Abstract

Reliability modeling and assessment for a single numerical control (NC) machine tool with zero-failure is a new problem that cannot be solved using classic statistical methods. Thus a Bayesian method is proposed aiming at this problem. In combination with the two-parameter Weibull distribution, the Bayes model of zero-failure problem for a single NC machine tool is built. The method of building the Weibull parameters’ prior distributions is presented. The theoretical formula for the parameter vector’s posterior distribution is derived. In software WinBUGS, the Markov chain Monte Carlo (MCMC) simulation is developed to simulate each parameter’s posterior distribution, solving calculation difficulties in high-dimensional integration and parameter estimation. The proposed method is applied to real data, obtaining the parameter estimators and meant time between failures (MTBF). The result is in consistent with the engineering reality. Given the fact that the actual MTBF cannot be achieved by any means, the proposed method achieves the fusion of the expert experience, multi-source prior information and data. The proposed method is advocated to be a standard solution to the zero-failure reliability assessment for NC machine tools.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

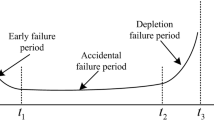

1.1 Zero-Failure Problem for a Single Machine Tool

Traditionally, a reliability test on NC machine tools relies on many machines and a long time to collect sufficient data required by classic statistical methods. For, example, Keller et al. [1], collected field data on 35 NC machine tools over three years, and Yang et al. [2], collected field data on 12 NC machine tools over five years. Nowadays, some high-end NC machine tools are of high cost and few copies. Thus the reliability test on a single machine tool has come to reality, and sometimes, zero failures occur. The zero-failure result is an event that the time between failures (TBF) is larger than the total test time. This event is equivalent to a censored datum. Under zero-failure case, the reliability modeling and assessment is named the zero-failure problem, and classic statistical methods cannot solve this problem since they require sufficient failure data. To solve this new problem, literatures on other products’ zero-failure cases are firstly reviewed, and then the solution to the zero-failure problem of single machine tool is developed.

1.2 Zero-Failure Cases of Other Products

In reliability demonstration tests, the zero-failure cases are common. Martz and Waller [3] presented a Bayesian reliability demonstration testing plan, which expects zero failures to demonstrate the pre-specified reliability target and determine the test time and the number of products to be tested, and the failure time of the tested products is assumed to follow an exponential distribution. To demonstrate a level of reliability of a technical system under zero failures, such as an alarm system, Coolen et al. [4] analyzed optimal test numbers for a type of task using Bayesian method, and tasks arrive as a Poisson process. Fan et al. [5] employed an accelerated experiment on electro-explosive devices of which the lifetime follows an exponential distribution, and the minimum sample size and testing length were designed under the assumption that zero failures occur. Obviously, in reliability demonstration test, the zero-failure is expected by researchers.

However, in reliability modeling and assessment, a zero-failure result is not expected by people, since it causes difficulties in reliability modeling and assessment. Some scholars have proposed methods to implement reliability modeling and assessment under zero failures. For example, Miller et al. [6] estimated the failure probability of software products under zero failures using Bayesian theory. Guo et al. [7] designed a Bayesian method to estimate the reliability of one-shot systems such as missiles and rockets when there are few or no failures. Aiming at zero-failure data, Mao et al. [8] estimated the reliability of engines, of which the failure time follows a Weibull distribution, and the method is based on Bayesian theory and expert experience.

After reviewing literatures, it is found that nearly all the above methods dealing with zero-failure problems fall into the framework of Bayes statistics. So far, no reports have been found aiming at the zero-failure problem of a single NC machine tool. Therefore, a Bayesian reliability modeling and assessment method is proposed aiming at the zero-failure result for a single NC machine tool.

1.3 Bayesian Method of the Zero-Failure Problem

In Sect. 2, the two-parameter Weibull distribution is firstly used to model the Bayesian zero-failure problem for a single machine tool. In Sect. 3, the method of obtaining the Weibull parameters’ prior distributions is proposed; Sect. 4 derives the formula of calculating parameter vector’s posterior distribution and parameters’ estimators. Section 5 applies the proposed method to real zero-failure data and develops an MCMC algorithm in software WinBUGS, obtaining the MTBF of the tested product.

2 Bayesian Model of Zero-Failure Problem for Single NC Machine Tools

In machine tools industry, the two-parameter Weibull distribution is usually adopted to describe the time between failures (TBF) by many scholars, such as Keller [1] and Jia [9]. In this study, random variable T denotes the TBF of a single machine tool; t denotes an observation of T. The cumulative distribution function (CDF) and reliability function of the two-parameter Weibull distribution are given as follows.

Where α > 0 and β > 0 are the scale and shape parameters, respectively. The parameter vector is denoted by θ = (α, β).

The prior distributions of the Weibull parameters are denoted by two probability density functions (PDF): π(α) and π(β), respectively; the prior distribution of the parameter vector is denoted by π(θ). The two parameters are assumed to be mutually independent and thus π(θ) is obtained as follows:

Suppose the total test time on a single NC machine tool is t c (c for censored), and zero failures occur after the test. This event is denoted as: T > t c , which is a censored datum. The likelihood function of data given parameter vector is given by Eq. (4).

The marginal probability distribution of data is given by Eq. (5)

Let π(θ|T > t c ) denote the posterior distribution of the parameter vector, which is obtained by the Bayes theorem given by Eq. (6).

A detailed theoretical formula for the posterior distribution can be obtained by substituting Eqs. (3)–(5) into (6).

The posterior distributions of α and β are denoted by π(α|T > t c ) and π(β|T > t c ), which are obtained from Eq. (7). The posterior means are usually adopted as the Bayesian parameter estimators. When the two parameters are both random variables, the double integral in (7) has no closed form, which is called the high-dimensional integration according to the study of Soland [10]. Thus, to get the estimators analytically based on formula (7) is impossible, and some numerical method is needed to calculate the estimators. Therefore, a Markov chain Monte Carlo algorithm is developed in software WinBUGS to simulate the parameters’ posterior distributions, calculate the parameter estimators and estimate MTBF.

3 Building Weibull Parameters’ Prior Distributions

In Bayesian methods, parameters are treated as random variables which have prior distributions. Parameters’ prior distributions are generally obtained by historical data, engineering experience and expert judgment [11]. However, experts with abundant engineering experience in machine tools industry are generally not familiar with probability or reliability knowledge. To ask experts to directly give the prior distributions of the Weibull parameters is not feasible. Hence, to assist the experts, an indirect method of building the Weibull parameters’ prior distributions are as follows.

The type of NC machine tool to be tested is denoted by A. The expert panel should identify two similar types of NC machine tools, A− and A+, with large samples of history data. If RL denotes reliability level of a product, then the following relations should be satisfied, that is, RL(A−) < RL(A) < RL(A+). Considering the multi-source prior information such as machine’s type, structure, functions, cost, and manufacturer’s technology level, the expert panel is responsible to identify A− and A+ satisfying the above requirements qualitatively based on their expertise.

Based on the large sample of history data, the Weibull parameter estimators for A− can be obtained by classic method such as least squares estimation (LSE) and denoted by α A- and β A-. Similarly, the Weibull parameter estimators for A+ can be obtained and denoted by α A+, β A+. Let α L = min(α A+, α A-) and α U = max(α A+, α A-), then the prior distribution interval for the Weibull scale parameter α for A is (α L , α U ). Let β L = min(β A-, β A+) and β U = min(β A-, β A+) then the prior distribution interval for the Weibull shape parameter β for A is (β L , β U ).

The two parameters are assumed to be uniformly, independently distributed on their own ranges of value, respectively. Thus the prior distributions are given by PDFs as follows:

4 Posterior Distribution and Parameter Estimation

Based on discussion in Sect. 2, there are no analytic solutions to the posterior distributions. Since the double integral in Eq. (7) is a constant which represents the unconditional probability of the event T > t c , Eq. (7) is rewritten in a proportionality form. See Eq. (10).

Given Eq. (10), the high-dimensional integration can be avoided and an MCMC algorithm can be developed. The developed MCMC algorithm can generate a large number of random values of parameters denoted as {α i , β i }, i = 1, 2, …, N. Two Markov chains are formed which are denoted as {α i } and {β i }, i = 1, 2, …, N. If the first B values of {α i } and {β i } are discarded as the burn-in period, the remaining values {α B+1, α B+2, ···, α N } and {β B+1, β B+2, ···, β N } are assumed to be generated from the posterior distributions π(α|t) and π(β|t), and this is how the MCMC algorithm simulate the posterior distributions [11].

MCMC algorithm or simulation is a name of a family of specific algorithms. The famous MCMC algorithms include the Metropolis algorithm, Metropolis-Hastings algorithm, Gibbs sampling [11] and Slice sampling [12]. The free software product WinBUGS can develop and run various algorithms. The MCMC algorithm for the zero-failure problem in this study is developed in WinBUGS.

The arithmetic averages of values of two sets ALPHA = {α B+1, α B+2, ···, α N } and BETA = {β B+1, β B+2, ···, β N } are usually adopted as the point estimator of the parameters.

The elements of the two sets are sorted in an ascending order respectively, to obtain \( ALPHA^{ *} { = }\left\{ {\alpha \left( 1\right),\,\alpha \left( 2\right)\,, \ldots ,\,\alpha \left( {N - B} \right)} \right\} \) and \( BETA^{ *} { = }\left\{ {\beta \left( 1\right),\,\beta \left( 2\right)\,, \cdots ,\beta \left( {N - B} \right)} \right\} \). Let \( m1 = \left\lfloor {0.025 \times \left( {N - B} \right)} \right\rfloor \) and \( m2 = \left\lfloor {0.975 \times \left( {N - B} \right)} \right\rfloor \); thus [α(m1), α(m2)] and [β(m1), β(m2)] are the 95 % credible intervals for α and β, respectively. WinBUGS calculates these statistics automatically after running algorithms.

Based on the theoretical formula of the expectation of the two-parameter Weibull distribution, the MTBF is given by Eq. (13).

5 Case Study

5.1 Zero-Failure Data

A reliability test was implemented on a single NC machine tool. Zero failures were observed. The type of this machine is denoted by A. the total test time is 415 h. See Table 1.

5.2 Building Prior Distributions

Two types of NC machine tools A− and A+ were identified by the expert panel according to the multi-source prior information on structure, type, functions, cost and the technology levels of manufacturers. A− and A+ have large samples of history data, and based on LSE [13], the Weibull parameters for these two types are α A- = 803.15, β A- = 0.9377, α A+ = 1298.33, β A+ = 1.5554. Thus the prior distributions are π(α) = 1/1(1298.33 − 803.15), α ∊ (803.15, 1298.33), π(β) = 1/1(1.5554 − 0.9377), β ∊ (0.9377, 1.5554).

5.3 BUGS Model for the Zero-Failure Problem

Substituting t c = 415 (h), π(α) and π(β) into Eq. (10) obtains the basis for developing an BUGS model in WinBUGS, and WinBUGS develops a suitable MCMC algorithm according to the BUGS model. A BUGS model consists of 3 parts: (1) describing prior distributions; (2) describing the likelihood function; and (3) describing the data.

Firstly, the prior distributions of α and β is described using BUGS language as follows

Where alpha and beta denote α and β, respectively; and “dunif” represents the uniform distribution.

Secondly, the likelihood function given by reliability function R(t c |θ) in Eq. (4) needs to be described. In WinBUGS, any likelihood function is treated as a probability distribution function, but the reliability function given by (4) is a non-standard distribution function. Non-standard distributions are common in Bayesian methods and programming skills are needed to represent them. The “zeros-trick” is utilized to describe the likelihood function. That is, Poisson distribution is utilized to represent R(t c |θ) equivalently. The principle of “zeros-trick” is introduced in literature [14], and the BUGS code for the case in this study is given as follows:

Where “L” denotes the likelihood function; “dpois” denotes the Poisson distribution; “lambda” is the parameter of the Poisson distribution; and “z” is a random variable following Poisson distribution.

Thirdly, since tc = 415 h, the data is described as follows

list(tc = 415)

The complete BUGS model is obtained by (1) creating a new blank document in WinBUGS; (2) typing the above three parts of BUGS code in the document; (3) enclosing the code of prior distributions and liklihood with a pair of curly braces; and (4) adding a keyword “model” at the front. The BUGS model for the zero-failure Bayesian problem is as follow.

After checking model, loading data, compiling code, generating initial values, setting nodes (monitoring alpha and beta) and specifying length of Markov chain (N = 10,000 in this application), WinBUGS is ready to select a suitable MCMC algorithm and run it. Clicking on “update” starts the simulation. See Fig. 1.

The dymanic trace of iterations in the simulation process are shown in Figs. 2 and 3.

The complete trace of iterations of the MCMC simulation is shown in Figs. 4 and 5.

The various posterior statistics are obtained by specifying the burn-in period B = 2000 and using the remaining 8000 generated values. See Fig. 6 and Table 2.

Based on Table 2, the posterior statistics are listed in Table 3.

The approximated posterior PDF curves for alpha and beta after simulation are displayed in Figs. 7 and 8.

Based on the simulation result, the posterior means are adopted as the parameter estimators, where \( \hat{\alpha } = 1058.0 \) and \( \hat{\beta } = 1.257 \). Substituting the corresponding values into Eq. (13) obtains the MTBF = 984.1609 h for the single NC machine tool A.

According to the parameters for A− and A+, the MTBFs are 827.1905 (h) and 1167.3 (h) repectively. It is concluded that MTBF(A−) < MTBF(A) < MTBF (A+). This conclusion is consistent with the expert judgment.

6 Conclusion

-

(1)

Compared with the expert judgment which only gives the qualitative conclusions, the proposed method achieves the combination of the subjective experience and the data and gives the quantitative results.

-

(2)

Given the zero-failure case, the actual value of MTBF cannot be obtained by any means, and the MTBF estimated by the proposed method cannot be compared with the actual MTBF mathematically.

-

(3)

However, since the proposed method utilizes the multi-source prior information in combination with the data, the results of the proposed method is believed to reflect the engineering realities and the expert experience accurately. The proposed method can serve as a new method of reliability assessment for a single NC machine tool under zero-failure case currently.

References

Keller, A.Z., Kamath, A.R.R., Perera, U.D.: Reliability analysis of CNC machine tools. Reliab. Eng. 3(6), 449–473 (1982)

Yang, Z.J., Chen, C.H., Chen, F., et al.: Reliability analysis of machining center based on the field data. Eksploatacja i Niezawodność 15(2), 147–155 (2013)

Martz, H.F., Waller, R.A.: A Bayesian zero-failure reliability demonstration testing procedure. J. Qual. Technol. 11, 128–138 (1979)

Coolen, F.P.A., Coolen-Schrijner, P., Rahrouh, M.: Bayesian reliability demonstration for failure-free periods. Reliab. Eng. Syst. Saf. 88(1), 81–91 (2005)

Fan, T.H., Chang, C.C.: A Bayesian Zero-failure reliability demonstration test of high quality electro-explosive devices. Qual. Reliab. Eng. Int. 25(8), 913–920 (2009)

Miller, K.W., Morell, L.J., Noonan, R.E., et al.: Estimating the probability of failure when testing reveals no failures. IEEE Trans. Softw. Eng. 18(1), 33–43 (1992)

Guo, H., Honecker, S., Mettas, A., et al.: Reliability estimation for one-shot systems with zero component test failures. In: 2010 Proceedings-Annual Reliability and Maintainability Symposium, pp. 1–7. IEEE (2010)

Mao, S.S., Xia, J.F.: The hierarchical Bayesian analysis of the zero-failure data. Appl. Math. 7, 411–421 (1992)

Jia, Y.Z., Wang, M.L., Jia, Z.X.: Probability distribution of machining center failures. Reliab. Eng. Syst. Saf. 50(1), 121–125 (1995)

Soland, R.M.: Bayesian analysis of the Weibull process with unknown scale and shape parameters. IEEE Trans. Reliab. 18(4), 181–184 (1969)

Hamada, M.S., Wilson, A.G., Reese, C.S., et al.: Bayesian Reliability. Springer, New York (2008)

Neal, R.M.: Slice sampling. Ann. Stat. 31(3), 705–767 (2003)

Zhang, L.F., Xie, M., Tang, L.C.: A study of two estimation approaches for parameters of Weibull distribution based on WPP. Reliab. Eng. Syst. Saf. 92(3), 360–368 (2007)

Lunn, D., Jackson, C., Best, N., et al.: The BUGS Book: A Practical Introduction to Bayesian Analysis. CRC Press, Boca Raton (2012)

Acknowledgments

The work is supported by The Science and Technology Development Program of Jilin Province(20130302009GX) and Project of Priority Funding for Basic Scientific Research Business of Jilin University(450060521026).

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2015 Springer-Verlag Berlin Heidelberg

About this paper

Cite this paper

Li, H., Chen, F., Yang, Z., Kan, Y., Wang, L. (2015). Bayesian Reliability Assessment Method for Single NC Machine Tool Under Zero Failures. In: Niu, W., et al. Applications and Techniques in Information Security. ATIS 2015. Communications in Computer and Information Science, vol 557. Springer, Berlin, Heidelberg. https://doi.org/10.1007/978-3-662-48683-2_26

Download citation

DOI: https://doi.org/10.1007/978-3-662-48683-2_26

Published:

Publisher Name: Springer, Berlin, Heidelberg

Print ISBN: 978-3-662-48682-5

Online ISBN: 978-3-662-48683-2

eBook Packages: Computer ScienceComputer Science (R0)