °C for 24 h) via a single-pot process [147]. These results emphasize the significant role that bifunctional catalysts will play in the efficient valorization of low-cost upstream biomass components to value-added products with high selectivity.

Reaction pathway for transforming glucose into lactic acid (LAC) and ester; L = Lewis acid, B = Brønsted acid [144]

6 Conclusions and Future Outlook

Bifunctional catalytic pathways have been demonstrated to be efficient for multi-step transformations of biomass derivatives into value-added chemcials and biofuels. The combination of Lewis acid or base centers with Brønsted acid sites can selectively promote sequential hydrolysis, isomerization and dehydration of sugars to produce HMF, furfural or organic acids (e.g., LA and LAC) with moderate to good yields, however, the results depend on the sugar type (hexose or pentose) as well as the distribution and charateristics of active sites on solid catalysts. With respect to the oxidation of furanic compounds (e.g., HMF) mediated by metal particles (e.g., Pt, Pb and Au), the catalytic process is greatly accelerated by the presence of basic species that promotes desorption of the acidic product from the metal surface. For the hydrogenation or HDO, the presence of acidic speices is able to promote the cleavage of the C-O bond in biomass derivatives, thus facilitating the removal of oxygen content over metal particles.

Some issues regarding the establishment of well-defined reaction systems and solid catalytic materials may be explored for further research on bifunctional catalytic pathways: (1) increasing the incompatibility of different active sites in a single solid catalyst; (2) suppressing the formation of undesirable products or humins; (3) controlling the sequence of cascade reactions as specified; (4) improving the uniformity, stability and recyclability of bifunctional solid catalysts; and (5) employing computational methods to comprehend preferred configurations or arrangements of active species, thus guiding the exploration of suitable approaches for the inclusion of catalytic sites.

A great number of opportunities exist for the development of bifunctional catalytic pathways mediated by well-defined solid materials in both fundamental and applied fields. The examples illustrated in this chapter provide an introduction into some of the ways for practical realization of multi-catalytic processes for biomass valorization.

References

Udaya V, Rao S, Gormley RJ. Bifunctional catalysis in syngas conversions. Catal Today. 1990;6:207–34.

Li H, Fang Z, Smith RL, Yang S. Efficient valorization of biomass to biofuels with bifunctional solid catalytic materials. Prog Energy Combust Sci. 2016;55:98–194.

Xiao K, Bao Z, Qi X, Wang X, Zhong L, Fang K, Lin M, Sun Y. Advances in bifunctional catalysis for higher alcohol synthesis from syngas. Chin J Catal. 2013;34:116–29.

Tanabe K, Yamaguchi T. Acid-base bifunctional catalysis by ZrO2 and its mixed oxides. Catal Today. 1994;20:185–98.

Huang Y, Long B, Tang M, Rui Z, Balogun MS, Tong Y, Ji H. Bifunctional catalytic material: an ultrastable and high-performance surface defect CeO2 nanosheets for formaldehyde thermal oxidation and photocatalytic oxidation. Appl Catal B Environ. 2016;181:779–87.

Bauer G, Kirchner KA. Well-defined bifunctional iron catalysts for the hydrogenation of ketones: iron, the new ruthenium. Angew Chem Int Ed. 2011;50:5798–800.

Roessner F, Roland U. Hydrogen spillover in bifunctional catalysis. J Mol Catal A Chem. 1996;112:401–12.

Sinfelt JH. Bifunctional catalysis. Adv Chem Eng. 1964;5:37–74.

Margelefsky EL, Zeidan RK, Davis ME. Cooperative catalysis by silica-supported organic functional groups. Chem Soc Rev. 2008;37:1118–26.

Li H, Wu H, Zhang Q, Liu J, Liu X, Liu Y, Yang S. Solid acid-base bifunctional catalysts in organic transformations. Curr Catal. 2013;2:173–212.

Li H, Bhadury PS, Riisager A, Yang S. One-pot transformation of polysaccharides via multi-catalytic processes. Cat Sci Technol. 2014;4:4138–68.

Guo F, Fang Z, CC X, Smith RL. Solid acid mediated hydrolysis of biomass for producing biofuels. Prog Energy Combust Sci. 2012;38:672–90.

Vilcocq L, Castilho PC, Carvalheiro F, Duarte LC. Hydrolysis of oligosaccharides over solid acid catalysts: a review. ChemSusChem. 2014;7:1010–9.

Hu L, Lin L, Wu Z, Zhou S, Liu S. Chemocatalytic hydrolysis of cellulose into glucose over solid acid catalysts. Appl Catal B Environ. 2015;174:225–43.

Schwiderski M, Kruse A, Grandl R, Dockendorf D. Comparison of the influence of a Lewis acid AlCl3 and a Brønsted acid HCl on the organosolv pulping of beech wood. Green Chem. 2014;16:1569–78.

Shimizu KI, Furukawa H, Kobayashi N, Itaya Y, Satsuma A. Effects of Brønsted and Lewis acidities on activity and selectivity of heteropolyacid-based catalysts for hydrolysis of cellobiose and cellulose. Green Chem. 2009;11:1627–32.

Kourieh R, Bennici S, Marzo M, Gervasini A, Auroux A. Investigation of the WO3/ZrO2 surface acidic properties for the aqueous hydrolysis of cellobiose. Catal Commun. 2012;19:119–26.

Carà PD, Pagliaro M, Elmekawy A, Brown DR, Verschuren P, Shiju NR, Rothenberg G. Hemicellulose hydrolysis catalysed by solid acids. Cat Sci Technol. 2013;3:2057–61.

Onda A, Ochi T, Yanagisawa K. Selective hydrolysis of cellulose into glucose over solid acid catalysts. Green Chem. 2008;10:1033–7.

Lanzafame P, Temi DM, Perathoner S, Spadaro AN, Centi G. Direct conversion of cellulose to glucose and valuable intermediates in mild reaction conditions over solid acid catalysts. Catal Today. 2012;179:178–84.

Sahu R, Dhepe PL. A one-pot method for the selective conversion of hemicellulose from crop waste into C5 sugars and furfural by using solid acid catalysts. ChemSusChem. 2012;5:751–61.

Zhou L, Liu Z, Shi M, Du S, Su Y, Yang X, Xu J. Sulfonated hierarchical H-USY zeolite for efficient hydrolysis of hemicellulose/cellulose. Carbohydr Polym. 2013;98:146–51.

Zhou L, Shi M, Cai Q, Wu L, Hu X, Yang X, Chem C, Xu J. Hydrolysis of hemicellulose catalyzed by hierarchical H-USY zeolites–the role of acidity and pore structure. Microporous Mesoporous Mater. 2013;169:54–9.

Zhang Z, Zhao ZK. Solid acid and microwave-assisted hydrolysis of cellulose in ionic liquid. Carbohydr Res. 2009;344:2069–72.

Bhaumik P, Deepa AK, Kane T, Dhepe PL. Value addition to lignocellulosics and biomass-derived sugars: an insight into solid acid-based catalytic methods. J Chem Sci. 2014;126:373–85.

Perego C, Bianchi D. Biomass upgrading through acid-base catalysis. Chem Eng J. 2010;161:314–22.

Chandel AK, Antunes FA, Anjos V, Bell MJ, Rodrigues LN, Polikarpov I, de Azevedo ER, Bernardinelli OD, Rosa CA, Pagnocca FC, da Silva SS. Multi-scale structural and chemical analysis of sugarcane bagasse in the process of sequential acid-base pretreatment and ethanol production by Scheffersomyces shehatae and Saccharomyces cerevisiae. Biotechnol Biofuels. 2014;7:63.

Jung YH, Park HM, Kim IJ, Park YC, Seo JH, Kim KH. One-pot pretreatment, saccharification and ethanol fermentation of lignocellulose based on acid-base mixture pretreatment. RSC Adv. 2014;4:55318–27.

Fang Z, Zhang F, Zeng HY, Guo F. Production of glucose by hydrolysis of cellulose at 423K in the presence of activated hydrotalcite nanoparticles. Bioresour Technol. 2011;102:8017–21.

Lee DG, Choi DJ, Park JK. Ketoisomeric conversion of glucose derived from microalgal biomasses. Process Biochem. 2015;50:941–7.

Zhao H, Cui Q, Shah V, Xu J, Wang T. Enhancement of glucose isomerase activity by immobilizing on silica/chitosan hybrid microspheres. J Mol Catal B Enzym. 2016;126:18–23.

Delidovich I, Palkovits R. catalytic isomerization of biomass-derived aldoses: a review. ChemSusChem. 2016;9:547–61.

Marianou AA, Michailof CM, Pineda A, Iliopoulou EF, Triantafyllidis KS, Lappas AA. Glucose to fructose isomerization in aqueous media over homogeneous and heterogeneous catalysts. ChemCatChem. 2016;8:1100–10.

Kitajima H, Higashino Y, Matsuda S, Zhong H, Watanabe M, Aida TM, Smith RL. Isomerization of glucose at hydrothermal condition with TiO2, ZrO2, CaO-doped ZrO2 or TiO2-doped ZrO2. Catal Today. 2016;274:67–72.

Souza RO, Fabiano DP, Feche C, Rataboul F, Cardoso D, Essayem N. Glucose-fructose isomerisation promoted by basic hybrid catalysts. Catal Today. 2012;195:114–9.

Moliner M, Román-Leshkov Y, Davis ME. Tin-containing zeolites are highly active catalysts for the isomerization of glucose in water. Proc Natl Acad Sci U S A. 2010;107:6164–8.

Bermejo-Deval R, Assary RS, Nikolla E, Moliner M, Román-Leshkov Y, Hwang SJ, Palsdottir A, Silverman D, Lobo RF, Curtiss LA, Davis ME. Metalloenzyme-like catalyzed isomerizations of sugars by Lewis acid zeolites. Proc Natl Acad Sci U S A. 2012;109:9727–32.

Rai N, Caratzoulas S, Vlachos DG. Role of silanol group in Sn-beta zeolite for glucose isomerization and epimerization reactions. ACS Catal. 2013;3:2294–8.

Li G, Pidko EA, Hensen EJ. Synergy between Lewis acid sites and hydroxyl groups for the isomerization of glucose to fructose over Sn-containing zeolites: a theoretical perspective. Cat Sci Technol. 2014;4:2241–50.

Li YP, Head-Gordon M, Bell AT. Analysis of the reaction mechanism and catalytic activity of metal-substituted beta zeolite for the isomerization of glucose to fructose. ACS Catal. 2014;4:1537–45.

Li G, Pidko EA, Hensen EJ. A periodic DFT study of glucose to fructose isomerization on tungstite (WO3·H2O): influence of group IV–VI dopants and cooperativity with hydroxyl groups. ACS Catal. 2016;6:4162–9.

Christianson JR, Caratzoulas S, Vlachos DG. Computational insight into the effect of Sn-beta Na exchange and solvent on glucose isomerization and epimerization. ACS Catal. 2015;5:5256–63.

Gao DM, Kobayashi T, Adachi S. Kinetic effect of alcohols on hexose isomerization under subcritical aqueous conditions. Chem Eng Res Des. 2015;104:723–9.

Gao DM, Kobayashi T, Adachi S. Promotion or suppression of glucose isomerization in subcritical aqueous straight-and branched-chain alcohols. Biosci Biotechnol Biochem. 2015;79:470–4.

Cho HJ, Dornath P, Fan W. Synthesis of hierarchical Sn-MFI as Lewis acid catalysts for isomerization of cellulosic sugars. ACS Catal. 2014;4:2029–37.

Gounder R, Davis ME. Monosaccharide and disaccharide isomerization over Lewis acid sites in hydrophobic and hydrophilic molecular sieves. J Catal. 2013;308:176–88.

Soisangwan N, Gao DM, Kobayashi T, Khuwijitjaru P, Adachi S. Kinetic analysis for the isomerization of cellobiose to cellobiulose in subcritical aqueous ethanol. Carbohydr Res. 2016;433:67–72.

Gounder R, Davis ME. Titanium-beta zeolites catalyze the stereospecific isomerization of D-glucose to L-sorbose via intramolecular C5–C1 hydride shift. ACS Catal. 2013;3:1469–76.

Saravanamurugan S, Paniagua M, Melero JA, Riisager A. Efficient isomerization of glucose to fructose over zeolites in consecutive reactions in alcohol and aqueous media. J Am Chem Soc. 2013;135:5246–9.

Saravanamurugan S, Riisager A, Taarning E, Meier S. Combined function of Brønsted and Lewis acidity in the zeolite-catalyzed isomerization of glucose to fructose in alcohols. ChemCatChem. 2016;8:3107–11.

Saravanamurugan S, Riisager A, Taarning E, Meier S. Mechanism and stereoselectivity of zeolite-catalysed sugar isomerisation in alcohols. Chem Commun. 2016;52:12773–6.

Paniagua M, Saravanamurugan S, Melian-Rodriguez M, Melero JA, Riisager A. Xylose isomerization with zeolites in a two-step alcohol-water process. ChemSusChem. 2015;8:1088–94.

Saravanamurugan S, Riisager A. Zeolite-catalyzed isomerization of tetroses in aqueous medium. Cat Sci Technol. 2014;4:3186–90.

Ren L, Guo Q, Kumar P, Orazov M, Xu D, Alhassan SM, Mkhoyan KA, Davis ME, Tsapatsis M. Self-pillared, single-unit-cell Sn-MFI zeolite nanosheets and their use for glucose and lactose isomerization. Angew Chem Int Ed. 2015;54:10848–51.

Li H, Yang S, Riisager A, Pandey A, Sangwan RS, Saravanamurugan S, Luque R. Zeolite and zeotype-catalysed transformations of biofuranic compounds. Green Chem. 2016;18:5701–35.

Liu Y, Li Z, Yang Y, Hou Y, Wei Z. A novel route towards high yield 5-hydroxymethylfurfural from fructose catalyzed by a mixture of Lewis and Brønsted acids. RSC Adv. 2014;4:42035–8.

Binder JB, Raines RT. Simple chemical transformation of lignocellulosic biomass into furans for fuels and chemicals. J Am Chem Soc. 2009;131:1979–85.

Choudhary V, Mushrif SH, Ho C, Anderko A, Nikolakis V, Marinkovic NS, Frenkel AI, Sandler SI, Vlachos DG. Insights into the interplay of Lewis and Brønsted acid catalysts in glucose and fructose conversion to 5-(hydroxymethyl) furfural and levulinic acid in aqueous media. J Am Chem Soc. 2013;135:3997–4006.

Yang Y, Hu C, Abu-Omar MM. The effect of hydrochloric acid on the conversion of glucose to 5-hydroxymethylfurfural in AlCl3-H2O/THF biphasic medium. J Mol Catal A Chem. 2013;376:98–102.

Pagan-Torres YJ, Wang T, Gallo JMR, Shanks BH, Dumesic JA. Production of 5-hydroxymethylfurfural from glucose using a combination of Lewis and Brønsted acid catalysts in water in a biphasic reactor with an alkylphenol solvent. ACS Catal. 2012;2:930–4.

Nikolla E, Román-Leshkov Y, Moliner M, Davis ME. “One-pot” synthesis of 5-(hydroxymethyl) furfural from carbohydrates using tin-beta zeolite. ACS Catal. 2011;1:408–10.

Wu L, Song J, Zhang B, Zhou B, Zhou H, Fan H, Yang Y, Han B. Very efficient conversion of glucose to 5-hydroxymethylfurfural in DBU-based ionic liquids with benzenesulfonate anion. Green Chem. 2014;16:3935–41.

Li H, Zhang Q, Liu X, Chang F, Hu D, Zhang Y, Xue W, Yang S. InCl3-ionic liquid catalytic system for efficient and selective conversion of cellulose into 5-hydroxymethylfurfural. RSC Adv. 2013;3:3648–54.

Tao F, Song H, Chou L. Catalytic conversion of cellulose to chemicals in ionic liquid. Carbohydr Res. 2011;346:58–63.

Tao F, Song H, Chou L. Hydrolysis of cellulose by using catalytic amounts of FeCl2 in ionic liquids. ChemSusChem. 2010;3:1298–303.

Tao F, Song H, Yang J, Chou L. Catalytic hydrolysis of cellulose into furans in MnCl2-ionic liquid system. Carbohydr Polym. 2011;85:363–8.

Li H, Zhang Q, Liu X, Chang F, Zhang Y, Xue W, Yang S. Immobilizing Cr3+with SO3H-functionalized solid polymeric ionic liquids as efficient and reusable catalysts for selective transformation of carbohydrates into 5-hydroxymethylfurfural. Bioresour Technol. 2013;144:21–7.

Nakajima K, Baba Y, Noma R, Kitano M, Kondo JN, Hayashi S, Hara M. Nb2O5·nH2O as a heterogeneous catalyst with water-tolerant Lewis acid sites. J Am Chem Soc. 2011;133:4224–7.

Ordomsky VV, van der Schaaf J, Schouten JC, Nijhuis TA. Glucose dehydration to 5-hydroxymethylfurfural in a biphasic system over solid acid foams. ChemSusChem. 2013;6:1697–707.

Ordomsky VV, Sushkevich VL, Schouten JC, Van der Schaaf J, Nijhuis TA. Glucose dehydration to 5-hydroxymethylfurfural over phosphate catalysts. J Catal. 2013;300:37–46.

Jiménez-Morales I, Teckchandani-Ortiz A, Santamaría-González J, Maireles-Torres P, Jiménez-López A. Selective dehydration of glucose to 5-hydroxymethylfurfural on acidic mesoporous tantalum phosphate. Appl Catal B Environ. 2014;144:22–8.

Dutta A, Patra AK, Dutta S, Saha B, Bhaumik A. Hierarchically porous titanium phosphate nanoparticles: an efficient solid acid catalyst for microwave assisted conversion of biomass and carbohydrates into 5-hydroxymethylfurfural. J Mater Chem. 2012;22:14094–100.

Zhang Y, Wang J, Ren J, Liu X, Li X, Xia Y, Lu G, Wang Y. Mesoporous niobium phosphate: an excellent solid acid for the dehydration of fructose to 5-hydroxymethylfurfural in water. Cat Sci Technol. 2012;2:2485–91.

Joo JB, Vu A, Zhang Q, Dahl M, Gu M, Zaera F, Yin Y. A sulfated ZrO2 hollow nanostructure as an acid catalyst in the dehydration of fructose to 5-hydroxymethylfurfural. ChemSusChem. 2013;6:2001–8.

Kourieh R, Rakic V, Bennici S, Auroux A. Relation between surface acidity and reactivity in fructose conversion into 5-HMF using tungstated zirconia catalysts. Catal Commun. 2013;30:5–13.

Yamaguchi K, Sakurada T, Ogasawara Y, Mizuno N. Tin-tungsten mixed oxide as efficient heterogeneous catalyst for conversion of saccharides to furan derivatives. Chem Lett. 2011;40:542–3.

Wang L, Zhang J, Wang X, Zhang B, Ji W, Meng X, Li J, DS S, Bao X, Xiao FS. Creation of Brønsted acid sites on Sn-based solid catalysts for the conversion of biomass. J Mater Chem A. 2014;2:3725–9.

Zhao Q, Wang L, Zhao S, Wang X, Wang S. High selective production of 5-hydroymethylfurfural from fructose by a solid heteropolyacid catalyst. Fuel. 2011;90:2289–93.

Jadhav AH, Kim H, Hwang IT. An efficient and heterogeneous recyclable silicotungstic acid with modified acid sites as a catalyst for conversion of fructose and sucrose into 5-hydroxymethylfurfural in superheated water. Bioresour Technol. 2013;132:342–50.

Zhao S, Cheng M, Li J, Tian J, Wang X. One pot production of 5-hydroxymethylfurfural with high yield from cellulose by a Brønsted-Lewis-surfactant-combined heteropolyacid catalyst. Chem Commun. 2011;47:2176–8.

Zheng H, Sun Z, Yi X, Wang S, Li J, Wang X, Jiang Z. A water-tolerant C16H3PW11CrO39 catalyst for the efficient conversion of monosaccharides into 5-hydroxymethylfurfural in a micellar system. RSC Adv. 2013;3:23051–6.

Gounder R. Hydrophobic microporous and mesoporous oxides as Brønsted and Lewis acid catalysts for biomass conversion in liquid water. Cat Sci Technol. 2014;4:2877–86.

Nandiwale KY, Galande ND, Thakur P, Sawant SD, Zambre VP, Bokade VV. One-pot synthesis of 5-hydroxymethylfurfural by cellulose hydrolysis over highly active bimodal micro/mesoporous H-ZSM-5 catalyst. ACS Sustain Chem Eng. 2014;2:1928–32.

Hu L, Wu Z, Xu J, Sun Y, Lin L, Liu S. Zeolite-promoted transformation of glucose into 5-hydroxymethylfurfural in ionic liquid. Chem Eng J. 2014;244:137–44.

Otomo R, Yokoi T, Kondo JN, Tatsumi T. Dealuminated Beta zeolite as effective bifunctional catalyst for direct transformation of glucose to 5-hydroxymethylfurfural. Appl Catal A Gen. 2014;470:318–26.

Dias AS, Lima S, Pillinger M, Valente AA. Acidic cesium salts of 12-tungstophosphoric acid as catalysts for the dehydration of xylose into furfural. Carbohydr Res. 2006;341:2946–53.

Bhaumik P, Dhepe PL. Efficient, stable, and reusable silicoaluminophosphate for the one-pot production of furfural from hemicellulose. ACS Catal. 2013;3:2299–303.

Agirrezabal-Telleria I, Hemmann F, Jäger C, Arias PL, Kemnitz E. Functionalized partially hydroxylated MgF2 as catalysts for the dehydration of D-xylose to furfural. J Catal. 2013;305:81–91.

Antunes MM, Lima S, Fernandes A, Candeias J, Pillinger M, Rocha SM, Ribeiro MA, Valente AA. Catalytic dehydration of D-xylose to 2-furfuraldehyde in the presence of Zr-(W,Al) mixed oxides; Tracing by-products using two-dimensional gas chromatography-time-of-flight mass spectrometry. Catal Today. 2012;195:127–35.

Mazzotta MG, Gupta D, Saha B, Patra AK, Bhaumik A, Abu-Omar MM. Efficient solid acid catalyst containing Lewis and Brønsted acid sites for the production of furfurals. ChemSusChem. 2014;7:2342–50.

Gallo JMR, Alonso DM, Mellmer MA, Yeap JH, Wong HC, Dumesic JA. Production of furfural from lignocellulosic biomass using beta zeolite and biomass-derived solvent. Top Catal. 2013;56:1775–81.

Dhepe PL, Sahu R. A solid-acid-based process for the conversion of hemicellulose. Green Chem. 2010;12:2153–6.

Weingarten R, Tompsett GA, Conner WC, Huber GW. Design of solid acid catalysts for aqueous-phase dehydration of carbohydrates: the role of Lewis and Brønsted acid sites. J Catal. 2011;279:174–82.

Gürbüz EI, Gallo JMR, Alonso DM, Wettstein SG, Lim WY, Dumesic JA. Conversion of hemicellulose into furfural using solid acid catalysts in γ-valerolactone. Angew Chem Int Ed. 2013;52:1270–4.

Setoyama T. Acid-base bifunctional catalysis: an industrial viewpoint. Catal Today. 2006;116:250–62.

Takagaki A, Ohara M, Nishimura S, Ebitani K. A one-pot reaction for biorefinery: combination of solid acid and base catalysts for direct production of 5-hydroxymethylfurfural from saccharides. Chem Commun. 2009;2009:6276–8.

Ohara M, Takagaki A, Nishimura S, Ebitani K. Syntheses of 5-hydroxymethylfurfural and levoglucosan by selective dehydration of glucose using solid acid and base catalysts. Appl Catal A Gen. 2010;383:149–55.

Takagaki A, Ohara M, Nishimura S, Ebitani K. One-pot formation of furfural from xylose via isomerization and successive dehydration reactions over heterogeneous acid and base catalysts. Chem Lett. 2010;39:838–40.

Shirotori M, Nishimura S, Ebitani K. One-pot synthesis of furfural from xylose using Al2O3–Ni-Al layered double hydroxide acid-base bi-functional catalyst and sulfonated resin. Chem Lett. 2015;45:194–6.

Tuteja J, Nishimura S, Ebitani K. One-pot synthesis of furans from various saccharides using a combination of solid acid and base catalysts. Bull Chem Soc Jpn. 2012;85:275–81.

Qi X, Watanabe M, Aida TM, Smith RL. Catalytical conversion of fructose and glucose into 5-hydroxymethylfurfural in hot compressed water by microwave heating. Catal Commun. 2008;9:2244–9.

Chareonlimkun A, Champreda V, Shotipruk A, Laosiripojana N. Catalytic conversion of sugarcane bagasse, rice husk and corncob in the presence of TiO2, ZrO2 and mixed-oxide TiO2-ZrO2 under hot compressed water (HCW) condition. Bioresour Technol. 2010;101:4179–86.

Watanabe M, Aizawa Y, Iida T, Nishimura R, Inomata H. Catalytic glucose and fructose conversions with TiO2 and ZrO2 in water at 473 K: relationship between reactivity and acid–base property determined by TPD measurement. Appl Catal A Gen. 2005;295:150–6.

Qi X, Watanabe M, Aida TM, Smith RL. Sulfated zirconia as a solid acid catalyst for the dehydration of fructose to 5-hydroxymethylfurfural. Catal Commun. 2009;10:1771–5.

Osatiashtiani A, Lee AF, Brown DR, Melero JA, Morales G, Wilson K. Bifunctional SO4/ZrO2 catalysts for 5-hydroxymethylfufural (5-HMF) production from glucose. Cat Sci Technol. 2014;4:333–42.

Peng WH, Lee YY, Wu C, KCW W. Acid-base bi-functionalized, large-pored mesoporous silica nanoparticles for cooperative catalysis of one-pot cellulose-to-HMF conversion. J Mater Chem. 2012;22:23181–5.

Zhao Q, Sun Z, Wang S, Huang G, Wang X, Jiang Z. Conversion of highly concentrated fructose into 5-hydroxymethylfurfural by acid-base bifunctional HPA nanocatalysts induced by choline chloride. RSC Adv. 2014;4:63055–61.

Xu Q, Zhu Z, Tian Y, Deng J, Shi J, Fu Y. Sn-MCM-41 as efficient catalyst for the conversion of glucose into 5-hydroxymethylfurfural in ionic liquids. Bioresources. 2013;9:303–15.

Zhang Z, Zhen J, Liu B, Lv K, Deng K. Selective aerobic oxidation of the biomass-derived precursor 5-hydroxymethylfurfural to 2, 5-furandicarboxylic acid under mild conditions over a magnetic palladium nanocatalys. Green Chem. 2015;17:1308–17.

Davis SE, Houk LR, Tamargo EC, Datye AK, Davis RJ. Oxidation of 5-hydroxymethylfurfural over supported Pt, Pd and Au catalysts. Catal Today. 2011;160:55–60.

Casanova O, Iborra S, Corma A. Biomass into chemicals: aerobic oxidation of 5-hydroxymethyl-2-furfural into 2,5-furandicarboxylic acid with gold nanoparticle catalysts. ChemSusChem. 2009;2:1138–44.

Gorbanev YY, Klitgaard SK, Woodley JM, Christensen CH, Riisager A. Gold-catalyzed aerobic oxidation of 5-hydroxymethylfurfural in water at ambient temperature. ChemSusChem. 2009;2:672–5.

Davis SE, Zope BN, Davis RJ. On the mechanism of selective oxidation of 5-hydroxymethylfurfural to 2, 5-furandicarboxylic acid over supported Pt and Au catalysts. Green Chem. 2012;14:143–7.

Pasini T, Piccinini M, Blosi M, Bonelli R, Albonetti S, Dimitratos N, Lopez-Sanchez JA, Sankar M, He Q, Kiely CJ, Hutchings GJ, Cavani F. Selective oxidation of 5-hydroxymethyl-2-furfural using supported gold-copper nanoparticles. Green Chem. 2011;13:2091–9.

Siankevich S, Savoglidis G, Fei Z, Laurenczy G, Alexander DT, Yan N, Dyson PJ. A novel platinum nanocatalyst for the oxidation of 5-hydroxymethylfurfural into 2, 5-furandicarboxylic acid under mild conditions. J Catal. 2014;315:67–74.

Zope BN, Davis SE, Davis RJ. Influence of reaction conditions on diacid formation during Au-catalyzed oxidation of glycerol and hydroxymethylfurfural. Top Catal. 2012;55:24–32.

Gupta NK, Nishimura S, Takagaki A, Ebitani K. Hydrotalcite-supported gold-nanoparticle-catalyzed highly efficient base-free aqueous oxidation of 5-hydroxymethylfurfural into 2, 5-furandicarboxylic acid under atmospheric oxygen pressure. Green Chem. 2011;13:824–7.

Gorbanev YY, Kegnæs S, Riisager A. Effect of support in heterogeneous ruthenium catalysts used for the selective aerobic oxidation of HMF in water. Top Catal. 2011;54:1318–24.

Gorbanev YY, Kegnæs S, Riisager A. Selective aerobic oxidation of 5-hydroxymethylfurfural in water over solid ruthenium hydroxide catalysts with magnesium-based supports. Catal Lett. 2011;141:1752–60.

Ståhlberg T, Eyjólfsdóttir E, Gorbanev YY, Sádaba I, Riisager A. Aerobic oxidation of 5-(hydroxymethyl)furfural in ionic liquids with solid ruthenium hydroxide catalysts. Catal Lett. 2012;142:1089–97.

Saha B, Gupta D, Abu-Omar MM, Modak A, Bhaumik A. Porphyrin-based porous organic polymer-supported iron(III) catalyst for efficient aerobic oxidation of 5-hydroxymethyl-furfural into 2, 5-furandicarboxylic acid. J Catal. 2013;299:316–20.

Gao L, Deng K, Zheng J, Liu B, Zhang Z. Efficient oxidation of biomass derived 5-hydroxymethylfurfural into 2, 5-furandicarboxylic acid catalyzed by Merrifield resin supported cobalt porphyrin. Chem Eng J. 2015;270:444–9.

Hu L, Lin L, Liu S. Chemoselective hydrogenation of biomass-derived 5-hydroxymethylfurfural into the liquid biofuel 2, 5-dimethylfuran. Ind Eng Chem Res. 2014;53:9969–78.

Qian Y, Zhu L, Wang Y, Lu X. Recent progress in the development of biofuel 2, 5-dimethylfuran. Renew Sust Energ Rev. 2015;41:633–46.

Nishimura S, Ikeda N, Ebitani K. Selective hydrogenation of biomass-derived 5-hydroxymethylfurfural (HMF) to 2, 5-dimethylfuran (DMF) under atmospheric hydrogen pressure over carbon supported PdAu bimetallic catalyst. Catal Today. 2014;232:89–98.

Zhu Y, Kong X, Zheng H, Ding G, Zhu Y, Li YW. Efficient synthesis of 2, 5-dihydroxymethylfuran and 2, 5-dimethylfuran from 5-hydroxymethylfurfural using mineral-derived Cu catalysts as versatile catalysts. Cat Sci Technol. 2015;5:4208–17.

Saha B, Bohn CM, Abu-Omar MM. Zinc-assisted hydrodeoxygenation of biomass-derived 5-hydroxymethylfurfural to 2,5-dimethylfuran. ChemSusChem. 2014;7:3095–101.

Yang P, Cui Q, Zu Y, Liu X, Lu G, Wang Y. Catalytic production of 2,5-dimethylfuran from 5-hydroxymethylfurfural over Ni/Co3O4 catalyst. Catal Commun. 2015;66:55–9.

Zu Y, Yang P, Wang J, Liu X, Ren J, Lu G, Wang Y. Efficient production of the liquid fuel 2,5-dimethylfuran from 5-hydroxymethylfurfural over Ru/Co3O4 catalyst. Appl Catal B Environ. 2014;146:244–8.

Wang GH, Hilgert J, Richter FH, Wang F, Bongard HJ, Spliethoff B, Weidenthaler C, Schüth F. Platinum–cobalt bimetallic nanoparticles in hollow carbon nanospheres for hydrogenolysis of 5-hydroxymethylfurfural. Nat Mater. 2014;13:293–300.

Nagpure AS, Lucas N, Chilukuri SV. Efficient preparation of liquid fuel 2, 5-dimethylfuran from biomass-derived 5-hydroxymethylfurfural over Ru–NaY catalyst. ACS Sustain Chem Eng. 2015;3:2909–16.

Huang YB, Chen MY, Yan L, Guo QX, Fu Y. Nickel-tungsten carbide catalysts for the production of 2,5-dimethylfuran from biomass-derived molecules. ChemSusChem. 2014;7:1068–72.

Upare PP, Hwang DW, Hwang YK, Lee UH, Hong DY, Chang JS. An integrated process for the production of 2,5-dimethylfuran from fructose. Green Chem. 2015;17:3310–3.

Kruger JS, Choudhary V, Nikolakis V, Vlachos DG. Elucidating the roles of zeolite H-BEA in aqueous-phase fructose dehydration and HMF rehydration. ACS Catal. 2013;3:1279–91.

Saravanamurugan S, Riisager A. Solid acid catalysed formation of ethyl levulinate and ethyl glucopyranoside from mono-and disaccharides. Catal Commun. 2012;17:71–5.

Yang F, Fu J, Mo J, Lu X. Synergy of Lewis and Brønsted acids on catalytic hydrothermal decomposition of hexose to levulinic acid. Energy Fuel. 2013;27:6973–8.

Saravanamurugan S, Riisager A. Zeolite catalyzed transformation of carbohydrates to alkyl levulinates. ChemCatChem. 2013;5:1754–7.

Ya’aini N, Amin NAS, Endud S. Characterization and performance of hybrid catalysts for levulinic acid production from glucose. Microporous Mesoporous Mater. 2013;171:14–23.

Ramli NAS, Amin NAS. Fe/HY zeolite as an effective catalyst for levulinic acid production from glucose: characterization and catalytic performance. Appl Catal B Environ. 2015;163:487–98.

Yang H, Wang L, Jia L, Qiu C, Pang Q, Pan X. Selective decomposition of cellulose into glucose and levulinic acid over Fe-resin catalyst in NaCl solution under hydrothermal conditions. Ind Eng Chem Res. 2014;53:6562–8.

Peng L, Lin L, Zhang J, Shi J, Liu S. Solid acid catalyzed glucose conversion to ethyl levulinate. Appl Catal A Gen. 2011;397:259–65.

Peng L, Lin L, Li H, Yang Q. Conversion of carbohydrates biomass into levulinate esters using heterogeneous catalysts. Appl Energy. 2011;88:4590–6.

Weingarten R, Kim YT, Tompsett GA, Fernández A, Han KS, Hagaman EW, Conner WC, Dumesic JA, Huber GW. Conversion of glucose into levulinic acid with solid metal(IV) phosphate catalysts. J Catal. 2013;304:123–34.

Holm MS, Saravanamurugan S, Taarning E. Conversion of sugars to lactic acid derivatives using heterogeneous zeotype catalysts. Science. 2010;328:602–5.

de Clippel F, Dusselier M, Van Rompaey R, Vanelderen P, Dijkmans J, Makshina E, Giebeler L, Oswald S, Baron GV, Denayer JFM, Pescarmona PP, Jacobs PA, Sels BF. Fast and selective sugar conversion to alkyl lactate and lactic acid with bifunctional carbon-silica catalysts. J Am Chem Soc. 2012;134:10089–101.

Dijkmans J, Dusselier M, Gabriëls D, Houthoofd K, Magusin PC, Huang S, Pontikes Y, Trekels M, Vantomme A, Giebeler L, Oswald S, Sels BF. Cooperative catalysis for multistep biomass conversion with Sn/Al Beta zeolite. ACS Catal. 2015;5:928–40.

Chambon F, Rataboul F, Pinel C, Cabiac A, Guillon E, Essayem N. Cellulose hydrothermal conversion promoted by heterogeneous Brønsted and Lewis acids: remarkable efficiency of solid Lewis acids to produce lactic acid. Appl Catal B Environ. 2011;105:171–81.

Acknowledgements

This work is financially supported by Nanjing Agricultural University (68Q-0603), International Postdoctoral Exchange Fellowship Program of China (20170026), Postdoctoral Science Foundation of China (2016M600422), and Jiangsu Postdoctoral Research Funding Plan (1601029A).

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2017 Springer Nature Singapore Pte Ltd.

About this chapter

Cite this chapter

Li, H., Kong, X., Fang, Z., Smith, R.L. (2017). Fundamentals of Bifunctional Catalysis for Transforming Biomass-Related Compounds into Chemicals and Biofuels. In: Fang, Z., Smith Jr., R., Li, H. (eds) Production of Biofuels and Chemicals with Bifunctional Catalysts. Biofuels and Biorefineries, vol 8. Springer, Singapore. https://doi.org/10.1007/978-981-10-5137-1_1

Download citation

DOI: https://doi.org/10.1007/978-981-10-5137-1_1

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-10-5136-4

Online ISBN: 978-981-10-5137-1

eBook Packages: Biomedical and Life SciencesBiomedical and Life Sciences (R0)