Abstract

Pretreatment is the central unit operation that plays a key role for efficient bioconversion of lignocellulosic biomass. However, a single pretreatment method cannot be an effective choice for all types of biomass. A distinct variation in biomass composition and structure is clearly evident, which complicates further the pretreatment optimization process. Fundamental understanding of pretreatment mechanisms and composition of biomass feedstocks is vital to develop an appropriate pretreatment method for each type of feedstock. Our study showed that at same processing conditions, acid pretreatment is significantly less effective than alkali pretreatment for grasses (switchgrass, sorghum stalk, and corn stover) and hardwood (poplar). Sugar released during enzymatic hydrolysis was 38, 65, 72, and 63 % less from acid pretreated biomass compared to alkali pretreated biomass for switchgrass, sorghum stalk, corn stover, and poplar, respectively. Among the various alkaline organic solvent pretreatments, an equal mixture (by volume) of isopropanol and ethanol led to the highest sugar yield (0.50 g/g) from corn stover, while glycerol yielded the highest sugar (0.40 g/g) from poplar. None of these pretreatment methods were effective for softwood (Douglas fir); sugar release was less than 0.1 g/g biomass. Brown midrib (bmr)-12 mutation of sorghum resulted in an increased total fermentable sugar recovery by 36 and 30 % in Atlas, and Kansas Collier cultivars, respectively, while a decreased sugar recovery by 12 % was observed in Early Hegari cultivar. These results showed that decreased lignin in biomass is not necessarily beneficial to increase the pretreatment efficiency, indicating that lignin composition and inter-lignin unit linkages also have significant impact in addition to total lignin content on biomass pretreatment efficiency. Furthermore, biomass feedstocks have various amounts of non-structural sugars, and a number of high-value phytochemicals, which must be extracted prior to biomass pretreatment. Consequently, a targeted biorefining strategy is required for each type of feedstock.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

1 Introduction

Transportation fuels and climate change are topics of keen discussion in political and scientific communities throughout the world. A gradual decrease in economically and sustainably recoverable petroleum reserves requires a search for alternative to fossil fuels. In addition, increasing instability in most of the oil-producing countries has further worsened the fuels crisis for the non-oil-producing countries (Mousdale 2008). Bio-based fuel and chemical production has rapidly increased in last one and half decades; however, current biorefineries predominantly use food-based materials as feedstocks (Guragain et al. 2016b), which is not sustainable due to a global food security issue. The abundantly available lignocellulosic residues are sustainable feedstocks for bio-based fuels and chemicals production without affecting global food supply (Guragain 2015a).

Bioprocessing of lignocellulosic biomass can be broadly divided into three unit operations: pretreatment, hydrolysis and fermentation, as shown in Fig. 1. Each step of this bioconversion process is associated with a number of challenges (Mousdale 2008); among them pretreatment is the central unit operation that significantly affects the efficiency of all subsequent steps of bioprocessing, and is the most expensive single unit operation in the context of existing biomass conversion technologies (Guragain 2015a). In addition, valorization of lignin stream is critical for the commercial viability of biorefinery industries (Ragauskas et al. 2014); biomass pretreatment significantly effects the quality of extracted lignin for high value application.

Pretreatment methods are broadly divided into physical, chemical, physico-chemical, and biological pretreatment methods. Each pretreatment method is associated with some advantages as well as disadvantages (Guragain 2015a). In addition, variations in biomass composition among different biomass feedstocks significantly affect the effectiveness of each pretreatment method. Moreover, structure of biopolymers, especially lignin, differs from biomass to biomass (Guragain et al. 2015b), which further affect the pretreatment efficiency. Biomass lignin is made up of three types of monomer units such as syringyl (S), guaiacyl (G) and p-hydroxyphenyl (H). In addition, grass lignin also contains a significant proportion of p-coumarate and ferulate monomers (Guragain et al. 2015b) (Fig. 2). The proportion of different lignin monomers, and type of linkages between these monomers in biomass lignin affect delignification efficiency during pretreatment process. The pretreatment efficiency is better for biomass containing higher S/G ratio, higher proportion of p-coumarate and ferulate monomers, and higher amount of ester and ether inter-unit linkages, whereas the efficiency decreases with increase in carbon-carbon linkages (Studer et al. 2011).

Lignin monomers and inter-lignin linkages in biomass lignin structure (Guragain et al. 2015b)

In this study, a wide range of biomass feedstocks, including grass, softwood and hardwood, were evaluated and compared for the most common biomass pretreatment methods, such as dilute acid and alkali pretreatment. These biomass feedstocks were also evaluated for the effectiveness of organic solvent pretreatment using alkali catalyst. Alkaline organosolv pretreatment is considered as the promising pretreatment method to extract good quality biomass lignin to produce high-value products from the extracted lignin (Guragain et al. 2016a). Effectiveness of these pretreatment methods were evaluated based on the sugar released during enzymatic hydrolysis of pretreated biomass. In addition, three sorghum cultivars (Early Hegari, Atlas and Kansas Collier) and brown midrib (bmr)-12 mutant of each cultivar were evaluated for sugar release during enzymatic hydrolysis of alkali pretreated biomass. The objective of bmr mutation is to perturb lignin biosynthesis pathways leading to change in total lignin content and/or proportion of different type of lignin monomers so that a new crop line with better feedstock quality for biofuels and biochemical production is developed (Guragain 2015a).

2 Materials and Methods

A schematic representation of the methodology used in this study is given in Fig. 3. Biomass composition was first determined using standard protocols (Guragain 2015a). Dilute acid and alkali pretreatment methods were evaluated and compared for a wide variety of biomass feedstocks such as grass (corn stover, switchgrass, and sorghum stalks), softwood (Douglas fir) and hardwood (poplar). In addition, alkaline organic solvent pretreatment method was evaluated using two types of organic solvents (high- and low-boiling point solvents) for corn stover, Douglas fir and poplar. Glycerol and 2,3-butanediol were used as high-boiling point solvents, and isopropanol, ethanol, butanol and water were used as low-boiling point solvents. Pretreatment conditions were optimized for processing temperature and catalyst (sodium hydroxide) concentration; temperature range was less than the boiling point of solvent for atmospheric pressure processing. The pretreated slurry was filtered, washed and residual solid was enzymatically hydrolysed using the methods used by Guragain et al. (2013). Monomers sugars were measured using high performance liquid chromatography (Shimadzu Corporation, Japan), and data from triplicate experiments were statistically analysed for Least Significant Difference (LSD) at 95 % confidence level (P < 0.05) using JMP software (SAS Institute Inc., Cary, North Carolina, United States).

Schematic representation of biomass processing. Sulfuric acid and sodium hydroxide (NaOH) were used in acid and alkali pretreatment process, respectively. Organosolv pretreatment using alkali (NaOH) catalyst was optimized separately for high- and low-boiling point solvents using corn stover as feedstock, and the optimized conditions were used for all biomass samples

In a separate experiment, three sorghum cultivars (Early Hegari, Atlas and Kansas Collier) and bmr12 mutant of each cultivar were evaluated and compared for non-structural content and sugar released from structural carbohydrates (cellulose and hemicellulose). The non-structural sugar content was determined by extracting ground biomass in water using Soxhlet extraction, and the sugar released from structural carbohydrates was determined by alkali pretreatment of ground biomass followed by enzymatic hydrolysis. Total fermentable sugar was then calculated by adding these two types of sugars: non-structural sugars and released sugars from structural carbohydrates.

3 Results and Discussion

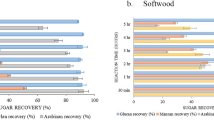

Figure 4 shows that biomass composition significantly varied among different biomass samples; the composition variation was not only among softwood (Douglas fir), hardwood (poplar) and grass (corn stover, switchgrass and sorghums), but also among different grass samples. The acid pretreatment was significantly less effective than alkali pretreatment at the same processing conditions, including processing time, temperature and acid/alkali concentration, to release sugar during enzymatic hydrolysis for all biomass feedstocks. Alkali pretreatment delignifies biomass, making the carbohydrate polymers accessible for enzyme hydrolysis; whereas, acid pretreatment expose cellulose for cellulase enzyme accessibility by hydrolysing hemicellulose (Leu and Zhu 2013). The results indicated that harsher conditions are required for hemicellulose hydrolysis by acid process compared to lignin degradation by alkali. The results also showed that acid pretreatment effectiveness increase with increase in hemicellulose content in extractives-free basis, indicating that structural variation in hemicellulose is not significant among different biomass samples. On the other hand, decrease in total lignin in biomass was not necessarily beneficial to increase alkali pretreatment effectiveness with the same proportion. For example, sugars released from alkali pretreated corn stover was 27 % more than switchgrass while both biomass had statistically equal lignin content; similar results were observed between sorghum stalks and poplar. Moreover, a decrease in lignin content by 50 % in bmr sorghum compared to wild type sorghum resulted in an increase in sugar yield only by 3 %. These results are consistent with the facts that S/G ratio in corn stover lignin is more than that of switchgrass lignin (Guragain et al. 2015b), thereby making corn stover more susceptible for alkali pretreatment. Poplar lignin contains higher S/G ratio compared to grass lignin; however, absence of p-coumarate and ferulate lignin monomers in poplar lignin polymer (Guragain et al. 2015b) indicate that the poplar lignin contains significantly lower proportion of alkali labile ether linkages, and higher proportion of strong carbon-carbon linkages compared to grass lignin. These differences in lignin structure could be the reason for a less alkali pretreatment effectiveness in poplar than a grass (sorghum stalks) with same amount of total lignin content. High total lignin (29 %) and low extractives (4 %) coupled with high proportion of C–C linkages in softwood (Douglas fir) lignin was the reason for ineffective pretreatment in both acid and alkali processes for this biomass sample.

Composition of different biomass feedstocks, and sugar released during enzymatic hydrolysis after alkali (NaOH) and acid (H2SO4) pretreatment at same processing conditions: 121 °C for 30 min using 1 and 2 % acid (v/v)/alkali (w/v) for grass and woody biomass, respectively. bmr = brown midrib sorghum mutant. Hydrolysis of pretreated biomass was carried out in citrate buffer using Cellic CTec2 and Cellic HTec2 enzymes. Composition data are average values of triplicate experiments, and the sugar yield data are average values of triplicate experiments ± sample standard deviation

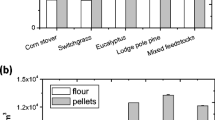

Table 1 shows that mixture of low-boiling point alcohols were better solvent system for corn stover pretreatment than high-boiling point solvents, whereas opposite was true for poplar; glycerol was the promising solvent for poplar pretreatment. None of these solvents worked well for Douglas fir pretreatment. These data indicated that an appropriate alkaline organic solvent for pretreatment (delignification) of any biomass feedstock depends on biomass types due to a distinct variation in composition (Fig. 4) and structure of biomass lignin (Guragain et al. 2015b). Therefore, each biomass feedstock must be separately optimized for each organic solvent to develop an effective organosolv pretreatment process.

We also evaluated and compared three sorghum cultivars (Early Hegari, Atlas and Kansas Collier) and bmr 12 mutant of each cultivar. Table 2 shows that bmr 12 mutants of Atlas and Kansas Collier had 36.2 and 30.1 % more total fermentable sugars, respectively, than their parent cultivars, whereas bmr 12 of Early Hegari had 12.1 % less total fermentable sugar than its parent line. Total sugar released during enzymatic hydrolysis was significantly higher in all bmr mutants than their parent cultivars, indicating that bmr mutation led to improved hydrolysis efficiency of sorghum biomass. Sugar yield per unit weight of sorghum biomass was further increased in bmr mutants compared to their parents because of higher amount of non-structural sugars (glucose, fructose and sucrose) in Atlas and Kansas Collier cultivars. However, the benefits from improved hydrolysis efficiency in bmr 12 mutant of Early Hegari was surpassed by decreased non-structural sugar content in this mutant compared to its parent line. These results showed that bmr 12 mutation leads to better feedstocks for biofuels and biochemical production in some sorghum cultivars, while the same mutation has adverse effects in other cultivar. Therefore, bmr mutation of each sorghum cultivar must be separately evaluated to develop a promising bioenergy crops.

As a consequence, above results show that effectiveness of different pretreatment methods differ from biomass to biomass. A number of factor other than gross biomass composition significantly affect the saccharification efficiency of pretreated biomass, including lignin structure and crystallinity of cellulose (Guragain et al. 2014). Therefore, a fundamental understanding of gross biomass composition, structure of each biopolymer, and the interactions among different biopolymers within a biomass is critical to develop an appropriate pretreatment method specific to each biomass feedstock. In addition, plant breeding, such as bmr mutation, to develop better feedstocks for biofuels and biochemical production should be separately evaluated for each plant cultivar because of a distinct variation on the effect of same mutation on different cultivars of a plant crop.

4 Summary and Conclusions

This study showed that a single pretreatment method cannot be an all-encompassing process for different types of biomass feedstocks due to distinct variations in the effectiveness among various pretreatment methods. Structure of biopolymers and their interactions within biomass are critical, in addition to gross biomass composition, in the development of an appropriate pretreatment method specific to each biomass feedstock. In addition, biomass pretreatment process must be tailored with the optimum use of each component of biomass, including lignin. For example, alkali pretreatment process solubilizes biomass lignin, opening up an opportunity to produce high-value phenolic compounds. Whereas acid pretreatment process solubilizes hemicellulose so that biomass lignin can be obtained after hydrolysis of cellulose from pretreated biomass, which can be used for composite materials production. Moreover, separate cellulose and hemicellulose hydrolyzates can be obtained in acid pretreatment process because hemicellulose and cellulose are hydrolyzed during pretreatment and enzymatic hydrolysis steps, respectively, in this process. A separate biomass-derived glucose and xylose sugar is beneficial for efficient fermentation to fuel and chemicals. Nevertheless, harsher pretreatment conditions are required in acid pretreatment compared to alkali pretreatment, leading to a need for additional detoxification process to generate clean sugars. Less pretreatment-induced inhibitory compounds are produced in alkali pretreatment compared to acid pretreatment due to the milder processing conditions; however, both cellulose and hemicellulose are hydrolyzed during enzymatic hydrolysis step leading to a mixture of glucose and xylose sugars in hydrolyzate, which is less efficient medium for fermentation compared to single sugar medium (Guragain 2015a). Furthermore, some biomass feedstocks, such as sorghum stalks, contain as high as 20 % (w/w) of non-structural sugars, including sucrose, glucose, and fructose, which must be extracted prior to biomass pretreatment to avoid their degradation during pretreatment process. Similarly, separate innovative strategies are required for the valorization of various phytochemicals such as terpenes, fats, waxes, phenolics, and alkaloids. However, all biomass feedstocks do not contain these non-structural sugars and phytochemicals in economically feasible level; therefore, a targeted biorefining strategy is required for each type of biomass feedstock.

References

Guragain, Y.N.: Sustainable bioprocessing of various biomass feedstocks: 2,3-butanediol production using novel pretreatment and fermentation. Doctoral Dissertation, Kansas State University, USA (2015a)

Guragain, Y.N., Wilson, J., Staggenborg, S., McKinney, L., Wang, D., Vadlani, P.V.: Evaluation of pelleting as a pre-processing step for effective biomass deconstruction and fermentation. Biochem. Eng. J. 77, 198–207 (2013)

Guragain, Y.N., Ganesh, K., Bansal, S., Sathish, R.S., Rao, N., Vadlani, P.V.: Low-lignin mutant biomass resources: effect of compositional changes on ethanol yield. Ind. Crop Prod. 61, 1–8 (2014)

Guragain, Y.N., Bastola, K.P., Madl, R.L., Vadlani, P.V.: Novel biomass pretreatment using alkaline organic solvents: a green approach for biomass fractionation and 2,3-butanediol production. BioEnerg. Res. 9, 643–655 (2016a). doi:10.1007/s12155-015-9706-y

Guragain, Y.N., Herrera, A.I., Vadlani, P.V., Prakash, O.: Lignins of bioenergy crops: a review. Nat. Prod. Commun. 10, 201–208 (2015b)

Guragain, Y.N., Probst, K.V., Vadlani, P.V.: Fuel alcohol production. In: Corke, H., Faubion, J., Seethraman, K., Wrigley, C. (eds.) Encyclopedia of Food Grain, pp. 235–244. Elsevier, Oxford (2016b)

Leu, S., Zhu, J.: Substrate-related factors affecting enzymatic saccharification of lignocelluloses: our recent understanding. Bioenerg. Res. 6, 405–415 (2013)

Mousdale, D.M.: Biofuels: Biotechnology, Chemistry, and Sustainable Development. CRC Press, Boca Rato (2008)

Ragauskas, A.J., Beckham, G.T., Biddy, M.J., Chandra, R., Chen, F., Davis, M.F., et al.: Lignin valorization: improving lignin processing in the biorefinery. Science 344(6185), 1246843 (2014)

Studer, M.H., DeMartini, J.D., Davis, M.F., Sykes, R.W., Davison, B., Keller, M., et al.: Lignin content in natural populus variants affects sugar release. Proc. Natl. Acad. Sci. U.S.A. 108, 6300–6305 (2011)

Acknowledgments

This work was funded by the Development Initiative Competitive Grants Program (BRDI; grant number: 2012-10008-20263), and the Small Business Innovation Research (SBIR), Department of Navy; Grant Number: N68335-13-C-0174. Author PVV thanks the Lortscher Endowment for their support. The authors are also grateful to Novozymes Inc. for enzyme samples.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2016 Springer Science+Business Media Singapore

About this chapter

Cite this chapter

Guragain, Y.N., Vadlani, P.V. (2016). Importance of Biomass-Specific Pretreatment Methods for Effective and Sustainable Utilization of Renewable Resources. In: B. D., P., Gummadi, S., Vadlani, P. (eds) Biotechnology and Biochemical Engineering. Springer, Singapore. https://doi.org/10.1007/978-981-10-1920-3_23

Download citation

DOI: https://doi.org/10.1007/978-981-10-1920-3_23

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-10-1919-7

Online ISBN: 978-981-10-1920-3

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)