Abstract

This chapter describes the activities in the Dissipation and Recycling Node of Global TraPs, a multistakeholder project on the sustainable management of the global phosphorus (P) cycle. Along the P supply and demand chain, substantial amounts are lost, notably in mining, processing, agriculture via soil erosion, food waste, manure, and sewage sludge. They are not only critical with respect to wasting an essential resource, but also contribute to severe environmental impacts such as eutrophication of freshwater ecosystems or the development of dead zones in oceans. The Recycling and Dissipation Node covers the phosphorus system from those points where phosphate-containing waste or losses have occurred or been produced by human excreta, livestock, and industries. This chapter describes losses and recycling efforts, identifies knowledge implementation and dissemination gaps as well as critical questions, and outlines potential transdisciplinary case studies. Two pathways toward sustainable P management are in focus: To a major goal of sustainable P management therefore must be to (1) quantify P stocks and flows in order to (2) identify key areas for minimizing losses and realizing recycling opportunities. Several technologies already exist to recycle P from different sources, including manure, food waste, sewage, and steelmaking slag; however, due to various factors such as lacking economic incentives, insufficient regulations, technical obstacles, and missing anticipation of unintended impacts, only a minor part of potential secondary P resources has been utilized. Minimizing losses and increasing recycling rates as well as reducing unintended environmental impacts triggered by P dissipation require a better understanding of the social, technological, and economic rationale as well as the intrinsic interrelations between nutrient cycling and ecosystem stability. A useful approach will be to develop new social business models integrating innovative technologies, corporate strategies, and public policies. That requires intensive collaboration between different scientific disciplines and, most importantly, among a variety of key stakeholders, including industry, farmers, and government agencies.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

- Phosphorus and eutrophication

- Environmental costs of phosphate reduction

- Phosphorus recycling in industry

- Phosphorus recycling in agriculture

- Phosphorus recycling from sewage

1 Background

Around 191 Mt of phosphate rock (PR), containing 83.3 Mt of phosphorus (P), was mined in 2011 (U.S. Geological Survey 2012), of which more than 80 % was used as agricultural fertilizer. Population growth and changing diets are increasing demands for PR, which is a finite resource, yet much of P is lost along its way through the supply chain, in mining, in processing, or in fertilizers as the most substantial form of use. Often P is lost into the natural environment, where it transforms from a resource into a pollutant of aquatic (Bennett et al. 2001; Ulrich et al. 2009) and terrestrial (Olde Venterink 2011) systems. Sustainable P management must map its stocks and flows to identify key points at which to minimize dissipation and increase recycling opportunities.

The Dissipation and Recycling Node covers the supply chain from the point where P-containing waste has been produced by humans, livestock, and industries. Recycling covers the processing, marketing, and use of recycled waste products, including biosolids, whereas dissipation refers to the intended or unintended loss of P in mining, processing, use, and, to a minor extent, recycling. The dissipated P is, depending on the sink, more or less accessible for subsequent recycling activities. P-recycling activities span diverse scales and contexts: from farms to households and to megacities, where food is consumed away from production; from simple household and livestock waste composting to complex recovery of P from sewage, food, and industrial waste products; and from large scale, advanced facilities in industrialized countries to small-scale efforts in developing countries, where direct local-level recycling would be carried out, e.g., urine diversion.

A very critical challenge for sustainable P management is to make P recovery economical, reliable, and predictable while ensuring that the use of recycled P products will not result in adverse health or environmental impacts. It is therefore crucial to manage P stocks and flows through a system-based approach, linking dissipation, eutrophication, and recycling. The primary focus is on current and potential markets, quality and price of products, costs of production processes, available and future technologies, institutional structures and public perception and behavior. Stakeholders involved are diverse, including industries creating waste streams and others focusing on P recovery such as farmers, governmental regulatory and specialized agencies, public environmental and health organizations, researchers and agricultural and health NGOs.

The overall aims of the chapter are to (1) give a comprehensive and structured overview of the current state of knowledge; (2) formulate major research gaps; and (3) outline potential case studies.

2 Flows, Stocks, and Balances of P

For sustainable management of P, an essential first step is mapping direct and indirect demands for P in an economy. For example, Fig. 1 shows the substance flows of P in the Japanese economy, which are estimated to be 618 kt (Matsubae et al. 2011). Approximately 284 kt of P is applied annually to farms and ranches in the form of fertilizer, one of the largest input flows in the entire domestic P flow. Input flows to food and feed sectors also have large values, mainly from world imports and marine resources (163.1 kt) and domestic crop production from farmlands (45.2 kt), with the P mainly consumed by humans and livestock (97.6 and 111.0 kt). Livestock grow by eating grass and feed on ranches, and the P in livestock manure ends up accumulating in the soil, the amount of which (285.3 kt) is nearly equal to input from fertilizer to farms and ranches. Another main output is the human waste that ends up flowing down rivers, in the ocean, or in landfill. In addition, 110.5 kt of P is associated with the steel industry as mineral resources, most of which is condensed in steelmaking slag.

Substance flows of P in the Japanese economy (2005). Source (Matsubae et al. 2011)

Figure 1 reveals a variety of potential P resources within the economy in Japan, including food waste, sewage sludge, steelmaking slag, and other industrial wastes, totaling approximately 240 kt per year, which is comparable to the P demand for fertilizer of approximately 284 kt per year. Hence, an appropriate nation-wide recycling strategy could potentially provide the majority of P required for agricultural production in the country. Sustainable P management is also of economic importance. While the size of the domestic fertilizer market is only five billion US dollars per year, it supports all the food-related industries and businesses in the country, whose total sales reach US$800 billion.

In the vegetation process, fertilizer is used for plant growth. Not all of P in fertilizer, however, is transformed into the harvested products, as loss is caused by absorption in the pedosphere, diffusion into the hydrosphere, and waste in residual portions of agricultural products. Substance flow analysis focusing on P contained in products tends to neglect such P flows. As a new indicator to consider the direct and indirect P requirements for our society, virtual P ore requirement (VPOR) is proposed (Matsubae et al. 2011). As in the case of virtual water (Hoekstra and Chapagain 2007), the estimation of VPOR requires to consider hidden P flows, which constitute the total P requirement excluding the amount contained in agricultural products, including the loss to the environment, non-edible parts, and feedstuff for livestock.

Figure 2 illustrates the example of VPOR for the Japanese economy in 2005. The economy consumed 3,662 kt of P ore in overseas countries to produce the agricultural products. While the amount of real P ore import was 774, 6,160 kt (=3,662 + 407 + 240 + 1,077 + 774) of P ore was required in total. The left side of the figure shows where that amount of ore came from, and the value refers to the direct and indirect demand of P ore by country of production. The largest virtual P ore supplier for Japan is China, followed by the USA and Morocco. Although there was no actual P ore imported from the USA, 20 % of VPOR came from the USA through fertilizer and food imports.

Virtual P ore requirement of the Japanese economy (2005). Source (Matsubae et al. 2011)

VPOR indicates the direct and indirect demand of P ore transformed into agricultural products and fertilizer. The amount of embodied P ore flow associated with commodities imported to Japan was 3,743 kt, which was based on 6,160 kt of VPOR. Approximately half of the imported embodied phosphate ore was transformed into fertilizer and utilized to produce agricultural products. An amount of 763 kt of P ore was actually eaten, and the rest ends up being dissipated in soil and water. The results suggest that P consumed in agricultural products accounts for only 12 % (=763/6,160) of VPOR. As the sites of direct and indirect P consumption are different, VPOR is useful to analyze the global network of P ore requirement derived from the consumption of agricultural products. For sustainable P resource management, it is very important to recognize the virtual P ore demand for the agricultural product consumption through the international P demand and supply network.

In the case of EU 27, it is estimated that an average of 8 kg P/ha per year has been accumulated in agricultural lands (Richards and Dawson 2008). There are significant national and regional differences. For instance, the Netherlands, with a high density of intensive livestock farming, accumulates 20 kg P/ha per year on average (Smit et al. 2009), whereas regions with a low livestock density often show a P deficit, resulting in nutrient mining from agricultural land (Albert 2004).

P is mostly lost in crop waste, food spoilage, as well as livestock and human waste. As an indicator of the scale, it is estimated that one-third of the global food production is discarded during its production and consumption process (Gustavsson et al. 2011). This does not only mean that considerable amounts of fertilizer and other resources for food production are used in vain, but also that a significant part of the contained P is lost in various waste streams. It is estimated that 70–80 % of the P mined in PR for food production actually never reaches the plate of the end consumer (Cordell et al. 2009) (see Chap. 1). Solid organic wastes such as slaughterhouse waste (bone, blood, etc.) and inedible parts of agricultural products are frequently mixed with other types of solid waste and thus are dumped into landfills or lost in the form of disposed incinerator ashes. Similarly, P caught in liquid wastes such as livestock manure and human excrement often ends up in bodies of water, where it is very difficult to recover from.

Figure 3 shows simplified substance flows of P for Switzerland based on a detailed substance flow analysis for phosphorus. In Switzerland, like in the rest of Europe, there are no natural phosphorus deposits. The most important factor for the phosphorus yield of the country is the return of farmyard manure and harvest residue back into agriculture. For decades, however, large quantities of phosphorus have been imported for feeding humans and animals. In the meantime, investigations have shown that the amount of phosphorus bound in sewage sludge per year is approximately the same as the quantity imported into Switzerland, with around 7.5 million inhabitants, in mineral fertilizer—approximately 6 kt per year. This is roughly the same ratio compared to the Japanese case discussed above. The P balance for Switzerland also indicates that there still remain losses to hydrosphere, despite of very effective modern sewage treatment plants removing large amounts of phosphorus out of sewage water to avoid environmental problems, i.e., eutrophication. Also, it reveals the remaining accumulation of phosphorus into the soil during agriculture activities. Besides the losses into the hydrosphere, the substance flow analysis for Switzerland also demonstrates the dissipation rate of waste management activities. At the time, being only about 1 kt of P in the form of compost is recycled in a year. From the total P potential of about 11 kt of P per year in waste fractions for recycling, including 5.6 kt of P per year in sewage sludge, currently more than 90 % of it is dissipated. With the disposal to a large extent in municipal waste incinerators (MSW) and cement kilns, P could be recovered for future use. If we could manage to treat the total amount of sewage sludge in monosludge incinerators and landfill the incinerator ash in interim monocompartment storage or apply phosphorus retrieval procedures from ash directly, approximately the amount of P equivalent to the yearly imported mineral fertilizer into Switzerland could be substituted. Compared to Japan, there are no activities related to the steel industry or other phosphorus-based industries in Switzerland with associated P consumption. A more detailed P balance for Switzerland can be found in Binder et al. (2009).

Simplified illustration of P balance in Switzerland. Source (AWEL 2008)

The mapping of stocks, flows, and balances of P provides critical data for understanding where P accumulates and dissipates, based on which we will be able to identify where we could intervene for promoting recycling of P effectively and efficiently. This analysis also illustrates the importance of collecting and analyzing accurate data on the quantity of flows and stocks, with geographical distributions of P supply and demand and potential gaps between them, for designing and implementing sustainable P management.

3 P Dissipation and Eutrophication

Parts of this section are derived from an unpublished report, Food and Water Security in the Lake Winnipeg Basin—Transition to the Future (Malley et al. 2009).

3.1 Eutrophication and Dead Zones

Until recently, P has been recognized as a nutrient that, in some circumstances, can cause nuisance bloom of microalgae known as the eutrophication problem. Excessive input of P to lakes, bays, and other surface waters causes algal bloom. In some cases, when algal bloom occurs, dissolved oxygen is consumed as the cells are decomposed. Economically important fishes and other aquatic organisms cannot survive under oxygen-depleted conditions. In addition, a toxic substance, called algal toxin, may be released from the bloom. This also causes a difficult problem in drinking water supply (Falconer 1993).

Eutrophication is attributed to such factors as the increase in human populations, lack of tertiary sewage treatment, intensive cropping, increased use of fertilizers, and increased cattle and hog production, all of which increase the loads of biowastes to the watershed. In particular, the use of phosphate fertilizers in agriculture has been associated with most cases of eutrophication (World Resources Institute 2012).

Large amounts of phosphate fertilizers are important in today’s agricultural systems. At this stage of P use, particularly in industrial fertilizers, the goal of agriculture to increase crop yields and the goal of environmental quality of aquatic ecosystems are essentially working at cross-purposes, though not intentionally. Nevertheless, it is not the total P, but the water-soluble, available form of P, i.e., dissolved reactive P, that is the most effective form in causing eutrophication and should be the focus of management of P losses from agricultural land (Foy 2005).

Unlike the often-conspicuous responses of freshwater ecosystems to severe eutrophication, the signs in oceans are often not directly visible. Rather, the oceans respond to the wasteful addition of nutrients, including P, washed from the land with dead zones. Dead zones are areas of low oxygen in the world's oceans and large lakes that can no longer support most marine life. Incidences of dead zones have been increasing since oceanographers began noting them in the 1960s. These occur near inhabited coastlines, where aquatic life is most concentrated. In March 2004, the first Global Environment Outlook Yearbook reported 146 dead zones in the world oceans where marine life could not be supported. Some of these were as small as 1 km2, but the largest dead zone covered 70,000 km2. A total area of more than 245,000 km2 is affected, functioning as a key stressor on marine ecosystems, which is shown in Fig. 4 (Selman et al. 2008). Their formation has been exacerbated by the increase in primary production and consequent worldwide coastal eutrophication fueled by riverine runoff of nitrogen (N) and P in fertilizers and the burning of fossil fuels. It is estimated that more than 0.212 Mt of food is lost to hypoxia in the Gulf of Mexico, an amount which would be enough to feed 75 % of the average brown shrimp harvest (Biello 2008).

Locations of hypoxic areas, areas of concern, and areas of recovery. Source (World Resources Institute 2012)

3.2 Processes Involving P in Soils

For the development of sustainable land management practices for agroecosystems, a fundamental understanding of the chemical, biological, and physical processes in soils is required, as they affect the availability of P to terrestrial plants and ultimately to humans and animals (Pierzynski et al. 2005). The fertility of agricultural systems and the protection of aquatic ecosystems from eutrophication both depend on a thorough understanding of soil chemistry and soil management. P cycling in soils is complex. It is influenced by the inorganic and organic solid phases present, forms and extent of biological activity, chemistry of the soil solution involving pH, ionic strength and redox potential, and environmental factors such as soil moisture and temperature. Soils, plants, and microorganisms all interact within the soil system. The largest challenge in agricultural management of P comes from its low solubility. While the P in soil solution must be replenished many times over the life of the growing plants to meet their P requirements, it is also prone to be removed by erosion in runoff or to become part of the sediment load and delivered to the aquatic ecosystems. Managing the soil P concentrations involves dissolution–precipitation, adsorption–desorption, mineralization–immobilization, and oxidation–reduction processes. In solution, P moves within soils primarily by diffusion. Crop removal is the main route by which P is removed from soil, whereas erosion and surface runoff are the environmentally significant removal processes.

3.3 Environmental Costs of P Dissipation

Environmental costs related to P dissipation need to be taken into account in considering P recycling. There are difficulties in measuring them accurately, however, although many methodologies have been proposed to deal with the problem, for example, contingent valuation methods. This issue will have important implications for policy intervention for incorporating the costs into market and pricing mechanisms.

An economic analysis is conducted on the impacts of higher mineral P prices and externality taxation on the use of organic P sources in US agriculture (Shakhramanyan et al. 2012). This study examines alternative hypothetical scenarios concerning the prices for PR-based mineral fertilizers and the taxation of external damages from the application of the latter fertilizers. These scenarios reflect both an increasing scarcity of PR, which led to substantial price increases in recent years, and increasing political efforts to address and correct adverse externalities from land use. To adequately depict adaptation of producers as well as adjustments in agricultural commodity markets, the authors modified and applied a price-endogenous agricultural sector model of the USA. They considered alternative fertilizer options which substitute mineral phosphorous by manure-based organic phosphorus sources and link phosphorous supply from livestock manure to phosphorous demand from crop production. The results indicate that substantial reductions in the use of mineral phosphorus in US agriculture are possible, if the price and tax signals are strong enough.

The results do not indicate a severe physical scarcity of organic phosphorus sources. Low rates of organic phosphorous at a low cost for mineral sources reflect mainly the cost of manure application. The shadow prices on the regional manure supply–demand balances remain zero or at fairly low levels throughout all examined scenarios. Thus, the substitution of mineral by organic phosphorus is primarily an economic or regulatory issue. Furthermore, the overall impact of a higher cost of mineral phosphorous would have little impact on aggregate crop and livestock production, trade, and prices, because of sufficient supply of organic P sources.

4 Recycling of P-Containing Wastes

In this section, four major domains are selected to describe P management and recycling practices in more details, namely manure, wastewater, solid wastes, and industrial wastes.

4.1 Manure

One of the main sources of P for recycling is animal manure. Manure is a valuable source of plant nutrients and organic matter. In the case of intensive livestock farming, P is imported to the farm with the animal feed. In particular, monogastric animals, such as chicken and swine, take up only a small portion of the P contained in the feed and most of the P is excreted in the manure (see Table 1). P in manure is mostly present in the inorganic form and similar to commercial fertilizer in that it is readily available for plant uptake. Substitution of inorganic fertilizers by manure, however, is often not a preferred choice because of higher transportation cost, difficulty to define the appropriate manure application rate, the risk of transmitting pathogens, and undesirable odor effects. Currently, 0.9 % of the agricultural land is organic; by region, the highest shares are in Oceania (2.9 %) and in Europe (2.1 %), and within the European Union, 5.1 % of the farmland is organic (Willer and Kilcher 2012). In principle, manure could be applied far more on cropland, mitigating the risks that arise from excessive concentrations of manure and replacing high-priced commercial fertilizers (MacDonald et al. 2009). As a result of the transport problems, animal manure is repeatedly spread on fields in the vicinity of the livestock farm, resulting in P surplus and causing water contamination. It is estimated that to balance the areas of P surplus and deficit in England (UK), 4.7 kt of P (2.8 Mt of manure) must be exported annually from the areas of livestock farming in the west to the areas of arable farming in the east of the country (Bateman et al. 2011).

In contrast to sewage sludge biosolids, inorganic pollutants (heavy metals) are not an issue in the case of animal manure, although organic pollutants such as veterinary medicines, antibiotics, and biocides could be problematic as well as pathogens. Thus, the main technological issues to be resolved are how to increase the transportability of P within the manure matrix and how to extract P from the manure matrix for further processing, for example, through crystallization as struvite or calcium phosphate. The P-depleted manure may then be applied on fields with a reduced P load.

An approach to increasing the transportability of P in manure could be to use manure as feedstock for energy production, although manure-to-energy projects are not currently in widespread use (MacDonald et al. 2009). Current available technologies include combustion power plants (Hermann 2011) and anaerobic digestion systems designed to capture methane gas and burn it as fuel for electricity generation. Anaerobic digestion does not consume the nutrients in manure and leave them in residuals. Anaerobic digestion reduces pathogen counts and denatures weed seeds in raw manure, and the odors of raw manure are greatly reduced in the effluent, thereby easing the storage, movement, and application of manure nutrients. During combustion processes, most nitrogen nutrients are burned, whereas the ash residues from combustion retain P and potassium in concentrated form. The resulting ashes would be free of organic pollutants and could be easily processed into P fertilizers (Schoumans et al. 2010).

4.2 Wastewater

Wastewater is a significant source of P; globally, wastewater contains approximately 4.6 Mt P per year, corresponding to more than 2 % of the world PR production. In 1890, approximately 90 % of P in global wastewater was recycled, which decreased to 30 % by the end of the twentieth century (Liu et al. 2008). A prerequisite for P recycling from wastewater is an adequate sanitization infrastructure, including wastewater treatment. Nutrient recycling in fast-growing urban areas is needed to address nutrient imbalances and to return P to the places of food production. The urban population is expected to double from currently 3.5–6.5 billion in 2050. By then, 4.7 Mt of P per year will be emitted to wastewater in urban areas alone.

4.2.1 Centralized Measures

Wastewater treatment plants may become important sources of P recovery and recycling. The removal of P from municipal wastewater is well established and widely applied; typically, 80–90 % of influent P is transferred from wastewater to sludge solids by chemical precipitation (Al3+ or Fe3+) or biological uptake (Petzet and Cornel 2011). Chemical precipitation is less amenable to P extraction and recovery because it forms insoluble phosphate precipitates within the sludge matrix, whereas biologically removed P is readily released as soluble phosphate and can be further recovered as struvite or calcium phosphate (Hirota et al. 2010). Complete recovery of P from wastewater is technically feasible using current technologies (Petzet and Cornel 2011) (Fig. 5).

P recovery from concentrated wastewater in wastewater treatment plants by crystallization as struvite (MgNH4PO4) or calcium phosphate (Ca10(OH)2(PO4)6) is a simple and proven technology, which in some cases is economically feasible. The overall recovery potential is limited, however, since it can only be applied to a certain type of wastewater treatment process, namely enhanced biological P removal. Even in this case, the recovery is limited to 30 % of the P contained in wastewater with existing sewage treatment systems; the rest remains in the sewage sludge and the effluent. While biological P removal is increasingly showing a higher performance of removing P, especially in places where P discharge limits are very low, chemical removal would be applied and crystallization technologies might not be feasible.

A full-scale struvite crystallization plant for P recovery was constructed at Matsue city in Japan more than twenty years ago. Without this P recovery, spontaneous struvite precipitation often causes difficult fouling problems in pipelines. To remove it, the reactor and downstream pipelines need to be repeatedly washed with acids, which is very time-consuming and costly. To address these problems, a relatively simple technology is being developed to recover P from P-rich liquor using amorphous calcium silicate hydrate (A-CSH) as an inexpensive adsorbent. A-CSH particles are put into P-rich liquor, and after 10 min mixing, P-binding A-CSH particles are recovered by settling without using any chemical coagulant. Most importantly, the recovered particles can be directly used as a by-product phosphate fertilizer. If a feasible business model is established, a cement company can produce A-CSH particles at low costs and deliver them to wastewater treatment plants using agitation trucks. The recovered A-CSH particles can be delivered to a fertilizer company and used as by-product phosphate fertilizer. Importantly, A-CSH can be synthesized from unlimitedly available resources such as calcium and silicate.

Many microorganisms can accumulate high levels of P in the form of polyphosphate (Hirota et al. 2010), a unique long-chain polymer of inorganic phosphate residues having a chain length of 1,000 or more. Enhanced biological P removal relies primarily on the ability of sludge microorganisms to accumulate polyphosphate. Anaerobic sludge digestion is a well-established process to stabilize waste sludge and to reduce its volume by methane production. If anaerobic sludge digestion process is available, P can be readily released from poly-P-rich sludge biomass to the liquid phase.

Recycling of processed (e.g., digested or composted) sewage sludge (biosolids) to land, the simplest method to recycle P from wastewater, is in some cases impeded by legal bans (e.g., Switzerland and Japan) due to concerns about potential organic and inorganic contaminants in the sludge, or by a lack of agricultural land in the vicinity of large urban agglomerations.

An increasing amount of sewage sludge (for example, 50 % in Germany) is incinerated in monoincineration plants or coincinerated in power plants, municipal waste incinerators, or cement kilns, where P is usually not recycled. In the case of coincineration of sewage sludge, P is permanently tied to the resulting ashes and products, and recovery is not economically and/or technically feasible. In the case of monoincineration, P and non-volatile metals are concentrated in the ashes, which are good raw material for P recycling.

Various options exist for P recovery from ashes, which depend on the chemical composition; in Germany, 30 % of the ashes with low heavy metal content can be directly recycled as fertilizers, although there is a debate about the plant availability of the P. In contrast to sewage sludge, organic contaminants (pharmaceuticals, endocrine disruptors, pathogens) are destroyed, and P can be solubilized by the addition of acid (Petzet and Cornel 2011). Some ashes can be directly recycled as a raw material in the production of yellow P. At least technically speaking, PR can be substituted with suitable sewage sludge ash. One requirement for both direct recycling options is a low iron content of the ashes, which can be achieved by using aluminum instead of iron as the precipitant in wastewater treatment or by using biological nutrient removal.

In cases where direct recycling of either sewage sludge or sewage sludge ashes is not possible, technologies are required to remove organic or inorganic pollutants and to transform P into a bioavailable form or into a raw product that can be used by the P industry. Many innovative approaches have been investigated, which can be divided into thermal and wet chemical processes; some of these are now ready for implementation: The ASH-DEC process removes heavy metals as chlorides by a thermochemical treatment of ashes. The Mephrec process is a smelting gasification technology for sewage sludge that simultaneously recovers energy and P as a P-rich slag. Both technologies have been successfully tested at pilot scales, and their full-scale implementation is envisaged. Wet chemical leaching procedures, including bioleaching, for sewage sludge and ashes have been extensively investigated. Usually, P is leached together with metals, followed by different separation steps that can be combined, such as ion exchange, liquid–liquid extraction, precipitation, and nanofiltration. Wet chemical processes have been tried on a large scale for sewage sludge in Germany; while they are technically feasible, they have high operating costs due to chemicals (Petzet et al. 2012).

Where P removal is operating in sewage works, sludge monoincineration ash contains P at concentrations similar to those of rock phosphate. A full-scale plant for P recovery from sludge incineration ash has recently started operation at Gifu city in Japan (Goto 2009). The full-scale plant is now making a great contribution to the sustainability of local agriculture, because the quality of recovered P matches well the local demand. There are critical challenges, however, including the high capital cost for plant construction and the difficulty in establishing stable channels for distribution and sale of recycled P, which might discourage expanded uses of this technology.

In Switzerland, similar to other countries in middle Europe, nutrients (P, N, etc.) had been used as a resource from sewage sludge through their direct application in agriculture since the construction of efficient sewage purification systems. But for the last 40 years, questions have been raised in connection with this use (heavy metals, persistent organic pollutants, BSE). Quality demands of consumers and wholesalers on agricultural products (e.g., organic farming, high environmental awareness, “no risk” strategy) have increased. These concerns led to the ban on the direct use of sewage sludge in agriculture from 2006 in Switzerland, based on the precautionary principle. From that time, thermal treatment of sludge to destroy the pollutants or to concentrate and store them safely (e.g., waste incineration plants) or to bind them in a mineral matrix (cement plant) was mandatory. This trend, however, was also associated with the fact that nutrients in sludge are no longer able to be used.

In 2006, it was recognized in the Canton Zürich that capacity bottlenecks are to be expected with this disposal concept from 2015. The Canton Zürich is the most populated canton of Switzerland, with roughly 1.4 million inhabitants and an area of about 1,600 km2. Also, the knowledge that phosphorus is severely limited as an important nutrient became increasingly evident. Both factors were then used as an opportunity to define a new sludge recycling strategy based on the goals of modern waste and resource management under consideration of the optimized conservation of resources regarding phosphorus (Morf 2012). With this new strategy, the three most relevant general conditions have been defined in a resolution in 2007 for the planning in the Canton Zürich: (1) the (later) retrieval of phosphorus is possible; (2) the renewable energy in sludge is used; and (3) regardless of the place, it is treated in the optimum economic manner.

In a long-term and holistic-oriented approach developed and defined during the last six years, the Canon Zürich managed to change from a decentralized resource-inefficient to a very efficient centralized system in less than eight years. The selected concept based on one single sewage sludge monoincinerator avoids further phosphorus dissipation to a large extent and secures this scarce resource starting in 2015. This strategy allows to roughly substitute the total phosphorus imported in the form of mineral fertilizer. It is planned to enable successful direct P recovery from incinerator ash soon, in order to avoid intermediate storage costs. Therefore, a project to evaluate in detail direct P recovery from monoincineration ash with the focus on wet chemical extraction similar to primary phosphate production (LEACHPHOS®-Process) has been started since 2012. The project incorporates (a) the technical evaluation with a first full-scale test at the end of 2012, (b) detailed investigations regarding product quality and management (phosphorus fertilizer or secondary raw material, e.g., for white phosphorus production), and (c) market and economical aspects. The wet chemical extraction process was compared with two alternatives, namely a thermochemical process (ASHDEC®-Process) and a phosphoric acid treatment (RECOPHOS®-Process) at the moment.

4.2.2 Decentralized Measures

Urine diversion is a relatively established technology and has been tested in several places in Germany and Sweden, with consequent nutrient recycling to agriculture (GTZ Deutscher Gesellschaft für Technische Zusammenarbeit 2005a; Tanum Kommun 2008; Sustainable Sanitation Alliance 2010). While urine constitutes no more than 1 % of the total volume of wastewater, it contains 50 % of the P (Vinneras and Jonsson 2002). Urine is almost free from heavy metals and pathogens and is easily hygienized by storage (Kvarnström et al. 2006), ozone, or UV light. Urine can also be evaporated or precipitated as struvite, as, for example, by local solar-driven systems in Nepal and Vietnam (Etter et al. 2011; Antonini et al. 2012). Through fertilization with separately collected urine, the input of heavy metals in general, and the disputed cadmium in particular, to agriculture could be remarkably decreased, compared with spreading of sewage sludge from combined systems (Remy and Jekel 2008). Although human urine contains ingested pharmaceuticals and hormones, the level of concentration is much lower than in animal manure, which is commonly used as crop fertilizer today (Lienert et al. 2007; Winker 2010).

In blackwater diversion, the whole toilet wastewater is transported either by gravity or by vacuum to a decentralized or semi-centralized treatment site and treated separately. Blackwater contains little pollutants as their main sources are the household greywater and urban stormwater (Vinnerås 2001; Lamprea and Ruban 2008; Hernandez Leal 2010). Addition of urea or ammonia reduces eventual pathogens in blackwater (Winker et al. 2009). Blackwater is then treated aerobically by liquid composting, storage, or ammonia treatment. Alternatively, it is treated anaerobically to produce biogas as an additional product. The anaerobic digestion process results in mineralization of nutrients in the digested sludge, and, in particular, nitrogen becomes more plant-available (Meinzinger 2010). Blackwater separation is being applied on a building scale as well as a district scale in Sweden (GTZ Deutscher Gesellschaft für Technische Zusammenarbeit 2005b; Karlsson et al. 2008).

4.3 Solid Wastes

A study of P flows for the EU 27 and for a municipality in Sweden recently showed that solid waste contains as much P as does the sewage sludge (Kalmykova and Harder 2012; Ott and Rechberger 2012). For the EU, per capita discharge through wastewater is larger: 0.6 kg P/cap per year, compared to 0.45 kg P/cap per year, through biowaste from households, restaurants, and canteens. P contained in a range of other waste materials, however, is not included: wood (0.31 kg P/t TS), textiles (0.14 kg P/t TS), paper and cardboard (0.24 kg P/t TS), porcelain, and chemical products (variable). Moreover, 20 % of the sewage sludge in the EU is landfilled directly, while another 11 % is incinerated before being landfilled. Also, equally large stocks of P were measured in the municipal solid waste incineration (MSWI) residues and the sewage sludge in Sweden (Kalmykova and Harder 2012).

Solid waste represents an underestimated sink of P and needs to be taken into account for sustainable P management. Extraction of P from untreated solid waste has not been investigated thoroughly. Incineration is a commonly used method for treatment of waste before landfilling, to reduce volume and sometimes also to recover energy. MSWI residue offers a relatively homogeneous and concentrated stock for mineral recovery, and methods for P recovery have been developed recently (Kalmykova and Karlfeldt Fedje 2012).

An estimation of the P flows in municipal solid waste based on the generation rates, waste composition, and subtracting recycling (recycled fractions are only available for OECD) results in 94,400 t of P per year for 60 % of the world’s population, that is, OECD, China, India, Brazil, Russia, and South Africa (Organisation for Economic Co-operation and Development 2008). Generation rates for 2005 have been used, and the landfilled sewage sludge, wood, and industrial wastes are not included. The biodegradable waste (biowaste) fraction is known to decrease with increasing affluence of the population. While the fraction of biowaste is 30 % for the EU, North America, and Australia, it is 60–80 % for China, India, Bangladesh, Latin America, and African countries. Therefore, potentially even larger quantities of P are landfilled in the developing countries.

4.3.1 Food Waste

Food and food-processing wastes are a major source of P in solid waste due to both the large quantities and high P content of 0.4 kg P/t TS. The extreme wastage of food is a unique modern phenomenon. A report by the UN FAO, Stockholm International Water Institute, and the International Water Management Institute indicates that close to half of all food produced worldwide is wasted (Lundqvist et al. 2008). This amounts to about 1.3 billion tonnes per year, even though calculations are still uncertain due to large data gaps (Gustavsson et al. 2011).

Developed and developing countries differ in their characteristics in food loss and waste. In developing countries, more than 40 % of the food losses occur at post-harvest and processing levels, while in industrialized countries, more than 40 % of the food losses occur at retail and consumer levels (Gustavsson et al. 2011). It is argued that the per capita food loss and waste by consumers in Europe and North America is 95–115 kg/year, whereas in sub-Saharan Africa and South/Southeast Asia, this amounts to 6–11 kg/year (Gustavsson et al. 2011). In the developing world, lack of infrastructure and technical and managerial skills in food production is a key driver in the creation of food waste. Consequently, the majority of uneaten food is lost, with P included in it also lost.

In the developed world, in contrast, the majority of the food waste is driven by the low price of food relative to the income, consumers’ high expectations of food cosmetic standards, and the increasing disconnection between consumers and the place where food is produced (Parfitt et al. 2010). Astonishingly, much of the food wasted in the developed countries is in entirely edible condition. For instance, in the EU, around 90 million tonnes of wasted food includes losses from agricultural production due to quality standards, which discharges food items not perfect in shape and appearance (39 %), distribution and retail (5 %), food services and catering (14 %), and final household consumption (42 %), due to, e.g., inconsistency in date labels (Commission of the European Communities 2010). Britain, for example, throws away half of all the food produced on farms, amounting to about 20 Mt of food, which would be equivalent to half of the food import needs for the whole of Africa (Mesure 2008). Approximately 16 Mt of this is wasted in homes, shops, restaurants, hotels, and food manufacturing. Much of the rest is thought to be destroyed between the farm field and the shop shelf.

Separate collection and treatment of food waste enable recycling of nutrients through application of compost, while both energy and nutrients can be recycled via biogas production with consequent agricultural application of the residue. In addition, diverting of biowaste from landfills prevents production of the landfill gas methane, a greenhouse gas 21 times more potent than carbon dioxide. Separate collection of food waste is implemented in several countries worldwide. Effective separate collection, however, is difficult to achieve due to the low collection rate from households and large non-separated flows from food distribution and retail, restaurants, and public institutions (Kalmykova and Harder 2012). In Scandinavia and Canada, 10–15 % of biowaste is composted, with higher efficiency of 20–40 % in Austria, Germany, the Netherlands, France, Italy, and Spain (Organisation for Economic Co-operation and Development 2008).

4.3.2 Slaughterhouse Waste

Slaughterhouse waste is another P-rich waste, which contains up to 60 g P/kg TS. Bones contain even around 100 g P/kg DM (Lamprecht et al. 2011). During the slaughter process, 33–43 % of live animal weight is discarded as inedible waste, so-called animal by-products. This waste is processed by the rendering industry into high-quality fats used by the oleochemical industry and the meat and bone meal (MBM) used as protein and phosphorous supplements for animal feed. Every year, 16 million tonnes of animal by-products is processed by renderers and fat-melters in the EU, 25 million tonnes in North America, and 12 million tonnes in Argentina, Australia, Brazil, New Zealand, and India (60 % water content).

In the EU, USA, Australia, and New Zealand, the use of animal by-products is severely restricted, due to the fear of BSE, what is often called “mad cow disease” (Australian Government 2011; Commission of the European Communities 2002; United States Food and Drug Administration 2008). Animal by-products are divided into three risk categories; that is, class 1 must be incinerated, while categories 2–3 can be composted or digested for biogas production. There are no data available on the amounts of slaughterhouse waste entering different disposal routes; therefore, the fraction of P either recycled as compost or landfilled as ash cannot be estimated. Several techniques have been developed in a laboratory scale for P extraction from animal by-products or its ash, and carbonization into charcoal has been tested on a pilot scale in the EU (Someus 2009; Zalouk et al. 2009).

4.4 Industrial Wastes

One of the most economically important pathways would be P recycling in the manufacturing sector, including some of the high-tech industries. P is used in surface treatment chemicals, for example, such as the iron phosphate coating material in the automotive industry. P is also one of the crucial raw materials for the production of rechargeable batteries such as lithium ion batteries. Furthermore, P is used in etching agents for aluminum line-patterned substrates in the production of computer chips and liquid crystal panels and flame retardants for a wide variety of industrial products.

In terms of quantity, P recycling in the steelmaking industry is particularly important. P is present in iron ore and coal at concentrations as low as 0.12 % and is removed into steelmaking slags at concentrations of 2–3 % at the maximum. Since the steelmaking is a very large industry, the amount of P emitted as slag is considerable.

The manufacturing industrial sectors require high-quality phosphoric acid, which is derived from elemental P. There would be a strong demand for maintaining domestic elemental P production from the manufacturing industrial sectors. Although the consumption of elemental P is minor from the quantitative point of view, it is strategically important especially for high-tech industries.

Industrial chemical processes such as direct hydration of ethylene to ethanol also use large amounts of quality phosphoric acid as the catalysts. P recovery has been put into operation in the process of synthetic alcohol production. The recovered P is reused in fertilizers for agricultural purposes. Edible oil refining process also uses large amounts of phosphoric acid to remove impurities from crude vegetable oil. Since no harmful substance is used in the edible oil refining process, the P recovered from wastes and wastewater is well suited to the use for agricultural purposes. This is also the case for fermentation wastewater. Fermentation companies have also been recovering P from the fermentation wastewater using the HAP precipitation technique. Several companies of electronic equipment manufacturing have been recovering P from liquid wastes and are attempting to use the recovered P in liquid fertilizer for urban plant factories.

Pulp and paper production is another industry disposing large volumes of P-containing waste. Annually 11 million tonnes of the waste is produced in the EU and 8 and 3 million tonnes in the USA and Japan, respectively (Monte et al. 2009; Wajima et al. 2006). The waste is usually incinerated in order to reduce the volume. While a part of the resulting ash is used as a construction material, mainly for landfill covering layers, most of it is simply landfilled. Although the P content of the ash is only 0.1 %, because of the large waste volumes, considerable amounts of P are disposed of as a result. Assuming 60 % of water content of the waste, an amount equivalent to 20,000 t of P is disposed annually in the EU, USA, and Japan.

5 Work in Global TraPs

5.1 Knowledge Gaps and Critical Questions

The current P management practices and approaches in the different sectors show diverse characteristics with regard to temporal and spatial scales of the issue; technological measures, including types of technology, energy consumption, costs of investment, and operation; key stakeholders involved, such as farmers, industry, consumers, and public sectors; and institutional conditions, including public policies and interventions. Solid understanding of the factors influencing P dissipation and recycling in different domains will be of critical importance for sustainable P management.

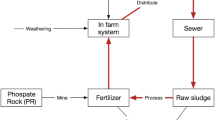

Potentially, there are three main areas for implementing P recycling as illustrated in Fig. 6:

Possibilities of P recycling in agricultural and industrial sectors. Source (Ohtake 2010)

-

1.

Recycling of P contained in food and feed;

-

2.

Recycling of P from wastewater; and

-

3.

Recycling of P from industries using high-quality phosphate.

Recognizing the significance and potential of P recycling, experts and practitioners have started to pay attention to the development of P management and recycling as a new green industry. Active involvement of industry, however, is still limited, and there are not many cases in which P recycling is successfully implemented in practice. At the current stage of development, recycling of P is not a feasible business opportunity, as the conventional practice of buying normal fertilizers while wasting water and sludge would be much cheaper. Recycling of P, therefore, has not yet become a strategic issue for major companies in the industry. One of the critical issues which we need to tackle is how to establish socially robust business models in a broader sense, integrating scientific understanding, technological development, corporate strategies, and public policies, for successful implementation of P recycling.

Based on the key guiding question above, other critical questions are identified for the node on dissipation and recycling as follows: (1) What are the relationships between nutrient cycling and ecosystem stability? (2) How can the social costs of P dissipation into the environment be assessed appropriately? (3) How can supply security of P and environmental impacts caused by P be balanced? (4) What are the technological challenges for reducing costs and/or improving the quality of recycled P? (5) How can we establish a system for effective and efficient matching between supplies and demands for recycled P? (6) What are the differences in P recycling between agricultural and industrial sectors? and (7) How can relevant stakeholder groups become engaged/interested in P recycling?

5.2 Roles, Functions, and Varieties of the Transdisciplinary Process

In the transdisciplinary process, it is crucial to build partnerships among key stakeholders to conduct joint problem definition and joint transdisciplinary case studies (Scholz 2011). Relevant actors in academia, industry, government, and NGOs need to be actively engaged in identifying the critical challenges (Yarime et al. 2012; Trencher et al. 2013). While the need for P recovery has been identified as an important issue by various institutions, actions taken by stakeholders around the world have been still limited. In the design of a P-recycling system, it is necessary to approach this issue at multiple levels, including local, national, and global levels. While the recycling system would be very much conditioned by local characteristics and contexts, at the same time, it is also influenced by national resource management strategies and institutional frameworks. Generally speaking, the recycling of P is not yet considered to be a high priority issue at the national level, except for a few countries such as Sweden, where a target is set to recover 60 % of P from sewages by 2015. A full commitment to implementing P recycling is not yet dedicated by the industry, which is increasingly influenced by the fluid business environment in the global economy.

As we have seen in the previous sections, there are many actors in different sectors that have stakes in recycling P. P can be characterized as an essential, non-substitutable, but low-cost commodity that each person consumes, as well as a source of environmental pollution. It is crucial to identify who has what kind of stake within the system and to find out the best way to realize a situation in which a common solution would satisfy different interests and objectives (Shiroyama et al. 2012). For instance, there can be a potential of implementing P recycling through close collaboration between cement companies, fertilizer companies, and the local government. The sewage department of the local government has to extract P to meet the water quality standard to avoid environmental degradation. Fertilizer companies need P for producing fertilizer. And cement companies require a low level of P contained in sludge because sludge with high concentration of P can weaken the strength of the product (Ohtake 2011). Currently, one of the most serious challenges for the recycling of P is how to expand the market for recycled P. For that purpose, it would be important to maintain the stability of supply and the quality of products involving recycled P. Institutional measures to accelerate the closing of the P chain would include the implementation of P discharge criteria in waste stream regulations and the revision of lengthy and costly permission procedures and requirements for recovery technologies (Drizo 2012).

We then need to prepare for sustainable transitions by exploring feasible strategies for social business models, with the relevant stakeholders closely involved. For that, it would be possible to consider pursuing consensus at two levels. The first one is whether we should go for a soft or detransformation of sewage and wastes. While there has been a concern about heavy metals, harmful chemicals, pathogens, and other biological issues, it is not completely clear what kind of soft processing including organic matters might be a better option, in comparison with incineration. This type of consensus building could take place in a precompetitive arena, although it might also affect industrial activities from a long-term perspective. Based on that, we could consider what technical process (thermal or chemical extraction) should be applied, probably in a competitive arena.

5.3 Suggested Case Studies

To address the key guiding questions and the dimensions of transdisciplinary processes, we can suggest case studies to be conducted for further research. First, it is very important to explore how to make an appropriate assessment of the external costs associated with the dissipation of P into the environment. A case study in highly contaminated regions would be useful to find out how much is actually caused and affected by P in a freshwater region in a sea area, for example, the Manila Bay in the Philippines, where P-based detergents are still used, probably with significant environmental impacts.

We also need to conduct detailed case studies to examine some of the emerging cases of successful implementation of recycling P in different sectors and regions. For example, P recycling in the sewage treatment plant in Gifu, Japan, has been operating since 2010, and the fertilizer involving recycled P has been sold to farmers. In Europe, a couple of companies that previously have operated in the detergent field are now utilizing their extensive knowledge on P for different types of purification and reprocessing. Ostara has been running five plants for recycling P in Europe. Companies such as ICL have already joined the Global TraPs project. It could be possible to conduct case studies at the watershed level such as Lake Winnipeg in Canada as well as the city level, for example, the case of urban metabolism in Gothenburg, Sweden. Development and implementation of innovative technologies are currently explored in Germany, and recovery measures in the water sector and from manure have started to be introduced in the UK.

The knowledge generated in the transdisciplinary process is expected to be used by the practitioners in their business and policy decisions for realizing sustainable use of P, which demands cooperation and coordination across different sectors. Close collaboration among relevant stakeholders including academia, industry, and the public sector is urgently required to cope with this critical challenge. In an attempt to address that, the Phosphorus Recycling Promotion Council of Japan (PRPCJ 2008) was established in 2008 by inviting experts and practitioners from academia, industry, and the public sector. This nation-wide association is supported by the four relevant ministries of the Japanese government and currently has approximately 140 members, including more than 70 corporate members. Based on the PRPCJ activities, a national platform for industry–academia–government collaboration was also initiated in 2011 to discuss and implement national strategies for robust P-recycling systems.

In Europe, the Nutrient Platform was established in 2011 in the Netherlands, with more than 20 Dutch companies, knowledge institutes, government authorities, and NGOs signing the Phosphate Value Chain Agreement (Dutch Nutrient Platform 2011). The Nutrient Platform is a cross-sectoral network of Dutch organizations that share a common concern for the global impact of phosphorus depletion and the way the society is dealing with nutrients in general. Together with the Dutch government, the Nutrient Platform is aimed at facilitating the organizations throughout the value chain in closing the phosphorus cycle. They all share the ambition of creating a sustainable market within two years, where as many reusable phosphate streams as possible will be returned to the cycle in an environmentally friendly way and where the recycled phosphate will be exported to the fullest extent possible, as long as surplus exists in the Dutch market, in order to contribute elsewhere to soil improvement and food production. To achieve the vision and mission, the platform practices an approach of learning by doing within a framework of action learning and new types of partnerships.

The first European Sustainable Phosphorus Conference 2013 was held in Brussels in March 2013, with the purpose of raising awareness about the necessity for a more sustainable phosphate management within the context of a Resource Efficient Europe (European Phosphorus Platform 2013). It was aimed at facilitating support for a clear and coherent legislative framework to create an enabling environment for ecoinnovation, a sustainable European market for secondary phosphorus and more efficient phosphorus use. Different nutrient waste flows and market possibilities will be connected between stakeholders, including private sector throughout different sectors, knowledge institutes, government, and NGO’s, for further development of sustainable nutrient chains within Europe. At the conference, participants reached consensus to launch the European Phosphorus Platform to continue dialogues, raise awareness, and trigger actions to address the phosphorus challenge, with significant implications for ensuring food security, geopolitical stability, and environmental sustainability.

In North America, a kickoff workshop was organized in May 2013 to launch Research Coordination Network (RCN) in Washington DC, USA (Sustainable P Initiative 2013). The workshop was mean to bring together some of the world’s top scientists, engineers, and technical experts to spark an interdisciplinary synthesis of data, perspectives, and understanding about phosphorus to envision solutions for P sustainability. Key stakeholders from relevant sectors shared their knowledge and expertise on various dimensions of the global phosphorus system, including farmers and growers, food processors, fertilizer producers, waste managers, water quality managers, regulators, legislators, and others. Two challenges of phosphorus efficiency and phosphorus recycling have been identified. RCN on coordinating phosphorus research has been funded by the National Science Foundation to create a sustainable food system.

These experiences of establishing national/regional platforms involving key stakeholders will provide valuable lessons and implications for implementing P recycling successfully in different technological, economic, and institutional contexts.

Notes

- 1.

Parts of this section are derived from the report, Food and Water Security in the Lake Winnipeg Basin—Transition to the Future (Malley et al. 2009).

References

Albert E (2004) Versuchsergebnisse zur Stickstoff- und Phosphorwirkung von Fleischknochenmehl. In: 93. Sitzung des DLG Ausschuss für Pflanzenschutz. Deutsche Landwirtschafts-Gesellschaft e.V., Derenburg, 25 Mai 2004. Sächsische Landesanstalt für Landwirtschaft

Antonini S, Nguyen PT, Arnold U, Eichert T, Clemens J (2012) Solar thermal evaporation of human urine for nitrogen and phosphorus recovery in Vietnam. Sci Total Environ 414:592–599

Australian Government (2011) Australia New Zealand Food Standards Code—Standard 2.2.1—Meat and Meat Products—F2011C00615

AWEL (2008) Phosphor im Klärschlamm—Informationen zur künftigen Rückgewinnung. Baudirektion Kanton Zürich, AWEL Amt für Abfall, Wasser, Energie und Luft [phosphorus in sewage sludge—Information about future retrieval, Building Department of the Canton of Zürich, AWEL Office for Waste, Water, Energy and Air] (http://www.klaerschlamm.zh.ch)

Bateman A, van der Horst D, Boardman D, Kansal A, Carliell-Marquet CM (2011) Closing the phosphorus loop in England: the spatio-temporal balance of phosphorus capture from anaerobically-digested manure versus crop demand for phosphorus. Resour Conserv Recycl 55:1146–1153

Bennett EM, Carpenter SR, Caraco NF (2001) Human impact on erodable phosphorus and eutrophication: A global perspective. Bioscience 51(3):227–234

Biello D (2008) Oceanic dead zones continue to spread. Scientific American. http://www.sciam.com/article.cfm?id=oceanic-dead-zones-spread. August 15

Binder CR, de Baan L, Wittmer D (2009) Phosphorflüsse in der Schweiz: Stand, Risiken und Handlungsoptionen. Abschlussbericht. Umwelt-Wissen Nr. 0928. Bundesamt für Umwelt, Bern

Commission of the European Communities (2002) Regulation (EC) No. 1774/2002 of the European parliament and of the Council of 3 October 2002 on management rules for animal by-products not intended for human consumption

Commission of the European Communities (2010) Preparatory study on food waste across EU 27. http://ec.europa.eu/environment/eussd/pdf/bio_foodwaste_report.pdf

Cordell D, Drangert J-O, White S (2009) The story of phosphorus: global food security and food for thought. Global Environ Change 19(2):292–305

Drizo A (2012) Innovative phosphorus removal technologies. Available at http://www.azocleantech.com/article.aspx?ArticleID=226-6. Accessed 7 Mar

Dutch Nutrient Platform (2011) Phosphate value Chain agreement. Dutch Nutrient Platform, 4 Oct

Etter B, Tilley E, Khadka R, Udert KM (2011) Low-cost struvite production using source-separated urine in Nepal. Water Res 45(2):852–862

European Phosphorus Platform (2013) Joint declaration for the launch of a European Phosphorus Platform. In: 1st European sustainable phosphorus conference 2013, Brussels, 6–7 March

Falconer I (ed) (1993) Algal Toxins in seafood and drinking water, 1st edn. Academic Press, London

Foy RH (2005) The return of the phosphorus paradigm: agricultural phosphorus and eutrophication. In: Sims JT, Sharpley AN (eds) Phosphorus agriculture and the environment, vol 46. American Society of Agronomy Monograph, Madison, pp 911–939

Goto K (2009) Advanced utilization of sludge incineration ashes (conversion to phosphorus fertilizers and use of incineration ashes). In: Ohtake H (ed) Recovery and effective utilization of phosphorus resources. Science & Technology, Tokyo, pp 365–382

Government of Manitoba (2008) MARC 2008 User's Manual: manure application rate calculator version 2.1.3. Government of Manitoba, represented by the Minister of Agriculture, Food and Rural Initiatives, January

GTZ Deutscher Gesellschaft für Technische Zusammenarbeit (2005a) Data sheets for ecosan projects: 004 ecological housing estate, Lübeck Flintenbreite

GTZ Deutscher Gesellschaft für Technische Zusammenarbeit (2005b) Data sheets for ecosan projects: 008 Gebers collective housing project, Orhem, Sweden

Gustavsson J, Cederberg C, Sonesson U, van Otterdijk R, Meybeck A (2011) Global food losses and food waste: extent, causes and prevention. FAO, Rome

Hermann L (ed) (2011) How energy from livestock manure can reduce eutrophication. Ecoregion perspectives. Fourth Issue: sustainable agriculture in the Baltic Sea region in times of peak phosphorus and global change. CBSS-Baltic21

Hernandez Leal L (2010) Removal of micropollutants from greywater. Ph.D. thesis, Wageningen University, The Netherlands

Hirota R, Kuroda A, Kato J, Ohtake H (2010) Bacterial phosphate metabolism and its application to phosphorus recovery and industrial bioprocesses. J Biosci Bioeng 109(5):423–432

Hoekstra AY, Chapagain AK (2007) Water footprints of nations: water use by people as a function of their consumption pattern. Water Resour Manage 21:35–48

Kalmykova Y, Harder R (2012) Pathways and management of phosphorus in urban areas. J Ind Ecol (forthcoming)

Kalmykova Y, Karlfeldt Fedje K (2012) Phosphorus recovery from municipal solid waste incineration fly ash. Under review

Karlsson P, Aarsrud P, de Blois M (2008) Återvinning av näringsämnen ur svartvatten—utvärdering projekt Skogaberg. Svenskt Vatten Utveckling, Report 2008-10

Kvarnström E, Emilsson K, Richert Stintzing A, Johansson M, Jönsson H, af Petersens E, Schönning C, Christensen J, Hellström D, Qvarnström L, Ridderstolpe P, Drangert J-O (2006) Urine diversion: one step towards sustainable sanitation. Report 2006-1, EcoSanRes

Lamprea K, Ruban V (2008) Micro pollutants in atmospheric deposition, roof runoff and storm water runoff of a suburban Catchment in Nantes, France. In: 11th International conference on urban drainage, Edinburgh, United Kingdom

Lamprecht H, Lang DJ, Binder CR, Scholz RW (2011) Animal bone disposal during the BSE crisis in Switzerland—an example of a “disposal dilemma”. Gaia 20(2):112–121

Lienert J, Bürki T, Escher B (2007) Reducing micropollutants with source control: substance flow analysis of 212 pharmaceuticals in feces and urine. Water Science Technology 56(5):87–96

Liu Y, Villalba G, Ayres RU, Schroder H (2008) Global phosphorus flows and environmental impacts from a consumption perspective. J Ind Ecol 12(2):229–247

Lundqvist J, de Fraiture C, Molden D (2008) saving water: from field to fork. Curbing losses and wastage in the food Chain. SIWI Policy Brief. Stockholm International Water Institute, Sweden

MacDonald JM, Ribaudo MO, Livingston MJ, Beckman J, Huang W (2009) Manure use for fertilizer and for energy: report to congress. Economic Research Service, United States Department of Agriculture, June

Malley DF, Ulrich AE, Watts PD (2009) Food and water security in the Lake Winnipeg Basin—transition to the future

Matsubae K, Kajiyama J, Hiraki T, Nagasaka T (2011) Virtual phosphorus ore requirement of Japanese economy. Chemosphere 84:767–772

Meinzinger F (2010) Resource efficiency of urban sanitation systems: a comparative assessment using material and energy flow analysis. Ph.D. thesis, Technischen Universität Hamburg-Harburg, Germany

Mesure S (2008) The £20 billion food mountain: britons throw away half of the food produced each year. The Independent: Sunday, 02 Mar

Monte MC, Fuente E, Blanco A, Negro C (2009) Waste management from pulp and paper production in the European Union. Waste Manage 29:293–308

Morf LS (2012) Phosphor aus Klärschlamm—Strategie des Kanton Zürichs und der Schweiz (Phosphorus from sewage sludge—the strategy of the Canton of Zürich and Switzerland), vol 45. Essner Tagung Wasser- und Abfallwirtschaft, 14–16 März 2012 in Essen (English version)

Ohtake H (2010) Biorecycle of phosphorus resource for sustainable agriculture and industry. OECD workshop on biotechnology for environment in the future: science, technology and policy, 16–17 Sept 2010

Ohtake H (ed) (2011) The coming phosphorus crisis (Rin shigen kokatsu mondai toha nanika). Handai Livre Publishing, Osaka

Olde Venterink H (2011) Legumes have a higher root phosphatase activity than other forbs, particularly under low inorganic P and N supply. Plant Soil 347(1–2):137–146

Organisation for Economic Co-operation and Development (2008) OECD environmental data: compendium 2006–2008. OECD, Paris

Ott C, Rechberger H (2012) The European phosphorus balance. Resour Conserv Recycl 60:159–172

Parfitt J, Barthel M, Macnaughton S (2010) Food waste within food supply chains: quantification and potential for change to 2050. Philos Trans R Soc B Biol Sci 365(1554):3065–3081

Petzet S, Cornel P (2010) Recycling of Phosphorus from Sewage Sludge—Options in Germany, Sonderausgaben Wasser und Abfall 1:34–36

Petzet S, Cornel P (2011) Towards a complete recycling of phosphorus in wastewater treatment—options in Germany. Water Sci Technol 64(1):29–35

Petzet S, Peplinski B, Cornel P (2012) On wet chemical phosphorus recovery from sewage sludge ash by acidic or alkaline leaching and an optimized combination of both. Water Res. doi:10.1016/j.watres.2012.1003.1068

Phosphorus Recycling Promotion Council of Japan (2008) Establishment of the phosphorus recycling promotion council of Japan. Phosphorus Recycling Promotion Council of Japan, Tokyo

Pierzynski GM, McDowell RW, Sims JT (2005) Chemistry, cycling, and potential movement of inorganic P in soils. In: Sims JT, Sharpley AN (eds) Phosphorus: agriculture and the environment. Agronomy Monograph, vol 46, pp 53–86

Remy C, Jekel M (2008) Sustainable wastewater management: life cycle assessment of conventional and source-separating urban sanitation systems. Water Sci Technol 58(8):1555–1562

Richards I, Dawson C (2008) Phosphorus imports, exports, fluxes and sinks in Europe. In: Society PotIF (ed). International Fertiliser Society

Scholz RW (2011) Environmental literacy in science and society: from knowledge to decisions. Cambridge University Press, Cambridge

Schoumans OF, Rulkens WH, Oenema O, Ehlert PAI (2010) Phosphorus recovery from animal manure: technical opportunities and agro-economical perspectives. Alterra report 2158, Alterra, Wageningen, The Netherlands

Selman M, Greenhalgh S, Diaz R, Sugg Z (2008) Eutrophication and hypoxia in coastal areas: a global assessment of the state of knowledge, eutrophication and hypoxia in coastal areas: a global assessment of the state of knowledge. World Resources Institute, Washington

Shakhramanyan N, Schneider UA, McCarl BA, Lang DJ, Schmid E (2012) The impacts of higher mineral phosphorus prices and externality taxation on the use of organic phosphorus sources in US agriculture. Working Paper IETSR-1, Institute of Ethics and Transdisciplinary Sustainability Research, University of Lüneburg, Germany

Shiroyama H, Yarime M, Matsuo M, Schroeder H, Scholz RW, Ulrich AE (2012) Governance for sustainability: knowledge integration and multi-actor dimensions in risk management. Sustain Sci 7(1):45–55

Smit AL, Bindraban PS, Schröder JJ, Conijn JG, van der Meer HG (2009) Phosphorus in agriculture: global resources, trends and developments. Report to the Steering Committee Technology Assessment of the Ministry of Agriculture, Nature and Food Quality, The Netherlands, in collaboration with the Nutrient Flow Task Group (NFTG), supported by Development Policy Review Network (DPRN). Wageningen Plant research International B.V., Wageningen

Someus E (2009) PROTECTOR—Recycling and upgrading of bone meal for environmentally friendly crop protection and nutrition. Final Report

Sustainable P Initiative (2013) Sustainable phosphorus research coordination network. Sustainable P Initiative. http://sustainablep.asu.edu/prcn. Accessed 19 Aug 2013

Sustainable Sanitation Alliance (2010) Urine and faecal wastewater separation at GTZ main office building, Eschborn, Germany. http://www.susana.org/docs_ccbk/susana_download/2-63-en-susana-cs-germany-eschbornhouse-1-2009.pdf

Tanum Kommun (2008) Urine separation. http://www.tanum.se/vanstermenykommun/miljo/toaletterochavlopp/urineseparation.4.8fc7a7104a93e5f2e8000595.html

Trencher G, Yarime M, McCormick KB, Doll CNH, Kraines SB (2013) Beyond the third mission: exploring the emerging university function of co-creation for sustainability. Science and Public Policy. doi:10.1093/scipol/sct044

U.S. Geological Survey (2012) Mineral commodity summaries 2012. U.S. Geological Survey

Ulrich AE, Malley DF, Voora V (2009) Peak phosphorus. Opportunity in the making. International Institute for Sustainable Development, Winnipeg

United States Food and Drug Administration (2008) Substances prohibited from use in animal food or feed. 21 CFR Part 589

Vinnerås B (2001) Faecal separation and urine diversion for nutrient management of household biodegradable waste and wastewater. Licentiate thesis, Swedish University of Agricultural Sciences, Uppsala

Vinneras B, Jonsson H (2002) The performance and potential of faecal separation and urine diversion to recycle plant nutrients in household wastewater. Bioresour Technol 84(3):275–282

Wajima T, Haga M, Kuzawa K, Ishimoto H, Tamada O, Ito K, Nishiyama T, Downs RT, Rakovan JF (2006) Zeolite synthesis from paper sludge ash at low temperature (90 °C) with addition of diatomite. J Hazard Mater 132:244–252

Willer H, Kilcher L (2012) The world of organic agriculture—statistics and emerging trends 2012. Research Institute of Organic Agriculture (FiBL), Frick, and International Federation of Organic Agriculture Movements (IFOAM), Bonn

Winker M (2010) Are pharmaceutical residues in urine a constraint for using urine as a fertilizer? Sustain Sanitation Pract 3:18–24

Winker M, Vinnerås B, Muskolus A, Arnold U, Clemens J (2009) Fertiliser products from new sanitation systems: their potential values and risks. Bioresour Technol 100(18):4090–4096

World Resources Institute (2012) Eutrophication and hypoxia: nutrient pollution in coastal waters. World Resources Institute, Washington. http://www.wri.org/project/eutrophication. Accessed 27 May 2012

Yarime M, Trencher G, Mino T, Scholz RW, Olsson L, Ness B, Frantzeskaki N, Rotmans J (2012) Establishing sustainability science in higher education institutions: towards an integration of academic development, institutionalization, and stakeholder collaborations. Sustain Sci 7(1):101–113

Zalouk S, Barbati S, Sergent M, Ambrosio M (2009) Disposal of animal by-products by wet air oxidation: performance optimization and kinetics. Chemosphere 74:193–199

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2014 Springer Science+Business Media Dordrecht

About this chapter

Cite this chapter

Yarime, M. et al. (2014). Dissipation and Recycling: What Losses, What Dissipation Impacts, and What Recycling Options?. In: Scholz, R., Roy, A., Brand, F., Hellums, D., Ulrich, A. (eds) Sustainable Phosphorus Management. Springer, Dordrecht. https://doi.org/10.1007/978-94-007-7250-2_6

Download citation

DOI: https://doi.org/10.1007/978-94-007-7250-2_6

Published:

Publisher Name: Springer, Dordrecht

Print ISBN: 978-94-007-7249-6

Online ISBN: 978-94-007-7250-2

eBook Packages: Earth and Environmental ScienceEarth and Environmental Science (R0)