Abstract

In this proposed integrated power and cooling plant, water/steam is the working fluid and it offers a cost-effective solution compared to aqua-ammonia- based plant. In only cooling system, i.e., without steam turbine, a more amount of heat (sensible heat of vapor and latent heat) is rejected at the condenser. So, this integration minimizes the condenser load by limiting to latent heat rejection only. The plant results 70 kW of power and 433 kW of cooling at the optimized conditions of strong solution (1 kg/s and 0.48 concentrations) and the supply temperature of 250 °C.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

The LiBr-water vapor absorption refrigeration (VAR) system is suitable at the cooling requirement above 0 °C. The latent heat of water is high compared to other working fluids and so, it absorbs more heat at the evaporator and results high coefficient of performance (COP). Florides et al. [1] designed and constructed a single effect VAR plant and recommended 0.58 strong solution concentrations at high sink temperature of 35 °C. An experiment has been carried out by Asdrubali and Grignaffini [2] on single effect LiBr-water VAR system and used an electrical heater in a boiler. They did experiment at different mass flow rates and various conditions of condenser, absorber, and evaporator.

To avoid the crystallization formation, James et al. [3] tested the refrigeration cycle by adding various additives and provided suitable additives for high temperature application. Similarly the water is mostly used for power production but the cost for making the water into steam is high so the researcher and scientists tried, direct steam solar thermal power plant. [4]. Yongping Yang et al. [5] explained the low heat solar thermal power plant and oil as thermic fluid and produces maximum power. The design and cost analysis is done for solar thermal power plant is connected to the grid by Montes [5]. Whatever the solar thermal power plant the separate power should be used for refrigeration cycle. To avoid the power to the refrigeration cycle the integration is needed with common working fluid. The integration of power and refrigeration cycle and helps to reduce the power used for refrigeration cycle, hence the vapor compression cycle still needs power for compressor. The LiBr-Water vapor refrigeration is good for cooling, but maintaining the vacuum is needed. The water is common for both power and cooling cycle, for the power it requires high pressure but for cooling less than atmospheric pressure. For both industrial and domestic needs power and cooling at a time, hence integration of power and cooling cycle helps to satisfy the need of power and cooling and reduces the power used for the cooling cycle. The main objective of this is paper is integration of solar power and cooling cycle and analysis are made to find the suitable working condition and parameters. The same author’s presented a paper about power and cooling run on aqua-ammonia cycle and explained more energy is available at the exit of the generator [6]. The thermo physical properties of LiBr-water are carried out by the equation proposed by Kaita [7] and ASHRAE [8].

1.1 Assumptions and Thermodynamic Equations

-

The absorption and condenser exit temperature is maintained as 30 °C.

-

The pinch point variation is 10 °C.

-

The isentropic efficiency of the pump and turbine is 75 %.

-

The mechanical efficiency of pump and turbine is 96 %.

Thermodynamic equations:

For power

For cooling

For generator

For re-heater

For efficiency

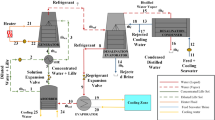

2 Principle and Working

The proposed cycle has a power cycle followed by the refrigeration cycle and interlinked as shown in the Fig. 1. Similar to the refrigeration cycle the absorber and pump is used as heat absorption and increasing pressure respectively. At the exit of the turbine the high pressure and temperature is there to run the turbine, so turbine is placed. The Reheater is provided next to the generator to make the water into superheated state. At the exit of the turbine the pressure is maintained as atmospheric pressure and the condenser is used to condense the water vapor.

The expansion valve used to expand up to absorber pressure, evaporator is placed as same as in the refrigeration cycle. The liquid mixture of LiBr-water from absorber is pumped into the generator via heat exchanger. As difference in the boiling point the water evaporates and pure water vapor moves to the super heater. The advantage of LiBr—water VAR is no need of reflux condenser as in aqua ammonia cycle. The water vapor is from generator is superheated before the turbine to get more power output. The proposed cycle has a power cycle followed by the refrigeration cycle and interlinked as shown in the Fig. 1. Similar to the refrigeration cycle the absorber and pump is used as heat absorption and increasing pressure respectively. At the exit of the turbine the high pressure and temperature is there to run the turbine, so turbine is placed. The Reheater is provided next to the generator to make the water into superheated state. At the exit of the turbine the pressure is maintained as atmospheric pressure and the condenser is used to condense the water vapor. The expansion valve used to expand up to absorber pressure, evaporator is placed as same as in the refrigeration cycle.

The liquid mixture of LiBr-water from absorber is pumped into the generator via heat exchanger. As difference in the boiling point the water evaporates and pure water vapor moves to the super heater. The advantage of LiBr—water VAR is no need of reflux condenser as in aqua ammonia cycle. The water vapor is from generator is superheated before the turbine to run the turbine more efficient. After work done by the turbine the exit is saturated water vapor with low pressure and low temperature. Because of the low pressure and temperature the condenser load is reduced for refrigeration cycle. Low pressure is needed for the water to complete refrigeration cycle, so the exit pressure of the turbine is fixed as 1.013 bar (atmospheric pressure). The liquid water is expanded from atmospheric pressure to absorber pressure that is the useful cooling is used in the evaporator.

3 Results and Discussion

The power and cooling output will vary as shown in the Fig. 2 and it depends on the working fluids. The aqua-ammonia as working fluids shows maximum power and cooling output of 18.6 kW and 107 kW, respectively [6]. The enthalpy of vaporization for ammonia is less compared to the LiBr-H2O pair and produces less power and cooling. The LiBr-H2O pair produces more power and cooling but the cooling temperature is more than 0 ℃ and aqua–ammonia pair is best suitable for less than 0 ℃. Absorber concentration of 0.45 and 30 ℃ produces cooling temperature of −12 ℃ and reflux condenser exit concentration of 0.99 [9].

Figure 3 shows the power produced by turbine in the interlinked VAR cycle. Increase in the collector exit temperature increase input load to the generator, so more water vapor will be produced by the generator. More water vapor results increase in concentration of LiBr into the water and exit concentration is limited to x = 0.6 to avoid the blockage in the heat exchanger. The absorber concentration plays a major role in production of power because of the mass variation. At the low concentration of x = 0.48, it gives maximum power output of 69.28 kW. Whereas high concentration of x = 0.52 it gives maximum power output of 39.22 kW and the operating temperature is low.

As similar to the power the cooling also gets increased as the same mass as shown in the Fig. 4. The latent heat of water is high and gives more cooling load output compared to the ammonia cooling load. In this proposed cycle it gives maximum cooling load of 433.56 kW at x = 0.48 and temperature of 250 °C. The cooling load is increases with respect to solar exit temperature that is directly proportional to the solar trough collector input load the generator. Water is used as thermic fluid for parabolic trough collector.

The addition of turbine for producing the power in the refrigeration cycle does not affect the cooling performance. The absorber concentration of x = 0.48 has lowest and highest possible working temperature range of 170–230 °C whereas the x = 0.52 limited working temperature range of 170–200 °C. The return solution concentration from the generator is limited to x = 0.6, so there is variation in temperature working range.

The efficiency of integrated cycle is increased and also depends on the absorber concentration and atmospheric conditions. The proposed cycle produces maximum efficiency of 58 % as shown in the Fig. 5 and it is high compared to aqua-ammonia pair at 30 °C atmospheric temperature [6].

4 Conclusion

The integration of power and VAR cycle improves the energy utilization and also reduces the condenser load. The strong solution concentration, 0.48 with the combination of 250 °C source temperature results 9.6 bar pressure at the turbine inlet. At these conditions, the maximum specific power is 70 kW and maximum cooling is 433 kW obtained at optimum conditions.

References

Florides GA, Kalogirou SA, Tassou SA, Wrobel LC (2003) Design and construction of a LiBr–water absorption machine. Energ Convers Manage 44:2483–2508

Asdrubali F, Grignaffini S (2005) Experimental evaluation of the performances of a H2O–LiBr absorption refrigerator under different service conditions. Int J Refrig 28:489–497

Dirksen JA, Ring TA et al (2001) Testing of crystallization inhibitors in industrial LiBr solutios, Int J Refrig, 24:856–859

Nezammahalleh H, Farhadi F, Tanhaemami M (2010) Conceptual design and techno-economic assessment of integrated solar combined cycle system with DSG technology, Sol Energ 84:1696–1705

Yongping Yang et al (2011) An efficient way to use medium-or-low temperature solar heat for power generation e integration into conventional power plant. Appl Therm Eng 31:157–162

Shankar R, Srinivas T (2012) Modeling of energy in vapor absorption refrigeration system. Procedia Eng 38:98–104

KaitaY (2001) Thermodynamic properties of Lithium bromide-water solutions at high temperatures. Int J Refrig 24(5):374–390

ASHRAE (1991) Thermo physical property data for lithium bromide/water solutions at elevated temperature, Final Rep

Shankar R, Srinivas T (2012) Solar thermal based power and vapor absorption refrigeration system, Procedia Eng 38:730–736

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2012 Springer India

About this paper

Cite this paper

Shankar, R., Srinivas, T. (2012). Integration of LiBr-H2O Vapor Absorption Refrigeration Cycle And Power Cycle. In: Sathiyamoorthy, S., Caroline, B., Jayanthi, J. (eds) Emerging Trends in Science, Engineering and Technology. Lecture Notes in Mechanical Engineering. Springer, India. https://doi.org/10.1007/978-81-322-1007-8_9

Download citation

DOI: https://doi.org/10.1007/978-81-322-1007-8_9

Published:

Publisher Name: Springer, India

Print ISBN: 978-81-322-1006-1

Online ISBN: 978-81-322-1007-8

eBook Packages: EngineeringEngineering (R0)