Abstract

This chapter reviews the bioprocess routes for algal-based biohydrogen production. Important factors such as pH, nutrients, light, immobilisation, substrates, inoculums, and reactors have been taken as prime objectives in this study. Highlights associated with economical stresses and major bottlenecks (in R&D and for commercialization) with biophotolysis (BP) and dark fermentation (DF) process routes are also reviewed with respect to the last 10 years of research-based data. The environmental benefits of biohydrogen economy in general are also reviewed very briefly to achieve a sustainable, economic, and viable evaluation of the bioprocesses. Hence, this study provides an overview of the better options available in algal-based biohydrogen production from lab scale to commercial scale.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

1 Introduction

Hydrogen is a most efficient fuel and has the highest energy density among known fuels (143 GJ/tonne) in terms of energy values as well as from an environmental point of view. It is a zero emission fuel which does not contain carbon, sulphur, or nitrogen and generates water only as a by-product on combustion. Recently it is being very efficiently used as a vehicle fuel in automobiles and also for electricity generation via fuel cells. Commercially, hydrogen is produced by using fossil fuels such as coal, methane, and other heavy hydrocarbons (Kothari et al. 2008). All these processes of hydrogen production are very expensive and not environmentally friendly. Recently, researchers have sought alternative methods for hydrogen production including photolysis of water and biological methods of hydrogen production (Nayak et al. 2014). Biologically produced hydrogen by using microorganisms such as bacteria and algae by photosynthetic and fermentative routes (Monlau et al. 2013; Julia et al. 2014; Kothari et al. 2011; Venkata et al. 2007; Levin et al. 2004) provides a sustainable approach for society. Biological processes can scale up biohydrogen production by using various microorganisms and making it potentially competitive with chemical processes including thermal gasification, pyrolysis, and reforming among others. Biohydrogen production via a biological route is beneficial because it is neutral regarding CO2 emission and free from other greenhouse gases such as carbon monoxide and hydrogen sulphide and it does not require any kind of treatment before use in the fuel cell to generate electricity. Yield of biohydrogen production depends on operating cost whereas its rate depends upon its installation cost or reactor cost.

Biophotolysis (direct biophotolysis and indirect biophotolysis), photofermentation, and dark fermentation (Venkata et al. 2009) are the emergent bioprocess routes for the production of biohydrogen. Among these, algae-based bioprocess production routes are projecting more scope in the R&D sector with commercialization. Indeed, algae present several advantages compared to terrestrial plants in virtue of: (1) algae have a higher growth rate than plants and they are more capable in CO2 fixation; (2) they can be grown easily in water and wastewater (Venkata et al. 2012); (3) they are rich in carbohydrates and have a lack of lignin (Nayak and Das 2013). Besides these, algae is a third-generation biofuel produced from macroalgae, and microalgae are more advantageous than second-generation biofuel produced from nonedible crops because they do not require fertile land for their growth and they have the potential to provide jobs for skilled and unskilled members of society.

There is very modest information available in the literature regarding the journey of lab-scale to large-scale commercial production of biohydrogen with algae. Hence, the present chapter aims to make available considerable research and developmental progress with major bottlenecks through bioprocess routes for algal-biomass–based biohydrogen production with emphasis on the major factors involved.

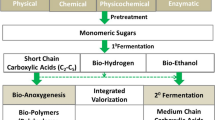

2 Bioprocess Routes for Biohydrogen Production by Algae

Algae have wide potential for bioenergy generation by their metabolic activity as well as their anaerobic fermentation due to their rapid growth and rich carbohydrate contents. Biohydrogen production through biological process is significant and economically viable by algae because it is less expensive, has an easily available feedstock, and can use waste material as a substrate for growth (Venkata et al. 2007). In this section, we mainly focus on biophotolysis (BP) routes and dark fermentation (DF) routes for biohydrogen using algal biomass.

2.1 Direct and Indirect Biophotolysis

2.1.1 Direct Biophotolysis

Direct biophotolysis is the process responsible for algal photosynthetic activities; solar energy is directly converted to hydrogen in the reaction routes of photosynthesis (Eq. (6.1)). This natural process is part of its attraction among scientists because it converts available substrate water to oxygen and hydrogen.

This process works at a partial pressure of near one atmosphere of O2. On the other hand, oxygen sensitivity to the hydrogenase enzyme reaction always creates a hindrance in the process (Frigon and Guiot 2010). Monlau et al. (2013) reported hydrogen production rates on the order of 0.07 mmol/h per litre in their experimental study with direct biophotolysis.

2.1.2 Indirect Biophotolysis

Algal-based biohydrogen production with indirect BP is completed in two stages: the first involves the synthesis of carbohydrate by using a photosynthetic process, and the second stage covers the degradation of stored carbohydrates in anaerobic condition (Azapagic and Stichnothe. 2011). Stage 1 and stage 2 are reported as photofermentation and dark fermentation with light and without light, respectively (Tommasi et al. 2012). Cyanobacteria also have the unique feature of using ambient CO2 as a carbon source and solar light as an energy source (Eq. (6.2)). The cells take up CO2 first to produce cellular substances, which are subsequently used for hydrogen production (Eq. (6.3)). The overall mechanism of hydrogen production in cyanobacteria can be represented by the following reactions:

Both algae and cyanobacteria have the capacity to produce biohydrogen but algae are better than cyanobacteria because they require high-energy intensive enzymes and ATP requires nitrogenase for biohydrogen production but in cyanobacteria production of biohydrogen and oxygen both take place at separate times and places known as indirect biophotolysis (Tommasi et al. 2012). Algae produce biohydrogen by a water-splitting process to form hydrogen, but the rate of biohydrogen production is not as high as the CO2 reduction. In this process oxygen is also produced, which inhibits the production of biohydrogen, because hydrogenase is highly sensitive to oxygen. Therefore, research work is being done in this field to discover the key component that reduces the production of oxygen out of which sulphur deprivation is best and potassium deficiency has also been found as a biological switch that reduces oxygen production. Here, oxygen is not a problem but solar conversion efficiency is low (Julia et al. 2014). Table 6.1 shows the result obtained after review of the existing literature based on algal and cyanobacteria biomass available for biohydrogen production by the bioprocess route of direct and indirect biophotolysis.

2.1.3 Factors Affecting Biophotolysis (BP)

Factors affecting the process are numerous but only a few important ones are discussed here in the subsections.

2.1.3.1 Immobilization

Microalgae cultivated in the form of immobilized cells would have versatile applications because their CO2 capturing rate is high to convert them into organic compounds. The rate of biohydrogen production via immobilized cells is higher than free cells (Brouers and Hall 1986).

2.1.3.2 pH

Biohydrogen production is directly related to pH (Table 6.2). Hydrogenases and nitrogenase are the biohydrogen-producing enzymes, sensitive to pH because at low pH (less than 5) it reduces the enzymatic activity and also the biohydrogen production rate. The pH value is also varied for freshwater algae and marine water because the requirement of the pH value for freshwater algae is different to marine water algae because marine algae require low nitrate uptake. The main factor responsible for the change in pH is nitrate uptake along with the fixation of carbon.

2.1.3.3 Carbon Source

The carbon source is one of the important factors for the cultivation of microalgae. During the process of photosynthesis these microalgae use carbon and store it in the form of starch and glycogen but the storage of this starch and glycogen is limited as a result of which biohydrogen production is also limited, thereby requiring an exogenic source of carbon (organic carbon such as glucose, fructose, malt extract, etc. in wastewater). The role of the carbon source in the cultivation of microalgae is not well understood but some research work has been done on the effect of the carbon source on microalgae in anaerobic conditions.

A cyanobacteria and green algae Microsystis aeruginosa, Chlorella vulgaris, respectively, were used on substrates including malt extract, glucose, and sucrose, and maximum biohydrogen production was on the malt extract: 1300 ml/l. Anabaena species strain CH3 was cultivated by using fructose, galactose, sucrose, and glucose as a feeding material and it was found that the most suitable substrate for biohydrogen production was fructose and sucrose that produced 0.0016 mol and 0.001 mol of biohydrogen production, respectively (Table 6.3).

2.1.3.4 Light

The most suitable light frequency that provides energy for algal growth is in the 400 to 700 nm wavelength. In a temperate climate algal biomass production is much lower than in a tropical climate because of variation in solar radiation. Sutherland et al. (2013) have investigated that in summer algae biomass production increased about 250 % because of the presence of three times more solar radiation in summer than in winter.

2.2 Dark Fermentation (DF)

Dark fermentation is a simple process manifested by anaerobic bacteria with the capacity to produce biohydrogen by using organic acid and waste material as a substrate. This process mainly involves two pathways: acetate and butyrate. There are two common pathways in the production of hydrogen by dark H2 fermentation (Kothari et al. 2012): one producing acetate and the second butyrate. Theoretically, the hydrolytic fermentation of 1 mol of glucose yields 4 and 2 mol of H2 through acetate and butyrate pathways, respectively (Angenent et al. 2004):

-

1.

$$ {\mathrm{C}}_6{\mathrm{H}}_{12}{\mathrm{O}}_6+2{\mathrm{H}}_2\mathrm{O}=4{\mathrm{H}}_2+2{\mathrm{C}\mathrm{O}}_2+2{\mathrm{C}\mathrm{H}}_3\mathrm{COOH} $$(6.4)

(Hydrogen fermentation to acetate pathways)

-

2.

$$ {\mathrm{C}}_6{\mathrm{H}}_{12}{\mathrm{O}}_6=2{\mathrm{H}}_2+{\mathrm{C}\mathrm{H}}_3{\mathrm{C}\mathrm{H}}_2{\mathrm{C}\mathrm{H}}_2\mathrm{COOH}+2{\mathrm{C}\mathrm{O}}_2 $$(6.5)

(Hydrogen fermentation to butyrate pathways)

2.2.1 Factors Affecting DF

2.2.1.1 Substrate

Microalgae and cyanobacteria have recently been more emphasised for bioenergy production. The algal biomass is rich in carbohydrates (starch/glycogen/cellulose) and does not contain lignin as does other biomass. Thus, it is easier to obtain monosaccharides from algal biomasses than other lignocellulose material. Some species of cyanobacteria such as Anabaena sp., Synechocystis PCC6803, Synechococus, and Spirulina sp. can accumulate contents up to 20–30 % of dry weight (Cao et al. 2010). However, some cyanobacteria store carbohydrate in the cytoplasm and in their cell walls in the form of polysaccharides. These sugars need to be converted to monomers by the application of some pretreatment; chemical (acids and alkaline) and enzymatic hydrolysis are common pretreatment methods.

2.2.1.2 Inoculums

The anaerobic fermentation of algal biomass is mostly done by an anaerobic consortium taken from wastewater treatment (Table 6.4). There are various types of pure strains also used, such as species of Clostridium and Enterobacter. A mixed fermentative culture is more common for biohydrogen production as it is simple to operate and does not require sterile conditions as do pure strains. The mixed culture inoculums are mostly taken from soil and anaerobic sludge of wastewater treatment plants. These inoculums are mainly characterised by the bacteria belonging to the genus Clostridia and Bacillus.

2.2.1.3 Temperature

The process of hydrogen production is highly affected by temperature changes as a small increase or decrease in temperature might alter the substrate utilization process, hydrogen yield, or formation of liquid products as well as microbial community of the system (d’Ippolito et al. 2010; Hafez et al. 2012). Most of the studies of biohydrogen production are done under mesophilic conditions as they are preferable from economic and technical points of view to thermophilic bacteria and they exhibit high yield under stable conditions (Zhang et al. 2003; Munro et al. 2009). However, the mesophilic biohydrogen production process also favours the growth of nonhydrogen-producing microbes.

2.2.1.4 pH

pH has a profound effect on the fermentative hydrogen production process due to its major role in determination of the acidic and alkaline condition of the system, in the limitation of the growth of bacteria, and regulation of solvent production. Solvent generated at the end of fermentation decreases the pH by acid accumulation. The optimum pH for hydrogen production is found between 5.5 and 6.5 avoiding the solvantogenic phase (Khanal et al. 2004).

2.3 Factor Affecting Both BP and DF Bioprocess Routes

2.3.1 Reactors

There are various types of bioreactors used for algal biomass production for production of biohydrogen in particular. Details of some important bioreactors, different in structural designs (Fig. 6.1) are as follows.

Different types of photobioreactors (Dasgupta et al. 2010)

2.3.1.1 Tubular Airlift and Bubble Column

This reactor having vertical transparent tubes made up of glass or polyethylene to get adequate light penetration and CO2 supply is allowed through bobbing. As we know, fabrication of a vertical tubular bioreactor is cheap but it is not versatile. It does not provide high culture volume and efficient gas transfer because a bioreactor should possess a high area–volume ratio and due to lack of these things its photosynthetic efficiency also decreases (Martnez-Jeronimo and Espinosa-Chavez 1994). Another drawback is that it has a large angle size in comparison to sunlight therefore most of the sunlight would be reflected back, making it a disadvantage in terms of biomass productivity.

2.3.1.2 Helical Tubular Bioreactor

This bioreactor possesses a flexible tubular pipe with a coiled framework along with a heat exchanger and gas exchange tower. Due to its coiled conical shape structure it receives maximum solar radiation for algal growth. In HTR the area-to-volume ratio is high therefore it is possible to gate 6.6 % photosynthetic efficiency and have volumetric productivity of 0.9 g L−1 d−1 (Tredici and Rodolfi 2004).

2.3.1.3 Flat Plate Bioreactor

Such type of reactor is fabricated mainly to achieve maximum solar radiation therefore it is made by using narrow panels to achieve the maximum area-to-volume ratio. The main advantage of such a reactor is that it possesses an open unit of gas transfer which is also important due to restriction in oxygen buildup, which plays an inhibitory role in biohydrogen production; the main drawback is that its open unit may increase the chances of contamination. It is also beneficial due to its high productivity and uniform light distribution. This system can also be oriented towards the sunlight to achieve maximum radiation. A flat plate solar bioreactor has been made to produce 10 ml hydrogen L−1 h−1 with 6.5 L capacity and at 30° temperature (Eroglu et al. 2008).

2.3.1.4 Fermentor Type of Bioreactor

The main advantage of this bioreactor is control of parameters such as sunlight, flow rate, and mixing but the main drawback is that it does not do well in receiving solar radiation. It is not applicable at the industrial level (Pohl et al. 1988)

Commercial algal production is low worldwide. Probably 6000 t/year in terms of dry biomass are produced autotrophically in the presence of sunlight and CO2. Today at the global level, there is no adequate and meaningful amount of algal-based biohydrogen being produced. Biohydrogen production using algal biomass is significant in terms of negative emission of carbon also because when bioenergy sources used atmospheric carbon for its growth at the same time it also removed atmospheric carbon, therefore it is also positive in the sense of carbon sequestration.

3 Economic Stresses on Bioprocess Routes

Economic feasibility of any system depends on the various parameters such as (1) algal biomass required; design of reactor; capital costs; operating costs including power, labour, and water; and general supplies for resulting biomass and energy balance outputs. In the case of biohydrogen production through algal biomass, capital costs were estimated based on vendor quotes, and prior literature studies on standard energy estimates (Tapie and Bernard 1988). Similarly, other factors responsible for economic stress may be fixed operation cost (labour, maintenance, insurance, tests), indirect capital cost, internal rate of return, plant’s life duration, and so on. In spite of this, algal biomass production rate with the type of culture/strain is also an important factor in observing the economic status of any bioprocess route. After an extensive literature survey on concerned bioprocess routes for the last 10 years, various researchers discuss the pros and cons in respect of economic inputs, and are listed in Table 6.5.

It has been reported that efficiency of biohydrogen production by using solar energy is very low, that is, less than 1.5 %. Research work has been done to enhance the efficiency by applying some nutrient stress such as sulphur and potassium to suppress the production of oxygen, yet it increases only 10 %. In the photosynthesis process water is used as the substrate thus the operating cost is very low and it requires only its maintenance cost but production of biohydrogen is very low, therefore the reactor should be large and the installation cost is very high. Zaborsky (1999) has reported that a reactor having 10 % light conversion efficiency would cost about $50/m2 for a single stage but will cost $100/m2 for a two-stage system; he has also suggested that for this process the cost of a tubular bioreactor would be $50/m2 and the project cost of biohydrogen production would be $15/gj. It has also been reported (Amos 2008) that a pond type of bioreactor having an area 110,000 m2 using unicellular green algae would have a reactor cost of $10/m2. It has also been reported that biohydrogen production by using cyanobacteria would incur a cost of $25/m2 (Block and Melody 1992).

Hence, economic stress for these discussed bioprocess routes (direct and indirect biophotolysis and dark fermentation) can be overcome through (1) biological and engineering improvement opportunities; (2) for significant cost reduction potential in capital and operating cost, research should be more focused on two parameters, lipid content and algal growth; and (3) optimizing nutrient stress conditions and CO2 requirements to reduce the capital cost by utilizing suitable wastewater (urban and industrial) as a substrate.

4 Major Bottlenecks in Bioprocess Routes

There are certain shortcomings associated with algae-based bioprocess routes of biohydrogen production, which are obstacles and affect biohydrogen production, therefore these conditions should try to be minimized.

4.1 R&D: In Growing Stage

4.1.1 Suitable Substrate: Demand in Search

Waste materials from the ecosystems that are suitable as a substrate for biohydrogen production are also a challenge because the complex nature of organic compounds sometimes adversely affects biodegradability. Simple sugars such as glucose, maltose, lactose, and sucrose can be easily degraded and suitable for biohydrogen production. Agricultural and food industry waste are highly rich in starch, cellulose, and also in terms of carbohydrate. It is easy to produce biohydrogen from waste containing starch or carbohydrate because it can easily hydrolyse to glucose and maltose to form organic acid and then biohydrogen gas whereas using agricultural waste containing cellulose and hemicelluloses always possesses the problem of pretreatment. First, it has to go through the process of delignification because lignin content and the efficiency of hydrolysis are inversely proportional to each other. There are some industrial wastes which, like dairy, tannery, olive mill, and brewery wastewater are potential applicants for biohydrogen but the main challenge in using these wastes is that they require pretreatment to remove undesirable substances, then convert to organic acid, and then biohydrogen production. In a wastewater treatment plant, a huge amount of waste sludge is generated which is also rich in carbohydrate and protein content so this sludge can also be used as raw material for biohydrogen production; however, it also has toxic substances and complex organic compounds which cannot be easily degraded due to their complex nature. Therefore they also require pretreatment which is cost effective and not economically viable thus the use of wastewater as a raw material for algal biomass is also challenging when producing biohydrogen (Kothari et al. 2010, 2012; Bhaskar et al. 2008).

4.1.2 Optimization of Parameters: Challenge from Lab Scale to Pilot Scale

At lab scale there are various parameters which play an important role in biohydrogen production such as pH, temperature, nutrient ratio, and substrate (Krupp and Widmann 2009) among others, and these parameters can be maintained easily at lab scale as a result of which biomass productivity would enhanced. When doing this at industrial scale it is quite difficult to maintain these parameters and the cost factor is also prominent and cannot be ignored. There are various factors which affect the production of biohydrogen when high-level large-scale cultivation of algae requires additional fertilizers such as phosphorus and nitrogen and these fertilizers from the dry algal biomass cannot be ignored as they may have an adverse impact on biohydrogen production; therefore some technologies should be developed for nutrient recycling (Ferreira et al. 2013). The use of excess fertilizers can also cause nutrient pollution or eutrophication as a result of which the structure and function of the ecosystem of concern may change. By the process of leaching, if these nutrients leach to a nearby water body they could have an adverse effect on aquatic flora and fauna. Under controlled conditions, algae cultivation requires inputs of fossil fuel in the form of electricity and drying algae to form dry biomass natural gas is also required. Algae are also temperature sensitive, therefore maintenance of temperature also requires use of fossil fuel so we have to develop such a technology and system designed to minimize the use of energy and enhance biomass productivity (Slade and Bauen 2013). It is important to know that algae also produce some toxic substances including polypeptide ammonia and polysaccharide. At the end of the process by-products are sometimes used as manure so these toxins can have an adverse impact in the food chain of the ecosystem, therefore care should be taken in the selection of algae species.

4.2 Road to Commercialization

Biohydrogen production as a third-generation fuel is very new. Most of the work is being performed on a lab scale by using different micro- and macroalgae and bacteria but its industrial application is not as high as it should be. Although it has been reported that for the growth of algae, pure culture medium was being used, the scenario has now changed and there is a shift from pure culture medium to food and industrial waste as a substrate, which is easily and cheaply available and a renewable source for energy generation. In biohydrogen production, rate and yield are two important parameters that should always be in consideration. Scientific research efforts have focused on microalgae that are already commercially significant with the greatest prospects for highly efficient energy production coming from species such as Chlorella, Spirulina, Dunaliella, and Haematococcus (Bruton et al. 2009). These algae are already used in commercial nonfuel operations, where they are used to make a variety of high-value products for use in human and animal nutrition, aquaculture, and cosmetics (Spolaore et al. 2006).

4.2.1 Reactors

One major challenge in biohydrogen production is reactor design at the commercial level because it is has a direct relation to algal biomass production. There are various types of bioreactors but designing a suitable bioreactor with relation to its efficiency is a tedious task. The most important parameters when designing a bioreactor are light penetration, mixing, and flow, which depend upon area-to-volume ratio. In order to get a high area and volume ratio several bioreactors of various shape and size have been designed which have given successful responses. The flat-plate bioreactor, tubular bioreactor, and fermentor type of bioreactor are designed to get high light penetration and based on the principle of high area-to-volume ratio for proper mixing, light penetration, and flow rate (Owende and Brennan 2010; Yeow et al. 2011).

Cultivation of algae at the commercial level is not feasible although it is technologically feasible at the lab-scale level. Commercialization of algal cultivation for biohydrogen production is too far from being realised (Richmond 1987). For the successful commercialization of algae-based biohydrogen production it is always a big obstacle to discover the best and most suitable fast-growing algae strain with high photosynthetic efficiency and high oil content. For commercialization of algae as a fuel two important things are that there should be an easy algae culture harvesting system and use of a photobioreactor should be economically viable (Davis et al. 2011). Supporting the infrastructure, maintenance, and operational costs for algae culture and biohydrogen production for its commercialization is very important. Today freshwater demand has increased and it is also required for agricultural crops therefore the freshwater requirement for algal growth would add pressure in areas where water is scarce. Algae cultivation for biohydrogen production in an open pond system is not suitable because the adjustment of parameters for optimum growth is not easy task. It is more suitable in a closed type of bioreactor but here we cannot enhance the production rate of biohydrogen. A life-cycle assessment report has shown that algae cultivation in an open pond system for biohydrogen production is not environmentally suitable in comparison to normal crop plants (Clarens et al. 2010) (Table 6.6).

5 Environmental Benefits of Biohydrogen Economy

For sustainable economic development in the world a biohydrogen economy with energy and environmental aspects provides a clean solution (Kothari et al. 2010, 2012; Panwar et al. 2012). These solutions are reviewed in the available literature and given in highlights below:

-

Waste material generated by the combustion of hydrogen is water.

-

It helps in the eradication of greenhouse gases.

-

Elimination of fossil fuel pollution.

-

Elimination of economy dependency.

-

Biohydrogen production routes are commonly done at ambient temperature and pressure, therefore less energy is used in bioprocess routes.

-

This is an ecofriendly method of bioenergy production and use of a renewable source of energy makes it significant because it is inexhaustible.

6 Conclusions

Technologies related to algae cultivation and bioprocess routes for biohydrogen production are commercially viable and give us a positive source of energy for our society. It is an integrated approach through which one can produce biohydrogen as energy, and at the same time it can also be used for wastewater treatment. Use of algal-based biohydrogen as an energy source is more significant than a conventional source of energy because it does not produce any kind of greenhouse gases and by the combustion of biohydrogen it produces only water vapour which is not harmful to our environment. Hence the economic analysis of biohydrogen production by algae shows that it is a most feasible feedstock for future energy production and in addition to a lack of lignin content and being rich in carbohydrate content make algae a promising feedstock for future energy production.

References

Abbas M, Rupert C, Mohammed MF (2015) Wastewater treatment high rate algal ponds (WWT HRAP) for low-cost biofuel production. Bioresour Technol 184:202–214

Amos WA (2008) Updated cost analysis of photobiological from Chlamydomonas reinhardtii, milestone completion report. NREL US Department of Energy, Washington, DC

Angenent LT, Karim K, Al-Dahhan MH, Ba W, Domíguez-Espinosa R (2004) Production of bioenergy and biochemicals from industrial and agricultural wastewater. Trends Biotechnol 22:477–485

Arni SA, Bosio B, Arato E (2010) Syngas from sugarcane pyrolysis: an experimental study for fuel cell applications. Renew Energ 35:29–35

Azapagic A, Stichnothe H (2011) Life cycle sustainability assessment of biofuels. In: Luque R, Campelo J, Clark J (ed) Handbook of biofuels production-processes and technologies. Wood Head Publishing, Cambridge, UK

Batista AP, Ambrosano L, Graça S, Sousa C, Marques PA, Ribeiro B, Botrel EP, Neto PC, Gouveia L (2015) Combining urban wastewater treatment with biohydrogen production – an integrated microalgae-based approach. Bioresour Technol 184:230–235

Bhaskar YV, Venkata Mohan S, Sarma PN (2008) Effect of substrate loading rate of chemical wastewater on fermentative biohydrogen production in biofilm configured sequencing batch reactor. Bioresour Technol 99:6941–6948

Block DL, Melody I (1992) Efficiency and cost goals for photoenhanced hydrogen production processes. Int J Hydrog Energ 17:853–861

Brouers M, Hall DO (1986) Ammonia and hydrogen production by immobilized cyanobacteria. J Biotechnol 3:307–321

Bruton T, Lyons H, Lerat Y, Stanley M, BoRasmussen M (2009) A review of the potential of marine algae as a source of biofuel in Ireland. Sustainable Energy Ireland

Cao GL, Ren NQ, Wang AJ, Guo WQ, Xu JF, Liu BF (2010) Effect of lignocellulose-derived inhibitors on growth and hydrogen production by Thermoanaerobacterium thermosaccharolyticum W16. Int J Hydrog Energy 35:13475–13480

Chader S, Haceneb H, Agathos SN (2009) Study of hydrogen production by three strains of Chlorella isolated from the soil in the Algerian Sahara. Int J Hydrog Energy 34:4941–4946

Chen PC, Fan SH, Chiang CL, Lee CM (2008) Effect of growth conditions on the hydrogen production with cyanobacterium Anabaena sp. strain CH3. Int J Hydrog Energy 33:1460–1464

Cheng J, Xia A, Liu Y, Lin R, Zhou J, Cen K (2012) Combination of dark and photo-fermentation to improve hydrogen production from Arthrospira platensis wet biomass with ammonium removal by zeolite. Int J Hydrog Energy 37:13330–13337

Clarens AF, Resurreccion EP, White MA, Colosi LM (2010) Environmental life cycle comparison of algae to other bioenergy feedstocks. Environ Sci Technol 44:1813–1819

d’Ippolito G, Dipasquale L, Vella FM, Romano I, Gambacorta A, Cutignano A et al (2010) Hydrogen metabolism in the extreme thermophilec Thermotoga neapolitana. Int J Hydrog Energy 35:2290–2295

Das D, Veziroglu N (2008) Advances in biological hydrogen production in processes. Int J Hydrog Energy 33:604–657

Dasgupta CN, Gilbert JJ, Lindblad P, Heidorn T, Borgvang SA, Skjanes K, Das D (2010) Recent trends on the development of photobiological processes and photobioreactors for the improvement of hydrogen production. Int J Hydrog Energ 35:10218–10238

Davis R, Aden A, Pienkos PT (2011) Techno-economic analysis of autotrophic microalgae for fuel production. Appl Energ 88:3524–3531

Demirbas A (2009) Biohydrogen for future engine fuel demands. Green energy and technology. Springer, New York. ISBN 978-1-84882-511-6

Eroglu I, Tabanoglu A, Gunduz U, Eroglu E, Yucel M (2008) Hydrogen production by Rhodobacter sphaeroides O.U.001 in a flat plate solar bioreactor. Int J Hydrog Energy 33:531–541

Ferreira AF, Ortigueira J, Alves L, Gouveia L, Moura P, Silva CM (2013) Biohydrogen production from microalgal biomass: energy requirement, CO2 emissions and scale-up scenarios. Bioresour Technol 144:156–164

Frigon JC, Guiot SR (2010) Biomethane production from starch and lignocellulosic crops: a comparative review. Biofuel Bioprod Biorefin 4:447–458

Hafez H, Nakhla G, El Naggar H (2012) Biological hydrogen production. In: Sherif SA (ed) Handbook of hydrogen energy. CRC Press, Taylor and Francis, Boca Raton

Hallenbeck PC, Benemann JR (2002) Biological hydrogen production; fundamentals and limiting processes. Int J Hydrog Energ 27:1185–1193

http://www.intech.unu.edu/events/workshops/hfc05/chopra_ppt.pdf

Jason CQ, Ryan D (2015) The potentials and challenges of algae based biofuels: a review of the techno-economic, life cycle, and resource assessment modelling. Bioresour Technol 84:444–452

Julia S, Campo M, Escalante R, Robledo D, Patino R (2014) Hydrogen production by Chlamydomonas reinhardtii under light driven and sulphur deprived conditions: using biomass grown in outdoor photobioreactors at the Yucatan Peninsula. Int J Hydrogen Energy 39:20950–20957

Khanal SK, Chen WH, Li L, Sung S (2004) Biological hydrogen production: effect op pH and intermediate products. Int J Hydrog Energy 29:1123–1131

Kim MS, Baek JS, Yun YS, Sim SJ, Park S, Kim SC (2006) Hydrogen production from Chlamydomonas reinhardtii biomass using a two-step conversion process: anaerobic conversion and photosynthetic fermentation. Int J Hydrog Energy 31:812–816

Kosourov S, Tsygankov A, Seibert M, Ghirardi ML (2002) Sustained hydrogen photo production by Chlamydomonas reinhardtii: effects of parameters. Biotechnol Bioeng 78:731–740

Kothari R, Buddhi D, Sawhney RL (2008) Comparison of environmental and economic aspects of various hydrogen production methods. Renew Sust Energ Rev 12:553–563

Kothari Richa, Tyagi VV, Pathak A (2010) Waste-to-energy: a way from renewable energy sources to sustainable development. Renew Sustain Energy Rev 14:3164–3170

Kothari Richa, Singh RP, Allen Tanu, Hakimi M. Ibrahim (2011) An overview for exploring the possibilities of potential energy generation from municipal solid waste (MSW) in Indian Scenario. Renew Sustain Energy Rev 15(9):4797–4808 (Impact Factor – 6.18)

Kothari Richa, Singh DP, Tyagi VV, Tyagi SK (2012) Fermentative hydrogen production – an alternative clean energy source. Renew Sustain Energy Rev 16:2337–2346 (Impact Factor – 6.18)

Krupp M, Widmann R (2009) Biohydrogen production by dark fermentation: experiences of continuous operation in large lab scale. Int J Hydrog Energy 34:4509–4516

Levin DB, Pitt L, Love M (2004) Biohydrogen production, prospect & limitation to practical application. Int J Hydrogen Energy 24:173–185

Liu CH, Chang CY, Cheng CL, Lee DJ, Chang JS (2012) Fermentative hydrogen production by Clostridium butyricum CGS5 using carbohydrate rich microalgal biomass as feedstock. Int J Hydrogen Energy 37:15458–15464

Martnez-Jeronimo F, Espinosa-Chavez F (1994) A laboratory-scale system for mass culture of freshwater microalgae in polyethylene bags. J Appl Phycol 6:423–425

Monlau F, Barakat A, Trably E, Dumas C, Steyer JP, Carrère H (2013) Lignocellulosic materials into biohydrogen and biomethane: impact of structural features and pretreatment. Crit Rev Environ Sci Technol 43:260–322

Munro M, Turok I, Livingston M (2009) Students in cities: a preliminary analysis of their patterns and effects. Environ Plan 41:1805–1825

Nath K, Das D (2003) Review article hydrogen from biomass. Curr Sci 85:265–271

Nayak BK, Das D (2013) Improvement of carbon dioxide biofixation in a photobioreactor using Anabaena sp. PCC 7120. Process Biochem 39:7553–7560

Nayak BK, Roy S, Das D (2014) Biohydrogen production from algal biomass (Anabaena sp. PCC 7120) cultivated in airlift photobioreactor. Int J Hydrog Energy 39:7553–7560

Nobre BP, Villalobos F, Barragán BE, Oliveira C, Batista P, Marques PSS (2013) A biorefinery from Nannochloropsis sp. microalga extraction of oils and pigments. Production of biohydrogen from the left over biomass. Bioresour Technol 135:128–136

Olga B, Pavel S (2012) Production of hydrogen from renewable resources and its effectiveness. Int J Hydrog Energy 37:11563–11578

Owende P, Brennan L (2010) Biofuels from microalgae are view of technologies for production, processing, and extractions of biofuels and coproducts. Renew Sustain Energ Rev 14:557–577

Panwar NL, Kothari Richa, Tyagi VV (2012) Thermo chemical conversion of biomass – eco friendly energy routes. Renew Sustain Energy Rev 16:1801–1816 (Impact Factor – 6.18)

Pinto FAL, Troshina O, Lindblad P (2002). A brief look at three decades of research on cyanobacterial hydrogen evolution. Int J Hydrog Energy. 27:1209–1215

Pohl P, Kohlhase M, Martin M (1988) Photobioreactors for the axenic mass cultivation of microalgae. In: Stadler T, Mollion J, Verdus MC, Karamanos Y, Morvan H, Christiaen D (ed) Algal biotechnology. Elsevier, New York, p 209e18

Rashid N, Lee K, Han J, Gross M (2011) Hydrogen production by immobilized Chlorella vulgaris: optimizing pH, carbon source and light. Bioprocess Biosyst Eng: 36(7):867–872

Ren Z, Ward TE, Logan BE, Regan JM (2007) Characterization of the cellulolytic and hydrogen-producing activities of six mesophilic Clostridium species. J Appl Microbiol 103:2258–2266, ISSN: 1364-5072

Resnick RJ (2004) The economics of biological methods of hydrogen production.Massachusetts Institute of Technology

Richmond A (1987) The challenge confronting industrial microagriculture: high photosynthetic efficiency in large scale reactors. Hydrobiology 151–152:117–121

Show KY, Lee DJ, Tay JH, Lin CY, Chang JS (2012) Biohydrogen production: current perspectives and the way forward. Int J Hydrog Energy 37:15616–15631

Slade R, Bauen A (2013) Micro-algae cultivation for biofuels: cost, energy balance, environmental impacts and future prospects. Biomass Bioenergy 53:29–38

Song W, Rashid N, Choi W, Lee K (2011) Biohydrogen production by immobilized Chlorella sp. using cycles of oxygenic photosynthesis and anaerobiosis. Bioresour Technol 102:8676–8681

Spolaore P, Joannis-Cassan C, Duran E, Isambert A (2006) Commercial applications of microalgae. J Biosci Bioeng 101:87–96

Sun J, Yuan X, Shi X, Chu C, Guo R, Kong H (2011) Fermentation of Chlorella sp. For anaerobic biohydrogen production: influences of inoculums substrate ratio, volatile fatty acids an NADH. Bioresour Technol 102:10480–10485

Sutherland DL, Howard-Williams C, Turnbull MH, Broady PA, Craggs RJ (2013) Seasonal variation in light utilisation, biomass production and nutrient removal by wastewater microalgae in a full-scale high-rate algal pond. J Appl Phycol 26:1–13

Tapie P, Bernard A (1988) Microalgae production: technical and economic evaluations. Biotechnol Bioeng 32(7):873–885

Tommasi T, Ruggeri B, Sanfilippo S (2012) Energy valorisation of residues of dark anaerobic production of hydrogen. J Clean Prod 34:91–97

Tredici MR, Rodolfi L (2004) University of Florence, Italy. Reactor for industrial culture of photosynthetic micro-organisms. PCT WO 2004/074423 A2

Venkata MS, Babu VL, Sarma PN (2007) Anaerobic biohydrogen production from dairy wastewater treatment in sequencing batch reactor (AnSBR): effect of organic loading rate. Enzyme Microb Technol 41:506–515

Venkata MS, Babu MLM, Reddy VM, Mohanakrishna G, Sarma PN (2009) Harnessing of biohydrogen by acidogenic fermentation of Citrus limetta peelings: effect of extraction procedure and pretreatment of biocatalyst. Int J Hydrog Energy 34:6149–6156

Venkata MS, Chiranjeevi P, Mohanakrishna G (2012) A rapid and simple protocol for evaluating biohydrogen production potential (BHP) of wastewater with simultaneous process optimization. Int J Hydrog Energy 37:3130–3141

Yeow SK, Jong DJ, Shu CJ (2011) Bioreactor and process design for biohydrogen production. Bioresour Technol 102:8524–8533

Zaborsky OR (1999) Biohydrogen. Springer, New York, pp 391–401

Zhang Y, Dube MA, McLean DD, Kates M (2003) Biodiesel production from waste cooking oil. 1. Process design and technological assessment. Bioresour Technol 89:1–16

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2015 Springer India

About this chapter

Cite this chapter

Kothari, R., Pandey, A., Kumar, V., Tyagi, V.V. (2015). Algae-Based Biohydrogen: Current Status of Bioprocess Routes, Economical Assessment, and Major Bottlenecks. In: Singh, B., Bauddh, K., Bux, F. (eds) Algae and Environmental Sustainability. Developments in Applied Phycology, vol 7. Springer, New Delhi. https://doi.org/10.1007/978-81-322-2641-3_6

Download citation

DOI: https://doi.org/10.1007/978-81-322-2641-3_6

Published:

Publisher Name: Springer, New Delhi

Print ISBN: 978-81-322-2639-0

Online ISBN: 978-81-322-2641-3

eBook Packages: Biomedical and Life SciencesBiomedical and Life Sciences (R0)