Abstract

Gallic acid (3,4,5-trihydroxybenzoic acid, GA) which is a key component of humic acids in combination with imidazole affects the catalytic performance of pentachlorophenol (PCP) decomposition by a Fe-porphyrin catalyst via diverse mechanisms. GA can improve drastically the yield and the kinetics of the catalytic oxidation of PCP by a factor of 20. In the presence of GA, imidazole acts competitively with PCP consuming oxidative equivalents. The data of catalytic oxidation products indicate a mechanism where decomposition of PCP occurs through oxidative dechlorination, initialized by an oxo-ferryl porphyrin π-cation radical complex formed on the Fe-porphyrin catalyst.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

Introduction

Chlorinated phenols, such as pentachlorophenol (PCP), are highly toxic and resistant to biodegradation. Therefore, efficient abiotic catalytic systems are needed for the removal of such pollutants from the environment. Among the most promising are Fe-based biomimetic catalysts, mainly metalloporphyrin derivative catalysts which can mimic heme enzymes on oxidation reactions. However, unraveling the exact mechanism may be proven a laborious task. This is mainly due to the fact that a fine balance of several interactions is tuning the redox/catalytic mechanism. In our recent works, we have shown an iron porphyrin catalyst – bearing 2,6-di-tert-butylphenols at the meso-aryl positions of the porphyrin ring (FeR4P) – to be very efficient for PCP decomposition when it was immobilized on SiO2 (heterogenized catalyst, FeR4P–SiO2) (Christoforidis et al. 2007, 2010). Fukushima et al. have shown that natural polyphenols such as humic acids studied can influence the catalytic decomposition of PCP by a Fe-porphyrin complex (Fukushima and Tatsumi 2005). Gallic acid (3,4,5-trihydroxybenzoic acid, GA) has both phenolic and carboxylic character, which are the main functional groups of HA (Stevenson 1994). Given the omnipresence of small polyphenols and humics in environmental systems, it is anticipated that their role in environmental catalytic remediation should be addressed. In the present work, we show that the catalytic efficiency of the FeR4P catalyst can be dramatically influenced by additives – other than imidazole. Gallic acid was found to modulate the catalytic efficiency of FeR4P catalyst for PCP decomposition. The aims of the present work were (a) to study the effect of additives on the performance of the FeR4P catalytic complex for PCP degradation and (b) by using a combination of analytical and spectroscopic methods, to understand the various mechanistic paths implicated.

Materials and Methods

The catalyst FeR4P was synthesized as described previously (Christoforidis et al. 2007; Fukushima and Tatsumi 2005) and purified by silica gel column chromatography using CHCl3, 80% CHCl3 and 20% hexane as the eluting solvents. Electron paramagnetic resonance (EPR) spectra were recorded with a Bruker ER200D spectrometer at liquid N2 temperatures, equipped with an Agilent 5310A frequency counter. Quantitative HPLC determinations for PCP were performed with a Dionex P680 HPLC chromatograph equipped with a Dionex 1024 diode array detector. Determination of Cl− ions, released during the oxidation of PCP, was performed with a Dionex ICS-1500 Ion Chromatography System. In all cases, the reactants were added to the reaction mixture with the following order: catalyst (FeR4P), imidazole, additive (GA or Et3N), substrate (PCP) and oxidant (NaIO4). All reaction mixtures and the ratio of the reactants with respect to the catalyst are summarized in Table 1. The quantification of PCP and TCQ by HPLC and Cl− by IC was based on comparison with standards.

Results and Discussion

-

Catalytic PCP Oxidation: Effect of Gallic Acid

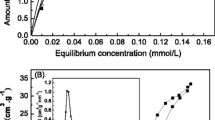

Figure 1 compares the catalytic decomposition of PCP by the FeR4P/NaIO4 system in the presence vs absence of GA. It is seen that for [FeR4P/Imid] = [1:10] in the absence of GA (Fig. 1, run 1), 11% of the initial PCP was oxidized within ~3 h. Strikingly, in the presence of GA, a dramatic enhancement of the catalytic performance was observed, resulting to full decomposition of PCP (Fig. 1, runs 2, 3 and 4). Increase of GA concentration, i.e., [FeR4P/Imid/GA] = [1:10:2], resulted to further increase of the catalytic performance, achieving complete oxidation of PCP within 80 min reaction time (Fig. 1, run 3). Runs 2 and 3 reveal that the ratio of Imid/GA plays a role in the catalytic performance. This is verified in run 4 where no imidazole was used, i.e., [FeR4P/Imid/GA] = [1:0:2]. Surprisingly, 100% oxidation of PCP was achieved within less than 45 min (Fig. 1, run 4). We underline that in all control reactions (i.e., those without the catalyst (FeR4P) or the oxidant (NaIO4) and in the presence of GA), PCP concentration remained unchanged within a period of t = 24 h (data not shown). Overall, the data in Fig. 1 show that (a) under the conditions of these experiments, GA enhances the catalytic performance of the system [FeR4P/PCP/IO4] and (b) imidazole appears to compete with GA in the catalytic mechanism.

Fig. 1 The effect of GA can be (a) due to copolymerization with PCP, i.e., oxidative coupling through radical reactions or (b) via a co-catalytic effect i.e., by enhancement of the performance of the FeR4P catalyst. Case (a) is discarded based on the following: the molar ratio of GA with respect to PCP (GA/PCP 1:10 in run 2 and 1:5 in runs 3 and 4) clearly indicates that GA cannot participate in a stoichiometric reaction with the substrate. In other words, the small GA/PCP molar ratio suggests that the enhancement of PCP disappearance cannot be due to polymerization phenomena.

This is supported by the analysis of the catalysis products, which is presented in the following:

-

Catalytic Products FeR 4 P/NaIO 4 /GA System

According to Fig. 2a, PCP disappearance is followed by the release of [Cl−] ions and formation of TCQ. The maximum [TCQ] was observed when the concentration of PCP was zero. However, dechlorination proceeded further after the complete oxidation of PCP (i.e., for t > 1.5 h). This indicates that the release of [Cl−] ions at t > 1.5 h comes from other oxidation products other than TCQ, since the [TCQ] remains unchanged for reaction time t > 1.5 (Fig. 2a).

-

EPR Spectroscopy

EPR spectroscopy (Fig. 3) shows that GA is not coordinated to the iron of FeR4P catalyst and does not displace imidazole from the coordination environment of the iron.

Fig. 3 This provides conclusive evidence that the observed competition between imidazole/GA, Fig. 1, can be attributed to a competitive role of imidazole competes vs PCP as catalytic substrate to the FeR4P/GA/NaIO4 system. At this point, it is instructive to underline that the present data preclude the – trivial – hypothesis for competition between GA and imidazole for the axial ligation to the Fe atom. Instead, a more complex picture emerges where imidazole consumes key oxidation equivalents.

References

Christoforidis, K.C., M. Louloudi, E.R. Milaeva, Y. Sanakis, and Y. Deligiannakis. 2007. EPR study of a novel [Fe–porphyrin] catalyst. Molecular Physics 105: 2185–2194.

Christoforidis, K.C., M. Louloudi, E.R. Milaeva, and Y. Deligiannakis. 2010. Mechanism of catalytic decomposition of pentachlorophenol by a highly recyclable heterogeneous SiO2–[Fe-porphyrin] catalyst. Journal of Catalysis 270: 153–162.

Fukushima, M., and K. Tatsumi. 2005. Effect of hydroxypropyl-β-cyclodextrin on the degradation of pentachlorophenol by potassium monopersulfate catalyzed with iron (III) − porphyrin complex. Environmental Science and Technology 39: 9337–9342.

Stevenson, F.J. 1994. Humus chemistry: Genesis, composition, reactions, 2nd ed. New York: Wiley.

Acknowledgments

This research has been cofinanced by the European Union (European Social Fund – ESF) and Greek national funds through the Operational Program “Education and Lifelong Learning” of the National Strategic Reference Framework (NSRF) – Research Funding Program: Thales. Investing in knowledge society through the ESF.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2013 Zhejiang University Press and Springer Science+Business Media Dordrecht

About this paper

Cite this paper

Louloudi, M., Papastergiou, M., Perlepes, S.P. (2013). Mechanisms of Co-catalytic Action of Humic-Like Additives on Pentachlorophenol Oxidation by a Fe-Porphyrin Catalyst. In: Xu, J., Wu, J., He, Y. (eds) Functions of Natural Organic Matter in Changing Environment. Springer, Dordrecht. https://doi.org/10.1007/978-94-007-5634-2_98

Download citation

DOI: https://doi.org/10.1007/978-94-007-5634-2_98

Published:

Publisher Name: Springer, Dordrecht

Print ISBN: 978-94-007-5633-5

Online ISBN: 978-94-007-5634-2

eBook Packages: Earth and Environmental ScienceEarth and Environmental Science (R0)