Abstract

Wastewater treatment high rate algal ponds fertilised with CO2 (HRAP + C system) provide a niche opportunity for algal biofuel production in combination with energy-efficient and cost-effective tertiary-level wastewater treatment. Wastewaters are excellent media (water, nutrients, alkalinity buffering) for the growth of naturally occurring algae that could be harvested by bioflocculation and low-cost gravity settling, especially when fertilised with CO2 obtained from biogas produced and used for power generation at the treatment plant. The harvested algal biomass is converted to biofuels, preferably by processes that use the entire biomass with little or no dewatering. Anaerobic digestion of the algal biomass along with settled primary sludge is the most readily available and economic technology. The wastewater treatment function can essentially cover the entire capital and operation costs of biofuel production. Additional environmental and financial incentives are due to GHG abatement and nutrient fertiliser recovery. Since wastewater treatment systems using facultative ponds are already a widely used technology for secondary-level wastewater treatment, upgrading these ponds provides an opportunity to develop and refine algal production and harvest from HRAP systems and algal biofuel conversion technologies. The HRAP + C system can produce biogas for power generation at essentially no additional cost to that incurred for wastewater treatment alone. Additional research, in particular, on selection and cultivation of superior algal strains, grazer control and cost-effective algal harvest is still required before widespread adoption of this technology is possible.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

These keywords were added by machine and not by the authors. This process is experimental and the keywords may be updated as the learning algorithm improves.

1 Municipal Wastewater Treatment Ponds

Municipal wastewater treatment ponds (called facultative ponds) rely on algal photosynthesis to convert sunlight energy, nutrients (N, P) and CO2 into algal biomass. The algae release O2 which promotes aerobic bacterial degradation of wastewater organic compounds to release more CO2 and nutrients that are, in turn, assimilated by the algae (Oswald et al., 1957; Oswald, 1988a). Facultative ponds typically have an organic loading rate of 50–100 kg BOD5 ha−1 day−1, a depth of 1–1.5 m and a hydraulic retention time of 30–60 days. Facultative pond systems (often 2–4 ponds in series) are used at many thousands of municipal, agricultural and industrial wastewater treatment facilities worldwide and provide efficient removal of wastewater solids and BOD. However, nutrient (N, P) and faecal indicator removal is often poor and highly variable, and annual algal biomass productivity (ash-free dry wt) is low at 10–15 t ha−1 year (Davies-Colley et al., 1995; Craggs et al., 2003). A major issue with facultative ponds is that the algal biomass is discharged to receiving waters in the pond effluent because current algal harvest technologies are too expensive for use at any but the largest pond systems.

2 Wastewater Treatment High Rate Algal Ponds

High rate algal ponds (HRAPs) are relatively shallow, gently mixed, raceway ponds that were developed by Oswald and colleagues as a more intensive wastewater treatment pond technology that enable much higher removal of wastewater organic compounds, nutrients and faecal indicators than facultative ponds (Oswald et al., 1957; Benemann et al., 1980; Oswald, 1988a; Craggs, 2005). As early as 1960, Oswald also proposed using wastewater treatment HRAPs for the large-scale production of algae for conversion to biofuels (Oswald and Golueke, 1960). Depending on climate, HRAPs are typically designed with an organic loading rate of between 100 and 150 kg BOD5 ha−1 day. HRAP depth, hydraulic retention time and mixing speed are the main operational control variables. HRAP depth varies with wastewater clarity (0.25–0.6 m), and may be related to hydraulic retention time which varies seasonally (with solar radiation and temperature) in temperate climates (3–4 day in summer and 7–9 day in winter).

The channelised raceway design of HRAP enables uniform, low-energy mixing (typically 0.15–0.30 m s−1) which is usually provided by a paddle wheel (Fig. 1). Mixing velocities higher than 0.3 m s−1 consume too much power (which increases as a cube function of mixing velocity), and cause scouring of the pond (when clay lined), and thus are not recommended. Horizontal mixing velocities greater than 0.15 m s−1 select for algal species which form colonies: species that are usually outcompeted in facultative ponds as the colonies settle faster than unicellular algae in quiescent water. Horizontal mixing also causes turbulent eddies that provide a vertical mixing component throughout the pond length and ensures that algal cells are intermittently exposed to sunlight as the depth of light penetration is usually only half to two-thirds of the pond depth depending on algal concentration (100–400 g m−3) and wastewater clarity.

3 Advanced Wastewater Treatment Pond Systems

Wastewater treatment HRAPs are usually a component of advanced pond systems (APS) that typically include four types of ponds that are arranged in series (Fig. 2): advanced facultative ponds that settle and anaerobically digest wastewater solids, high rate algal ponds, algal settling ponds that harvest algae by gravity sedimentation and maturation ponds that provide additional disinfection mainly through exposure to sunlight UV radiation (Oswald, 1990, 1991; Craggs, 2005). The four ponds have an overall land requirement similar to that of two-pond facultative systems (Oswald, 1996).

APS not only achieve more efficient wastewater treatment than facultative pond systems but recover resources from the wastewater through capture of biogas in the advanced facultative pond and harvest of algae in the algal settling ponds (Oswald, 1991, 1996; Green et al., 1995; Craggs, 2005). However, APS technology has only been applied for wastewater treatment in some small Northern California cities, such as St. Helena (in 1967) and Hilmar (in 2000) (Fig. 3), and a few other installations around the world. There are several reasons for the low uptake of this technology: (1) until recently, nutrient removal has not been a major requirement of the wastewater treatment plants of most cities worldwide; (2) efficient harvest of HRAP algal biomass by gravity settling could not be reliably achieved, and current algal harvest technologies are too expensive; (3) use of harvested algal biomass as a soil amendment has had little economic value due to the low cost of inorganic fertiliser; (4) there is a lack of widespread APS knowledge and design skills amongst the engineering profession; (5) although cost competitive with electromechanical treatment systems, APS require a relatively large land area; and (6) despite the high power demand of electromechanical treatment systems, operation costs are low due to the current low price of fossil fuel-derived electricity.

4 Commercial Algal Production

HRAP have much lower capital costs than closed photobioreactors but similar productivity and are therefore used to grow the majority (>90%) of current worldwide commercial algal production (for high-value nutritional products, pigments and chemicals). However, even the simplest, lowest cost HRAP (e.g. individual clay-lined ponds of >1 ha) growing algae on nutrient media with CO2 addition could not produce biofuels economically (at current and near-future fossil fuel prices) without major advances in technology, including much higher algal and biofuel productivities than presently feasible (Benemann, 2003).

5 Wastewater Treatment HRAP with CO2 Addition

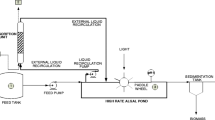

Many of the wastewater treatment issues of APS and the poor economic viability of algal biofuel production using nutrient culture medium fed HRAP could be addressed by returning to the original concept of Oswald and Golueke (1960) in which algal biofuels are produced as a by-product of wastewater treatment in HRAP (Fig. 4). Conventional primary treatment (that removes wastewater solids) is used instead of an advanced facultative pond; the HRAP wastewater treatment (especially nutrient removal) capability, algal production and algal biomass harvestability are all enhanced by CO2 addition; and the harvested algal biomass is then converted to biofuels (Benemann et al., 1978, 1980; Benemann and Oswald, 1996; Benemann, 2003).

6 Algal Production in Wastewater Treatment HRAPs

Productivity of wastewater treatment HRAPs varies with climate, local weather, wastewater strength, pond operation (e.g. depth, hydraulic retention time), dominant algal species, invertebrate grazing and infection by fungi, bacteria or viruses. Moreover, the biomass in wastewater treatment HRAP effluents is a combination of algae, bacteria and detritus formed during the wastewater treatment process. This biomass is poorly quantified but, based on microscopic observation, is typically composed of 70–90% algae. At moderate latitudes and Mediterranean climates, annual biomass productivities for wastewater treatment HRAPs are typically 30 t ha−1 year which are 2–3 times that of facultative ponds (10–15 t ha−1 year). Pilot-scale HRAPs treating domestic wastewater in New Zealand had productivities of about 30 t ha−1 year (Craggs et al., 2003), and somewhat higher productivities were reported in California (Benemann et al., 1980). However, algal productivity in wastewater treatment HRAP is depressed by severe carbon limitation, indicated by high daytime pond water pH levels (typically above 10), due to photosynthetic uptake of CO2 and bicarbonate (Oswald, 1988a; Garcia et al., 2000; Craggs, 2005; Kong et al., 2010; Park and Craggs, 2010).

Carbon limitation is due, in part, to the low C:N ratio of wastewaters (typically 3:1 to 4:1 for municipal wastewater) compared to algal biomass (typically 6:1, ranging from 10:1 to 5:1 depending on whether N is limiting or not) (Benemann et al., 1980; Lundquist, 2008). Thus, domestic wastewaters contain insufficient C to remove all the N (and P) by direct assimilation into algal biomass. More importantly, C limitation, and the concomitant rise in pond water pH above 8.5, severely depresses the growth rates and productivity of algae (Weissman and Goebel, 1987; Kong et al., 2010). Although, by using available bicarbonate, some algal species are able to grow (with low productivity) even above pH 10. The inhibition of algal growth at high pH in wastewater treatment HRAP could also be in part due to high levels of free ammonia at high pH (Azov and Goldman, 1982; Azov et al., 1982; Konig et al., 1987). Further, intense photosynthesis in HRAPs also increases daytime dissolved O2 levels, typically to 200–300% saturation, while supersaturation of oxygen promotes bacterial degradation of wastewater organic compounds, it can inhibit algal productivity, particularly at high pH and carbon limitation (Weissman et al., 1988). High pond pH, above ∼8.5, can also inhibit the growth of aerobic heterotrophic bacteria that oxidise wastewater organic matter to CO2 (Craggs, 2005). This sets up a feedback loop, which amplifies the effect of high pH and carbon limitation.

Addition of CO2 to wastewater treatment HRAPs increases carbon availability and enables pond water pH to be maintained at an optimum (pH 7.5–8.5) for both algae and bacteria. The biomass productivity of wastewater treatment HRAPs can potentially be doubled with CO2 addition to 60 t ha−1 year, of which perhaps 20% of the measured volatile suspended solids is non-algal (bacterial and detrital) biomass, as observed in small-scale trials (Benemann et al., 1980; Azov et al., 1982; Lundquist, 2008). Recent pilot-scale research during New Zealand summer conditions has shown that CO2 addition to wastewater HRAP can increase algal biomass production by up to 100%, with projected productivities of 60 t ha−1 year (Heubeck et al., 2007; Park and Craggs, 2010). CO2 addition also promotes nutrient removal by assimilation into algal biomass.

For wastewater treatment HRAPs, any available source of CO2 could be used, the most likely being the flue gas from an electricity generator using biogas produced by anaerobic digestion of wastewater solids (“primary sewage sludge”) and algal biomass harvested from the HRAPs (Eisenberg et al., 1981; Benemann, 2003). Pond water can also be used to directly purify biogas (e.g. scrub CO2 and H2S) (Conde et al., 1993; Mandeno et al., 2005), if the biogas needs to be compressed for use as vehicular fuel or for addition to a natural gas pipeline. However, loss of methane (a potent greenhouse gas) in the scrubbing water is an issue that needs to be resolved for biogas water scrubbing processes.

The algal biomass production potential (t/ML of wastewater) in wastewater treatment HRAPs is directly related to C utilisation, both from the wastewater and any added CO2. With CO2 addition, nutrients (N, P) can be assimilated to the maximum extent possible. Productivity and thus nutrient removal are limited mainly by daily solar radiation and temperature, and winter values determine the area necessary for effective year-round wastewater treatment, which increases with increasing latitude (Oswald et al., 1957; Bouterfas et al., 2002; Jeon et al., 2005; Voltolina et al., 2005).

Further algal productivity increases, beyond those that could be achieved through CO2 addition, are desirable to reduce the area of the wastewater treatment HRAP system and thus improve the economics of both wastewater treatment and wastewater algal biofuels production. It must be noted that further increasing productivity would not increase the amount of algal biomass produced, as that is limited by the amounts of nutrients present in the wastewater and assimilated into the biomass, but increasing productivity will reduce the area of ponds required. One necessary, but not sufficient, approach to increase algal productivity is to select for algal strains that thrive in the HRAP environment – high sunlight, diurnal temperature fluctuations and supersaturated dissolved O2 (Weissman et al., 1988).

Achieving high productivity also requires dealing with herbivorous zooplankton such as rotifers and cladocerans, which graze on algae and can rapidly proliferate and reduce algal biomass concentrations to low levels within a few days (Benemann et al., 1980; Picot et al., 1991; Cauchie et al., 1995; Nurdogan and Oswald, 1995; Smith et al., 2009). For example, rotifers and cladocerans at densities greater than 100 L−1 were reported to reduce the algal concentration in a wastewater treatment HRAP by 90% within two days (Oswald, 1980), and several days of grazing by a population of the cladoceran, Daphnia sp., reduced the chlorophyll a concentration of a pond by 99% (Cauchie et al., 1995). Algae are also susceptible to fungal parasitism and bacterial or viral infection which can deplete the pond algal population within a few days and result in changes in algal morphology, species diversity and succession (Wommack and Colwell, 2000; Short and Suttle, 2002; Kagami et al., 2007).

Therefore, to maximise HRAP algal productivity, populations of zooplankton grazers, parasitic fungi and infective bacteria and viruses must be controlled. Zooplankton grazer populations may be limited by application of chemicals or invertebrate hormone mimics or by increasing pond water pH to 11, particularly if the pond water has a high ammoniacal-N concentration (O’Brien and De Noyelles, 1972; Schluter and Groeneweg, 1981; Oswald, 1988b). There are no practical control methods yet for fungal parasitism or bacterial and viral infections, and further research is required to fully understand their influence on algal productivity in wastewater treatment HRAP.

7 Performance of Wastewater Treatment HRAP with CO2 Addition (HRAP + C System)

The HRAP with CO2 addition (HRAP + C) system can be used to provide more effective aerobic treatment (oxidation of wastewater organic compounds, BOD) and improved removal of nutrients, faecal indicators and algal biomass than both facultative pond systems and advanced pond systems. Moreover, the HRAP + C system is much more cost-effective and energy efficient than electromechanical wastewater treatment technologies providing an equivalent level of wastewater treatment. A 5 ha wastewater treatment HRAP + C system was successfully operated in Christchurch, New Zealand (Fig. 5), to demonstrate upgrading facultative ponds and production of algae for whole biomass conversion to biofuel using a near critical water reactor (NCWR).

7.1 Aerobic Treatment

Although some aeration is provided by paddle wheel mixing, daytime supersaturated dissolved O2 levels resulting from algal photosynthesis in the HRAP + C system enable very efficient aerobic treatment (organic matter degradation). The power required for HRAP paddle wheel mixing depends mainly on mixing velocity. For an HRAP with a water depth of 0.3 m and a horizontal flow velocity of 0.15 m s−1, the power required to operate the paddle wheel is ∼15 kW ha−1. The aeration efficiency of HRAP varies between 0.05 and 0.20 kWhe kg−1 O2 produced depending on season, insolation and other factors (Benemann et al., 1980; Oswald, 1988b; Green et al., 1995). For a wastewater with BOD5 concentration of 200 g m−3, this equates to a power requirement of between 15 and 60 kWhe ML−1. In comparison, activated sludge requires from 230 to 970 kWhe ML−1 (based on the efficiency of different types of aerators: 0.4 to 1.7 kWhe kg−1 O2) (Owen, 1982; Metcalf and Eddy, Inc., 1991; Green et al., 1995).

7.2 Algal Nitrogen Removal

Nitrogen removal by nitrification-denitrification is a common electromechanical nutrient removal process, but it is costly and energy intensive. A typical wastewater primary effluent (after settling) with an organic nitrogen concentration of 40 g N m−3 would require aeration energy of ∼400–1,000 kWhe ML−1 of wastewater for the nitrification step alone (this is in addition to that required for BOD removal) (Owen, 1982). The HRAP + C system, where sufficient land is available, could provide low-energy tertiary-level nutrient removal, for little more energy than an HRAP designed for BOD removal (Benemann et al., 1978; Eisenberg et al., 1981; Nurdogan and Oswald, 1995; Woertz, 2007; Park and Craggs, 2010). For example, assuming a 3:1 C:N ratio in the wastewater, a 6:1 C:N ratio for algal biomass (48% C, 8% N) and no change in CO2:O2 stoichiometry, a doubling (100% increase) in biomass production resulting from CO2 addition could enable complete nitrogen removal (Heubeck et al., 2007; Park and Craggs, 2010).

7.3 Algal Phosphorus Removal

Algal biomass can exhibit N:P ratios ranging from nearly 4:1 (under nitrogen-limiting conditions) to about 30:1. These N:P ratios correspond to algal N and P compositions ranging from a high of 8% N and about 1% P to a low of about 4% N and 0.35% P (under nitrogen- or phosphate-limiting conditions, respectively). Near-complete assimilation of both N and P into algal biomass from wastewaters with a large range of concentrations of these nutrients is therefore theoretically possible in HRAP with CO2 addition (Benemann, 2003) and has been recently demonstrated experimentally by Woertz et al. (2009) and at pilot-scale by Park and Craggs (2010,2011). Nutrient assimilation rates can reach 16 kg N ha−1 day and 2 kg P ha−1 day, based on the typical algal nutrient composition of 8% N and 1% P, and an average productivity of 20 g m−2 day of algal biomass. These removals are achieved at much lower capital and operation costs compared to conventional electromechanical treatment technologies (Owen, 1982; Craggs et al., 1999). A key issue for tertiary-level nutrient removal is that the algal cultures have the ability to maintain high productivity when dissolved N has been reduced to low levels (e.g. <1 g m−3). This is based on the fact that it is the internal, not external, nutrient concentration which determines growth rates and productivity, and nutrients are supplied continuously in the influent wastewater (Benemann, 2003; Woertz et al., 2009). In temperate locations, seasonal variation in algal productivity will limit nutrient removal by assimilation into algal biomass during winter.

7.4 Algae Augmented Nutrient Removal Processes

Nutrient removal processes such as ammonia volatilisation and phosphate precipitation with cations occur in wastewater treatment HRAPs without CO2 addition, when intense daytime algal photosynthesis results in CO2 limitation and increases the pond water pH (Nurdogan and Oswald, 1995; Garcia et al., 2000; Craggs et al., 2003; Heubeck et al., 2007). However, these processes are greatly reduced by CO2 addition to the ponds. For example, Park and Craggs (2011) demonstrated that daytime control of maximum pH to below 8 with CO2 addition reduced nitrogen loss by ammonia volatilisation from 24% (in a control HRAP without CO2 addition) to ∼9%.

7.5 Disinfection

Disinfection of wastewater treatment plant effluent is typically provided by chlorination, ozonation or UV treatment. Chlorination requires 20–540 kWhe ML−1 to generate chlorine, depending on the organic content of the effluent (Owen, 1982). Therefore, if the algal biomass is not efficiently harvested, chlorine requirements are high. Ozonation (100–200 kWhe ML−1) and UV (20–100 kWhe ML−1) use less power, but UV requires a very low turbidity effluent and thus a high level of algal removal (Owen, 1982). HRAPs promote natural disinfection mechanisms driven by sunlight, augmented by daytime supersaturated O2 levels (100–300%) due to algal photosynthesis (Davies-Colley, 2005).

8 Harvesting Wastewater Treatment HRAP Algae

Effective and low-cost removal of algal biomass from HRAP effluent is imperative to achieve both a high effluent quality and an economically competitive wastewater treatment process. HRAP algal harvesting is challenging due to (1) low and varying solid concentration (typically 0.01% to 0.04% solids), (2) cell densities similar to water (1.08–1.13 kg L−1), (3) small cell size (5–25 μm) and (4) strong negative surface charge. The latter (known as “zeta potential”) may be associated with exponential growth (Moraine et al., 1979; Lavoie and de la Noue, 1987).

Various harvesting methods have been applied over the years, the main ones being (1) centrifugation (energy intensive, ∼1 kWhe m−3 pond water or ∼2–3 kWhe kg−1 algae), (2) filtration (ineffective due to clogging of filters and/or high cost), (3) microstraining (only effective for filamentous or large colonial algae) and (4) chemical flocculation followed by sedimentation or dissolved air flotation (DAF) (Oswald and Golueke, 1960; Benemann et al., 1980; Benemann and Oswald, 1996; Shen et al., 2009; Tampier, 2009; Brennan and Owende, 2010; Mata et al., 2010). However, these processes are either not applicable to the algae growing in wastewater treatment HRAP (e.g. filtration) or are too expensive (centrifugation, chemical flocculation).

The process currently employed for algal biomass removal from large facultative oxidation pond effluents is chemical flocculation (using lime, alum, ferric chloride, cationic polyacrylamides, etc.) to form large (1–5 mm) flocs that can be removed by simple settling or by dissolved air flotation (DAF). DAF provides somewhat higher concentration of solids and uses less flocculating chemicals but adds a further ∼0.6 kWhe kg−1 algae for air compression. The large amounts of chemical flocculants required are expensive and make it difficult to use the algal biomass, even in anaerobic digestion. Thus, the chemically flocculated algal sludge is typically disposed of either back to the ponds (long-term storage) or to landfill. Centrifugation provides a high-solids biomass, of about 20–25% solids, but the high capital cost and operating energy requirements of centrifugation make this process economically viable only for secondary thickening of harvested algae which already has a 2–4% solid concentration. The challenge is thus to develop a low-cost harvesting method that can produce algal biomass with such a solid concentration.

Wastewater treatment HRAPs select for particular genera of green algae, including Scenedesmus sp., Micractinium sp., Actinastrum sp., Pediastrum sp., Dictyosphaerium sp. and Coelastrum sp., that often form large (50–200 μm) colonies (Benemann et al., 1980; Oswald, 1988a; Banat et al., 1990; Green et al., 1996; Wells, 2005; Heubeck et al., 2007; Park and Craggs, 2010). Microstraining was first proposed as a low-cost harvest method for the large algal colonies (Benemann et al., 1978). However, it was observed that algae removed from the ponds, under quiescent conditions, could self-flocculate, aggregating to form large flocs (“bioflocculation”), and settle with over 90% solid removal (Benemann et al., 1980; Craggs et al., 2003). This bioflocculation phenomenon is not well understood, but it has been observed with many algae and growth conditions. Bioflocculation can produce a concentrated algal biomass slurry (3–4% DM) and may be promoted by stress conditions, such as nutrient (e.g. N) limitation, or by recycling some of the settled algal biomass (Benemann et al., 1980; Eisenberg et al., 1981; Park and Craggs, 2010). Further research is required to understand and perfect this low-cost harvest process and increase its reliability.

9 Biofuels Production from Wastewater Treatment HRAP Algal Biomass

Conversion of algal biomass harvested from wastewater treatment HRAPs to biofuels could involve one or a combination of four main pathways, discussed briefly below:

-

1.

Anaerobic digestion to produce biogas (methane and CO2).

-

2.

Extraction and conversion of algal lipids (oils) to biodiesel, green diesel, etc.

-

3.

Fermentation of algal carbohydrates to ethanol.

-

4.

Near-critical water catalytic conversion, gasification or pyrolysis of algal biomass to produce hydrocarbon gases and/or biocrude oils.

9.1 Anaerobic Digestion to Biogas Methane

Harvested algal biomass (or the algal residues remaining after oil extraction or ethanol fermentation, see below) can be anaerobically digested to produce biogas (60–80% methane, balance CO2), with a typical yield similar to that of heated mixed digesters (0.30–0.45 m3 CH4 kg−1 added algal volatile solids, VS), usually with 50–60% volatile solid conversion (Golueke and Oswald, 1959; Eisenberg et al., 1981; Lundquist et al., 2010; Sukias and Craggs, 2011). Lower yields, compared to other organic substrates, have been attributed to both the relatively refractory nature of algal cell walls and ammonia inhibition. Pretreatment (e.g. heating) of algal biomass has been shown to improve digestibility under mesophylic conditions (Chen and Oswald, 1998). Inhibition of anaerobic digestion can occur at free ammonia concentrations above 4,000–6,000 g NH3–N m−3 (Siegrist et al., 2005). Algal biomass contains typically 8% N of which up to 70% may be released as ammonia during digestion (Golueke and Oswald, 1959). Ammonia toxicity of algal digestion could be overcome by (1) concentrating algal biomass to no more than 5% solids prior to anaerobic digestion (to maintain ammonia levels below 3,000 g m−3), (2) co-digestion with low N organic wastes (e.g. wastepaper, primary sewage sludge) or (3) adaptation of the methanogenic bacterial inoculum to higher ammonia levels. All three options could be applied simultaneously. Co-digestion of HRAP algae biomass with primary sewage sludge can be readily demonstrated (Heubeck et al., 2007; Lundquist et al., 2010) and is similar to electromechanical wastewater treatment plant co-digestion of primary and secondary sludges. Addition of other available wastes (e.g. wastepaper, Yen and Brune, 2007) increases methane production but would need to be justified economically based on tipping fees received and value of the methane, minus other values of wastepaper use and any additional cost of digestate disposal. Cost-effective anaerobic digestion could be achieved using simple covered digester ponds, which could be fed with algal biomass harvested by bioflocculation (typically 3–4% solids concentration), compared to the 5–10% solids required for conventional, and more expensive, mesophylic heated mixed digesters.

9.1.1 Uses of Biogas

Biogas methane has an energy content of 33.8 MJ m−3 (0.67 kg) CH4 at STP (equivalent to about 1 L of petrol) and can be used directly for heating (9.39 kWhheat m−3 CH4) or for electricity generation at 30% conversion efficiency (2.82 kWhe m−3 CH4 and simultaneous heat generation ∼4.70 kWhheat m−3 CH4). Essentially ∼1 kWhe can be generated from the biogas produced from 1 kg algae assuming a yield of 0.35 m−3 CH4/kg of VS of algal biomass added (Oswald, 1988a, b). This power can be used to displace electricity requirements of the wastewater treatment plant, with any surplus exported to the grid (though this would require additional capital investment for transformers, line upgrades, etc). Biogas can also be cleaned (desulphurised, stripped of CO2), dried and compressed (>20 MPa) for export into natural gas pipelines or use as transport fuel. However, loss of methane (a potent greenhouse gas) in the scrubbing water is an issue that needs to be resolved. For wastewater treatment plants, power generation is the most widely applicable and lowest cost option.

9.2 Transesterification of Algal Oil to Biodiesel

Biodiesel production from oils extracted from algae grown in HRAPs (though not on wastewaters) was the main research focus of the 1980–1996 US Dept. of Energy Aquatic Species Program (ASP) (Sheehan et al., 1998). The ASP projected that in suitable climates, algae could have higher oil yields than most terrestrial crop plants, due to their potential high productivity, of up to 100 t algae dry matter ha−1 year, with up to 50% oil (as triglycerides) content thought to be attainable (Benemann and Oswald, 1996). However, these productivities and oil contents were long-term, speculative projections, with currently achievable values for both productivity and oil content perhaps only half of these values. Moreover, they are dependent on the algal species and even more importantly on strains of species, and with culture conditions, e.g. nitrogen limitation, which often greatly increases oil content of the algae, but not productivity (Feinberg, 1984; Coleman et al., 1987; Cooksey et al., 1987; Benemann and Tillett, 1988; Chelf, 1990; Weyer et al., 2010; Brennan and Owende, 2010). How to simultaneously maximise oil content and productivity is one of the major unresolved problems in algal biofuels production and has not yet been practically shown at scale.

9.2.1 Algal Oil Extraction

Another major issue is the economical extraction of the oil from the algae. Benemann and Oswald (1996) proposed a process involving cell breakage, homogenisation and centrifugation to recover the oil, and much work is ongoing in this area. If drying of the biomass is required, this will add significantly to the overall costs, even for sun or waste heat drying (the only plausible methods). Also, algal oils are not pure triglycerides, but generally contain large amounts of free fatty acids and mono- and diglycerides that are not suitable for direct transesterification (Feinberg, 1984). Further, a high proportion of fatty acids in algae are polyunsaturated, often long-chain, fatty acids that are not suitable for biodiesel production. Therefore, processes that recover and can use all algal lipids classes (mono-, di-, triglycerides, etc.) are of particular interest. In the case of algal biomass grown on wastewaters, harvested algae typically contain 20–30% oil. Maximising oil content, yield or quality would not be a priority, as any oil co-product would only be part of the revenue stream, with the residues anaerobically digested to produce biogas.

9.3 Fermentation of Carbohydrate to Bioethanol

Bioethanol (and biobutanol, although not yet commercialised) could be produced from the fermentable carbohydrate (e.g. starch) portion of algal biomass by conventional yeast fermentation, followed by distillation. However, the carbohydrate content of algal biomass (typically less than 20% of dry matter) is too low for practical ethanol fermentation. As in the case of algal oil production, a higher content of fermentable carbohydrates can be induced by nitrogen (and other nutrient) limitation, depending on the species and strain of algae used. Production of algal biomass with a high starch (e.g. 70%) content, at high productivity, appears to be more feasible than production of algal oils. However, this option has received relatively little attention.

9.4 Near-Critical Thermochemical Conversion

Wet algal biomass (75–95% water content) may be converted to hydrocarbon gases and biocrude oil at high pressure (>20 MPa) and temperature (>300°C) in the presence of a catalyst (Chandler et al., 1998; Yesodharan, 2002; Matsumura et al., 2005). This conversion technology has the similar advantage to anaerobic digestion, in that the algal biomass does not have to be dried, the entire biomass can be converted into biofuels and that the nutrients (in particular N) can be recovered in the process water and are not emitted to the atmosphere as in conventional thermochemical, including combustion, processes. However, more research is required to demonstrate the viability of this technology.

10 Economics of Algal Wastewater Treatment and Biofuels Production with HRAP + C

Capital and operating costs of advanced pond systems for secondary wastewater treatment (BOD5 removal) (Figs. 2 and 3) are estimated to be only a quarter to a third those of electromechanical secondary-level activated sludge treatment (Green et al., 1995; Downing et al., 2002). Similar or even lower ratios would likely apply in comparing tertiary treatment (nutrient removal) with the HRAP + C system to electromechanical systems that achieve nutrient removal. By replacing the advanced facultative pond and the algal settling ponds of an advanced pond system with conventional primary sedimentation and a bioflocculation settling process for algal removal, respectively, the HRAP + C system would have no more, and possibly less, land area. For the HRAP + C system, the capital and operating costs of algal production and harvesting are essentially fully covered by the wastewater treatment function, with biofuels a relatively minor co-product, which does not significantly impact the overall HRAP + C system economics.

11 Environmental Benefits of HRAP + C Wastewater Treatment and Biofuels Production

Beyond economics, algal wastewater treatment with coproduction of biofuels has fewer environmental impacts (“footprint”) in terms of land, water, energy and fertiliser use than schemes for algal biomass production exclusively for biofuels (Borowitzka, 1999, 2005; Benemann, 2003; Tampier, 2009; Clarens et al., 2010). The environmental benefits, from greenhouse gas (GHG) abatement and sustainability in general, also strongly favour HRAP + C systems compared to electromechanical treatment processes (typically advanced activated sludge systems). Algal biofuel production from wastewater treatment HRAP with CO2 addition abates GHG emissions by several mechanisms (Benemann, 2003; Lundquist et al., 2010):

-

Reduction in energy use (mostly electricity and GHG emissions from fossil fuel used for generation) compared with electromechanical wastewater treatment processes. By using sunlight energy and photosynthesis, HRAP + C wastewater treatment systems abate between 100 and 400 kg of CO2 ML−1 treated, compared to fossil energy that would have powered electromechanical treatment (e.g. activated sludge; Green et al., 1995; Benemann, 2003). Nitrogen removal in HRAP + C would abate a further 100–400 kg of CO2 ML−1 treated, compared to conventional processes. The solar disinfection also provided by the HRAP + C system decreases the need for GHG emission from the chemicals and power used by other disinfection processes.

-

Substitution of biofuels for fossil fuels (such as biogas-generated electricity) offsets GHG emission from fossil fuel use for generation. GHG abatement resulting from biofuels replacing fossil fuels depends on the source of power and specific fuel being replaced. For example, generation of electricity from biogas methane abates 0.4 kg CO2 kWh −1e from natural gas electricity generation compared to about 0.8 kg for CO2 kWh −1e from coal electricity generation (NZMED, 2007). Assuming an intermediate value between natural gas and coal, as well as 1,000 kWh generated from the biogas produced by 1 t of algal biomass, 0.6 t of CO2 could be abated per tonne of algae produced.

-

Use of recovered wastewater nutrients and carbon in algal biofuel residues as fertiliser offsets GHG emissions associated with nitrogenous fertiliser production and phosphate rock mining. Recycling algal biomass (∼8% N, ∼1% P) or nutrient-rich residues following biofuel conversion for fertiliser use would reduce the need for synthesis of ammonia fertilisers and mining of phosphate rock. The energy required for the manufacture of 1 kg of N fertiliser (as ammonia) is about 16 kWh (mostly natural gas, with emissions of 3.15 kg CO2EQV) and the mining and processing of 1 kg of P (as phosphate) fertiliser requires the equivalent of 4.5 kWh of fuel (mostly liquid fuels, with emissions of 1.4 kg CO2EQV) (West and Marland, 2001; Wood and Cowie, 2004). Therefore, the use of 1 kg of algae (8% N, 1% P) as fertiliser would reduce CO2 emissions from inorganic fertiliser manufacture by about 0.27 kg CO2EQV.

-

Reduced GHGs emitted during conventional electromechanical wastewater treatment, such as methane and nitrous oxide.

12 Conclusions

Municipal wastewater treatment using HRAPs with CO2 addition, and with algal biofuels as coproducts – the HRAP + C system – provides the potential for energy-efficient and effective tertiary-level wastewater treatment at significantly lower costs compared to electromechanical technologies. Wastewater enriched with flue gas CO2 is an excellent growth medium (water, nutrients and buffering) for naturally occurring algae. Bioflocculation of algal biomass followed by settling is a very promising low-cost approach to algal harvesting, but further research is required to demonstrate it at a full-scale with year-round reliability. Of the several pathways to convert harvested algal biomass to biofuel, those that use the whole algal biomass and require little or no dewatering of the harvested algae appear to be most appropriate for use in combination with wastewater treatment. In particular, anaerobic digestion of algal biomass along with the settled wastewater solids would be the easiest to apply as the capital and operation costs of anaerobic digestion, and biogas use infrastructure would be funded by the wastewater treatment plant. Harvesting algae from wastewater treatment HRAP effluent enables recovery of wastewater nutrients that can be recycled as fertiliser after biofuel conversion. Wastewater treatment HRAP also provides GHG abatement from a combination of low-energy wastewater treatment, renewable fuel production and fertiliser recovery. Since the HRAP + C system is already a viable technology for near tertiary-level wastewater treatment, it could provide a “testing ground” to develop and refine full-scale algal production, harvest and biofuel conversion technologies that may be implemented in the future when higher fossil fuel costs make stand-alone HRAP systems for biofuel production economical.

References

Azov Y, Goldman JC (1982) Free ammonia inhibition of algal photosynthesis in intensive cultures. Appl Environ Microbiol 43:735–739

Azov Y, Shelef G, Moraine R (1982) Carbon limitation of biomass production in high-rate oxidation ponds. Biotechnol Bioeng 24:579–594

Banat I, Puskas K, Esen I, Daher RA (1990) Wastewater treatment and algal productivity in an integrated ponding system. Biol Wastes 32:265–275

Benemann JR (2003) Biofixation of CO2 and greenhouse gas abatement with algae – technology roadmap. Report No. 7010000926. Prepared for the U.S. Department of Energy National Energy Technology Laboratory, Morgantown

Benemann JR, Oswald WJ (1996) Systems and economic analysis of algae ponds for conversion of CO2 to biomass. Final report. US DOE-NETL No. DOE/PC/93204-T5. Prepared for the Energy Technology Center, Pittsburgh.

Benemann JR, Tillett DM (1988) Lipid productivity and species competition in laboratory models of algae mass cultures. Prepared for the U.S. Department of Energy Solar Energy Research Institute, Golden, Colorada. Report No. 40413606

Benemann JR, Koopman BL, Baker DC, Goebel RP, Oswald WJ (1978) Design of the algal pond subsystem of the photosynthetic energy factory. Final report for the US Energy Research and Development Administration Contract Number EX-76-(−01-2548). Report No. 78–4. SERL, Boulder

Benemann JR, Koopman BL, Weissman JC, Eisenberg DM, Goebel P (1980) Development of algae harvesting and high rate pond technologies in California. In: Shelef G, Soeder CJ (eds) Algae biomass: production and use. Elsvier North Holland Press, Amsterdam, pp 457–496

Borowitzka MA (1999) Commercial production of algae: ponds, tanks, tubes and fermenters. J Biotechnol 70:313–321

Borowitzka MA (2005) Culturing algae in outdoor ponds. In: Andersen IRA (ed) Algal culturing techniques. Elsevier/Academic Press, New York, pp 205–218

Bouterfas R, Belkoura M, Dauta A (2002) Light and temperature effects on the growth rate of three freshwater algae isolated from a eutrophic lake. Hydrobiologia 489:207–217

Brennan L, Owende P (2010) Biofuels from algae – a review of technologies for production, processing, and extractions of biofuels and co-products. Renew Sustain Energy Rev 14:557–577

Cauchie HM, Hoffmann L, Jaspar-Versali MF, Salvia M, Thomé JP (1995) Daphnia magna Straus living in an aerated sewage lagoon as a source of chitin: ecological aspects. J Zool 125:67–78

Chandler K, Liotta CL, Eckert CA, Schiraldi D (1998) Tuning alkylation reactions with temperature in near-critical water. AICHE J 44:2080–2087

Chelf P (1990) Environmental control of lipid and biomass production in two diatom species. J Appl Phycol 2:121–129

Chen P, Oswald WJ (1998) Thermochemical treatment for algal fermentation. Environ Int 24(8):889–897

Clarens AF, Resurreccion EP, White MA, Colosi LM (2010) Environmental Life Cycle Comparison of Algae to Other Bioenergy Feedstocks. Environ Sci Technol 44:1813–1819

Coleman LW, Rosen BH, Schwartzbach SD (1987) Biochemistry of neutral lipid synthesis in algae. In: Johnson DA (ed) FY 1986 aquatic species program annual report. Solar Energy Research Institute, Golden, SERI/SP-231-3071, 255

Conde JL, Moro LE, Travieso L, Sanchez EP, Leiva A, Dupeiron R, Escobedo R (1993) Biogas purification using intensive algae cultures. Biotechnol Lett 15(3):317–320

Cooksey KE, Guckert JB, Williams SA, Collis PR (1987) Fluorometric determination of the neutral lipid content of algal cells using Nile Red. J Microbiol Methods 6:333–345

Craggs RJ (2005) Advanced integrated wastewater ponds. In: Shilton A (ed) Pond treatment technology. IWA scientific and technical report series. IWA, London, pp 282–310

Craggs RJ, Green FB, Oswald WJ (1999) Economic and energy requirements of advanced integrated wastewater pond systems (AIWPS). In: Proceedings of the NZWWA annual conference, pp 1–7

Craggs RJ, Davies-Colley RJ, Tanner CC, Sukias JPS (2003) Advanced ponds systems: performance with high rate ponds of different depths and areas. Water Sci Technol 48(2):259–267

Davies-Colley RJ (2005) Pond disinfection. In: Shilton A (ed) Pond treatment technology. IWA scientific and technical report series. IWA, London, pp 100–136

Davies-Colley RJ, Hickey CW, Quinn JM (1995) Organic matter, nutrients and optical characteristics of sewage lagoon effluents. N Z J Mar Freshw Res 29:235–250

Downing JB, Bracco E, Green FB, Ku AY, Lundquist TJ, Zubieta IX, Oswald WJ (2002) Low cost reclamation using the advanced integrated wastewater pond systems technology and reverse osmosis. Water Sci Technol 45(1):117–125

Eisenberg DM, Koopman BL, Benemann JR, Oswald WJ (1981) Algal bioflocculation and energy conservation in algae sewage ponds. Bioeng Biotechnol 11:429–448

Feinberg DA (1984) Technical and economic analysis of liquid fuel production from microalgae. Prepared for the Solar Energy Research Institute, Golden

Garcia J, Mujeriego R, Hernandez-Marine M (2000) High rate algal pond operating strategies for urban wastewater nitrogen removal. J Appl Phycol 12:331–339

Golueke CG, Oswald WJ (1959) Biological conversion of light energy to the chemical energy of methane. Biol Convers Light Energy 7:219–227

Green FB, Lundquist TJ, Oswald WJ (1995) Energetics of advanced integrated wastewater pond systems. Water Sci Technol 31(12):9–20

Green FB, Bernstone L, Lundquist TJ, Oswald WJ (1996) Advanced integrated wastewater pond systems for nitrogen removal. Water Sci Technol 33(7):207–217

Heubeck S, Craggs RJ, Shilton A (2007) Influence of CO2 scrubbing from biogas on the treatment performance of a high rate algal pond. Water Sci Technol 55(11):193–200

Jeon YC, Cho CW, Yun YS (2005) Measurement of algal photosynthetic activity depending on light intensity and quality. Biochem Eng J 27:127–131

Kagami M, de Bruin A, Ibelings B, Van Donk E (2007) Parasitic chytrids: their effects on phytoplankton communities and food-web dynamics. Hydrobiologia 578:113–129

Kong Q-X, Li L, Martinez B, Chen P, Ruan R (2010) Culture of Algae Chlamydomonas reinhardtii in Wastewater for Biomass Feedstock Production. Appl Biochem Biotechnol 160:9–18

Konig A, Pearson HW, Silva SA (1987) Ammonia toxicity to algal growth in waste stabilisation ponds. Water Sci Technol 19(12):115–122

Lavoie A, de la Noue J (1987) Harvesting of Scenedesmus obliquus in wastewaters: auto- or bioflocculation. Biotechnol Bioeng 30:852–859

Lundquist TJ (2008) Production of algae in conjunction with wastewater treatment. In: Proceedings of the 11th international conference on applied phycology, National University of Ireland, Galway, 22–27 June 2008

Lundquist TJ, Woertz IC, Quinn NWT, Benemann JR (2010) A realistic technological and economic assessment of algae biofuels. Report prepared for the BP Energy Biosciences Institute, Berkeley, p 154

Mandeno G, Craggs R, Tanner C, Sukias J, Webster-Brown J (2005) Potential biogas scrubbing using a high rate pond. Water Sci Technol 51(12):153–161

Mata TM, Martins AA, Caetano NS (2010) Algae for biodiesel production and other applications: a review. Renew Sustain Energy Rev 14:217–232

Matsumura Y, Minowa T, Potic B, Kersten S, Prins W, van Swaaij W, van de Beld B, Elliott D, Neuenschwander G, Kruse A, Antal M (2005) Biomass gasification in near- and super-critical water: status and prospects. Biomass Bioenergy 29(4):269–292

Metcalf & Eddy, Inc. (1991) Wastewater engineering: treatment, disposal, and reuse, 3rd edn. McGraw-Hill Inc., New York

Moraine R, Shelef G, Meydan A, Levi A (1979) Algal single cell protein from wastewater treatment and renovation process. Biotechnol Bioeng 21:1191–1207

New Zealand Ministry of Economic Development (2007) New Zealand energy greenhouse gas emissions 1990–2006. Report. Wellington, New Zealand

Nurdogan Y, Oswald WJ (1995) Enhanced nutrient removal in high rate ponds. Water Sci Technol 31(12):33–43

O’Brien WJ, De Noyelles F (1972) Photosynthetically elevated pH as a factor in zooplankton mortality in nutrient enriched ponds. Ecology 53:605–624

Oswald WJ (1980) Algal production – problems, achievements and potential. In: Shelef G, Soeder CJ (eds) Algae biomass. Elsevier North/Holland/Biomedical Press, Amsterdam, pp 1–8

Oswald WJ (1988a) Micro-algae and waste-water treatment. In: Borowitzka MA, Borowitzka LJ (eds) Micro-algal biotechnology. Cambridge University Press, Cambridge, pp 305–328

Oswald WJ (1988b) Large-scale algal culture systems (engineering aspects). In: Borowitzka MA, Borowitzka LJ (eds) Micro-algal biotechnology. Cambridge University Press, Cambridge, pp 357–395

Oswald WJ (1990) Advanced integrated wastewater pond systems. In: proceedings of the 1990 ASCE convention: supplying water and saving the environment for six billion people, Env. Eng. Div., New York

Oswald WJ (1991) Introduction to advanced integrated wastewater ponding systems. Water Sci Technol 24(5):1–7

Oswald WJ (1996) A syllabus on advanced integrated wastewater pond systems. A Syllabus on Advanced Integrated Pond Systems, University ofCalifornia, Berkeley, pp 323

Oswald WJ, Golueke CG (1960) Biological transformation of solar energy. Adv Appl Microbiol 2:223–262

Oswald WJ, Gotaas HB, Golueke CG, Kellen WR (1957) Algae in waste treatment. Sewage Ind Waste 29(4):437–457

Owen WF (1982) Energy in wastewater treatment. Prentice-Hall, Englewood Cliffs, pp 71–72

Park JBK, Craggs RJ (2010) Wastewater treatment and algal production in high rate algal ponds with carbon dioxide addition. Water Sci Technol 61:633–639

Park JBK, Craggs RJ (2011) Nutrient removal in high rate algal ponds with carbon dioxide addition. Water Sci Technol 63(8):1758–1764

Picot B, El Halouani H, Casellas C, Moersidik S, Bontoux J (1991) Nutrient removal by high rate pond system in a mediterranean climate (France). Water Sci Technol 23:1535–1541

Schluter M, Groeneweg J (1981) Mass production of freshwater rotifers on liquid wastes: I. The influence of some environmental factors on population growth of Brachionus rubens. Aquaculture 25:17–24

Sheehan J, Dunahay T, Benemann J, Roessler P (1998) A look back at the U.S. department of energy’s aquatic species program – biodiesel from algae. National Renewable Energy Laboratory, Golden, 80401 NERL/TP-580-24190

Shen Y, Yuan W, Pei ZJ, Wu Q, Mao E (2009) Algae mass production methods. Trans ASABE 52:1275–1287

Short SM, Suttle CA (2002) sequence analysis of marine virus communities reveals that groups of related algal viruses are widely distributed in nature. Appl Environ Microbiol 63:1290–1296

Siegrist H, Hunziker W, Hofer H (2005) Anaerobic digestion of slaughterhouse waste with UF – membrane seperation and recycling of permeate after free ammonia stripping. Water Sci Technol 52(1–2):531–536

Smith VH, Sturm BSM, de Noyelles FJ, Billings SA (2009) The ecology of algal biodiesel production. Trends Ecol Evol 25(5):301–309

Sukias JPS, Craggs RJ (2011) Digestion of wastewater pond algae and potential inhibition by alum and ammoniacal-N. Water Sci Technol 63(5):835–840

Tampier M (2009) Algae technologies and processes for biofuels/bioenergy production in British Columbia: current technology, suitability and barriers to implementation. Prepared for The British Columbia Innovation Council, 14 Jan 2009

Voltolina D, Gómez-Villa H, Correa G (2005) Nitrogen removal and recycling by Scenedesmus obliquus in semicontinuous cultures using artificial wastewater and a simulated light and temperature cycle. Bioresour Technol 96:359–362

Weissman JC, Goebel RP (1987) Factors affecting the photosynthetic yield of algae. In: Johnson DA (ed) FY 1986 aquatic species program annual report, Solar Energy Research Institute, Golden, SERI/SP-231-3071, pp 139–168

Weissman JC, Goebel RP, Benemann JR (1988) Photobioreactor design: mixing carbon utilization and oxygen accumulation. Biotechnol Bioeng 31:336–344

Wells CD (2005) Tertiary treatment in integrated algal ponding systems. Master of science thesis, biotechnology, Rhodes University, South Africa

West TO, Marland G (2001) A synthesis of carbon sequestration, carbon emissions, and net carbon flux in agriculture: comparing tillage practices in the United States. Agric Ecosyst Environ 1812:1–16

Weyer KM, Bush DR, Darzins A, Willson BD (2010) Theoretical maximum algal oil production. Bioenerg Res 3:204–213

Woertz IC (2007) Lipid productivity of alge grown on dairy wastewater as a possible feedstock for biodiesel. Master’s thesis, Faculty of Civil and Environmental Engineering, California Polytechnic University, San Luis Obispo

Woertz I, Feffer A, Lundquist T, Nelson Y (2009) Algae grown on dairy and municipal wastewater for simultaneous nutrient removal and lipid production for biofuel feedstock. J Environ Eng 135(11):1115–1122

Wommack KE, Colwell RR (2000) Virioplankton: viruses in aquatic ecosystems. Microbiol Mol Biol Rev 64:69–114

Wood S, Cowie A (2004) A review of greenhouse gas emission factors for fertiliser production. Prepared for the Research and Development Division, State Forests of New South Wales. Cooperative Research Centre for Greenhouse Accounting. For IEA Bioenergy Task 38

Yen HW, Brune DE (2007) Anaerobic co-digestion of algal sludge and waste paper to produce methane. Bioresour Technol 98(1):130–134

Yesodharan S (2002) Supercritical water oxidation: an environmentally safe method for the disposal of organic wastes. Curr Sci 82(9):1112–1122

Acknowledgements

The authors wish to thank Jason Park, Stephan Heubeck and Ian Woertz who provided valuable contributions to this chapter. NIWA funding was provided by the New Zealand Foundation for Research Science and Technology.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2012 Springer Science+Business Media Dordrecht

About this chapter

Cite this chapter

Craggs, R.J., Lundquist, T., Benemann, J. (2012). Wastewater Treatment Pond Algal Production for Biofuel. In: Gordon, R., Seckbach, J. (eds) The Science of Algal Fuels. Cellular Origin, Life in Extreme Habitats and Astrobiology, vol 25. Springer, Dordrecht. https://doi.org/10.1007/978-94-007-5110-1_23

Download citation

DOI: https://doi.org/10.1007/978-94-007-5110-1_23

Published:

Publisher Name: Springer, Dordrecht

Print ISBN: 978-94-007-5109-5

Online ISBN: 978-94-007-5110-1

eBook Packages: Biomedical and Life SciencesBiomedical and Life Sciences (R0)