Abstract

Water is a universal solvent and a vital constituent of living organisms. It recirculates in the environment through the hydrologic cycle which can be hampered due to human activities in terms of pollution. Polluted water, known as wastewater or effluent, should not be drained without treatment, as it constitutes a serious threat to living beings. Parameters like biochemical oxygen demand (BOD), chemical oxygen demand (COD), total dissolved solids (TDS), etc. are used to determine water quality. Therefore, wastewater treatment methods are targeted to get these parameters at optimum level. Such processes are either physico-chemical or biotechnological in nature and may be categorised as preliminary, primary, secondary and tertiary treatments. All of these must be followed by disinfection to obtain potable water. Major objectives of preliminary and primary treatment include removal of coarse and fine particle by screening, filtration, sedimentation, equalisation and flotation. Secondary treatment consists of biological treatment, i.e. aerobic, anaerobic and specialised reactors. Tertiary treatment entails chemical processes to purify wastewater. In the future, as the world’s population continues to grow, such research priorities will become increasingly paramount. At present, a change in research priorities can be observed, and new technologies that meet the requirements of sustainable development and multidisciplinary approach are being applied. Therefore, modified methods must be developed to be used in systemic combination to fulfil the demand of potable and reusable water.

Access provided by CONRICYT-eBooks. Download chapter PDF

Similar content being viewed by others

Keywords

- Activated sludge

- Trickling filters

- Rotating biological contactor

- Anaerobic process/digesters

- Aerobic processes

6.1 Introduction

Water is indispensable in the living world for many reasons. It is an essential constituent of photosynthetic process that is important to animal and plant ecosystems. It establishes itself as a means of nutrition for plants and forms the natural living conditions for many living species and acts as a solvent of organic and inorganic materials (universal solvent). It is also a vital constituent of living organisms. The amount of water contained in the human body represents about 65–70 % of the body weight. The protoplasm of most living cells contains approximately 80 % water, and any reduction of this amount can have damaging effects and may even be fatal. Thus, water plays an important role in metabolism and exists as necessary component of body fluids. Most biochemical reactions take place in the presence of water. It thus supports the entire system of life on our planet, constituting crucial elements for all ecosystems. In fact, the availability of water has governed the establishment of civilisations and the development and progress of man’s economic activities.

6.1.1 The Earth’s Water Resources

Water is in recirculation in the environment through the hydrologic cycle. This signifies the movement of water evaporated from surface waterbodies or evapotranspirated from plants to the atmosphere where it condenses and precipitates to the earth as rain, snow or in some other forms. On the surface of the earth, some of the precipitated water then runs off into streams, lakes, ponds and the sea. The rest percolates through soil strata to form groundwater aquifers that ultimately flow into surface waterbodies.

Although 70 % of the world’s surface area is covered with water, only 0.00192 % of the total stock is available for human use because 98 % water occurs in oceans and seas and 1.998 % is locked up in arctic regions, glaciers, mountains and clouds and, thus, remains unavailable.

6.2 Wastewater

Wastewater may be defined as ‘a combination of liquid or water – carried wastes removed from residences, institutions and commercial and industrial establishment together with such groundwater, surface water and storm water as may be present’. It is the used water supply of a community and consists of domestic waterborne wastes, called sewage, which include human excrement and wash water as well as everything that goes down the drain of a home and into a sewage system.

Most industries are water based and release a considerable volume of wastewater which is generally discharged into water courses either untreated or inadequately treated and causes water pollution (Noorjahan 2014). Industrial waterborne wastes usually contain acids, alkaline materials, oils, greases and animal and vegetable matters discharged by factories. Industrial growth encompasses setting up of new industries, producing new chemicals and biochemicals. Varied industries such as distilleries, tanneries, textiles, antibiotics, drugs and pharmaceuticals, pulp and paper, dairies, oil refineries, petrochemicals, fertilisers, organic chemicals, etc. in the process of manufacturing contribute to water pollution. Thus, all small-, medium- and large-scale industries have their own role in water pollution. Water pollution is also caused by solid and hazardous wastes dumped on land.

6.2.1 Problems Associated with Improper Wastewater Discharge

Generally, problems associated with improper wastewater discharge include the following:

-

(a)

Wastewater affects natural water quality through the production of taste, odour and malodorous gases. The gases that may be produced include CO2, H2S, CH4, NH3 and other trace gases such as H2 and N2.

-

(b)

Wastewater contains pathogenic microorganisms that cause many diseases.

-

(c)

Wastewater sludge may introduce highly persistent detergents, pesticides and other toxic wastes and compound.

-

(d)

Massive quantity of solids may produce objectionable and dangerous levels of sludge on the bottom of waterbodies or along their banks. These solids add to the chemical, biological and physical degradation of natural water courses.

-

(e)

Wastewaters containing grease and oils render bathing sites unusable, present extra problems for treatment works, produce unsightly conditions and interfere with the process of biodegradation.

-

(f)

Wastewater may produce eutrophication or the enrichment of water by plant nutrients, biomass of phytoplankton, attached algae, macrophytes, etc.

For the aforementioned reasons, the immediate and nuisance-free removal of wastewater from its sources of generation, succeeded by proper treatment and final disposal, is not only desirable but also necessary for appropriate environmental sanitation.

6.3 Classification of Wastewater

The sources of origin and generation of wastewater may be grouped as follows:

-

(a)

Domestic (Sanitary) Wastewater – Domestic wastewater includes discharges from residences and commercial, institutional and similar facilities.

-

(b)

Industrial Wastewater – Industrial wastewater signifies the industrial waste generated from industrial localities. It varies with the type and size of the industry and other factors affecting production and processes.

-

(c)

Infiltration/Inflow – Infiltration as a class of wastewater addresses extraneous water that enters the sewer system from the ground through various means. Likewise, it includes storm water that is discharged from sources such as roof leaders, foundation drains and storm sewers.

-

(d)

Storm Water – Storm water refers to the water resulting from precipitation runoff.

6.4 Properties and Characteristics of Water and Wastewater

6.4.1 Physical Characteristics

6.4.1.1 Temperature

Temperature is one of the physical parameters that reveal a great deal of information about the water source and its state. Changes in temperature may be due to seasonal or daily variation or disposal of hot water or due to disposal of wastes from industrial processes and power stations (thermal pollution). Notable effects of temperature increase include:

-

(a)

Speeding up and motivation of chemical reaction and reaction rate. The temperature may affect the reaction rate of microorganisms to the extent of doubling it for each 10 °C increase. Higher temperature can support the growth of undesirable aquatic plant and wastewater fungus.

-

(b)

Reduction of dissolved oxygen concentration.

-

(c)

Reduction of solubility of gases.

-

(d)

An increase of biochemical oxygen demand (BOD).

-

(e)

An increase in the rate of corrosion of substances.

-

(f)

An increase in sensitivity of aquatic animals for toxic dissolved substances in the aquatic environment.

-

(g)

An increase in malodour.

The change in temperature depends on the latitude and altitude of the earth too.

6.4.1.2 Turbidity

Turbidity is the phenomena whereby a specific portion of a light beam passing through a liquid medium is deflected from undissolved particles. Organic particles, oil, algae, colloidal and soluble substances present in water often initiate turbidity or colour in wastewaters. Small particles with density close to water may never settle and stabilise in the water. However, coagulation and flocculation of these particles into larger flocs are the necessary steps for their removal followed by sedimentation. Measurement of turbidity can be made easily and rapidly by using turbidimeters. Turbidity is an expression of optical property that causes light to be scattered and absorbed rather than transmitted in straight line through the sample. Measurements of turbidity in water can be defined in two ways: the turbidity resulting from 1 mg per litre of fuller’s earth suspended in water or the depth of the column of water that just obscures the image of burning standard candle viewed vertically through the sample (Jackson candle unit, JCU)

1 nephelometric turbidity unit (NTU) ~ JCU

It is also measured by Beer-Lambert’s law

Here,

-

ε is the molar absorbance coefficient.

-

c is the concentration of the solute in Moll−1.

-

l is the light path of liquid in cell or cuvette in cm.

6.4.1.3 Taste

Usually, drinking water must be almost tasteless to please the consumer. The taste and odour are subjective properties which are rather difficult to measure. The presence of taste may be due to dissolved impurities organic or inorganic in origin. Examples of organic substances are phenols, chlorophenols, oils, fats, grease and unsaturated hydrocarbons. Inorganic substances include dissolved salts, iron, manganese, chlorides and gaseous substances such as hydrogen sulphide that are produced by decomposition of organic matter by microorganism such as fungi, algae, protozoa, bacteria, etc. These chemicals may be originated from municipal and industrial waste discharges, from natural sources such as decomposition of vegetables matters or from associated microbial activity. Taste and odour may also result from decaying aquatic vegetation as well as decaying leaves, weeds, grasses, etc.

Measurement of taste is rather difficult and classification generally included salty, bitter, sour or sweet. While it is relatively easy and safe for a person to evaluate the taste of drinking water supply, no one would be anxious to taste wastewater before or after conventional treatment. Production of potable water from unchlorinated effluent needs lime treatment, recarbonation, filtration, ion exchange, carbon absorption, ozonation, another carbon absorption treatment, reverse osmosis and finally chlorine dioxide treatment which make it costly.

6.4.1.4 Odour

A wholesale supply of water is odour-free. Existence of odour in water may be due to a number of reasons such as:

-

(a)

Biodegradation of organic and inorganic compounds of nitrogen, phosphorus and sulphur

-

(b)

Decomposition of algae and other microorganisms

-

(c)

Generation of substances such as ammonia sulphide, chlorine, cyanide and hydrogen sulphide

It is easy to check for an odour associated with a drinking water supply. Offensive odours are generally associated with the raw wastewater that has been in the sewage system too long and aerobic conditions have developed. The sewage turns black and gives off hydrogen sulphide. The effects of this unpleasant odour include psychological stress, headache, nausea, vomiting, mental depression and blurred vision, fatigue or loss of appetite, impaired respiration, irritation of eyes, loss of sleep as well as reduction in production and work efficiency.

6.4.1.5 Colour

Sources of water colour include:

-

(a)

Natural sources such as extracts from organic debris (leaves, wood and peats)

-

(b)

Industrial origins such as mine waste, textile industry, paper industry and dye industry

-

(c)

Domestic sewage

Pure water is colourless. True colour in natural water is caused by large organic molecules. Colour in water may also result from the presence of natural metallic ions such as iron oxide (causes red colour) and manganese oxide (causes brown and black colour). Other sources are humus and peat material, plankton, weed and industrial waste (e.g. textile and dye operation, paper and pulp production, food processing, chemical manufacturing, mining, refining and slaughterhouse operation). The greatest contribution of colour by plants is humic acid which produces a yellow brownish colour together with tanning and humate from the decomposition of lignin. These lignin derivatives are highly coloured and resist biological degradation.

6.4.1.6 Conductivity

Conductivity is a numerical expression of the tendency of an aqueous solution to carry an electric current. This ability depends on:

-

(a)

First presence and type of ion

-

(b)

Total concentration of ions

-

(c)

Mobility, balance and relative concentration of ions

-

(d)

Temperature of solution

Solutions of most organic acids, bases and salts are relatively good conductors. Electrical resistance, R (in ohms), of conductor may be derived as

where

-

R s = resistivity of conductor

-

R = resistance

-

L = length of conductor

-

A = cross-sectional area of conductor

The reciprocal of resistance is conductance expressed in reciprocal ohms or mhos.

where

-

R s = specific resistance

-

Ac = cell constant

-

Rm = measured resistance

Conductivity may be defined as the electrical conductance of a conductor of unit length and unit cross-sectional area and commonly expressed in μmhoscm−1.

Freshly distilled water has a conductivity of 0.5–2.0 μmhoscm−1, increasing after a few weeks of storage to 2–4 μmhoscm−1. The increase is mainly due to absorption of atmospheric CO2 and to a lesser extent NH3. Pure water is thus normally not a good conductor of electricity. Increase of dissolved salts in water increases its conductivity. As such, the conductivity of water is sometimes used for indicating the degree of its purification or pollution. The conductivity is proportional to the concentration of dissolved solids.

where

-

EC = electrical conductivity

-

TDS = total dissolved solids

-

a = constant

6.4.1.7 Salinity

Salinity is the total dissolved solids in water after all carbonates have been converted to oxides, all bromides and iodides have been replaced by chlorides and all organic matter has been oxidised.

The sources of chlorides in natural water can be from:

-

(a)

Leaching of chloride containing rocks and soils

-

(b)

Salt water intrusion (coastal areas)

-

(c)

Agricultural, industrial and domestic wastewater

6.4.1.8 Solid Content

Solid content is defined as the matter that remains as residue upon evaporation and drying at 103–105 °C. According to particle size, wastewater solids have been classified as indicated in Table 6.1.

6.4.1.8.1 Dissolved Solids

In potable water, these consist of inorganic salts and a small concentration of organic matter. Water with high dissolved solids is generally of inferior palatability and may induce an unfavourable physiological reaction in the consumer. Highly mineralised water is also unsuitable for many industrial applications.

6.4.1.8.2 Suspended Solids

These may be inorganic particles such as clay, silt and other soil constitutes, or they may be of organic origin such as plant fibres and biological solids like algae, bacteria, etc. These are the solids that can be filtered out by a fine filter paper. Water high in suspended solids may be aesthetically unsatisfactory for such purposes as bathing. Suspended solids also provide adsorption sites for chemical and biological agents.

6.4.1.8.3 Volatile and Fixed Solids

They give a measure of the amount of organic matter present in a sample. The test is carried out by burning organic matter to convert it to carbon dioxide and water, at a controlled temperature of 550 °C, to prevent the decomposition and volatilisation of inorganic substances.

6.4.1.8.4 Settleable Solids

These are solids in suspension that can settle in quiescent conditions under the influence of gravitational attraction.

6.4.1.9 Density

The density of fluid is defined as its mass per unit volume.

For water at standard pressure 760 mmHg and at 4 °C the density is 1000 Kgm−3

The reciprocal of the density is termed as specific volume. It is defined as the volume of a fluid occupied by a unit mass of the fluid. The ratio of the weight (density, ρ s) of a substance to the weight (density, ρ w) of an equal volume of water at standard conditions is denoted as the specific gravity (s.g.)

Since molecular activity and spacing increase with temperature, fewer molecules exist in a given volume of fluid as the temperature is increased. Therefore, density decreases with an increase in temperature. The application of pressure forces a larger number of molecules into a given volume. This results in an increase in density.

6.4.1.10 Radioactivity

Radiation is a characteristic feature of unstable atoms. Therefore, the approach to understanding radioactivity should begin at the level of atom. Certain nuclides spontaneously emit particles or gamma radiation or X radiation following orbital electron capture or undergo spontaneous fission.

Radioactivity may be of artificial, induced and natural types. Artificial radioactivity is a man-made radioactivity produced by particle bombardment or electromagnetic irradiation as opposed to natural radioactivity. Induced radioactivity is produced in substance after bombardment with neutrons or other particles. The resulting activity is naturally induced radioactivity if formed by nuclear reaction occurring in nature and artificially induced radioactivity if the reactions are caused by man. The property of radioactivity exhibited naturally by more than 50 radionuclides such as uranium, thorium, radium, polonium, etc. is known as natural radioactivity.

6.4.2 Chemical Characteristics

6.4.2.1 Hydrogen Ion Concentration (pH)

pH is a measure of the acidic or alkaline nature of a solution and affects the quality of a water or wastewater.

where [H+] is the concentration of hydrogen ions.

pH ranges from 0 to 14, with 7 as neutral, <7 being acidic and >7 being alkaline. It is an important parameter for both natural water and wastewater. The concentration range suitable for the existence of most biological life is narrow and critical. Wastewater with an adverse concentration of pH is difficult to treat by biological means, and if the concentration is not altered before discharge, the wastewater effluent may change the pH in natural water (Frobisher et al. 1974). Most microorganisms cannot survive below pH 4, but sulphate-oxidising bacteria can exist at pH 0.1. In practice, pH control is the most significant economic control the sanitary microbiologist has over the growth and death of microorganism.

6.4.2.2 Alkalinity

Alkalinity is the measure of buffering capacity of water. Alkalinity is caused primarily by chemical compounds dissolved from rocks and soil and is mainly due to the presence of hydroxyl, carbonate and bicarbonate ions. These compounds are mostly carbonates and bicarbonates of sodium, potassium, magnesium and calcium. Normally, wastewater is alkaline. In the anaerobic digestion process, sufficient alkalinity has to be present to ensure that the pH will not drop below 6.2, because the methane bacteria cannot function below that point. When digestion is proceeding satisfactorily, the alkalinity will normally range from 1000 to 5000 mg/l as CaCO3.

Alkalinity in water is determined by titrating a sample of water with 0.02 N, H2SO4 solution. Total alkalinity is found by titrating to pH 4.5 (methyl orange end point) with a colour change from orange to pink.

where

-

A = ml standard acid used for sample

-

B = ml standard acid used for blank

-

N = normality of acid (0.02 N)

6.4.2.3 Acidity

Acidity is usually attributed to sample with a pH below the value of 7. In unpolluted water, acidity comes from dissolved CO2 or organic acids leached from the soil. Atmospheric pollution may cause acidity. Acid water corrodes metal or concrete.

The acidity of water is determined by titrating a water sample with 0.02 N NaOH to pH 8.3.

Acidity as \( \mathrm{mg}\ {\mathrm{CaCO}}_3/\mathrm{l}=\left[\left(A-B\right)\times C\right]-\left[\left(D\times E\right)\right]\times 50,000/\mathrm{ml}\;\mathrm{sample} \)

where

-

A = ml NaOH titrant used for sample

-

B = ml standard NaOH titrant used for blank

-

C = actual normality of standard NaOH titrant (0.02 N)

-

D = ml standard H2SO4 used

-

E = actual normality of standard H2SO4 (0.02 N)

6.4.2.4 Hardness

Hardness in water will prevent the formation of soap lather and is usually due to divalent cations such as Ca2+, Mg2+, Sr2+, Fe2+ and Mn2+. When hardness is numerically greater than the sum of carbonate and bicarbonate alkalinity, that amount of hardness equivalent to the total alkalinity is called carbonate hardness. The amount of hardness in excess of this is called non-carbonate hardness. When the hardness is less than or equals total alkalinity, all hardness is carbonate hardness and non-carbonate hardness is absent.

Hardness, \( \left[\mathrm{mg}\ \mathrm{equivalent}\ {\mathrm{Ca}\mathrm{CO}}_3/\mathrm{l}\right]=2.497{\mathrm{Ca}}^{2+}\left[\mathrm{mg}/\mathrm{l}\right]+4.118{\mathrm{Mg}}^{2+}\left[\mathrm{mg}/\mathrm{l}\right] \) (Rice et al. 2012).

When alkalinity < total hardness, carbonate hardness = alkalinity [mg/l].

Alkalinity > total hardness, carbonate hardness = total hardness [mg/l].

Impact of hardness includes:

-

(a)

Economic losses to water uses through consumption of soap.

-

(b)

Formation of precipitates on hot water appliances, boilers, kettles and domestic appliances, bath tubs, sinks, dishwashers and washbasins.

-

(c)

Staining of clothes, dishes and other household utensils.

-

(d)

Residues of the soap precipitate may remain in pores of skin making it feel rough and uncomfortable.

-

(e)

Development of laxative effect on new consumers, especially due to the presence of MgSO4.

The total hardness of water sample can be easily determined by the EDTA titrimetric method.

6.4.2.5 Dissolved Oxygen

Oxygen dissolved in sewage or water is needed for the maintenance of aerobic conditions, but the solubility of the oxygen in water is low. Drinking water saturated with oxygen has a pleasant taste, while water lacking dissolved oxygen has an insipid taste.

where

-

C g = gas concentration in gas phase (g/m3)

-

P g = partial pressure of respective gas in gas phase [P a = N/m2]

-

MW = molecular weight of gas

-

Ru = universal gas constant (8.3143 J/K.mol)

-

T = absolute temperature (K)

Oxygen is slightly soluble in water. The actual quantity of oxygen that can be present in solution is governed by solubility of gas, partial pressure of gas in atmosphere, temperature and purity of water.

6.4.2.6 Oxygen Demand

Oxygen demand is the amount of oxygen needed to stabilise organic water.

-

(a)

Biochemical oxygen demand (BOD) is a measure of amount of pollution by organic substances in water.

-

(b)

Permanganate value (PV) is the chemical oxidation of water sample using a potassium permanganate solution.

-

(c)

Chemical oxygen demand (COD) is the chemical oxidation of water sample using a mixture of concentrated H2SO4 and K2Cr2O7.

6.4.2.7 Dissolved Gases

Natural water contains dissolved gases with varying concentration depending upon their solubility in water. When water is anaerobic and microbial activity exists, free ammonia, hydrogen sulphide and methane may exist. In the latter case the water needs to be oxygenated before use. From the point of view of water purity, the most important gases are oxygen and CO2.

6.4.2.8 Chloride

Sources of chloride in natural water include leaching of chloride from rocks and soils; salt water intrusion (in coastal areas); agricultural, industrial, domestic and human wastewaters; and infiltration of groundwater into sewers adjacent to salt water. Chloride in the form of Cl− ions is one of the major inorganic anions in water and wastewater. In potable water, the salty taste produced by chloride concentration is variable and depends on the chemical composition of water. Some waters containing 250 mg/l chloride have a detectable salty taste if the cation involved is Na+ ion. On the other hand, the typical salty taste may be absent in water containing as much as 1000 mg/l Cl− when predominant cations are calcium and magnesium (Rice et al. 2012).

The chloride concentration is higher in wastewater than in raw water because NaCl is a common part of diet and passes unchanged through the digestive system. When chlorine dioxide is used in water treatment (disinfection), chlorite ion is formed as a by-product. Chlorite is known to cause methaemoglobinaemia [a condition in which haemoglobin of the blood is oxidised to a metabolically inactive (ferric) state].

6.4.2.9 Nitrogen

In waters and wastewaters, nitrogen exists in four main forms, and biological treatment cannot proceed unless some of these forms are present:

-

(a)

Organic nitrogen N is organically bound in the tri-negative oxidation state. Organic nitrogen includes such natural materials as proteins, peptides, nucleic acids, urea and numerous synthetic materials.

$$ \mathrm{Total}\ \mathrm{oxidised}\ \mathrm{nitrogen}=\mathrm{nitrite}\ \mathrm{nitrogen}+\mathrm{nitrate}\ \mathrm{nitrogen} $$ -

(b)

Ammonia NH3-N is present naturally in surface and wastewaters. Its concentration generally is low in groundwater because it adsorbs to soil particle and clays and is not leached readily from soil. It is produced largely by deaeration of organic nitrogen-containing compound and by hydrolysis of urea.

-

(c)

Nitrite NO2-N is an intermediate oxidation state of nitrogen. It can enter a water supply system through use as a corrosion inhibitor in industrial purpose water. Nitrite is the actual etiologic agent of methaemoglobinaemia. Nitrous acid, which is also formed from nitrite under acidic conditions, can react with secondary amine to form nitrosamines, many of which are known to be carcinogens.

-

(d)

Nitrate NO3-N is derived from the oxidation of ammonia. High concentration of nitrate (>10 mg/l) in water can cause cyanosis in infants. Nitrate is an essential nutrient of many photosynthetic photoautotrophs and in some cases has been identified as a growth-limiting nutrient.

6.4.2.10 Toxic Metals

Toxicity is the adverse effect a substance has on a test organism exposed to that substance. Toxicity is the result of a concentration and time exposure test, modified by variables such as temperature, chemical form and availability. Toxicity may be:

-

(a)

Acute (short-term lethal)

-

(b)

Chronic (long-term effects that may be related to changes in appetite, growth, metabolism, reproduction and even death or mutations)

The degree of toxicity depends upon the element involved such as copper, lead, silver, chromium, arsenic and boron. These metal(loid)s have to be taken into consideration when designing biological treatment system. The presence of other trace metals such as nickel, manganese and mercury at high concentrations also interferes with wastewater treatment processes. Toxic anions such as cyanide and chromates, often found in industrial wastewater, also hinder biological treatment and should be removed by pretreatment at the source before discharge to the municipal sewage system.

6.4.2.11 Nutrients

Nitrogen and phosphorus are essential growth factors together with other trace elements like iron, potassium, magnesium, calcium, cobalt, copper, sulphur and zinc. If wastewaters are to be treated by biological processes, the nutrient balance has to be considered in order to establish optimum operating conditions.

6.4.2.12 Proteins

Proteins are nitrogenous organic substances of higher molecular weight found in the animal kingdom and to a lesser extent in the plant kingdom. The amount present varies from a small percentage in watery fluids (e.g. tomatoes) and in the fatty tissue of meat to quite a high percentage in beans and lean meats. Protein consists wholly or partially of very large numbers of amino acids united by peptide links. They contain carbon, hydrogen, oxygen, nitrogen, sulphur and sometimes phosphorus.

It has been shown that proteinaceous materials constitute a large part of the wastewater sludges and that the sludge particles, if they do not consist of pure protein, are covered by a layer of protein which governs their physical and chemical behaviour. Under the influence of microorganisms, proteins undergo decomposition, giving end products which often have objectionable foul odours.

6.4.2.13 Oil and Greases

Oil and grease compounds are insoluble in water but dissolve in such organic substances as petroleum, chloroform, ether, etc. These are esters of alcohol or glycerol and fatty acids. Fats are among the more stable organic compounds and are not easily decomposed by bacteria. However, they can be attacked by mineral acids resulting in the formation of glycerin and fatty acids.

When grease is encountered in sufficient quantities, it causes clogging of filters, nozzles and sand beds. It coats the walls of sedimentation tanks and on decomposing increases the amount of scum. If grease is not removed before discharge of wastewater, it can interfere with the biological processes in the surface waters and create unsightly floating matter. Both trickling filters and activated sludge process are adversely affected by grease which can coat the biological forms sufficiently to interfere with oxygen transfer from the liquid to the interior of living cells.

6.4.2.14 Carbohydrates

Carbohydrates are organic substances that include starch, cellulose and sugars. They contain carbon, hydrogen and oxygen. Carbohydrates may be grouped as simple sugar (monosaccharides) or complex sugars (disaccharides and polysaccharides).

Bacteria utilise carbohydrates for the synthesis of fats and proteins as well as for energy. The majority of carbohydrates in wastewater are in the form of large molecules that cannot penetrate the cell membrane of microorganisms. It should be noted that formation of organic acids (anaerobic respiration) in large quantities can overtax the buffering capacity of wastewater resulting in a drop in pH and a cessation of biological activity.

6.4.2.15 Phenols

Phenols are a group of aromatic compounds with one or more hydroxyl group attached to the benzene ring. Phenols can be recovered from coal tar while greater amounts are manufactured synthetically. Phenols in wastewater may be industrial in origin, such as from coal, gas or petroleum operations. Phenols cause taste problem in drinking water, particularly when the water is chlorinated. This is due to the formation of chlorophenol.

6.4.2.16 Detergents

Detergents are large organic molecules. They are slightly soluble in water and may cause foaming in wastewater treatment plants and in the surface water into which the wastewater effluent is discharged. They can also seriously reduce the oxygen uptake in biological treatment processes. Synthetic detergents are classified as anionic, cationic or nonionic due to their electrical charge or lack of one when they dissolve in water (Frobisher et al. 1974). Synthetic detergents are used in households and industry. Detergents affect the wastewater treatment adversely as they lower the surface or interfacial tension of water and increase its ability to wet surfaces with which they come in contact; emulsify grease and oils and deflocculate colloids; induce floatation of solids and give rise to foams; and may kill useful bacteria and other living organisms.

6.4.2.17 Biochemical Oxygen Demand

BOD determination involves the measurement of the dissolved oxygen consumed by microorganisms in the biochemical oxidation of organic matter. The test determines the appropriate quantity of oxygen that will be required to biologically stabilise the organic matter present. Advantages of the test include:

-

(a)

Determination of the size of waste treatment facilities

-

(b)

Measurement of the efficiency of some treatment processes

-

(c)

Determination of the approximate quantity of oxygen needed for the stabilisation of organic matter present

Biological oxidation is a slow process and theoretically takes an infinite time to go to completion. Within a 20-day period, the oxidation is about 95–99 % complete, and in the 5-day period used for the BOD test, oxidation is 60–70 % complete. The 20 °C temperature used is an average value for slow-moving streams in temperate climates and is easily duplicated in an incubator. Different results would be obtained at different temperature because biochemical reaction rates are temperature dependent. The test requires exclusion of light during the incubation period to prevent oxygen formation by alga in the sample.

6.4.2.17.1 BOD Kinetics

Waste management studies are usually done using calibrated and verified water quality models. Dissolved oxygen (DO) in rivers results from the combined effect of aeration and oxidation of organic matter. A commonly used one-dimensional steady-state mathematical model to predict DO level in the rivers receiving organic matter can be written as (Thomann and Mueller 1987)

where DO is the initial oxygen deficit, Lo is the ultimate carbonaceous biochemical oxygen demand (CBOD) in the river after mixing, Lno is the ultimate nitrogenous biochemical oxygen demand (NBOD) in the river after mixing, K a is the re-aeration rate coefficient, K r is the BOD removal rate coefficient and K d is the river CBOD deoxygenation rate coefficient, K n is the NBOD deoxygenation rate coefficient and ‘t’ is the travel time in the river. K a can be determined by using different empirical relationships.

These calibrated and verified DO models are used to determine the required degree of wastewater treatment to maintain DO standards to meet the specific use of the waterbody. The models can then be used to formulate river water quality management strategies.

The rate coefficients K r , K d and K n are related to the oxygen sink and depend upon the nature of the wastewater and other physical, chemical and biological factors particular to the river. K r is the removal rate of carbonaceous organic matter and is determined from river surveys and is equal to

where K s is the removal rate due to settling. K d may be considered to consist of a component (K), characteristic of the type of wastewater, and can be determined from the analysis of long-term BOD measurements. Significant portion of particulate BOD is removed up to the secondary level treatment (i.e. suspended solids <30 mg/L); therefore, for such effluents, K s in Eq. (6.2) may be neglected. The other component is ‘ϕ’, the characteristic of the conditions in the river, and may include factors that are not included in long-term BOD analysis. These components can be related to each other as

Wastewaters from urban areas are a mixture of carbohydrates, proteins and fats and vary in nature. With respect to biodegradation, their value changes with the level of treatment as readily biodegradable organic matter is first consumed. As such, the K r , K d and K n which represent the biokinetic rates in rivers also change with the level of treatment. Bhargava (Bhargava 2008) developed a composite model considering the effect of settleable BOD for a river receiving wastewater from multiple outfalls by relating the rate constants with discrete and flocculent settling types.

The exertion of BOD is a first-order reaction kinetics and may be expressed as

where

-

t = time, days

-

BODr = amount of BOD remaining at time t

-

k1 = first-order reaction rate, 1/day

Integrating the above expression between the limits of UBOD and BODt and t = 0 and t = t yields

where UBOD = total or ultimate carbonaceous BOD, mg/L

The amount of BOD exerted at time t (what gets regulated) is\( \begin{array}{c}\mathrm{BOD}\mathrm{t}=\mathrm{UBOD}-\mathrm{BODr}=\mathrm{UBOD}-\mathrm{UBOD}\ \left({e}^{-k1t}\right)\\ {}\kern1.5em =\mathrm{UBOD}\ \left(1-{e}^{-k1t}\right)r\ r\ k\ \mathrm{BOD}\ dt\ \mathrm{dBOD}\ \mathrm{r}\end{array} \)

The higher the concentration of waste matter in wastewater, the stronger it is said to be. Wastewater strength is most often judged by its BOD or COD.

Limitations of the BOD test include:

-

(a)

A high concentration of active acclimated seed bacteria is required.

-

(b)

Pretreatment is needed when dealing with toxic wastes, and effects of nitrifying organisms must be reduced.

-

(c)

Only the biodegradable organics are measured.

-

(d)

The test does not have stoichiometric validity after the soluble organic matter present in solution has been used.

-

(e)

An arbitrary long period of time is required to obtain results.

Perhaps the most serious limitation is that the 5-day period may or may not correspond to the point where the soluble organic matter that is present has been reduced. This reduces the usefulness of the test results.

6.4.2.18 Chemical Oxygen Demand

The COD test involves an acid oxidation with potassium dichromate. A measured amount of dichromate is added, the acidified samples is boiled for 2 h, cooled and the amount of dichromate remaining is measured by titration with a 0.25 N solution of ferrous ammonium sulphate, using ferroin indicator for end point determination. COD results are generally higher than BOD values since the test oxidises material such as fats and lignin which are only slowly biodegradable.

6.4.3 Biological and Bacteriological Characteristics

6.4.3.1 Environmental Microbiology

Environmental microbiology is a growing field of biology which often brings together issues of concern to engineers, geologists, hydrologists, microbiologists and public health officials.

Microbes are nature’s decomposers. Drinking water is obtained either from surface sources such as rivers and lakes or from underground water. Such natural waters are likely to be polluted with domestic and industrial wastes. Although water purification systems envisage protection from pollution, sometimes the water supply can become a potential carrier of pathogenic organisms and endanger public health. A number of diseases such as cholera, typhoid, viral hepatitis, etc. are known to be waterborne. These pathogens are commonly transmitted through drinking water and cause infection of the intestinal tract. It is, therefore, necessary to employ treatment facilities to purify water and to provide safe drinking water (potable water).

Water can be perfectly clear in appearance and free from odour and taste and yet be contaminated by microorganisms. Pathogenic organisms enter into water through sewage contamination or discharges from animals or humans into the reservoirs. The coliforms (E. coli and related organisms), Streptococcus faecalis and Clostridium perfringens which are normal inhabitants of the large intestine of animals and humans enter water supplies through faecal contamination. The presence of any of these bacterial species in water is evidence of sewage or faecal pollution. Techniques are available by which the presence of these specific groups can be easily identified. The routine bacteriological examination consists of (i) plate count to determine the number of bacteria present and (ii) biochemical test to reveal the presence of coliform bacteria since these are indicator organisms for faecal contamination.

A variety of other bacteria and organisms which may not be serious pathogens including faecal streptococci, slime-forming bacteria, sulphur bacteria, algae, etc. may also cause problems of odour, colour and taste, and it is essential that these are eliminated from the drinking water.

It is important therefore that the fundamental activity of microorganisms and their metabolic and biochemical control should be more fully understood by those who are involved.

6.4.3.2 Bacteria

The word bacteria comes from a Greek word meaning rod or staff, a shape characteristic of many bacteria. Bacteria are single-celled microscopic organisms that multiply by binary fission. In order to multiply, they need carbon obtained from carbon dioxide if they are autotrophs or from organic compounds (dead vegetation, sewage, meat) if they are heterotrophs. Their energy comes either from sunlight if they are photosynthetic or from chemical reaction if they are chemosynthetic. Bacteria are present in air, water, earth, rotting vegetation and the intestines of the animal. Bacteria are fundamental to all biological processes, especially in the degradation of organic matter which takes place in trickling filter, activated sludge processes and sludge digestion.

The bacterial communities found in wastewater treatment plants are complex. The bacterial flora of all aerobic treatment systems is basically the same and includes Zoogloea, Pseudomonas, Chromobacter, Achromobacter, Alcaligenes and Flavobacterium.

6.4.3.2.1 Facultative Bacteria

Most of the bacteria that absorb the organic material in a wastewater treatment system are facultative in nature. This means they are adaptable to survive and multiply in either anaerobic or aerobic conditions. The nature of individual bacteria is dependent upon the environment in which they live. Usually, facultative bacteria will be anaerobic unless there is some type of mechanical or biochemical process used to add oxygen to the wastewater. When bacteria are in the process of being transferred from one environment to the other, the metamorphosis from anaerobic to aerobic state (and vice versa) takes place within a couple of hours. When mixed cultures are present, aerobic and facultative bacteria first decompose organic matter, gradually depleting the dissolved oxygen. When dissolved oxygen is exhausted, facultative bacteria continue to use O2 in the form of SO4 and NO3, while some facultative and anaerobic organisms produce organic acids, alcohol, methane, etc.

6.4.3.2.2 Anaerobic Bacteria

Anaerobic bacteria (Methylococcus, Desulfovibrio, Clostridium, Thiobacillus denitrificans, Enterobacter, etc.) live and reproduce in the absence of free oxygen. These carry on fermentation activity using organic substances as electron donors and acceptors. They produce organic acids, alcohol and least amount of energy.

If methane-producing bacteria are present, then the anaerobic digestion process is completed by converting organic acids into methane and CO2.

Some anaerobic bacteria use nitrate and sulphate as an electron acceptor.

H2S is given out by sulphate-reducing bacteria if the wastewater becomes anaerobic. Slightly acidic gas is absorbed in water. Sulphur bacteria can tolerate even pH 1.0 and oxidise H2S to H2SO4.

H2SO4 reacts with lime in concrete to form calcium sulphate which lacks structural strength.

In order to remove a given amount of organic material in an anaerobic treatment system, the organic material must be exposed to a significantly higher quantity of bacteria and/or detained for a much longer period of time. A typical use for anaerobic bacteria would be in a septic tank. The slower metabolism of the anaerobic bacteria dictates that the wastewater should be held several days in order to achieve even a nominal 50 % reduction in organic material. That is why septic tanks are always followed by some type of effluent treatment and disposal process. The advantage of using the anaerobic process is that electromechanical equipment is not required. Anaerobic bacteria release hydrogen sulphide and methane gas, both of which can create hazardous conditions. Even as the anaerobic action begins in the collection lines of a sewer system, deadly hydrogen sulphide or explosive methane gas can accumulate and be life-threatening.

6.4.3.2.3 Aerobic Bacteria

Aerobic bacteria (Azotobacter, Pseudomonas, Nitrosomonas, Nitrobacter, hydrogen-oxidising bacteria, etc.) live and multiply in the presence of free oxygen. Facultative bacteria always achieve an aerobic state when oxygen is present. While the name ‘aerobic’ implies breathing air, dissolved oxygen is the primary source of energy for aerobic bacteria. The metabolism of aerobes is much higher than that of anaerobes. This increase means that up to 90 % fewer organisms are needed compared to the anaerobic process or that treatment is accomplished in 90 % less time.

\( \begin{array}{l}\mathrm{Organic}\ \mathrm{matter}+{\mathrm{O}}_2\to \left(\mathrm{Aerobic}\ \mathrm{condition}\right){\mathrm{H}}_2\mathrm{O}+{\mathrm{CO}}_2+\mathrm{Biomass}\hfill \\ {}\kern8em +\mathrm{Energy}\left(\mathrm{e}.\mathrm{g}.\ Escherichia\ coli\ \mathrm{reaction}\ \mathrm{in}\ \mathrm{wastewater}\right)\hfill \end{array} \)Aerobic procedures are biochemically efficient and rapid. Their by-products are chemically simple and highly oxidised like CO2 and H2O. Iron bacteria occur normally in mine wastewater which is iron-rich. They can also occur in wastewater. They also contribute to corrosion and clogging of iron pipes.

Concrete pipes can collapse if they become too weak due to corrosion problem. Vitrified clay or PVC may be used to overcome the corrosion problem. Sewers can be lined with corrosion-resistant coating.

Aerobic procedures provide a number of advantages including a higher percentage of organic removal. The by-products of aerobic bacteria are carbon dioxide and water. Aerobic bacteria live in colonial structures called floc and are kept in suspension by the mechanical action used to introduce oxygen into the wastewater. This mechanical action exposes the floc to the organic material while treatment takes place. Following digestion, a gravity clarifier separates and settles out the floc. Because of the mechanical nature of the aerobic digestion process, maintenance and operator oversight are required.

Autotrophic Aerobes

Autotrophs do not use organic matter. They oxidise inorganic compounds for energy and use CO2 or CO3 as carbon source. In wastewater treatment, autotrophs are relatively less important if high organic matter is the problem. Nitrifying bacteria, sulphur bacteria and iron bacteria are particularly important. Nitrifying bacteria oxidise ammonia.

Conventional biological wastewater treatment generates large amounts of low-value bacterial biomass. The treatment and disposal of this excess bacterial biomass, also known as waste activated sludge, account for about 40–60 % of the wastewater treatment plant operation cost.

6.4.3.3 Fungi

Fungi are tiny aerobic, heterotrophic Protista containing no chlorophyll. They can tolerate dryer and more acidic conditions than most bacteria. They live in the earth, freshwater and sea water. Many grow as filaments and may be seen in polluted rivers, trickling filters and activated sludge. The optimum pH for most types is between 2 and 9. Because fungi are wholly aerobic, they can, in animals, exist only on the skin or in the bloodstream or lungs. Consequently, there are relatively very few fungi that cause disease in humans. Many organic substances can be attacked by fungi such as cellulose, phenols and hydrocarbons. Attacked organic compounds are converted into simple compounds which can be used as nutrients by other organisms. They produce aflatoxins that are harmful to man and animals. Fungi produce biomass with a higher value that can significantly change the economics of wastewater treatment. The biomass produced during fungal wastewater treatment has, potentially, a much higher value than that from the bacterial activated sludge process. The fungi can be used to derive valuable biochemicals and can also be used as a protein source. Various high-value biochemicals are produced by commercial cultivation of fungi under aseptic conditions using expensive substrates. Food-processing wastewater is an attractive alternative as a source of low-cost organic matter and nutrients to produce fungi with concomitant wastewater purification. Some species of fungi Bjerkandera adusta, Aspergillus niger, Penicillium, Rhizopus arrhizus, Rhizopus oryzae, etc. are useful in various sewage treatments.

6.4.3.4 Algae

Algae form a large group in the Protista. Being photosynthetic, they are classified as plants. Algae are single-celled or multicellular autotrophs. At night, some algae consume oxygen by chemosynthesis. Thus, water containing algae has a diurnal variation in dissolved oxygen. However, during sunlight, the carbon dioxide concentration falls. The CO2 originated from the symbiotic relation with bacteria or from bicarbonates releases hydroxyl ion which tends to raise the pH of water: \( {\mathrm{HCO}}^{3-}\to {\mathrm{CO}}_2+{\mathrm{OH}}^{-} \). Photosynthetic reaction during the day can be represented by the following reaction: \( {\mathrm{CO}}_2+{\mathrm{H}}_2\mathrm{O}+\mathrm{Sunlight}\to {\mathrm{CH}}_2\mathrm{O}+{\mathrm{O}}_2 \). This process utilises CO2. The utilisation of CO2 during the day may lead to a considerable rise of pH and results in a softening of water due to precipitation of CaCO3, as represented by the following reaction: \( \mathrm{C}\mathrm{a}{\left({\mathrm{H}\mathrm{CO}}_3\right)}_2\to {\mathrm{CaCO}}_3+{\mathrm{H}}_2\mathrm{O}+{\mathrm{CO}}_2 \). For most waste stabilisation ponds to function properly, algae such as Chlamydomonas, Chlorella and Euglena are needed to supply oxygen to aerobic heterotrophic bacteria that consume and oxidise the organic matter in sewage. The history of the commercial use of algal cultures spans about 75 years with application to wastewater treatment and mass production of different strains such as Chlorella and Dunaliella. The most important classes of freshwater algae are Chlorophyta, Euglenophyta, Chrysophyta and Cyanophyta. Biotreatment with microalgae is particularly attractive because of their photosynthetic capabilities, converting solar energy into useful biomasses and incorporating nutrients such as nitrogen and phosphorus causing eutrophication (Abdel-Raoufa et al. 2012). The other frequently found algae are Ankistrodesmus, Scenedesmus, Oscillatoria, Micractinium and Golenkinia.

In drinking water, algae are troublesome because they clog filters, may leave a taste when they die and produce toxin that can poison cattle. Algae in reservoirs can be reduced by oxygenating the water and reducing its CO2 content or by adding an algicide such as copper sulphate or potassium paramagnet or by destratification of lake or reservoir. Algae growth in the catchment area of water supply system may lead to obnoxious taste and other odour problem that are hard to remove and may require treatment with activated carbon.

6.4.3.5 Protozoa

Protozoa are single-celled eukaryotic organisms. Some protozoa are parasitic organisms that are present in municipal sewage so are present in the treatment tanks. Such organisms are disease-causing agents, so part of the treatment of sewage is aimed to kill these organisms, e.g. Cryptosporidia and Giardia. Some protozoa scavenge and digest bacteria, and these are important for controlling bacterial pathogens as well as the overgrowth of other bacteria in a treatment system, e.g. Paramecium and Vorticella. Protozoa may indicate, by their type, the condition of activated sludge. They are also important in the operation of trickling filters. They feed on the bacteria and some utilise alga. Most protozoa are harmless and only a few cause illness in humans. Entamoeba histolytica (amoebiasis), Giardia lamblia (giardiasis), Trypanosoma (trypanosomiasis: sleeping sickness) and Plasmodium (malaria).

6.4.3.6 Rotifers

Rotifers are tiny aerobic creatures ranging from 50 to 250 μm in length; rotifers are the simplest of the multicelled invertebrate animals. They have cilia around their mouth and can swallow bacteria or other organic matter. Their presence in an effluent indicates highly efficient aerobic biological treatment. These organisms are important to wastewater treatment because their main source of food is bacteria. It is believed that rotifers scavenge free-floating bacteria, thus reducing BOD and also the numbers of pathogenic organisms in the water.

6.4.3.7 Crustaceans

Crustaceans mainly are water animals that use O2, consume organic substances and have a hard body or crust. They are an important food for fish. Crustaceans are not normally found in the biological treatment processes. Usually they are an indicator of clean water. The metabolic complexity of the crustaceans limits their growth to relatively stable streams and lakes.

6.4.3.8 Worms and Larvae

Worms and larvae are the normal inhabitant in organic mud and biological slime. They have aerobic requirements but can metabolise solid organic matter not readily degraded by other microorganisms. The common organism used in stream pollution studies as indicators of pollution are the worm, tubifex and the midge fly larva of Chironomidae.

6.4.3.9 Viruses

A virus is an entity that carries the information for its replication but does not possess the machinery for such replication. Thus, all viruses are obligatory parasite and they are unable to reproduce outside a host cell. Viruses are disease-causing agents that are present in sewage and are removed during sewage treatment by adsorption to the floc. Some kind of floc or support is necessary to prevent washout of the active cells. A rich carbon source is a benefit in that it allows the formation of extracellular polymers which provide a glue-like substance to allow organisms to stick together (floc) or to a solid support. Viruses of particular interest in drinking water are hepatitis A, Norwalk-type viruses, rotaviruses, adenoviruses, enteroviruses and reoviruses.

6.5 Impact of Pollutants on Biotreatment

Industrial effluents may have a different impact on microorganisms depending on the nature and composition of effluent pollutants. This can be as follows.

6.5.1 Biodegradation

Biodegradation is nature’s way of recycling wastes or breaking down organic matter into nutrients that can be used and reused by other organisms. Biodegradation is a process of biological catalytic reduction in complexity of chemical compounds using living microbial organisms (Asthana et al. 2014; Gupta et al. 2014; Kumar et al. 2015; Marinescu et al. 2009). There is, therefore, complete compatibility between the bacterial floral and oxo-biodegradable degradation of compounds. The term is often used in relation with ecology, waste management, environmental remediation (bioremediation) and for plastic materials, due to their long life span.

6.5.1.1 Inhibition of Biodegradation

Heavy metals like Cd, Cr, Cu, Hg, Zn, Ni, Pb, etc. are often present in a variety of industrial effluents and will inhibit biological activity. The presence of metals and metalloids will not allow otherwise degradable organic matter also to get degraded. Among organic solvents, chlorinated organics and alcohols are toxic to biological processes. Also phenols, pesticides and surfactant are inhibitory to biological activities in treatment plants.

Anaerobic processes are susceptible to sulphides (H2S). High sulphides are present in the effluents of molasses fermentation industry, tanneries, petrochemical industry and paper mills. Anaerobic processes are also sensitive to pH outside the range of 6.5–8.2. Volatile fatty acids in excess of 2000 mg l−1, NH4 + concentration in excess of 3000 mgl−1 and free ammonia at a concentration of 150mgl−1 are also very toxic.

6.5.2 Incidental Removal

Incidental removal of pollutant may occur by absorption, adsorption, precipitation and consequential concentration into sludge produced. Activated sludge has the capacity to bind heavy metals by polysaccharides of microbial flocs. Incidental removal of organic compounds by association with settleable solids or floatable scum or grease also takes place. This may occur if the compounds are insoluble or slightly soluble in water or hydrophobic.

6.5.3 Co-metabolism

When a particular compound is altered chemically by microbial metabolism without that compound serving as a source of carbon or energy, that compound is said to be co-metabolised or co-oxidised. A co-metabolite does not support the growth of organism concerned, and end products of transformation are accumulated stoichiometrically. The transformation does not require energy consumption. Co-metabolism is thought to occur because some enzymes produced by organisms for metabolism of their major carbon source are not substrate specific and can act on other compounds (Table 6.2). The rate of co-metabolism is often quite slow.

In pure culture, co-metabolism can be considered as a dead end transformation without benefit to that microorganism. Synergistic transformation and substrate utilisation may lead to recycling of relatively recalcitrant compound.

Co-metabolism appears to be an important route for the degradation of hydrocarbon, especially the more recalcitrant alicyclic compound in the environment. It is also an important pathway for pesticide degradation.

6.6 Wastewater Treatment Process

Selection of a treatment process depends on the characteristics of wastewater (i.e. form of pollutants like suspended, colloidal or dissolved; biodegradability; toxicity of the components), required effluent quality, cost, availability of treatment devices and area (land). Wastewater treatment units can be classified according to their capacity.

Small Wastewater Treatment Plants

Small wastewater treatment units address wastewater treatments as applied to individual household or small community. Usually they are on-site treatment and disposal units.

Large Wastewater Treatment Units

Large wastewater treatment plants are wastewater works that govern the discharge and treatment of large population sector. Sewage is collected from different localities and diverted to a central treatment plant.

Reasons for Treatment

The major reasons for the wastewater treatment may be as follows:

-

Reduction in the spread of communicable diseases – to be achieved through the elimination or reduction of pathogens in the sewage

-

Prevention or reduction of pollution that may enter the surface or groundwater sources

-

Stabilisation of sewage without causing any odours or nuisances and without endangering the public health

-

Water reuse aspects or for waste by-product recovery

Typical Strategies of Wastewater Treatment Processes

Wastewater may be treated on site or as sewage treatment works (STW) by the following methods:

-

Preliminary treatment

-

Physical (primary) treatment

-

Secondary treatment

-

Tertiary treatment (chemical)

-

Disinfection of wastewater

6.6.1 Preliminary Treatment

Preliminary treatment is used essentially to prepare wastewater for treatment. The objective of preliminary treatment is the removal of coarse particles and other large materials often found in raw wastewater, which could obstruct flow through the plant or damage equipment. Removal of these materials is necessary to enhance the operation and maintenance of subsequent treatment units. These materials are composed of floating objects such as rags, wood, faecal material and heavier grit particles.

Elements that could damage treatment units are removed, and usually the flow is equalised, reducing maximum flow conditions and allowing a smaller plant treat the wastewater flow. A typical pretreatment unit contains the following.

6.6.1.1 Bar Racks

A bar rack (or bar screen) traps debris as wastewater influent passes through. Typically, a bar screen consists of a series of parallel, evenly spaced bars or a perforated screen placed in a channel used to remove large objects that could damage other plant devices (Singh et al. 2012). Large floating objects can be removed by passing the sewage through bars spaced at 20–60 mm. Retained material is raked from the bars at regular intervals. Bar screens with relatively large openings of 75–150 mm are provided ahead of pumps, while those ahead of sedimentation tanks have smaller openings of 50 mm.

6.6.1.2 Grit Chamber

These are designed to remove grit (inert dense material, such as sand, broken glass, silt, pebbles) from wastewater, to keep it from eroding and damaging pumps and other mechanisms. Preliminary treatment operations typically include coarse screening and grit removal of large objects. Sufficiently high velocity of water flow is maintained in grit chambers, or air is used, so as to prevent the settling of most organic solids.

6.6.1.3 Equalisation Basin

Most treatment devices must be designed with specific conditions of maximal and minimal flow, but normally the wastewater flow from a community is far from being constant. So, in order to keep the wastewater flow entering the primary treatment unit constant, an equalisation basin is used to collect and store wastewater flow. From this basin the wastewater is pumped at a constant rate into the primary treatment unit.

6.6.2 Primary Treatment

The objective of primary treatment is the removal of settleable organic and inorganic solids and the removal of materials that will float (scum) by skimming. Approximately 25–50 % of the incoming biochemical oxygen demand (BOD5), 50–70 % of the total suspended solids and 65 % of the oil and grease are removed during primary treatment. Some organic nitrogen, organic phosphorus and heavy metals associated with solids are also removed during primary treatment, but colloidal and dissolved constituents are not affected. Pathogen removal during primary treatment is highly varied with various removal rates reported for different organisms.

6.6.2.1 Screening

Screening is the first operation at any wastewater treatment works. This process essentially involves the removal of large non-biodegradable and floating solids that frequently enter a wastewater works, such as rags, papers, plastics, tins, containers and wood.

Efficient removal of these constituents will protect the downstream plant and equipment from any possible damage, unnecessary wear and tear, pipe blockages and the accumulation of unwanted material that will interfere with the required wastewater treatment processes. The screening equipment is designed for efficient and cost-effective solution with durable and dependable operations.

Wastewater screening is generally classified into either coarse screening or fine screening.

6.6.2.1.1 Coarse Screens

Coarse screens remove large solids, rags and debris from wastewater and typically have openings of 6 mm (0.25 in.) or larger. Types of coarse screens include mechanically and manually cleaned bar screens, including trash racks (Fig. 6.1).

6.6.2.1.2 Fine Screens

Fine screens are typically used to remove material that may create operation and maintenance problems in downstream processes, particularly in systems that lack primary treatment. Typical opening sizes for fine screens are 1.5–6 mm (0.06–0.25 in.). Very fine screens with openings of 0.2–1.5 mm (0.01–0.06 in.) placed after coarse or fine screens can reduce suspended solids to levels near those achieved by primary clarification.

Most modern wastewater treatment plants utilise a combination of coarse and fine screening (i.e. upstream coarse screens providing protection to downstream fine screens).

6.6.2.2 Equalisation

For sewage treatment plants of small community, where wastewater flow rates vary considerably with time, and for industrial wastewater treatment plants, where wastewater flow and characteristic vary with time, equalisation becomes essential to obtain proper performance of the treatment plant by avoiding shock loading (hydraulic and organic) to the systems. Due to possibility of variation in flow rate received at treatment plant, there may be deterioration in performance of the treatment plant. To facilitate maintenance of uniform flow rate in the treatment units, flow equalisation is used. Equalisation can also be used to provide continuous feeding to the treatment system when the wastewater generation is intermittent, to control pH fluctuations or to control toxic concentration in the feed to the biological reactor, and this can also be used to control the discharge of industrial effluent in to the sanitary sewers.

Equalisation can be of two types:

-

(a)

Inline: where all flow passes through equalisation basin.

-

(b)

Offline: where the flow above average daily flow is diverted to equalisation basin. The pumping is minimised in this case, but the amount of pollutant concentration damping is considerably reduced.

Location of equalisation: Location of equalisation basin after primary treatment and before biological treatment is appropriate. This arrangement considerably reduces problem of sludge and scum in the equalisation basin. If the equalisation basin is placed before primary treatment, it must be provided with sufficient mixing to prevent deposition of solids and concentration variations and aeration to prevent odour problem. Most commonly used submerged or surface aerators have power levels of approximately 0.003–0.004 KW/m3. In diffused air mixing, air requirement of 3.74 m3/m3 (air flow rate to water flow rate) is used.

6.6.2.3 Sedimentation

After removal of the coarse materials, sewage passes to sedimentation tanks, which aims to remove the settleable solids (represent up to 70 % of the total settleable solids) by gravity. A well-designed sedimentation tank can remove 40 % of the BOD in the form of settleable solids. Sedimentation is used to remove suspended solids present in wastewaters. In fishery wastewaters, these include fish scales, portions of fish muscle and offal (relative proportions varying with the particular process being used).

Sedimentation is based on the difference in density between the bulk of the liquid and the solid particles, which results in the settling of the solids present. The terms sedimentation and settling are often used interchangeably. This operation is conducted as part not only of the primary treatment but also in the secondary treatment for separation of solids generated in the biological treatments such as activated sludge or trickling filters. Depending on the properties of solids present in the wastewater, sedimentation can proceed as:

-

Discrete settling, if the wastewater is relatively diluted and the particles do not interact.

-

Flocculent settling, if the particles that coalesce or flocculate are living particles of larger mass and faster settling rate. This is typical of untreated wastewater and is encountered in primary settling facilities.

-

Zone settling, which is also called hindered settling and occurs when the particles adhere together and settle as a blanket, forming a distinguishable interface with the liquid above it. This reaction occurs in secondary clarifiers for sludges of biological treatments.

Each case has different characteristics. For discrete settling, calculations can be made on the settling velocity of individual particles. In a settling tank, these move both downwards (settling) and towards the outlet zone with the waterflow (Fig. 6.2). The particles that reach the bottom before the outlet will be separated from the effluent while the rest will pass through the settling tank. The critical velocity (v c ) below in which a particle will be carried out of the tank is given by the depth of liquid (d), the volume of the tank (V) and the flow rate (Q):

The ratio of V/Q is also known as the residence time of the liquid in the tank. It is called the overflow rate when v c is expressed in terms of volume of effluent per unit surface area of the tank per unit of time. This case may be present in fishery wastewaters but is not the most common.

In the case of a flocculant suspension, the formation of larger particles due to coalescence depends on several factors, e.g. the nature of the particles and the rate of coalescence. A theoretical analysis is not feasible due to the interaction of particles which depends among other factors on the overflow rate, the concentration of particles and the depth of the tank.

A settling column is used to evaluate the settling characteristics of a flocculant suspension (Fig. 6.3). The same kind of column using only one sampling port can be used to study discrete settling.

The zone (or hindered) settling, which occurs when the particles do not settle independently, is also studied by batch tests. In this case, an effluent that is initially uniform in solid concentration (Fig. 6.4), if allowed to settle, will do so in zones, the first of which is that of clarified water (1) and below is the interfacial zone (2) in which the solid concentration is considered uniform. In the bottom, a compact sludge develops in the so-called compaction zone (4). Between (2) and (4), a transition zone (3) generally exists.

Diagram of a zone settling process: Zone (Type III) Settling. In the bottom, a compact sludge develops in the so-called compaction zone (4). Between (2) and (4), a transition zone (3) generally exists. As time proceeds, the clarified effluent and compaction zones will increase in size, while the two intermediates will eventually disappear

In some cases, further compaction may occur. The detailed design procedures for all these cases are beyond the scope of this document and can be found elsewhere. The actual configuration of a sedimentation tank can be either rectangular or circular. Rectangular settling tanks (Fig. 6.5) are generally used when several tanks are required and there is space constraint, since they occupy less space than several circular tanks.

For removal of solids, a series of chain-driven scrapers are used: these span the width of the tank, are regularly spaced and move at 0.5–1 m/min. The sludge is collected in a hopper in the end of the tank, where it may be removed by screw conveyors or pumped out. Configurations exist in which the sludge is forced opposite to the flow, as shown here, but concurrent flow of the liquid and solids is also used.

Circular tanks are reported to be more effective. In these, the effluent circulates radially, the water being introduced at the periphery or from the centre. The solids are generally removed from near the centre, for which a slope of 10 % is required in the bottom of the tank. The sludge is forced to the outlet by two or four arms provided with scrapers which span the radius of the tank. For both types of flow, a means of distributing the flow in all directions is provided: for centre feed tanks there is a circular well, while for the rim-fed tanks a baffle is usually installed and the effluent enters tangentially. An even distribution of inlet and outlet flows is important to avoid short-circuiting in the tank that would reduce the separation efficiency.

A critical factor for selection of tank size is the so-called surface-loading rate, generally expressed as volume of wastewater per unit time and unit area of settler (m3/m2d). This loading rate depends on the characteristics of the effluent and the solids content and can be determined from the settling tests described above. The retention time in the settlers is generally in the order of 1–2 h, but the capacity of the tanks must be determined taking into account the peak flow rates so that good separation is also obtained in these cases.

In cases of small or elementary settling basins, the sludges can be removed using an arrangement of perforated piping placed in the bottom of the settling tank. The pipes must be regularly spaced, they must be of a diameter wide enough to be cleaned easily in case of clogging, and the flow velocities should also be high enough to prevent sedimentation. These last two requisites are somewhat contradictory, and a compromise is usually reached, using pipes of 5 cm in diameter, perforated with holes of 1–1.5 cm in diameter, 1 m apart. Flow in individual pipes may be regulated by valves. This configuration is best used after screening and is also found in biological treatment tanks for sludge removal. An alternative to the above configurations for settling tanks is that of the inclined tube separators. These separators consist of tubes (although there are alternate designs that use plates close to each other) which are tilted.

The concept is that, when a settling particle reaches the wall of the tube or the lower plate, it coalesces with another particle to give one of larger mass and higher settling rate.

The media are usually inclined at 45–60°. They are also commonly used to upgrade existing settling tanks since they have a higher separation rate.

6.6.2.4 Floatation

Flotation is an operation that removes not only oil and grease but also suspended solids. The most common procedure is that of dissolved air floatation (DAF), in which the waste stream is first pressurised with air in a closed tank. After passing through a pressure-reduction valve, the wastewater enters the floatation tank where, due to the sudden reduction in pressure, minute air bubbles in the order of 50–100 μm in diameter are formed. As the bubbles rise to the surface, the suspended solids and oil or grease particles adhere to them and are carried upwards. It is common practice to use chemicals to enhance floatation performance. As with coagulants (discussed later), these aids should preferably be innocuous, since these recovered solids are frequently used in animal feed formulations.

One alternate design involves the recycling of part (10–30 %) of the treated water. All systems contain a mechanism for removing the solids that may settle to the bottom of the flotation tanks, usually by a helical conveyor placed in the conical bottom. The main advantage claimed by DAF systems is the faster rate at which very small or light suspended solids can be removed in comparison with settling.

In one case, oil removal was reported to be 90 %. In tuna-processing wastewaters, the DAF removed 80 % of oil and grease and 74.8 % of suspended solids in one case and 64.3 % of oil and grease and 48.2 % of suspended solids in another case.

Another floatation system exists in which air is not dissolved but forced through the wastewater by surface aerators. This system generates air bubbles of larger sizes than DAF systems, and no report exists about its application to fishery wastewaters.

Prior to the design or selection of a DAF system, it is advisable to carry out laboratory experiments to evaluate its applicability and critical operating factors such as the air-to-solid ratio, the effectiveness of flocculants and the proper pH. This can be conveniently done in laboratory units. In these devices, water with or without chemicals and pH adjustment is introduced, and the pressure is increased to the desired value. After mixing to saturate the liquid with air, pressure is released and the liquid flows to a graduated cylinder where time is allowed for separation. The detailed procedures for conducting the evaluations are available elsewhere.

6.6.3 Secondary Treatment

The main purpose of the primary sedimentation stage is to produce both a generally homogeneous liquid capable of being treated biologically and a sludge that can be separately treated or processed. The secondary treatment process aims to reduce the BOD exerted by reducing organic matter. This is mediated, primarily, by a mixed population of heterotrophic bacteria that utilise the organic constituent for energy and growth.

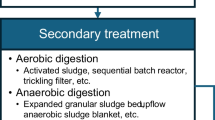

Secondary treatment includes biological treatment: aerobic processes, anaerobic processes and specialised (Table 6.3). The objective of secondary treatment is the further treatment of the effluent from primary treatment to remove the residual organics and suspended solids.

6.6.3.1 Aerobic Processes

In most cases, secondary treatment follows primary treatment and involves the removal of biodegradable dissolved and colloidal organic matter using aerobic biological treatment processes. Aerobic biological treatment is performed in the presence of oxygen by aerobic microorganisms (principally bacteria) that metabolise the organic matter in the wastewater, thereby producing more microorganisms and inorganic end products (principally CO2, NH3 and H2O). Several aerobic biological processes are used for secondary treatment differing primarily in the manner in which oxygen is supplied to the microorganisms and in the rate at which organisms metabolise the organic matter.