Abstract

Strategic or long-term management planning plays a key role in the development of forest schedules as the temporal dimension is a determinant characteristic of all forestry production systems. In this chapter we address the representation of industrial forest strategic forest management problems as well as the interpretation of its solution. We start with a simple harvest scheduling model aiming at the maximization of economic returns while addressing concerns with the sustainability of a product flow. This policy scenario is expanded to reflect concerns with the volume in the ending inventory, with the average carbon stock, with the environmental impacts of clearcuts and with the integration of road building and maintenance decisions. Several modeling approaches are considered to represent and solve each problem. An example forest is used to illustrate all problems and how they may be addressed by each modeling approach. Several applications of the modeling approaches to strategic management planning of industrial plantations are briefly described in six Management Planning in Action boxes. A list of problems at the end of the chapter build from the same example forest to support model building, model solving and interpretation of results by readers.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

1 Introduction

Strategic management planning plays a key role in the development of forest schedules as the temporal dimension is a determinant characteristic of all forestry production systems. Strategic or long-term management planning typically encompasses temporal horizons extending over more than 10 years so that forestry economic and biological processes may be adequately acknowledged (Chap. 2). The importance of this planning level was highlighted in a recent review of forest management problems that are prevalent world-wide (Borges et al. 2014b). Forest management experts representing 26 countries from Europe, North and South America, Africa and Asia involved in the FORSYS Cost Action (http://www.cost.eu/domains_actions/fps/Actions/FP0804) did include strategic management planning in the list of the most important problems that foresters have to face in their countries (Borges et al. 2014b).

Long term stand-level problems tend to be more important in countries where the forest is mostly privately owned and highly fragmented (Borges et al. 2014b). This spatial scale structures a problem with specific features and that requires specialized solution techniques (Chap. 6). In this chapter we will focus on long-term management planning at the regional and forest-level spatial scales (Chap. 2). The latter typically encompasses several contiguous stands and is more frequent in the case of industrial plantations. Nevertheless, in the case of the vertically integrated forest industry its land base is often dispersed over a region. Further, the industry is often concerned with the supply of raw material from other ownerships within a regional framework.

Socioeconomic development and demographic trends have led to an increasing awareness of the externalities that derive from the use of forests for commercial purposes over extended planning horizons. Strategic management scheduling of industrial forests is thus increasingly framed by demands other than by the forest industry (Chap. 2). As a consequence, the long term sustainability of an industrial forest is currently assessed by a set of indicators (Chap. 13) to characterize both the supply of industrial product flows and the ecological/economic features of its land base. Moreover, the forest industry competitiveness often depends on the success of certification processes where a wide range of ecological and socioeconomic indicators are considered (Chap. 15).

In this context, strategic or long term management scheduling of industrial forests has to address objectives that range from traditional products’ even-flow goals to stock control and landscape structure targets. Borges et al. (2014b) reported that even when strategic management planning addresses only market wood products thus excluding all other goods and services, forest managers often target multiple objectives rather than a single one. For that purpose, forest managers sometimes sequence land allocation and harvest scheduling decisions. For example, in Brazil, land allocation decisions in areas managed by the industry are often made prior to harvest scheduling decisions. The legal framework prescribes the amount of land that a rural property has to preserve for environmental purposes or to maintain uncultivated, protecting soils and water streams (usually referred in Brazil as APPs – Permanent Preservation Areas), or to reserve as a precautionary measure to maintain a constant stock of wood and forest resources (also referred in Brazil as RLs – Legal Reserves) (Rodriguez and Nobre 2013). Nevertheless, even when uses are segregated in space the management of the industrial plantation may still be framed by concerns other than with the sustainability of the product flow to the factory.

The spatial context of harvest scheduling decisions is typically addressed at tactical and operational planning scales (Chap. 2). The importance of locational specificity in a management plan, i.e. the definition of the spatial location where management options are actually to be implemented, grows when tactical and operational concerns are to be addressed (Chap. 7). Nevertheless the possibility of balancing strategic and tactical goals may be facilitated if long-term management planning does address locational specificity. The management of the industrial plantation is often framed by spatial considerations that require the acknowledgement of neighboring relations between stands. If these are totally ignored by strategic management planning it may even more difficult to reconcile the long-term and medium and short-term perspectives and schedules. Accordingly, in countries where strategic forest-level management planning targeting only wood products is reported as a prevalent problem, locational specificity of the long-term solution is typically required (Borges et al. 2014b). In fewer cases it was reported that neighborhood relations should also be fully acknowledged.

The practice of strategic management scheduling of industrial plantation thus focus on the structuring, the representation and the solution of a range of long-term planning problems. These may be classified according to dimensions that include the spatial scale, the number of objectives as well as of products and the spatial context. In any case, thoughtful development of all stages of the decision process requires information and knowledge about the structure of the planning process, the land base that is the object of the planning exercise, the models available to make projections of forest products and the models available to generate prescriptions that may be implemented in each stand (Chap. 2). Last but not the least it requires the application of forest economic and finance models (Chap. 5).

Problem structuring issues may be better addressed in the framework of the development of information systems that may encapsulate the data and the model base needed to support the integration of temporal planning levels (Chap. 9). In this chapter we will address the representation of industrial forest strategic forest management problems as well as the interpretation of its solution. We will start with a simple harvest scheduling model aiming at the maximization of economic returns while addressing concerns with the sustainability of a product flow (Problem 1). This policy scenario will be expanded to reflect concerns with the volume in the ending inventory and with the average carbon stock (Problem 2). Further concerns with the environmental impacts of clearcuts will be addressed in Problem 3. The integration of road building and maintenance decisions within strategic forest management scheduling will be discussed as Problem 4.

Several modeling approaches will be considered to represent and solve each problem. In the case of Problems 1 and 2 we will start with linear programming formulations, the technique most widely used in long-term forest management scheduling (Chap. 2). Mixed integer programming formulations will be used to ensure the locational specificity of the solutions to Problems 1 to 3. We will present a goal programming representation of the multiple objective policy scenarios in Problems 1 to 3. A meta-heuristic – simulated annealing – will be considered as an alternative integer solution approach in the case of Problems 1 to 3. Further, a Pareto frontier approach will be used to illustrate how the setting of management planning targets may benefit from a priori display of trade-offs between objectives. The reader is referred to Chap. 2 for an introduction to each modeling approach.

1.1 Example Forest and Applications

In this chapter, an example forest will be used to illustrate all problems and how they may be addressed by each modeling approach. Several applications of the modeling approaches to strategic management planning of industrial plantations will be briefly described in six Management Planning in Action boxes.

Our example forest encompasses a set of 16 stands from Leiria National Forest (LNF), a pine forest in Portugal (Fig. 6.1). Land classification led to stand areas that range from 28.5 to 31 ha (Table 6.1). Long-term planning typically extends over the number of years corresponding to 1.5 rotations (Chap. 2). In the case of LNF the planning horizon extends over 100 years (Tomé et al. 2010; Garcia-Gonzalo et al. 2013). Nevertheless, for illustration purposes we will consider a four 10-year period planning horizon.

These stands were assigned LNF inventory plot information (Table 6.1). Stand age ranges from 23 to 53 years. The volume ranges from 107. 5 to 331.3 m3/ha in the case of younger and older stands, respectively. A prescription writer was used to generate 3–5 prescriptions for each stand. For simplicity, the prescriptions involve only clearcuts and it is assumed that stands regenerate naturally. Prescriptions are available that involve clearcuts in alternative years of the same planning period.

An empirical growth and yield model was used to estimate the values of volume harvested in each planning period and at the ending inventory as well as of the carbon stock, resulting from the assignment of each prescription to each stand (Table 6.2). The corresponding revenues were computed considering a constant price equal to 15.5 €/m3. Their present value in year 1 of the planning horizon was computed considering a discount rate equal to 3 % (Table 6.2).

What You Will Learn in This Chapter

-

The dimensions of strategic forest management planning in the case of industrial plantations.

-

How to build a model that may represent a strategic forest management planning problem.

-

How to analyze the potential of operations research techniques to address several long-term management planning problems.

-

How to interpret the long-term schedules provided by several modeling approaches.

2 Volume and Area Control in Long Term Industrial Forest Management Planning (Problem 1)

The demand of timber has played a major role in defining strategic forest management planning problems as well as in early modeling approaches to address it (Chap. 2). Ecological and socioeconomic conditions prevailing in nineteenth century Europe, e.g. extensive deforestation of areas close to urban centers and limited transportation technology, prompted the development of management models emphasizing the stability of timber supply (Borges and Hoganson 1999). Theoretical concepts such as “sustainable yield” and “normal forest” (Alves 1984, Chap. 2) emerged in order to address that society economic requirements. Biological or financial parameters contributed explicitly to time the harvest (Chap. 5). Socioeconomic factors were implicitly considered by area or volume harvested control methods (Chap. 2) that targeted the sustainability of timber flows over extended planning horizons.

The area control method aims to get to the maximum sustainable timber even flow by balancing the age-class distribution as quickly as possible. It achieves this goal by simply harvesting A/r hectares each period where A is the forest area and r is the number of periods in the rotation. The area to be harvested in each period may be adjusted to take into account the productivity of each hectare in the forest. In the worst-case scenario, this will result in a regulated forest in r periods. The problem with area control is that during the periods where the age-class distribution of the initial forest is being regulated – which can be a long time if r periods is very long – the volume harvested each period can vary dramatically. The more unbalanced the initial age-class distribution, the larger this problem will be.

Volume control methods were developed to try to produce a more even flow of volume while still eventually producing a regulated forest. In area control, the forester cuts a constant area of forest each period and hopes to produce a steady flow of timber, sometimes not too successfully. With volume control, the forester cuts a certain volume each period and hopes to eventually produce a regulated forest. With area control, the question of how much area to cut each period is straightforward. With volume control, the problem of determining how much to cut each period is less obvious.

An approach that would be analogous to the area control solution would be to simply cut the long term sustainable yield (LTSY) each period. Unfortunately, depending on the initial age-class distribution of the forest, this approach could result in severe overcutting, eventually reducing the inventory of the forest to zero, or cut so little that it would take a very, very long time to regulate the forest. For example, the Hundeshagen method of determining the volume to cut adjusts the LTSY by the ratio of the current total forest inventory over the total forest inventory that will be present when the forest is regulated. The logic of this is that if the forest currently has more inventory than it will have once it is regulated, then more volume should be cut to reduce the excess inventory. Conversely, if the forest currently has less inventory than it will have once it is regulated, then less volume should be cut to allow the inventory to build up.

Mathematically, Let I 0 be the current inventory (at time 0) and let I Reg be the inventory that will be present in the forest when it is regulated. The volume to cut in the first period, H 1 , according to the Hundeshagen method is:

In many cases, if this volume is harvested each period, one will achieve a fairly constant volume of timber over time and the forest will eventually be regulated. However, depending on the initial age-class distribution of the forest, this formula can lead to overcutting, followed by undercutting, followed by overcutting, until the age-class distribution approaches a somewhat balanced state, and the harvest level fluctuations settle into a more constant level. Other volume control formulas have been developed, some as general rules and others for very specific situations, but none of them ideal for all situations. The main problem with classical approaches, however, is that all of them, when confronted with the detailed inventory information and varied conditions and constraints of modern forestry, fail to handle the complexity of industrial forest management planning.

Furthermore, more sophisticated approaches are available that can handle much of this complexity. Management science and computational capacity developments enhance management planning processes by providing the ability to further analyze alternative strategies through the use of mathematical programming or simulation (Chap. 2). Automation provided the means to process huge amounts of data and enabled the use of these more sophisticated techniques. As a result, the potential for the definition of more sound strategic schedules for industrial forests has been increased. Therefore, we now turn our attention to the application of modern techniques introduced in Chap. 2 to address Problem 1.

2.1 Linear and Integer Programming

While many different objective functions can be defined for harvest scheduling models, and even combined in a single, multi-objective model, the two most common objectives are maximizing the discounted net revenues from the forest or minimizing the cost of managing the forest. We will consider the former for illustration purposes as most planning models developed for industrial forest plantations use the discounted net revenues objective function. Moreover, to enhance readability we will list a sub-set of the decision variables when describing each equation.

In the case of our example forest, a model to address sustainability concerns with the supply of volume through both volume and area control may be described by Eqs. 2.1, 2.2, 2.3, 2.4, 2.5, and 2.6 in Chap. 2. The LP formulation of Problem 1 (F1) will thus include (a) an objective function that expresses the management objective of maximizing the forest net present value subject to (b) a set of area constraints to ensure that the area managed in each stand does not exceed the area available, (c) a set of accounting equations to determine the volume harvested in each period, (d) a set of accounting equations to determine the area harvested in each period, (e) a set of volume control constraints, (f) a set of area control constraints and (g) a set of non-negativity constraints.

-

(a)

Objective function Z. In this abbreviated form it displays the decision variables x kj, i.e. the area of stand k assigned to prescription j, for stands 1, 2 and 16:

The coefficients of the decision variables c kj correspond to the net present value per hectare associated with prescription j for stand k. They include the value of the ending inventory. For example the net present value resulting from the assignment of an hectare of stand 1 to its prescription 1 is equal to 5.0 × 103 €/ha (c 11 ).

This value was computed by adding the discounted return associated to the volume harvested in year 8 of planning period 1 to the value of ending inventory. The former was computed by multiplying the volume harvested – v 111 (307.4 m3/ha) in Table 6.2 – by the stumpage price – 15.5 €/m3 – and by the discount factor – ((1/(1 + 0.03)7) – and is thus equal to, approximately, 3.9 × 103 €/ha. The latter was computed assuming a perpetual series of optimal rotations. In the case of stand 1, the optimal rotation is 50 years. Thus the Soil Expectation Value (SEV) (Chap. 5) was computed by first multiplying v 111 (30.7 × 10 m3/ha) in Table 6.2) – by the stumpage price – 15.5 €/m3 to get the revenue resulting from selling the stumpage from the second rotation in year 58. This was multiplied by the discount factor ((1/((1 + 0.03)50 − 1)) to get the present value of a perpetual series of revenues occurring every 50 years (1.4 × 103 €/ha). As the initial year of this series corresponds to the 8th year of the planning horizon that value must be discounted further 7 years. The present value of ending inventory is thus estimated as 1.4 × 103 €/ha times 1/(1 + 0.03)7 = 1.1 × 103 €/ha. In summary, approximately, c 11 = 3.9 + 1.1 = 5.0 × 103 €/ha (5019.4 €/ha in Table 6.2).

The maximization is subject to

-

(b)

The set of area constraints stating that the sum of the stand area assigned to each prescription cannot exceed the total stand area (Eq. 2.2 in Chap. 2) (6.3)

-

(c)

The set of accounting equations to determine the volume harvested in each period H 1 to H 4 (Eq. 2.3 in Chap. 2). Each Eq. (6.4) includes all decision variables that involve a harvest in the corresponding period.

The coefficients of the decision variables v kjt correspond to the volume harvested per hectare in period t when prescription j is assigned to stand k. For example, as we have just checked, the volume harvested in period 1 from stand 1 if it is assigned to its prescription 1 (v 111 ) is equal to 30.7 × 10 m3/ha (Table 6.2).

-

(d)

The set of accounting equations to determine the area harvested in each period AH 1 to AH 4. Each equation (6.5 – analogous to Eq. 2.3 in Chap. 2) includes all decision variables that involve a harvest in the corresponding period.

$$ \begin{array}{l}{x}_{11}+{x}_{21}+{x}_{31}+{x}_{41}+\dots +{x}_{81}+{x}_{82}- AH1=0\hfill \\ {}{x}_{12}+{x}_{13}+{x}_{22}+{x}_{23}+\dots +{x}_{111}+{x}_{121}- AH2=0\hfill \\ {}{x}_{14}+{x}_{15}+{x}_{24}+{x}_{25}+\dots +{x}_{151}+{x}_{161}- AH3=0\hfill \\ {}{x}_{94}+{x}_{95}+{x}_{104}+{x}_{105}+\dots +{x}_{162}+{x}_{163}- AH4=0\hfill \end{array} $$(6.5) -

(e)

The set of volume control constraints (6.6 – Eq. 2.4 in Chap. 2). It expresses a policy aiming at non-declining volume flows and at a maximum 10 % increase of volume harvested in consecutive periods.

$$ \begin{array}{l} H1- H2\le 0\hfill \\ {} H2- H3\le 0\hfill \\ {} H3- H4\le 0\hfill \\ {} H2-1.1 H1\le 0\hfill \\ {} H3-1.1 H2\le 0\hfill \\ {} H4-1.1 H3\le 0\hfill \end{array} $$(6.6) -

(f)

The set of area control constraints (6.7 - – analogous to Eq. 2.4 in Chap. 2). It expresses a policy aiming at maximum 10 % fluctuations of area harvested in consecutive periods.

$$ \begin{array}{l} AH2-0.9 AH1\ge 0\hfill \\ {} AH2-1.1 AH1\le 0\hfill \\ {} AH3-0.9 AH2\ge 0\hfill \\ {} AH3-1.1 AH2\le 0\hfill \\ {} AH4-0.9 AH3\ge 0\hfill \\ {} AH4-1.1 AH3\le 0\hfill \end{array} $$(6.7) -

(g)

The set of non-negativity constraints (6.8 – Eq. 2.6 in Chap. 2).

$$ {x}_{11},{x}_{12},{x}_{13}\dots, {x}_{164},{x}_{165}\ge 0 $$(6.8)

According to the solution by the LP model (Table 6.3), the optimal long-term management plan is associated with an objective function value Z equal to 2,041.3 × 103 €. It encompasses a periodic harvest of 4,089 × 10 m3. The area harvested ranged from 116.2 to 119.1 ha in periods 4 and 3, respectively. The solution thus demonstrates that the LP model may address efficiently and effectively both volume and area control objectives.

The plan proposed by the LP model reflects the stand age distribution. Younger stands are harvested later (Table 6.4) in periods 3 (stand 13) or 4 (stands 14–16). Conversely, older stands are harvested earlier in periods 1 (stands 5–8) or 2 (stands 1–4) in order to avoid opportunity costs associated with the delay of harvesting mature timber. Classical approaches might meet the regulation objectives and yet at a cost that might be higher than needed. The LP plan is efficient as it meets the regulation objectives while minimizing the opportunity costs of doing so.

Nevertheless the LP solution aims at providing further insight about the forest management planning problem. The distinction made by Geoffrion (1976) between the mathematical programming “ostensible purpose” – optimization of a particular problem, and its “true purpose” – generation of information to support decision making is illuminating. The value of the LP dual variables (shadow prices) conveys the impact of changing the independent term in a constraint in the value of the objective function (Chap. 2). Thus the LP solution may be used to check the impact of setting alternative area and volume control objectives.

The usefulness of this information may be illustrated by analyzing the value of the shadow prices associated to the area constraints (Eq. 6.3). They reflect the marginal value of each stand for the forest owner (Table 6.5). As expected the marginal value of younger stands (stands 13 –16) is lower as they are harvested later in the planning horizon. The highest marginal value of stand 6 is due both to its age and its productivity (Table 6.2). This information provides insight about the value structure of the current inventory as well as about the management planning problem. The forest owner may take advantage further of this information when making decisions on whether and how to expand the forest land base. The LP solution provides an estimate of the maximum amount he might pay when buying an additional hectare of each stand. Conversely, it conveys the minimum price he should consider when selling one hectare of each stand.

The LP solution also provides information about the opportunity costs associated with the selection of alternative plans. The reduced costs of decision variables measure the impact of selecting a non-optimal prescription on the value of the objective function (Chap. 2). For example, the solution highlights the costs of anticipating or delaying the timing of harvests (Table 6.6). It further shows that the option of not harvesting when available (stands 13–16) is associated with the highest costs. These result both from the loss of revenue that results from the harvests in those stands and from the loss of revenue that results from the need of adjusting the timing of harvests in other stands in order to meet the area and volume control targets.

However useful, LP is not able to convey the geographical location of forest activities. Yet this may be important even in a long-term planning framework. LP divisibility may lead to solutions where stands are split into non spatially referenced units to be managed differently. For example stand 10 was split into 2 units of 29.4 and 0.1 ha to be managed according to its prescriptions 2 and 4, respectively. Further, computational constraints lead frequently to the aggregation of stands into analysis areas thus compounding the impact of LP divisibility. Solutions to such highly aggregated models are very sensitive to changes in assumptions and aggregation schemes (Rose 1984). In this context, the information produced by the solution may be of little value to understand the management problem and to support effectively decision-making. Formulation F1 may then be changed within a Model I framework to further address concerns with locational specificity. The resulting MIP formulation of Problem 1 (F2) may be described as:

-

(a)

Objective function Z. In this abbreviated form it displays the decision variables x kj, i.e. whether stand k is assigned to prescription j, for stands 1, 2, 3 and 16:

$$ \begin{aligned} {\it MAX}\ Z =\; & 155.6{x}_{11}{+}143.7{x}_{12}{+}131.5{x}_{13}{+}119.3{x}_{14}{+}107.6{x}_{15}{+}155.7{x}_{21}\\ & {+}143.8{x}_{22}{+}131.5{x}_{23}{+}119.4{x}_{24}{+}107.7{x}_{25}{+}152.1{x}_{31}{+}140.5{x}_{32}\\ & {+}128.5{x}_{33} +116.7{x}_{34}+105.2{x}_{35}+\dots +85.9{x}_{161}+79.4{x}_{162}\\ & {+}72.6{x}_{163}+68.5{x}_{164} \raisetag{12pt} \end{aligned} $$(6.9)In this model, the decision variables are integer to ensure that stands are not split by the assignment of prescriptions. Thus the coefficients of the decision variables c kj correspond to the total net present value associated with prescription j for stand k. Again they include the value of the ending inventory. For example the net present value resulting from the assignment of stand 1 to its prescription 1 (c 11 ) is equal to 155.6 × 103 €. This is computed by multiplying the net present value per ha that results from this assignment – 5.0 × 103 €/ha – by the stand area – 31 ha (Table 6.1).

The maximization is subject to

-

(b)

The set of area constraints (Eq. 2.8 in Chap. 2) (6.10)

$$ \begin{array}{l}{x}_{11}+{x}_{12}+{x}_{13}+{x}_{14}+{x}_{15}=1\hfill \\ {}{x}_{21}+{x}_{22}+{x}_{23}+{x}_{24}+{x}_{25}=1\hfill \\ {}{x}_{31}+{x}_{32}+{x}_{33}+{x}_{34}+{x}_{35}=1\hfill \\ {}\dots \hfill \\ {}{x}_{161}+{x}_{162}+{x}_{163}+{x}_{164}=1\hfill \end{array} $$(6.10) -

(c)

The set of accounting equations to determine the volume harvested in each period H 1 to H 4 (Eq. 2.9 in Chap. 2). Each Eq. (6.11) includes all decision variables that involve a harvest in the corresponding period.

$$ \begin{array}{l}953.0{x}_{11}{+}953.5{x}_{21}{+}931.7{x}_{31}{+}\dots {+}1027.5{x}_{81}{+}1106.4{x}_{82}{-} H1{=}0\\ {}1040.5{x}_{12}{+}1120.4{x}_{13}{+}1041.2{x}_{22}{+}\dots {+}933.2{x}_{91}{+}956.8{x}_{121}{-} H2{=}0\\ {}1193.6{x}_{14}{+}1260.5{x}_{15}{+}1194.3{x}_{24}{+}\dots {+}941.6{x}_{151}{+}950.3{x}_{161}{-} H3{=}0\\ {}1156.5{x}_{94}{+}1221.2{x}_{95}{+}1182.2{x}_{104}{+}\dots {+}1037.6{x}_{162}{+}1117.2{x}_{163}{-} H4{=}0\end{array} $$(6.11)The coefficients of the decision variables v kjt correspond to the volume harvested in stand k in period t when assigned to prescription j. For example, the volume harvested in period 1 from stand 1 if it is assigned to its prescription 1 (v 111 ) is approximately equal to 953 × 10 m3. This was computed as the product of the stand area (31 ha) by the volume per hectare in period 1 that results from that assignment (307.4 m3/ha (Table 6.2)).

-

(d)

The set of accounting equations to determine the area harvested in each period AH 1 to AH 4 (analogous to Eq. 2.9 in Chap. 2). Each Eq. (6.12) includes all decision variables that involve a harvest in the corresponding period. Its coefficients correspond to the stand area.

$$ \begin{array}{l}31{x}_{11}+29.8{x}_{21}+30{x}_{31}+\dots +30{x}_{81}+30{x}_{82}- AH1=0\hfill \\ {}31{x}_{12}+31{x}_{13}+29.8{x}_{22}+\dots +29.6{x}_{111}+30.5{x}_{121}- AH2=0\hfill \\ {}31{x}_{14}+31{x}_{15}+29.8{x}_{24}+\dots +29{x}_{151}+29.7{x}_{161}- AH3=0\hfill \\ {}29{x}_{94}+29{x}_{95}+29.5{x}_{104}+\dots +29.7{x}_{162}+29.7{x}_{163}- AH4=0\hfill \end{array} $$(6.12)

-

(e) and (f)

Volume and area control constraints may now be expressed just like in the case of the linear programming model (6.6 – Eq. 2.4 in Chap. 2 and 6.7 – analogous to Eq. 2.4 in Chap. 2).

-

(g)

The set of constraints stating that the decision variables may take only the values 1 (if the prescription is assigned to the stand) or 0 (if the prescription is not assigned to the stand) (6.13 – Eq. 2.8 in Chap. 2)

$$ {x}_{11},{x}_{12},{x}_{13},\dots, {x}_{165}\ \mathrm{are}\ \mathrm{binary} $$(6.13)

According to the solution by the IP model (Table 6.3), the optimal objective function value Z decreased to 2,021.0 × 103 €. Stands 2 and 10 are no longer split by different prescriptions (Table 6.4) and this thus cost 20.3 × 103 €. The harvest timings shifted in the case of three other stands in order to meet the new requirements. The requirement of locational specificity impacted the volumes and areas harvested in each period. They still meet the volume and area control constraints and yet are more uneven as management flexibility decreased (Table 6.3). In the case of larger forests with more stands the requirement of locational specificity may not have an impact as substantial on the evenness of areas and volumes harvested in each period. Yet it may have a higher impact on the computational cost.

Management Planning in Action 6.1: Volume Control in Long Term Industrial Forest Management Planning at Celbi in Portugal

Celbi is currently a factory of Altri, a leading Portuguese eucalypt pulp producer, with a capacity of up to 600 × 106 tonnes (http://en.altri.pt/aboutaltri/). Currently Altri manages about 84 × 103 ha of forest in Portugal all certified by the Forest Stewardship Council (FSC) and PEFC. Its wood self-sufficiency rate stands around 30 % and all its mills are entirely self-sufficient on power that is produced through the burning of wood components not suitable for pulp production (http://en.altri.pt/aboutaltri/).

In 2000, a priority of former Celbi owners (Stora Enso) was the assessment of the sustainability of pulpwood supply to this mill from its eucalypt land base extending over about 39 × 103 ha. This prompted the development of a linear programming (LP) model within a sustainability assessment project coordinated by the Forest Research Centre (http://www.isa.ulisboa.pt/cef/). The LP model included about 664 × 103 decision variables corresponding to prescriptions associated with 3,361 stands in Celbi eucalypt land base. The planning horizon included 31 one-year periods extending up to 2030. The model aimed at maximizing net present value. It included area and volume control constraints similar to the ones presented in 6.2. It further included constraints on the maximum area to be converted each year.

The project was successful as the LP model provided the information needed by the firm – e.g. the pulpwood potential supply ranging from 475 to 535 × 103 m3, according to scenarios of productivity growth after a conversion as well of expansion of the eucalypt land base – to develop its strategic plan (Borges and Falcão 2000).

2.2 Heuristics

The locational specificity requirement may also be addressed by heuristic approaches. A heuristic may be defined as a technique that seeks good solutions at a reasonable computational cost without being able to guarantee optimality or even feasibility (Reeves 1993). The computational complexity of some industrial forest strategic management planning problems sometimes suggests the use of heuristics as these techniques may be more flexible and capable of addressing more complicated objective functions and constraints than exact algorithms. Moreover, given the uncertainties that derive from the large-scale attributes of the general forest management problem, good solutions may be adequate (Borges et al. 2002). As Gunn and Rai (1987) pointed out, solutions that are near optimal and near feasible may be adequate and even preferable if they can be produced with a greatly reduced solution effort, given the uncertainty about biological, technical and economic data in most forest management problems.

The design of heuristic approaches may often take advantage of the specific form of the forest management scheduling problem. Based on this design, specialized optimization solution processes can sometimes be evolved to address very large and complex problems (Borges et al. 2002). For example, Hoganson and Rose (1984) developed a specialized LP decomposition approach that may be used to solve this management planning problem thus circumventing the need to use MIP to address locational specificity requirements. Just like LP, this heuristic approach conveys information about the marginal values of resources and the volume flow targets thus contributing to the effectiveness of management planning.

The reader is referred to Borges et al. (2002) for a detailed review of the use of heuristics in multiple objective forest management. In this chapter we will consider for illustration purposes a meta-heuristic – simulated annealing (SA) – that has been widely used to address forest management planning problems (e.g. Lockwood and Moore 1993; Dahlin and Sallnas 1993; Murray and Church 1995; Tarp and Helles 1997; Boston and Bettinger 1999; Van Deusen 1999; Falcão and Borges 2002). In this illustration, the simulated annealing approach involved the conversion of the MIP formulation (Eqs. 6.6, 6.7, 6.9, 6.10, 6.11, 6.12, and 6.13) into a new objective (or evaluation) function. The resulting SA formulation of Problem 1 (F3) may be represented in abbreviated form as:

Where θ stands for a global penalty function that decreases the value of Z if the constraints are violated. The literature reports several approaches to design a penalty function (e.g. Michalewicz 1996). In this chapter we will follow the approach proposed by Falcão and Borges (2001) so that the penalty function is more sensitive to large violations of the constraints and less responsive to small deviations. The separable penalty functions thus consisted of parabolas where deviations from the area constraints and the volume and area control objectives do contribute to decrease the value of Z. In all cases it was assumed that a 5 % deviation from feasibility was equivalent to a 1 % deviation from unconstrained NPV when estimating the parameter that characterizes the shape of the parabola for each constraint. Thus this parameter was computed as

Where ΔNPV stands for an unconstrained NPV reduction of 1 % and ΔD const _ j stands for a 5 % deviation from feasibility in constraint j. A const _ j is equal to zero if constraint j is met. In the case of our example problem, the penalty function will thus include three terms, one per Eqs. 6.6, 6.7 and 6.10. θ may thus be described in an abbreviated form as

with x 11, x 12, x 13, …, x 165 as binary

In summary, the SA objective (or evaluation) function thus included as its first term the MIP objective function and as its second term a penalty function. The latter penalizes the violation of the area constraints (the first term in Eq. 6.16), of the volume control constraints (the second term in Eq. 6.16) and of the area control constraints (the third term in Eq. 6.16).

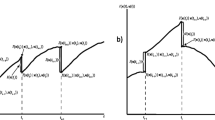

Afterwards, the SA approach involved an iterative process (Fig. 6.2) where solutions in each iteration were represented by a vector with 16 elements corresponding to the 16 stands. The value of each vector element consisted of a pointer to the prescription assigned to the corresponding stand. Solutions are thus integer.

Flowchart of the simulated annealing heuristic. Z1 and Z2 solution values before and after a proposed move, T system “temperature”, rand random number between 0 and 1 (From Borges et al. 2002)

The solution process started by selecting randomly a solution vector and by computing its objective function value (Fig. 6.2). Each SA iteration consisted of changing randomly the assignment of a prescription in 5 stands (5-opt approach) and computing its objective function value Z2. In order to avoid premature convergence to a local optimum, an inferior solution i.e. a solution associated with a lower objective function value might be accepted.

The SA solution strategy was implemented as described by Borges et al. (2002). It involved the design of a solution acceptance function and the definition of a stopping criterion. The former determined whether an inferior solution might be accepted. The probability of accepting inferior solutions increased with the temperature and it decreased with the magnitude of the inferior move (Fig. 6.2):

where exp stands for the exponential function, Z 2 and Z 1 stand for the value of the SA objective (fitness evaluation) function (Eq. 6.14) after and before the 5-opt move, respectively, T stands for the control parameter (temperature) which decreases with the number of iterations according to the cooling schedule and rand stands for a random number in the interval [0 1]. In this example, the initial temperature was equal to 100,000. The temperature was decreased in each iteration according to a cooling rate equal to 0.9999. The stopping criteria was the number of iterations (100,000).

Meta-heuristic solutions are sensitive to parameter and penalty values. Typically these are problem specific and require pre-testing so that values are selected that may lead to approximate the optimal solutions. In this illustration, the parameterization did lead to the optimal MIP solution (2021.1 × 103 €) (Table 6.3). This is also a consequence of the problem small size.

2.3 Goal Programming and Pareto Frontier

Both LP and MIP have single criteria objective functions. Other objectives e.g. area and volume control were represented as constraints in the model. An alternative to this approach is to consider all criteria in the objective function. Goal programming is a technique that has been widely used for that purpose in strategic forest management planning. In the case of our example forest, the goal programming formulation of Problem 1 (F4) may be described as:

-

(a)

Objective function Z

$$ \begin{aligned}[b] \mathrm{Min}\ \mathrm{Z}&=8.4746\ {\it PdevAH1}+8.4746\ {\it NdevAH1}+8.4746\ {\it PdevAH2} \\ {}& \quad +8.4746\ {\it NdevAH2}+ 8.4746\ {\it PdevAH3}+8.4746\ {\it NdevAH3} \\ {}& \quad +8.4746\ {\it PdevAH4}+8.4746\ {\it NdevAH4} +0.0244\ {\it NdevH1} \\ {}& \quad +0.0244\ {\it NdevH2}+0.0244\ {\it NdevH3}+0.0244\ {\it NdevH4} \\ {}& \quad +0.0049\ {\it NdevNPVt} \raisetag{12pt} \end{aligned} $$(6.18)Where the decision variables consist of the deviations from the levels of the criteria set by the decision-maker. The variables PdevAH1 to PdevAH4 and NdevAH1 to NdevAH4 represent, respectively, the positive and the negative deviations from the target set to the area harvested in each planning period to reflect the area control regulation objectives. The variables NdevH1 to NdevH4 correspond to the deviations from the harvest levels targeted in each period. It was assumed that there was no constraint to harvesting higher volumes in each period and thus positive deviations were not minimized. Finally, the third criteria corresponds to the discounted net revenue from the forest e.g. the criteria listed in the LP and the MIP objective functions. The coefficients of the decision variables correspond to the product of 1,000 by the inverse of the criteria target levels measured in hectares, cubic meters and Euros, in the case of the area harvested, the volume harvested and the discounted revenues, respectively. The GP model was set to minimize the percent deviations to overcome dimensional constraints to the treatment of all three criteria. The discounted revenues criteria was provided with a weight equal to 10 while the remaining two were weighted equally as 1. For example, in the case of NdevNPVt the coefficient is computed as 10*1,000*1/2,041,298 = 0.0049 while in the case of PdevAH1 the coefficient is computed as 1*1,000*1/118 = 8.4746.

-

(b)

The equation that computes the discounted net revenue from the forest

$$ \begin{aligned} {}& \Big(155.6{x}_{11}+143.7{x}_{12}+131.5{x}_{13}+119.3{x}_{14}+107.6{x}_{15}+155.7{x}_{21} \\ {}& \quad +143.8{x}_{22}+131.5{x}_{23}+119.4{x}_{24}+ 107.7{x}_{25}+152.1{x}_{31}+140.5{x}_{32}\\ {}& \quad +128.5{x}_{33} +116.7{x}_{34}+105.2{x}_{35}+\dots 85.9{x}_{161}+79.4{x}_{162}+ 72.6{x}_{163}\\ {}& \quad +70.2{x}_{164}\Big) \times {10}^3- NPVt=0 \raisetag{12pt} \end{aligned} $$(6.19) -

(c)

The Eq. 6.20 that set the target for the area harvested in each period (118 ha) to reflect the area control objectives, where this area is defined by Eq. 6.12

$$ \begin{array}{l} AH1- PdevAH1+ NdevAH1=118\hfill \\ {} AH2- PdevAH2+ NdevAH2=118\hfill \\ {} AH3- PdevAH3+ NdevAH3=118\hfill \\ {} AH4- PdevAH4+ NdevAH4=118\hfill \end{array} $$(6.20) -

(d)

The Eq. (6.21) that set the target for the volume harvested in each period (41 × 103 m3) to reflect the volume control objectives, where this harvest level is defined by Eq. 6.11.

$$ \begin{array}{l} H1- PdevH1+ NdevH1=4100\hfill \\ {} H2- PdevH2+ NdevH2=4100\hfill \\ {} H3- PdevH3+ NdevH3=4100\hfill \\ {} H4- PdevH4+ NdevH4=4100\hfill \end{array} $$(6.21) -

(e)

The Eq. 6.22 that sets the target for the discounted net revenue from the forest (2,041,298 €).

$$ {\it NPVt} - {\it PDevNPVt} + {\it NDevNPVt} =2,041.3 $$(6.22) -

(f)

The set of constraints stating that the decision variables may take only the values 1 (if the prescription is assigned to the stand) or 0 (if the prescription is not assigned to the stand) (Eq. 6.13)

$$ {x}_{11},{x}_{12},{x}_{13},\dots, {x}_{165}\ \mathrm{are}\ \mathrm{binary} $$

In this illustration, the target values were set to emulate the area and volume control objectives and took advantage of the insights provided by the solutions by the other techniques. For example, the target for the criteria NPV was set as the value of the optimal LP solution. Generally, the targets are set based on a priori knowledge about the criteria space e.g. about the productive potential of the industrial forest.

The solution by the GP model (Table 6.3) shows that the NPV criteria target was almost achieved (2,040,967.45 €) while still guaranteeing that no stand was assigned to more than one prescription (Table 6.4). Yet this was at the cost of deviations from other targets. The MIP solution did point out that in order to meet the volume and area control objectives, while ensuring locational specificity of management options, the maximum net returns from the forest were equal to 2,021,000 €. For example, in the GP model the harvest levels in periods 1 and 2 did not meet the 41 × 103 m3 targets. Further, there was a decline in harvest levels in periods 3 and 4.

This solution highlighted that often decision-makers lack the a priori knowledge about the productive potential of the industrial forest that is needed to specify coherent targets. It showed that setting a higher target level for the NPV criteria led to the underachievement of criteria emulating the area and volume control objectives. In fact, the information regarding the long-term impact of forest management options on objectives and conditions of interest is hardly ever perfect. The efficiency and the effectiveness of a multiple criteria approach to industrial forest strategic management planning calls for the use of models and methods as learning devices. The quality of decisions may be enhanced by a learning process that may provide additional insights about the resource capability model and the trade-offs between objectives (Borges et al. 2014a).

Most multiple criteria approaches reported in the forestry literature typically require the decision-maker to either specify the desired level of achievement or specify the preferences for the various objectives (Martins and Borges 2007). As often there is little information about what is possible to achieve (e.g. volume flows), defining a priori the goals and preferences may not be realistic and lead to poor management decisions (Tóth et al. 2006). Shortcomings of mechanistic approaches to the specification of the levels of achievement of various objectives as well as of the decision-makers preferences have been pointed out by Tóth and McDill (2009) and Romero (2004). In order to overcome them, Tóth and McDill (2009) demonstrated the possibility of developing and displaying a Pareto frontier e.g. of finding the non-dominated points in the feasible set in the criteria space (FSCS) in the case of problems with up to three forest management planning objectives. Romero (2004) discussed the use of several achievement functions and corresponding assumptions regarding decision-makers preferences.

Providing information about the set of efficient solutions can help the decision-maker understand the trade-offs between competing objectives. The analysis of these trade-offs may provide further insight about the forest management planning problem and help set adequate levels of achievement for various objectives (Borges et al. 2014a). In this section, we will apply an interactive modelling approach to generate the Pareto frontier of our industrial forest strategic management planning problem (Problem 1). The approach builds from the LP formulation of Problem 1 to display the trade-offs between discounted returns (NPV) and timber volume harvested (Fig. 6.3). The reader is referred to Borges et al. (2014a) for a detailed description of the modelling approach.

Decision map showing the Edgeworth-Pareto Hull for a two criteria planning problem – NPV and Timber – subject to volume and area control constraints, considering minimum achievement levels min NPV = 1,700 × 103 € and min Timber = 162 × 103 m3. Point A corresponds to the point in the Pareto frontier with NPV = 2,012.4 × 103 € and Timber = 166.9 × 103 m3

This trade-off information helps decision-makers set informed levels of achievement that reflect their preferences. It shows that harvesting over about 163 × 103 m3 leads to a decrease of NPV. The LP solution did indeed highlight that it was not profitable to harvest more timber while meeting the volume and area control objectives. For illustration purposes lets assume that the decision-maker took advantage of this information to set as levels of achievement NPV = 2,012,415.5 € and Timber = 166,914.5 m3 (Point A in Fig. 6.3). The modeling approach may then be used to retrieve the corresponding LP solution in the feasible set in the decision space (Table 6.3). The solution highlights that the timber volume increase results from higher harvest levels in periods 3 and 4 at the cost of lower harvest values in earlier periods (Table 6.3). Harvesting later stands 9 and 14 (Table 6.4) leads to higher volumes yet this timber was financially mature earlier. As a consequence the value of NPV decreases.

2.4 Binary Search

Simulation is a technique that has also been widely used to address volume and area control objectives. In summary, binary search starts by setting the harvest level deemed as sustainable and by ordering the forest stands according to the priority for harvesting or harvest rule (Fig. 6.4).

The simulation approach proceeds by going down the list of ordered stands and harvesting them until the harvest level is met. Afterwards it projects the inventory to the next planning period. In this step, simulation parameters such as the area burned or new forest areas to include may be used to update the inventory. The stands are again ordered according to the harvest rule and this process is iterated successively to check whether the target volume level is sustainable or not. If, for example it finds that the initial level was too high, the estimate is decreased while if the inventory becomes too high the estimate is increased.

For illustration purposes, lets assume that the target level is set at 40,865 m3 (the volume in the LP solution) and that stands are ordered according to the age. Results from the simulation approach show that the average age of the forest decreases over time from 43.7 years in the current inventory to 13.2 years in the inventory in period 7 when that harvest level may no longer be met. This suggests that the length of the planning horizon considered in Formulations 1–4 may have been too short. The harvest levels are not sustainable over longer periods. The simulation of other harvest levels help estimate the long term sustainable yield (Fig. 6.5).

Management Planning in Action 6.2: Assessing the Sustainability of National Pulpwood Supply: An Application in Portugal

Eucalypt (Eucalyptus globulus Labill) is the most important pulpwood producing species in Portugal. Eucalypt plantations extend over 647 × 103 ha – about 20.6 % of the total forest area in Portugal with a total yield of about 5.75 × 106 m3 per year. Nevertheless the land base owned or managed by vertically integrated pulp and paper companies provides at most 30 % of its pulpwood needs. In 2004 a priority of CELPA (http://www.celpa.pt), the Portuguese pulp and paper association, was the assessment of the sustainability of pulpwood supply from areas not owned or managed by the industry.

This prompted the development of a simulation approach similar to the one presented in 6.2 by the Large-Scale Informatics Systems Laboratory (http://lasige.di.fc.ul.pt/) and the Forest Research Centre (http://www.isa.ulisboa.pt/cef/). The eucalypt area not owned or managed by the industry was classified into analysis areas according to criteria such as age, coppice cycle, site index and location. Analysis areas were ranked for harvesting according to a weighted average of age, location and quadratic mean diameter. Simulation parameters included the probabilities of wildfire occurrence, of conversion i.e. of a clearcut and of abandonment. The possibility of expansion of the eucalypt area was also considered (Falcão 2006). This approach is being used by CELPA since 2004.

The mathematical programming and the simulated annealing approaches to address volume and area control in long term industrial forest management planning considered the objective of maximizing net present value. However, it is worthwhile to briefly note how the choice of objective function can influence the “personality” of the resultant model and the implications for how key constraints should be formulated. In a nutshell, the cost minimization model tends to be “lazy” and the profit maximization model tends to be “greedy.”

In the case of the cost minimization model, the production constraints such as volume constraints must be specified as minimum targets (i.e., greater-than-or-equal-to constraints) or the optimal solution will be to produce nothing. This can be the most appropriate model when the plantation is owned by a vertically-integrated company that requires the forest to produce a certain volume of wood each year to meet the production requirements of a mill. In such models, a key concern may be the feasibility of meeting other constraints – such as sustainability or environmental constraints – while meeting the needs of the mill. Another possibility is that the mill requirements can be met too easily, and the forest is underutilized, which should make it easy to meet sustainability and environmental constraints but may not be in the best interest of the company.

With profit-maximization models, it is generally best to let the model determine the profit-maximizing level of production over time, but to add constraints that prevent the outputs (or inputs) of some products from fluctuating too wildly from one period to the next as illustrated in this section. If the model projects more production than is required by the mill this excess can potentially be sold to other companies, and if the projected production is less than is required, the company can either buy wood on the open market, buy more forestland, or develop more intensive management prescriptions that will produce higher yields.

Unless specifically required to by model constraints, profit maximization models often will not meet sustainability and environmental constraints. In particular, with a finite planning horizon, a profit-maximizing model will tend to harvest anything it can before the end of the planning horizon. This was highlighted by the binary approach to solve Problem 1. This is usually not a desirable outcome, so some kind of ending constraints must usually be imposed on profit-maximizing harvest scheduling models. As with any other aspect of harvest scheduling models, there are many ways to ensure that the model leaves the forest in a desirable condition at the end of the planning horizon. Furthermore, more than one approach can be incorporated into a model. One approach is to require the model to achieve a specific age-class distribution – such as a regulated forest – at the end of the planning horizon. While this approach may be useful in some circumstances, there are two disadvantages of this approach. First, if the planning horizon is not long enough it may not be possible to achieve the desired age-class distribution within that time frame and the model will be infeasible. Second, even if it is feasible, these constraints will tend to drive much of what the model does, especially in the final periods, and it leaves the model with very little flexibility to achieve any other management objectives. Three more promising ways to ensure that the model will leave the forest in a desirable ending condition are (1) to include a value of the ending forest in the objective function coefficients as in our case study, (2) to require the average age of the forest as a whole at the end of the planning horizon to be greater than or equal to some target, or (3) to require the total forest inventory at the end of the planning horizon to be greater than or equal to some target, as illustrated in the next section.

3 Long-Term Industrial Forest Management Planning to Address Both Multiple Product and Stock Control Objectives (Problem 2)

The focus of strategic management planning is on the assessment of the long-term sustainability of the industrial forest resource base. The implementation of volume and area control policies targets the provision of even or non-declining product flows from the industrial forest over the planning horizon. The solution of Problem 1 by several techniques (Sect. 6.2) did demonstrate the success of those policies. Nevertheless it highlighted that those policies, in particular if framed by revenue maximization objectives, do not guarantee the long-term sustainability of the industrial forest. Thus, Problem 1 was modified to address concerns with that sustainability. Specifically, for illustration purposes, the policy model was extended to include a condition on the value of the inventory at the end of the planning horizon.

Climate change concerns have led society and forest managers to focus on the potential of forests as carbon sinks. Accordingly, since 2000, carbon has emerged as an important product of industrial plantations (Chap. 14). The scale and scope of the carbon market has since expanded. Therefore it is increasingly important to assess the sustainability of carbon stock targets in strategic industrial forest management planning. The policy model of Problem 1 was thus further expanded to include conditions on the fluctuations of the carbon stock in the industrial forest.

In this section we will illustrate how to build mathematical programming models and how to design heuristic approaches to address jointly revenue optimization, area and volume control objectives as well as stock control concerns. The introduction of the new policy scenario defines our strategic management planning Problem 2. We will further interpret the solution of the new problem and assess the impact of constraints on the value of the ending inventory and on the average carbon stock on the harvest schedule and on the timber supply. Finally, we will illustrate how to assess the potential of specific solution techniques to address Problem 2.

3.1 Linear and Integer Programming

In the case of our example forest, the LP formulation of Problem 1 (F1) may be extended to represent Problem 2 (Formulation 5) by including (a) an accounting equation to compute the volume of the ending inventory, (b) a set of accounting equations to determine the average carbon stock in each planning period, (c) a constraint on the value of the ending inventory and (d) a set of constraints on the average carbon stock over the planning horizon.

-

(a)

The accounting equation to compute the volume of the ending inventory. In this abbreviated form, it displays the decision variables x kj, i.e. the area of stand k assigned to prescription j, for stands 1, 2 and 16:

$$ \begin{aligned} {}& 18.2{x}_{11}+14.0{x}_{12}+9.7{x}_{13}+5.4{x}_{14}+2.1{x}_{15}+18.9{x}_{21}{+}14.6{x}_{22}{+}10.1{x}_{23}\\ {}& \quad +5.7{x}_{24}+2.1{x}_{25}+\dots +2.2{x}_{161}+0.2{x}_{162}+38.6{x}_{164}- VolEI=0\end{aligned} $$(6.23)Where VolEI represents the volume of standing timber in the whole forest at the end of the planning horizon. The coefficients of the decision variables VolEI kj correspond to the volume per hectare in the ending inventory in stand k if it is managed according to prescription j. For example, if one hectare of stand 1 is managed according to prescription 1, the value of the ending inventory in that hectare will be VolEI 11 = 18.2 × 103 m3 (Table 6.2).

-

(b)

The set of accounting equations to determine the average carbon stock in each planning period (Eq. 6.24):

$$ \begin{aligned} {}& 6.1{x}_{11}+9.0{x}_{12}+9.0{x}_{13}+9.0{x}_{14}+9.0{x}_{15}+6.4{x}_{21}+9.4{x}_{22}+9.4{x}_{23}\\ {}& \quad +9.4{x}_{24}+9.4{x}_{25}+\dots {+}4.9{x}_{161}{+}4.9{x}_{162}{+}4.9{x}_{163}{+}4.9{x}_{164}{-} {\it CStock1} \\ {}& 23.6{x}_{11}+20.1{x}_{12}+7.2{x}_{13}+10.6{x}_{14}+10.6{x}_{15}+2.5{x}_{21}{+}21.0{x}_{22}{+}7.6{x}_{23}\\ {}& \quad +11.0{x}_{24}{+}11.0{x}_{25}+\dots {+}7.4{x}_{161}{+}7.4{x}_{162}{+}7.4{x}_{163}{+}7.4{x}_{164}- {\it CStock2} \\ {}& 20.5{x}_{11}+9.2{x}_{12}+23.6{x}_{13}+22.9{x}_{14}+8.2{x}_{15}+21.4{x}_{21}+9.6{x}_{22}{+}2.5{x}_{23}\\ {}& \quad +23.8{x}_{24}+8.5{x}_{25}+\dots {+}6.4{x}_{161}{+}9.4{x}_{162}{+}9.4{x}_{163}{+}9.4{x}_{164}{-} {\it CStock3} \\ {}& 4.7{x}_{11}+3.4{x}_{12}+20.5{x}_{13}+9.2{x}_{14}+23.6{x}_{15}+4.9{x}_{21}+3.5{x}_{22}+21.4{x}_{23}\\ {}& \quad +9.6{x}_{24}{+}2.4{x}_{25}{+}\dots {+}24.5{x}_{161}{+}20.9{x}_{162}{+}7.5{x}_{163}{+}11.0{x}_{164}{-} {\it CStock4} \end{aligned} $$(6.24)Where CStockt represents the average carbon stock in our example forest in period t. The coefficients of the decision variables CS kjt correspond to the average carbon stock in period t in an hectare of stand k when managed according to prescription j. For example, if one hectare of stand 1 is managed according to prescription 1, the value of the average carbon stock in period 1 in that hectare will be CS 111 = 6.2 × 10 Mg C (Table 6.2).

-

(c)

The constraint on the value of the ending inventory (Eq. 6.25)

$$ VolEI\ge 5,500 $$(6.25)It is thus assumed that sustainability concerns may be addressed by setting the volume of the ending inventory criteria as 55,000 m3.

-

(d)

The set of constraints on the average carbon stock over the planning horizon (Eq. 6.26).

$$ \begin{array}{l}0.9 CStock1- CStock2\le 0\hfill \\ {}0.9 CStock2- CStock3\le 0\hfill \\ {}0.9 CStock3- CStock4\le 0\hfill \\ {} CStock2-1.1 CStock1\le 0\hfill \\ {} CStock3-1.1 CStock2\le 0\hfill \\ {} CStock4-1.1 CStock3\le 0\hfill \end{array} $$(6.26)No fluctuations over 10 % are thus allowed between the average carbon stocks in two consecutive periods.

According to the solution by the LP model (Table 6.3), the optimal long-term management plan is associated with an objective function value Z equal to 1,937.7 × 103 €. It encompasses a periodic harvest of 4,020.2 × 10 m3. The area harvested ranged from 106.8 to 116.6 ha in periods 4 and 1, respectively. The average carbon stock decreased from 2,799.1 × 10 Mg C in period 1 to 2,040.6 × 10 Mg C in period 4. The solution thus demonstrates that the LP model may address too efficiently and effectively both volume and area control regulation objectives as well as concerns with stock control and the sustainability of the resource.

The LP solutions to Problems 1 and 2 also provide information about the opportunity cost associated with the new policy scenario. In fact, the NPV as measured by the objective function decreased by 5 % while the period harvest levels decreased by about 690 m3. The constraint on the volume at the ending inventory is active and harvest levels must be lowered in order to meet the 55,000 m3 target. The average carbon stock is always higher than in the solution to F1 yet it decreases substantially over time. This suggests that the current harvest levels may still not be sustainable and that the target for the volume of ending inventory may need to be adjusted. In fact, the simulation approach described in Sect. 6.2.4 did highlight that the 4,020.2 × 10 m3 harvest level is not sustainable in the long term.

The plan proposed by the LP model reflects again the stand age distribution. Younger stands are proposed to be harvested later than in the case of F1 in periods 3 or 4 or are proposed not be harvested in order to meet the ending inventory constraint (Table 6.4). Conversely, just like in the case of F1, older stands are harvested earlier in periods 1 (stands 5–8) or 2 (stands 1–4) in order to avoid opportunity costs associated with the delay of harvesting mature timber. Nevertheless, some additional stands were split into more than one prescription in order to meet the stock control constraints.

The value of the shadow prices associated to the area constraints (Eq. 6.3) shows that in general the marginal value of each stand for the forest owner is higher in the case of F5 (Table 6.5). As expected the marginal value of younger stands (Stands 13–16) increases the most as they are instrumental to meet the stock control objectives. An additional hectare of one of these stands contributes directly to the net present value through the revenues resulting from its harvest. It contributes further indirectly to the net present value by relaxing the need to shift the harvest of older stands to later periods. Stand 6 is still the stand with the highest marginal value due both to its age and its productivity (Table 6.2). Nevertheless its value decreased as its harvest forces costly shifts of harvest timings in other stands. The LP solution thus adjusted the estimates of the maximum amount the forest owner might pay when buying an additional hectare of each stand when stock control objectives are considered. It further provided updated information about the opportunity costs associated with the selection of alternative plans e.g. the costs of anticipating or delaying the timing of harvests in each stand (Table 6.6). In particular it highlights the opportunity costs associated with the anticipation of harvest in older stands. These result from the loss of revenue that results from the need of adjusting the timing of harvests in other stands in order to regulate the harvest schedule and to meet the stock control objectives.

The strategic targets may turn out to be infeasible because of tactical and operational considerations that were left out from Problem 2. Feasible strategic targets may be approximated by enforcing locational specificity constraints. This may be even more critical in the case of Problem 2 as more stands had to be split between prescriptions to comply with the new policy scenario. It may thus be interesting to modify F5 within a Model I framework to further address concerns with locational specificity. The resulting MIP formulation of Problem 2 (F6) is an extended version of the MIP Formulation of Problem 1 (F2) to include further (a) an accounting equation to compute the volume of the ending inventory, (b) a set of accounting equations to determine the average carbon stock in each planning period, (c) a constraint on the value of the ending inventory and (d) a set of constraints on the average carbon stock over the planning horizon:

-

(a)

The accounting equation to compute the volume of the ending inventory. In this abbreviated form, it displays the decision variables x kj, i.e. whether stand k is assigned to prescription j, for stands 1, 2 and 16:

$$ \begin{aligned} {}& 563.6{x}_{11}{+}434.1{x}_{12}{+}299.6{x}_{13}+168.3{x}_{14}{+}64.1{x}_{15}+563.8{x}_{21}{+}434.4{x}_{22}\\ {}& \quad +299.7{x}_{23} +168.4{x}_{24}+64.1{x}_{25}+\dots +63.9{x}_{161}+7{x}_{162}+1147.2{x}_{164}\\ {}& \quad - {\it Vol\ EI}{=}0 \raisetag{12pt} \end{aligned} $$(6.27)The coefficients of the decision variables VolEI kj correspond now to the volume in the ending inventory in stand k if it is managed according to prescription j. For example, if stand 1 is managed according to prescription 1, the value of the ending inventory in that stand will be VolEI 11 = 563.3 × 103 m3. This was computed as the product of the stand area (31 ha) by the volume per hectare at the end of the planning horizon that results from this assignment (18.2 × 103 m3 (Table 6.2)).

-

(b)

The set of accounting equations to determine the average carbon stock in each planning period (Eq. 6.28):

$$ \begin{aligned} {}& 190.1{x}_{11}{+}279.5{x}_{12}{+}279.5{x}_{13}{+}279.5{x}_{14}{+}279.5{x}_{15}{+}190.2{x}_{21}{+}279.6{x}_{22}\\ & \quad +279.6{x}_{23}{+}279.6{x}_{24}{+}279.6{x}_{25}{+}\dots {+}145.9{x}_{161}{+}145.9{x}_{162}{+}145.9{x}_{163}\\ & \quad +145.9{x}_{164}- {\it CStock1} \\ {}& 73.2{x}_{11}+62.5{x}_{12}+225.1{x}_{13}+328{x}_{14}+328{x}_{15}+73.2{x}_{21}+624.8{x}_{22}\\ & \quad +225.2{x}_{23}{+}328.2{x}_{24}{+}328.2{x}_{25}{+}\dots {+}216.9{x}_{152}{+}216.9{x}_{153}{+}216.9{x}_{154}\\ & \quad +219{x}_{161}+219{x}_{162}+219{x}_{163}+219{x}_{164}- {\it CStock2}\\ {}& 637.5{x}_{11}+286.2{x}_{12}+732{x}_{13}+710.3{x}_{14}+253.6{x}_{15}{+}637.8{x}_{21}{+}286.4{x}_{22}\\ & \quad +73.2{x}_{23}+710.6{x}_{24}{+}253.8{x}_{25}{+}\dots {+}189.5{x}_{161}{+}278.7{x}_{162}{+}278.7{x}_{163}\\ & \quad +278.7{x}_{164}- {\it CStock3} \\ {}& 146.3{x}_{11}+105.2{x}_{12}+637.58{x}_{13}{+}286.3{x}_{14}{+}732{x}_{15}{+}146.4{x}_{21}{+}105.2{x}_{22}\\ & \quad +637.8{x}_{23}+286.4{x}_{24}{+}73.2{x}_{25}{+}\dots {+}729.9{x}_{161}{+}622.7{x}_{162}{+}224.4{x}_{163}\\ & \quad +327.1{x}_{164}- {\it CStock4} \raisetag{12pt} \end{aligned} $$(6.28)The coefficients of the decision variables CS kjt correspond now to the average carbon stock in period t in stand k when managed according to prescription j. For example, if one hectare of stand 1 is managed according to prescription 1, the value of the average carbon stock in period 1 in that stand will be CS 111 = 190.1 × 10 Mg C. This was computed as the product of the stand area (31 ha) by the average carbon per hectare in stand 1 that results from this (6.2 × 10 Mg C (Table 6.2)).

-

(c) and (d)

The constraints on the value of the ending inventory and on the average carbon stock may now be expressed just like in the case of the LP model F5 (Eqs. 6.25 and 6.26, respectively)

According to the solution by the IP model (Table 6.3), the optimal objective function value Z decreased to 1,867.1 × 103 €. No stands are split between different prescriptions (Table 6.4) and this thus cost 106.6 × 103 €. The requirement of locational specificity in Problem 2 is thus five times more expensive than in Problem 1. The model proposed to delay the harvest of most stands. It further proposed a no harvest prescription in the case of the younger stands (stands 13–16). The stock control objectives when combined with the requirement of locational specificity thus did impact substantially the volumes and areas harvested in each period, which are considerably lower. The average carbon stock is thus higher. Moreover, the lack of management flexibility lead to a harvest plan that left a volume at the ending of the planning horizon that is much higher than required (83,355 m3). Again, in the case of larger forests with more stands the requirement of locational specificity may not have an impact as substantial on the adjustment of harvest plans and on the criteria levels. Yet it may have an even higher impact on the computational cost.

3.2 Heuristics

The locational specificity requirement in Problem 2 may also be addressed by heuristic approaches such as simulated annealing (SA). In the case of our example forest, the SA approach involved the extension of the SA formulation for Problem 1 (F3) to address the new policy scenario. In summary, the SA formulation for Problem 2 (F7) takes the objective (evaluation) function of F3 (Eq. 6.14) and modifies its penalty function to include two further terms that penalize deviations from the target volume at the end of the planning horizon and from the average carbon stock constraints. In both cases, it was assumed that a 5 % deviation from feasibility was equivalent to a 1 % deviation from unconstrained NPV when estimating the parameter that characterizes the shape of the parabola for each of these two constraints. The penalty function may thus be represented in abbreviated form as:

Afterwards, the SA approach involved an iterative process identical to the process described in Sect. 6.2.2 (Fig. 6.2) where solutions in each iteration were represented by a vector with 16 elements corresponding to the 16 stands. Penalties and heuristic parameters were the same as in the case of Problem 1. In this illustration, the parameterization did lead again to the optimal MIP solution (1,867.1 × 103 €) (Table 6.3). This is also a consequence of the problem small size.

Management Planning in Action 6.3: Impacts of Timber Management Scheduling on Multiple Product and Stock Control Objectives in Minnesota

Minnesota is located in the United States Upper Midwest and it extends over about 21 × 106 ha. Its forest area extends over about one third of the territory. In 1989, a citizen petition was submitted to the Minnesota Environmental Quality Board (EQB) to seek action to address a potential increase of nearly 3.62 × 106 m3 in annual timber harvesting activity associated with a proposed 2.2 × 109 USD increase in the state’s primary wood processing plant capacity (Kilgore 1992). As a consequence, the state of Minnesota decided to develop a Generic Environmental Impact Statement (GEIS) of timber harvesting.

For that purpose, prescriptions were associated to 13,536 USDA Forest Service’s Forest Inventory and Analysis (FIA) plots, assumed to represent forest conditions in Minnesota. The most appropriate prescription for each stand/plot was selected by a scheduling model that matched demand for a product with the stand or forest area best able to supply that product and in consideration of mitigations and other constraints (Rose et al. 1993; Jaakko Consulting Inc 1994). The scheduling model was based on a Lagrangean relaxation of a typical forest management planning LP model such as the ones presented in 6.2 and 6.3 (Hoganson and Rose 1984). This model, developed at the University of Minnesota (http://www.forestry.umn.edu/), encompassed specialized techniques to search for the values of the dual variables of the LP model as well as the design of maps of wood procurement zones for each market to overcome the combinatorial nature of integrating harvest timing decisions and wood shipping decisions (Hoganson and Kapple 1991).

The GEIS involved over 60 scientists and it represented one of the most extensive studies of timber harvesting and forest resources conducted in the United States (http://iic.gis.umn.edu/download/geis/documnts.html). It was influential to (1) determine the extent of industrial timber harvesting and related timber management activities in Minnesota; (2) identify and assess the environmental and related impacts of industrial timber harvesting; and (3) recommend strategies to mitigate adverse impacts where such were found to be significant (Kilgore and Ek 2007).

3.3 Goal Programming and Pareto Frontier Methods

In the case of our example forest, the goal programming formulation of Problem 2 (F8) consists of a modification of its formulation for Problem 1 (F4). The objective function includes new terms in order to minimize the deviations from targets regarding the average carbon stock in each planning period and the volume at the end of the planning horizon. The formulation may be described as

-

(a)

Objective function Z

$$ \begin{aligned} \mathrm{Min}\ Z& =8.4746\ PdevAH1+8.4746\ NdevAH1+8.4746\ PdevAH2 \\ & \quad +8.4746\ NdevAH2+ 8.4746\ PdevAH3+8.4746\ NdevAH3 \\ {}& \quad +8.4746\ PdevAH4 +8.4746\ NdevAH4+0.0244\ NdevH1 \\ {}& \quad + 0.0244\ NdevH2 +0.0244\ NdevH3 +0.0244\ NdevH4 \\ {}& \quad +0.0049\ NdevNPVt {+}0.04\ NdevCStock1 {+} 0.04\ NdevCStock2\\ {}& \quad +0.04\ NdevCStock3{+}0.04\ NdevCStock4 {+}0.04\ PdevCStock1 \\ {}& \quad +0.04\ PdevCStock2{+}0.04\ PdevCStock3{+}0.04\ PdevCStock4\\ {}& \quad +0.0182\ NdevVolEI \raisetag{12pt}\end{aligned} $$(6.30)Where the decision variables consist again of the deviations from the levels of the criteria set by the decision-maker. Two additional criteria were added, the average carbon stock CStock in period t and the volume of ending inventory VolEI. In the case of CStock the objective function penalizes both over and under achievements while in the case of VolEI it aims at minimizing the under achievement. The coefficients of the corresponding decision variables correspond to the product of 1,000 by the inverse of the criteria target levels measured in Mg and cubic meters, in the case of the average carbon stock and the volume of the ending inventory, respectively. Like before, the new GP model was set to minimize the percent deviations to overcome dimensional constraints to the treatment of all five criteria. The discounted revenues criteria was provided again with a weight equal to 10 while the remaining four were weighted equally as 1.

-

(b)

The Eq. 6.20 setting a new target (89 ha) for the area harvested in each period to reflect the area control objectives, where this area is defined by Eq. 6.12.

-

(c)

The Eq. 6.21 setting a new target for the volume harvested in each period (35 × 103 m3) to reflect the volume control objectives, where this harvest level is defined by Eq. 6.11.

-

(d)

The Eq. 6.22 setting a new target for the discounted net revenue from the forest (1,870,000 €), where the discount net revenue is defined by Eq. 6.19

-

(e)

The Eq. 6.31 setting a target for the volume of ending inventory, where this volume is defined by Eq. 6.27:

$$ VolEi+ PdevVolEi+ NdevVolEi=5,500 $$(6.31) -

(f)

The Eq. 6.32 setting a target for the average carbon stock in each period (24 × 103 Mg C) to reflect the stock control objectives, where this average is defined by Eq. 6.28.

$$ \begin{array}{l} Cstock1- PdevCstock1+ NdevCstock1=2,400\hfill \\ {} Cstock2- PdevCstock2+ NdevCstock2=2,400\hfill \\ {} Cstock3- PdevCstock3+ NdevCstock3=2,400\hfill \\ {} Cstock4- PdevCstock4+ NdevCstock4=2,400\hfill \end{array} $$(6.32) -

(g)

The set of constraints stating that the decision variables may take only the values 1 (if the prescription is assigned to the stand) or 0 (if the prescription is not assigned to the stand) (Eq. 6.13)

$$ {x}_{11},{x}_{12},{x}_{13},\dots, {x}_{165}\ \mathrm{are}\ \mathrm{binary} $$

In this illustration, the target values were set by taking advantage of the insights provided by the solutions by the other techniques. For example, the target for the criteria NPV was set as the value of the optimal MIP solution. The solution by the GP model (Table 6.3) shows that the NPV criteria target was almost achieved (1,866,130 €) while still guaranteeing that no stand was assigned to more than one prescription (Table 6.4). Else the solution has a pattern similar to the MIP and SA solutions i.e. under achievement of harvest levels and over achievement of targets for both average carbon stock and volume in the ending inventory.

The Pareto frontier method may again be used to explore further the tradeoffs between the criteria and help set meaningful targets. The approach may build now from the LP formulation of Problem 2 (F5). Lets assume that the decision-maker wants to analyze the tradeoffs between four criteria e.g. NPV, VolEI, the average carbon stock over the whole planning horizon and the total volume harvested.

The Pareto frontier method may then be used to generate three-dimensional decision maps for which the values of the third, fourth,… criterion are fixed (e.g. Fig. 6.6 where the value of total timber harvested is fixed for each map and where the value of the average carbon stock is fixed for each set of decision maps). The maps are monotonic: a map contains all maps with better values of the third, fourth,…criterion (e.g. Fig. 6.6). When arranged in the form of horizontal series or even matrices, bi- or three-dimensional decision maps developed by this approach may provide information about the Pareto frontier in spaces up to five dimensions (Borges et al. 2014a).