Abstract

Mineral trioxide aggregate (MTA) has been introduced as a root-end filling material due to its hydraulic properties since most dental materials deteriorate when in contact with moisture. This chapter looks into the composition of un-hydrated MTA, the properties of the freshly mixed material and the characteristics of the set cement. Un-hydrated MTA is composed of tricalcium and dicalcium silicate, tricalcium aluminate and bismuth oxide. On addition of water, the MTA hydrates and forms calcium hydroxide and calcium silicate hydrate together with small quantities of ettringite and monosulphate phases. Chemical and mineral additives modify the properties of fresh and set MTA. These additives are used mostly to reduce the setting time, improve the workability, enhance the properties of the set material and reduce material washout. The use of Portland cement can increase the risk of trace element incorporation in MTA, and bismuth oxide has been reported to interfere with the material hydration.

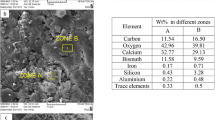

Several characterisation techniques have been used to assess both the un-hydrated and hydrated cement. Scanning electron microscopy (SEM) and energy-dispersive spectroscopy (EDS) provide data on both the material surface characteristics and microstructure and also allow the determination of the extent of hydration by observation of the formation of hydration products in polished sections. EDS analysis provides information on the elemental analysis. Since the cement components and bismuth oxide are crystalline, phase analysis accomplished by X-ray diffractometry (XRD) provides data on the phases present in both the un-hydrated and the hydrated MTA. Other techniques such as laser Raman and Fourier transform infrared spectroscopy (FT-IR), together with the XRD and SEM/EDS thus, provide information on composition and hydration of MTA.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

These keywords were added by machine and not by the authors. This process is experimental and the keywords may be updated as the learning algorithm improves.

2.1 Introduction

Mineral trioxide aggregate (MTA) has been introduced as a root-end filling material due to its hydraulic properties. Most dental materials exhibit a deterioration in physical properties upon contact with moisture. Thus, a hydraulic material used in the construction industry was introduced in order to counteract this problem. The first US patent [79, 80] drawn for MTA explains this invention saying ‘Due to the presence of blood and moisture, the mouth is a less than ideal environment for many materials which could otherwise be useful as dental filling and sealing materials. For example, typical amalgams are sensitive to moisture and set less than adequately if care is not taken to minimize moisture. Not only is the cement of the present invention not adversely affected by moisture in the mouth, but such moisture actually plays an important role in the hydration reactions responsible for the hardening and sealing process’. The composition of MTA and the processes of hydration will be discussed in this chapter.

2.2 Composition of Un-hydrated Material

MTA is composed of a mixture of Portland cement and bismuth oxide. The bismuth oxide is added to the cement to enhance the radiopacity of the material. The original MTA patent registered in 1995 [79] stated that ‘MTA consists of 50–75 % (wt) calcium oxide and 15–25 % silicon dioxide. These two components together comprise 70–95 % of the cement. When these raw materials are blended, they produce tricalcium silicate, dicalcium silicate, tricalcium aluminate, and tetracalcium aluminoferrite’. The patent also stated that ‘MTA is Type 1 Portland cement (American Society for Testing Materials), with a fineness (Blaine number) in the range of 4,500–4,600 cm2/g. A radiopacifier (bismuth oxide) is added to the cement for dental radiological diagnosis’.

Calcium oxide and silicon dioxide are the raw materials used for the manufacture of Portland cement. When these oxides are sintered together with other raw materials, tricalcium silicate, dicalcium silicate, tricalcium aluminate and tetracalcium aluminoferrite are produced. The aluminoferrite phase is only present in the grey cement [64]. White MTA was introduced later (circa 2001). The current US patent for white MTA is dated 2011. This supersedes all previous applications. The white MTA uses the same formulation of the grey version patented in 1995; however, the 2011 patent specifies the use of white Portland cement with low levels of iron [69].

The US patent also states that the cement component is to be ASTM International Type 1 Portland cement with a specific Blaine fineness [2]. Portland cements used in industry are classified into different subcategories depending on their intended use. ASTM Type 1 Portland cements are common Portland cements that are intended for general purpose use, precluding contact with any chemical substances. The specified Blaine fineness is 4,500–4,600 cm2/g indicating a very fine cement. In fact, the Colton Fast-Set brand was suggested for use.

The chemical composition and material microstructure of un-hydrated MTA have been investigated using various techniques. These techniques include scanning electron microscopy (SEM) [13, 17, 18, 21] and energy-dispersive spectroscopy (EDS) [5, 13, 17, 18, 21, 28, 30], X-ray fluorescence [17, 30] and X-ray diffraction (XRD) analysis [5, 7, 66] as well as XRD with Rietveld refinement [7, 17, 18]. The latter is valuable for quantitative analysis.

Scanning electron microscopy of polished sections of un-hydrated MTA embedded in resin shows distinctive cement grains and bismuth oxide particles, which are separated from one another. This feature indicates that the material is composed of a simple mixture of the two components (Fig. 2.1). The elemental composition of MTA as shown by EDS analysis indicates the presence of calcium, silicon and oxygen with minor peaks for aluminium, potassium, magnesium and bismuth. A semi-quantitative assessment of the elemental composition can be worked out using a cobalt standard assuming they are in the oxide form (Fig. 2.2). The oxide percentage composition depends on the mineralogy of the original cement. This can be quantitatively determined by X-ray fluorescence. The levels of silicon and calcium vary with the type of Portland cement used. Hence, these elemental levels are different for each brand of MTA.

Back-scatter scanning electron micrograph of polished surface of MTA powder (Reprinted with permission from Camilleri 2007 [21]. Copyright ©2007, John Wiley and Sons)

The phases present in MTA are determined using X-ray diffraction analysis. Using this method of analysis, un-hydrated MTA exhibits peaks for tricalcium silicate, dicalcium silicate and bismuth oxide. Using a copper Kα tube, each phase has a particular pattern as shown in Fig. 2.3, which can then be searched and matched with data derived from the International Centre of Diffraction Data (ICDD) bank. Bismuth oxide (ICDD: 27-0053) exhibits typical peaks at 25.757, 26.906, 27.386, 28.010 and 33.229°2θ. Tricalcium silicate (ICDD: 86-0402) exhibits peaks at 29.414, 32.193, 32.504, 32.623, 34.355 and 41.298°2θ. Dicalcium silicate, usually exhibits a peak at 32.7°2θ, however such a peak is difficult to discern, due to its superimposition with the peaks present in the tricalcium silicate phase. Tricalcium aluminate is also present in un-hydrated MTA but in minimal quantities. X-ray diffraction analysis of MTA thus eliminates the myth that MTA is composed mainly of oxides. Thus, the term ‘trioxide aggregate’ is essentially a misnomer.

Quantitative phase analysis can be performed by Rietveld refinement using an internal standard such as rutile (titanium dioxide) added to the un-hydrated MTA. The principle of Rietveld analysis is to compare the experimental pattern with a pattern simulated based on the presumed amounts, crystal parameters and equipment parameters of a mixture of known phases. Rietveld refinement enables the amounts of different phases in anhydrous cementitious materials to be determined to a high degree of precision [71]. Quantitative assessment of ProRoot MTA (Dentsply Tulsa Dental, Johnson City, TN, USA) and MTA Angelus (Angelus, Londrina, Brazil) is shown in Table 2.1. Both cements exhibit different quantities of tricalcium silicate and dicalcium silicate when compared to Portland cement. The difference is due to variations in the manufacturing of Portland cement used as a raw material for preparing MTA. Phase analysis of ProRoot MTA has been published by Camilleri in 2008 [18] and has been validated by other researchers using Rietveld X-ray diffraction analysis [7] (Table 2.1). The main difference between the two studies is the presence of tricalcium aluminate in ProRoot MTA in the latter study [7]. Lack of an aluminate phase was also evident in scanning electron microscopy of polished sections of ProRoot MTA powder [18]. The absence of tricalcium aluminate phase, low levels of anhydrite and absence of gypsum may infer that the cement component in ProRoot MTA may not be a commercial Portland cement manufactured in a kiln but a laboratory-made cement. The manufacturer of ProRoot MTA (Dentsply Tulsa Dental Specialties, Tulsa, OK, USA) in fact claims that ProRoot MTA does not utilise a commercial Portland cement but the raw materials are certified for purity by inductively coupled plasma (ICP) spectroscopy. In the same document, the manufacturer also disclaims the presence of phosphate, which was stated to be the main constituent of MTA in the original publication [78]. In that publication, MTA was purportedly reported to be composed of ‘calcium oxide and calcium phosphate. Further analysis demonstrated that the former appeared as discrete crystals and the latter as an amorphous structure with no apparent crystal growth but a granular appearance. The mean value of the prisms was 87 % calcium and 2.47 % silica, the remainder being oxygen. In areas of amorphous structure, there seemed to be 33 % calcium, 49 % phosphate, 2 % carbon, 3 % chloride, and 6 % silica’.

Another calcium silicate-based cement, MTA Angelus, was found to contain tricalcium aluminate but no sulphate-containing phase (Table 2.1). The absence of the gypsum is claimed by the manufacturer to reduce the setting time of the material. In fact, MTA Angelus has been shown to set in less than 50 min [59], as opposed to ProRoot MTA which was reported to have a setting time of over 2 h [9, 10, 20, 25, 30, 78]. Furthermore, 8 % calcium oxide is present in MTA Angelus [17]. This calcium oxide is a result of a raw mix with poor combustibility and with an unstable thermal profile. ProRoot MTA exhibits a higher level of bismuth oxide when compared to MTA Angelus (Table 2.1). This accounts for the higher radiopacity of ProRoot MTA [15, 20].

2.3 MTA Fineness

The MTA patent [79, 80] specifies the brand of Portland cement used in the original MTA formulation (Colton Fast-Set brand: Blaine number in the range of 4,500–4,600 cm2/g). The Blaine number is a numerical value which is calculated using the Blaine fineness measuring equipment. This is the industrial standard for measuring cement fineness. The Blaine method is specified by both European (EN 196-6) [34] and American (ASTM C204) [3] standards. Both standards specify an air permeability method wherein a bed of cement of known density is prepared; the resistance to a flow of air passing through the cement is measured and the fineness of the cement is calculated. This method measures cement fineness compared to standard cement. A range of 4,500–4,600 cm2/g is considered a fine cement.

Other industrial methods for measuring cement fineness include the Lea and Nurse apparatus. This method is an absolute method for determining the fineness of a cement and is adopted by most cement manufacturers. The particle size distribution of MTA has been calculated using laser particle size analysis [14], optical methods which involve measuring particle sizes of cement on polished sections of cement powder [5, 30], flow particle image analyser [54, 55] and by using the BET (Brunauer–Emmett–Teller) gas adsorption method [12] to calculate the specific surface area of MTA [13, 17]. The latter method is an extension of the Langmuir theory, which is a theory for monolayer molecular adsorption to multilayers. This theory hypothesises that gas molecules physically adsorb on a solid in layers infinitely; as there is no interaction between each adsorption layer, the Langmuir theory may be applied to each layer. The BET method is widely used in materials and surface science for the calculation of surface areas of solids by physical adsorption of gas molecules. By application of the BET theory, it is even possible to determine the inner surface area of hardened cement paste.

Optical assessment of MTA shows that the cement contains more uniform and finer-sized particles than Portland cement [5, 30]. However, other researchers using the same method reported coarser and more irregularly shaped crystalline particles in MTA [5]. Optical assessment shows that MTA consists of particles with diameters ranging from less than 1 μm to approximately 30 μm, and occasionally up to 50 μm. Particles of bismuth oxide (10–30 μm) are numerous [30]. Flow particle image analyses of various calcium silicate-based hydraulic cements indicate that the cumulative percentages of particles ranging from 6 to 10 μm for grey ProRoot MTA, white ProRoot MTA, grey MTA Angelus, white MTA Angelus and Portland cement are 65, 73, 48, 53 and 70 %, respectively. Thus, MTA Angelus contains a larger number of small particles with relatively low circularity and a wider range of size distribution and is less homogeneous than ProRoot MTA. Furthermore, white MTA contains smaller particles with a narrower range of size distribution than grey MTA [54]. The cumulative percentage of particles that are between 0.5 and 3 μm in size was reported to be 88 % [55]. Laser granulometry of MTA confirmed that this cement has a smaller particle size when compared to Portland cement [28]. Moreover, bismuth oxide, which is not present in Portland cement, exhibits a large particle size when examined microscopically [13] and with the use of laser granulometry [15].

ProRoot MTA and MTA Angelus were found to have a similar fineness when tested using the BET gas adsorption method [13, 17]. Both materials exhibit a specific surface area of approximately 1 m2/g. A novel MTA (MTA Plus compounded by Prevest Denpro, Jammu, India, for Avalon Biomed Inc. Bradenton, FL, USA) has a specific surface area of 1,537 m2/g [13], which is higher than the values obtained for MTA Angelus [17]. The higher specific surface area results in more surface available for cement reaction, which, in turn, results in a more rapid reaction rate.

2.4 Manipulation

Mineral trioxide aggregate is a water-based dental cement. It is usually supplied in pre-dosed powder and liquid that are mixed together to obtain a homogeneous paste. The recommended water/powder ratio is about 0.33. Changing the water/powder ratio affects the properties of MTA. The degree of solubility and the porosity of the cement increases when the water/powder ratio is increased. Cement pastes with a water/powder ratio higher than 0.33 are not viscous enough for clinical application. A ratio of 0.26 was the minimum that allowed a mix of putty consistency that can be manipulated [39]. Most MTA manufacturers supply prepacked 1 g powders with ampoules containing 0.33 g of water. Since the amount of material in each package is large enough for several applications, clinicians commonly estimate the amount of water and powder at the chairside, which results in using an unknown water/powder ratio. Variations in the water/powder ratio do not seem to affect the clinical performance of the material, No significant difference in material expansion [48] and no influence on the histological outcome was observed for MTA mixed at different water/powder ratios when used as a direct pulp-capping material on human healthy pulps [74]. When taking into consideration water/powder ratios in MTA, a distinction from water/cement ratio should be made. MTA contains 20 % bismuth oxide, which does not react with water. Thus effectively the water/cement ratio for MTA mixed at a water/powder ratio of 0.33 would be 0.41. Thus, comparison of properties of MTA with those of other systems using a different quantity or no radiopacifier or mineral additives is not possible since the effective water/cement ratio will vary depending on the quantity of additive. Modification of the water/cement ratio affects the properties of the set cement [29].

There have been a large number of reports on addition of various chemicals to the mixing liquid or replacement of the water by other liquids. The most popular is calcium chloride [1, 4, 10, 53, 56, 85], calcium nitrite/nitrate and calcium formate [85]. These chemical additions are also used in the industry to accelerate the setting of Portland cement. Setting accelerators affect the setting reaction of both tricalcium silicate and tricalcium aluminate [65].

Addition of water-soluble polymers [11, 14, 16, 19] increases material flow. ProRoot Endo Sealer is a commercial formulation using cement particles dispersed in a water-soluble polymer [49, 84]. The water-soluble polymer creates charges on the cement particles, resulting in repulsion of these charged particles with reduced flocculation and increased material flow at low water/cement ratios [65]. Propylene glycol has also been used to improve MTA flow [33]. Other polymers have been included to reduce washout of the unset cement. Anti-washout liquid is included in the MTA Plus formulation (compounded by Prevest Denpro, Jammu, India for Avalon Biomed Inc. Bradenton, FL, USA).

Other clinically available liquids have been added to MTA to improve its handling characteristics. These include local anaesthetic solution [40, 50, 53, 81, 83], sodium hypochlorite, chlorhexidine gluconate, saline and physiological solution [42, 50, 53], calcium lactate gluconate [51, 56] and citric acid [56]. The use of un-hydrated MTA as a root-end filling material has been reported [67]. Un-hydrated MTA will hydrate using the physiological fluid available at the root-end cavity. Non-specific and contradicting effects have been reported with the use of these chemicals. Physiological and synthetic tissue fluids contain chloride ions and glucose. The former is a cement hydration accelerator [65] while glucose is a hydration retarder. The combination of these effects may adversely alter the cement paste microstructure. Local anaesthetic solution contains both chloride and sulphate ions which again have a conflicting effect on cement hydration. A higher content of sulphate in the cement may lead to sulphate attack, whereby excessive expansion and cracking will be observed over time due to delayed ettringite deposition [64]. MTA is known to have low levels of sulphate ions and, although these ionic levels would alter the relative proportions of ettringite and monosulphate phases for a given degree of cement hydration, they are unlikely to create sulphate attack of the set cement. The chloride present in both synthetic tissue fluids and anaesthetic solutions may also alter the relative proportions of ettringite and monosulphate phases due to the formation of Friedel’s salt (calcium chloroaluminate, 3CaO•Al2O3•CaCl2•10H2O). The formation of Friedel’s salt will change the lattice structure of hydrated cement monosulphate phases and can potentially lead to microcracking [64].

Other variations to the mixing liquid include replacement of the water by various resins. These modifications result in the development of light-activated MTA and resin-modified MTA for use as root canal sealer cement. Resin-modified MTA reduces the setting time and enhances the bonding to both dentine and overlying composite, thus purportedly reducing micro-leakage. The use of a number of resin systems has been reported, with the main ones being light-curing systems containing bisphenol A-glycidyl methacrylate (bis-GMA) and a biocompatible resin [45, 46] consisting of 2-hydroxyethyl methacrylate (HEMA), triethylene glycol dimethacrylate (TEGDMA), camphorquinone and ethyl-4-(dimethylamino)benzoate (EDMAB), with or without polyacrylic co-maleic acid [42, 43], bis-GMA and TEGDMA [36] and bis-GMA, pyromellitic acid diethylmethacrylate (PMDM) and HEMA [70]. Chemically cured resins have also been employed [26, 36]. Other resins were added with the aim of increasing material flow, thus making MTA suitable to be used as a sealer cement [45, 46]. One such formulation is marketed by Angelus (Angelus, Londrina, Brazil) as MTA Fillapex. The latter is composed of MTA, a salicylate resin (methyl salicylate, butylene glycol and colophony) and other additives. Other proprietary brands such as MTA Obtura and Endo CPM Sealer exist. These sealer cements contain other additives to the MTA formula, that enhance material flow. Other experimental epoxy resin-based systems that incorporate MTA as fillers have also been reported as sealer cements [57].

Classically, MTA is mixed by manipulating the powder and liquid components on a mixing pad. Alternative mixing techniques such as the use of an amalgamator have been investigated [6, 63, 73]. MM MTATM, manufactured by MICRO-MEGA (Besançon Cedex, France), is supplied as MTA capsules that enable the MTA to be mixed using an amalgamator. Ultrasonic agitation has also been employed for mixing MTA [6, 63, 73]. The effectiveness of mechanical mixing and ultrasonic agitation is not clear, although mechanical mixing was shown to enhance the compressive strength of the set material, while ultrasonic agitation was found to improve the compressive strength of the material regardless of the mixing technique [6]. In addition to enhanced material micro-hardness [63], other research has shown that the various mixing methods have no significant effects on the resultant MTA mixtures [73]. Application of a condensation pressure of 1.68 MPa results in enhanced compressive strength. Higher condensation pressures result in fewer voids and microchannels, while specimens prepared with lower condensation pressures exhibit distinctive crystalline structures [62].

2.5 Washout

One of the drawbacks of MTA is washout after it is placed in situ. Washout refers to the tendency of a freshly prepared cement paste to ‘disintegrate upon early contact with blood or other fluids’ [82]. Washout can be measured using different methods. Most methods involve immersion of the unset cement in a liquid [24, 52, 58]. Agitation [82] or freeze drying [52] is then employed to disrupt the cement; alternatively the cement is sprayed with air from a specified distance [68]. The amount of material lost is then determined using photography [68] or quantified using a gravimetric method [52, 82]. One of the latest reported methods [37] includes a setup based on Specification CRD-C 661-06 [75] which was scaled down to allow testing of dental materials. When the results were compared to a metered water spray, they were found to yield quantitative, objective and reproducible results [37]. In the same study, MTA Plus and MTA Angelus exhibited washout when compared to Intermediate Restorative Material (IRM, Dentsply Caulk, Milford, Delaware, USA) and dental amalgam. The addition of anti-washout gel manufactured by Avalon Biomed Inc. reduced washout considerably [38].

2.6 Setting Reaction

Mineral trioxide aggregate hydrates when it comes in contact with water and undergoes two main reactions. The tricalcium silicate and dicalcium silicate react with water to form calcium silicate hydrate and calcium hydroxide. The tricalcium aluminate reacts with water and, in the presence of calcium sulphate, produces ettringite initially. When the sulphate-containing phases are depleted, a monosulphate phase is formed [21]:

(2.1)

(2.2)

(2.3)

The reactions that occur in MTA after hydration are the same reactions that are seen in Portland cement. During the initial stages of reaction, calcium silicate hydrate is formed; coating the cement particles with calcium silicate hydrate prevents further reaction. Tricalcium aluminate dissolves and reacts with the calcium and sulphate ions present in the liquid phase to produce ettringite that also precipitates on the cement particle surface. The initial phase is followed by a dormant period wherein the hydrate coating on the cement grains prevents further hydration. The dormant period lasts for 1–2 h, and is a period of relative inactivity when the cement is plastic and workable. Following the completion of the dormant period, setting of the cement proceeds to the acceleration stage wherein the hydration process accelerates again. The rate of tricalcium silicate hydration increases and more calcium silicate hydrate gel is formed. Hydration of dicalcium silicate also increases at this stage. Sulphate ions are depleted and monosulphate forms from ettringite. Crystalline calcium hydroxide also precipitates from the liquid phase.

The hydration progress can be monitored using calorimetry. The heat flux released by the chemical reaction is monitored over time and enables estimation of the beginning of setting and the rate of increase of the mechanical performance of the cement paste. Both MTA Angelus and MTA Plus present an initial endothermic peak followed by an exothermic peak (Fig. 2.4). The first 2 h correspond to an induction period followed by initial setting and then hardening of the material. The initial endothermic peak is due to the wetting of the surface. The first part of the exothermic peak is correlated with the very rapid and very exothermic hydration [13, 17]. It is interesting to note that MTA Angelus exhibits a higher exothermic peak, which occurs ahead of that of MTA Plus. This is caused by reaction of the calcium oxide present in MTA Angelus with water [17].

2.7 Characterisation of Set MTA

A combination of microscopy, elemental analysis and phase analysis has been used to characterise and evaluate the hydration mechanisms of MTA [13, 17, 18, 21]. The X-ray diffractograms are useful as MTA materials are mostly crystalline and individual mineral phases can be identified. Scanning electron microscopy allows observation of material microstructure and surface visualisation. Moreover, characterisation by X-ray energy dispersive analysis provides qualitative information of the elemental constitution of the test materials. Other useful methods have been employed for characterisation of MTA, including Fourier transform infrared spectroscopy (FT-IR) and Laser Raman spectroscopy. Laser Raman spectroscopy is largely complementary to infrared spectroscopy, but spectral interpretation is simpler [8]. The major components of Portland cement give distinctive Raman spectra [41, 44]. Both FT-IR and Raman spectroscopy have been used to investigate the interaction of calcium silicate cements with physiological solutions [27, 47, 76, 77]. These techniques are an adjunct to phase analysis by XRD and aid to verify the phases identified when peak overlap exists; which is the main disadvantage associated with the use of XRD to analyse Portland cement-based materials. This problem may be addressed by using the Rietveld method [71], which allows standardisation of powder diffraction analysis through the use of calculated reference diffraction patterns based upon crystal structure models.

Reaction by-products produced upon hydration of the cement are deposited around the periphery of the un-hydrated cement particles. As hydration proceeds, there is evidence of more reaction by-products. The hydration reaction takes several years to complete, although the cement mass would have achieved the final hardening and maximum physical and mechanical properties by 28 days. Hydrating MTA can be observed on back-scatter scanning electron micrographs of polished cement specimens (Fig. 2.5). The formation of cement by-products can be monitored by scanning electron microscopy in secondary electron mode. Calcium silicate hydrate exhibits a typical honeycomb appearance, while calcium hydroxide is deposited in the form of hexagonal plates (Fig. 2.6). The surface deposits are evident on the cement surface and may be measured by optical profilometry [35] (Fig. 2.7). The composition of the surface deposits in turn can be assessed using XRD analysis with the glancing angle modification. Phase analysis is usually performed by powder diffractometry using the Bragg–Brentano principle and thus moving both the X-ray source and the detector at a specified angle and speed. With the glancing angle technique, the surface analysis is greatly enhanced by reducing the interference from the sample substrate and increasing the absorption path of the incident beam within the layer itself. An X-ray diffractogram of the MTA surface deposits exhibited a definite peak for beta-calcium phosphate when MTA was immersed in a physiological solution, whereas no peaks were visible when the material was immersed in water (Fig. 2.8).

Surface noncontact profilometry of MTA surface (a) before and (b) after immersion in Hank’s balanced salt solution (Reprinted from Formosa et al. [35], copyright 2012, with permission from Elsevier)

Leaching of calcium hydroxide in solution may be monitored by inductive-coupled plasma mass spectroscopy (ICP-MS). High levels of calcium ions have been demonstrated in solution. If MTA is left exposed to the environment, the calcium hydroxide reacts with the atmospheric carbon dioxide resulting in deposition of calcium carbonate on the cement surface. These deposits are commonly mistaken to be an integral part of the cement microstructure.

Calcium silicate hydrate is amorphous and thus cannot be detected by X-ray diffraction analysis. However, the other cement components and bismuth oxide are crystalline. As hydration progresses, a rise in calcium hydroxide peak (ICDD: 44-1481) is seen at 18.008 and 34.102°2θ using a copper Kα X-ray radiation. The un-hydrated tricalcium silicate phase (ICDD: 86-0402) at 29.414, 32.193, 32.504, 32.623, 34.355 and 41.298°2θ usually decreases in intensity (Fig. 2.9). Quantitative measurements of the different phases of MTA may be performed using Rietveld refinement of X-ray diffraction plots (Table 2.2). This quantitative assessment verifies the reduction in tricalcium silicate and dicalcium silicate levels of the un-hydrated cement as hydration proceeds, with the formation of calcium silicate hydrate. Calcium hydroxide and low levels of ettringite are also produced.

X-ray diffractogram of un-hydrated and hydrated MTA after 1 and 28 days showing the main phases present. The tricalcium silicate peaks are more pronounced in the un-hydrated MTA compared to the hydrated forms. Portlandite is only present in the hydrated MTA. BO bismuth oxide, P portlandite or calcium hydroxide, TCS tricalcium silicate

Energy-dispersive spectroscopy gives the elemental distribution of particular elements in the hydrated MTA. A series of X-ray spectra are collected and quantified using suitable mineral standards. The data plotted in a standard format shows atomic ratios of silicon and calcium (Si/Ca) plotted against aluminium and calcium ratios (Al/Ca). These atomic ratio plots are used in scanning electron microscopy and X-ray energy-dispersive analyses (SEM/EDS) studies of cementitious materials and enable the principal hydration products to be differentiated. An atomic ratio plot for MTA’s main constituents is shown in Fig. 2.10a. The atomic ratio plots of MTA show a mixture of calcium hydroxide and calcium silicate hydrate.

(a, b) Atomic ratio plots of (a) Al/Ca versus Si/Ca indicating a mixture of calcium hydroxide and calcium silicate hydrate. C calcium hydroxide, C–S–H calcium silicate hydrate, AFm monosulphate, AFt ettringite and (b) Bi/Ca and Si/Ca demonstrating the relationship of bismuth and calcium silicate hydrate gel of MTA mixed with water and cured in different environmental conditions (blue dots are in the core region, while red crosses in the periphery) (Reprinted with permission from Camilleri [21]. Copyright ©2007, John Wiley and Sons)

Infrared and Raman spectra also exhibit distinctive features for MTA [36, 44, 76]. Typical FT-IR plots for un-hydrated MTA and hydrated material before immersion and after immersion in solution for 28 days are shown in Fig. 2.11. The un-hydrated MTA displays a tricalcium silicate peak at ~875 cm−1. Tricalcium silicate (peaking at ~875 cm−1) is also identified in all the set cements with the peak reduced in intensity when compared to the un-hydrated material. The set MTA exhibits a characteristic set of bands at 973–981 cm−1 which are attributed to tricalcium silicate hydrate. These are the most intensive bands in all the spectra and can be assigned to Si–O stretching. In addition, very weak bands at 821–842 cm−1 also assigned to Si–O stretching vibrations are also present. The splitting of the band in the 1,000–850 cm−1 region results from the presence of silicate phases. The bands in the region of 1,640 cm−1 are due to H–O–H bending vibrations of H2O molecules. Calcium hydroxide, which is a by-product of hydration of tricalcium silicate cement, also exhibits bands in the region of 1,600–1,400 cm−1. The bands at 1,600–1,300 cm−1 correspond to the asymmetric stretching of CO3 2–. Calcium carbonate is formed from the surface carbonation of cements by reaction of the calcium hydroxide with the atmospheric carbon dioxide.

Bismuth oxide is added to MTA to act as a radiopacifying agent since Portland cement is not sufficiently radiopaque. Quantitative X-ray diffraction analysis (Table 2.2) identifies a reduction of bismuth oxide after cement hydration, with 8.4 % present in the hydrated cement as opposed to the 21.6 % in the un-hydrated material [18]. Atomic ratio plots of Bi/Ca versus Si/Ca demonstrate a linear relationship between bismuth and silicon; the result infers that bismuth is replacing silicon in the calcium silicate hydrate structure (Fig. 2.10b).

2.8 Trace Elements

Since the main constituent of MTA is Portland cement, some concerns have been raised about the inclusion of trace elements in MTA. Portland cement is manufactured from naturally occurring raw materials in a kiln. Sometimes, waste materials are used as raw materials in the manufacturing of Portland cement for the construction industry. Additionally, waste materials are also used as replacement for primary fuels in order to keep the manufacturing costs low. This potentially leads to the inclusion of trace elements in the final product. Traces of arsenic, lead and chromium have been reported in both grey and white MTA [22, 23, 31, 32, 60, 61, 72]. Although the levels of acid-extractable trace elements are high, the amounts leached in solution are negligible. The inclusion of heavy metals in Portland cement has raised concerns regarding its use as a base material for MTA, since the latter is applied in contact with both hard and soft human tissues.

2.9 Conclusions

Mineral trioxide aggregate is composed of Portland cement and bismuth oxide radiopacifier. The cement component is in turn composed of tricalcium and dicalcium silicate and tricalcium aluminate which on reaction with water form calcium silicate hydrate and calcium hydroxide from the reaction of tri- and dicalcium silicate and ettringite and monosulphate from the reaction of tricalcium aluminate with water in the presence of gypsum. Addition of chemical and mineral oxides, cement fineness and incorporation of anti-washout gel can modify the setting time, workability, washout characteristics and reaction kinetics of the cement. Un-hydrated and set MTA can be characterised by a variety of techniques including SEM and EDS analysis, XRD with and without Rietveld correction, FT-IR and laser Raman techniques. A combination of techniques is always advisable.

References

Abdullah D, Ford TR, Papaioannou S, Nicholson J, McDonald F. An evaluation of accelerated Portland cement as a restorative material. Biomaterials. 2002;23(19):4001–10.

American Standards for Testing Materials. ASTM C150/C150M – 12; Standard specification for Portland cement. West Conshohocken: ASTM International; 2011.

American Standards for Testing Materials. ASTM C204 – 11 Standard Test Methods for fineness of hydraulic cement by air-permeability apparatus. West Conshohocken: ASTM International; 2011.

Antunes Bortoluzzi E, Juárez Broon N, Antonio Hungaro Duarte M, de Oliveira Demarchi AC, Monteiro Bramante C. The use of a setting accelerator and its effect on pH and calcium ion release of mineral trioxide aggregate and white Portland cement. J Endod. 2006;32(12):1194–7.

Asgary S, Parirokh M, Eghbal MJ, Stowe S, Brink F. A qualitative X-ray analysis of white and grey mineral trioxide aggregate using compositional imaging. J Mater Sci Mater Med. 2006;17(2):187–91.

Basturk FB, Nekoofar MH, Günday M, Dummer PM. The effect of various mixing and placement techniques on the compressive strength of mineral trioxide aggregate. J Endod. 2013;39(1):111–4.

Belío-Reyes IA, Bucio L, Cruz-Chavez E. Phase composition of ProRoot mineral trioxide aggregate by X-ray powder diffraction. J Endod. 2009;35(6):875–8.

Bensted J. Uses of Raman spectroscopy in cement chemistry. J Am Ceram Soc. 1976;59:140–3.

Ber BS, Hatton JF, Stewart GP. Chemical modification of ProRoot MTA to improve handling characteristics and decrease setting time. J Endod. 2007;33(10):1231–4.

Bortoluzzi EA, Broon NJ, Bramante CM, Felippe WT, Tanomaru Filho M, Esberard RM. The influence of calcium chloride on the setting time, solubility, disintegration, and pH of mineral trioxide aggregate and white Portland cement with a radiopacifier. J Endod. 2009;35(4):550–4.

Bryan TE, Khechen K, Brackett MG, Messer RL, El-Awady A, Primus CM, Gutmann JL, Tay FR. In vitro osteogenic potential of an experimental calcium silicate-based root canal sealer. J Endod. 2010;36(7):1163–9.

Brunauer S, Emmett P, Teller E. Adsorption of gases in multimolecular layers. J Am Chem Soc. 1938;60:309–19.

Camilleri J, Formosa L, Damidot D. The setting characteristics of MTA Plus in different environmental conditions. Int Endod J. 2013;46(9):831–40.

Camilleri J, Gandolfi MG, Siboni F, Prati C. Dynamic sealing ability of MTA root canal sealer. Int Endod J. 2011;44(1):9–20.

Camilleri J, Gandolfi MG. Evaluation of the radiopacity of calcium silicate cements containing different radiopacifiers. Int Endod J. 2010;43(1):21–30.

Camilleri J, Mallia B. Evaluation of the dimensional changes of mineral trioxide aggregate sealer. Int Endod J. 2011;44(5):416–24.

Camilleri J, Sorrentino F, Damidot D. Investigation of the hydration and bioactivity of radiopacified tricalcium silicate cement, Biodentine and MTA Angelus. Dent Mater. 2013;29(5):580–93.

Camilleri J. Characterization of hydration products of mineral trioxide aggregate. Int Endod J. 2008;41(5):408–17.

Camilleri J. Evaluation of selected properties of mineral trioxide aggregate sealer cement. J Endod. 2009;35(10):1412–7.

Camilleri J. Evaluation of the physical properties of an endodontic Portland cement incorporating alternative radiopacifiers used as root-end filling material. Int Endod J. 2010;43(3):231–40.

Camilleri J. Hydration mechanisms of mineral trioxide aggregate. Int Endod J. 2007;40(6):462–70.

Camilleri J, Kralj P, Veber M, Sinagra E. Characterization and analyses of acid-extractable and leached trace elements in dental cements. Int Endod J. 2012;45(8):737–43.

Chang SW, Baek SH, Yang HC, Seo DG, Hong ST, Han SH, Lee Y, Gu Y, Kwon HB, Lee W, Bae KS, Kum KY. Heavy metal analysis of ortho MTA and ProRoot MTA. J Endod. 2011;37(12):1673–6.

Chen CC, Lai MH, Wang WC, Ding SJ. Properties of anti-washout-type calcium silicate bone cements containing gelatin. J Mater Sci Mater Med. 2010;21(4):1057–68.

Chng HK, Islam I, Yap AU, Tong YW, Koh ET. Properties of a new root-end filling material. J Endod. 2005;31(9):665–8.

Chung H, Kim M, Ko H, Yang W. Evaluation of physical and biologic properties of the mixture of mineral trioxide aggregate and 4-META/MMA-TBB resin. Oral Surg Oral Med Oral Pathol Oral Radiol Endod. 2011;112(5):e6–11.

Coleman NJ, Awosanya K, Nicholson JW. A preliminary investigation of the in vitro bioactivity of white Portland cement. Cem Conc Res. 2007;37:1518–23.

Comin-Chiaramonti L, Cavalleri G, Sbaizero O, Comin-Chiaramonti P. Crystallochemical comparison between Portland cements and mineral trioxide aggregate (MTA). J Appl Biomater Biomech. 2009;7(3):171–8.

Cutajar A, Mallia B, Abela S, Camilleri J. Replacement of radiopacifier in mineral trioxide aggregate; characterization and determination of physical properties. Dent Mater. 2011;27(9):879–91.

Dammaschke T, Gerth HU, Züchner H, Schäfer E. Chemical and physical surface and bulk material characterization of white ProRoot MTA and two Portland cements. Dent Mater. 2005;21(8):731–8.

De-Deus G, de Souza MC, Sergio Fidel RA, Fidel SR, de Campos RC, Luna AS. Negligible expression of arsenic in some commercially available brands of Portland cement and mineral trioxide aggregate. J Endod. 2009;35(6):887–90.

Duarte MA, De Oliveira Demarchi AC, Yamashita JC, Kuga MC, De Campos FS. Arsenic release provided by MTA and Portland cement. Oral Surg Oral Med Oral Pathol Oral Radiol Endod. 2005;99(5):648–50.

Duarte MA, Alves de Aguiar K, Zeferino MA, Vivan RR, Ordinola-Zapata R, Tanomaru-Filho M, Weckwerth PH, Kuga MC. Evaluation of the propylene glycol association on some physical and chemical properties of mineral trioxide aggregate. Int Endod J. 2012;45(6):565–70.

European Standards. BS EN 196-6:2010. Methods of testing cement. Determination of fineness. London: British Standards Institutions; 2010.

Formosa LM, Mallia B, Bull T, Camilleri J. The microstructure and surface morphology of radiopaque tricalcium silicate cement exposed to different curing conditions. Dent Mater. 2012;28(5):584–95.

Formosa LM, Mallia B, Camilleri J. The chemical properties of light- and chemical-curing composites with mineral trioxide aggregate filler. Dent Mater. 2013;29(2):e11–9.

Formosa LM, Mallia B, Camilleri J. Mineral trioxide aggregate with anti-washout gel – properties and microstructure. Dent Mater. 2013;29(3):294–306.

Formosa LM, Mallia B, Camilleri J. A quantitative method for determining the antiwashout characteristics of cement-based dental materials including mineral trioxide aggregate. Int Endod J. 2013;46(2):179–86.

Fridland M, Rosado R. Mineral trioxide aggregate (MTA) solubility and porosity with different water-to-powder ratios. J Endod. 2003;29(12):814–7.

Gandolfi MG, Perut F, Ciapetti G, Mongiorgi R, Prati C. New Portland cement-based materials for endodontics mixed with articaine solution: a study of cellular response. J Endod. 2008;34(1):39–44.

Gandolfi MG, Shah SN, Feng R, Prati C, Akintoye SO. Biomimetic calcium-silicate cements support differentiation of human orofacial mesenchymal stem cells. J Endod. 2011;37(8):1102–8.

Gandolfi MG, Taddei P, Siboni F, Modena E, Ciapetti G, Prati C. Development of the foremost light-curable calcium-silicate MTA cement as root-end in oral surgery. Chemical-physical properties, bioactivity and biological behavior. Dent Mater. 2011;27(7):e134–57.

Gandolfi MG, Taddei P, Siboni F, Modena E, De Stefano ED, Prati C. Biomimetic remineralization of human dentin using promising innovative calcium-silicate hybrid “smart” materials. Dent Mater. 2011;27(11):1055–69.

Gandolfi MG, Van Landuyt K, Taddei P, Modena E, Van Meerbeek B, Prati C. Environmental scanning electron microscopy connected with energy dispersive x-ray analysis and Raman techniques to study ProRoot mineral trioxide aggregate and calcium silicate cements in wet conditions and in real time. J Endod. 2010;36(5):851–7.

Gomes-Filho JE, de Faria MD, Bernabé PF, Nery MJ, Otoboni-Filho JA, Dezan-Júnior E, de Moraes Costa MM, Cannon M. Mineral trioxide aggregate but not light-cure mineral trioxide aggregate stimulated mineralization. J Endod. 2008;34(1):62–5.

Gomes-Filho JE, de Moraes Costa MT, Cintra LT, Lodi CS, Duarte PC, Okamoto R, Bernabé PF, Nery MJ, Cannon M. Evaluation of alveolar socket response to Angelus MTA and experimental light-cure MTA. Oral Surg Oral Med Oral Pathol Oral Radiol Endod. 2010;110(5):e93–7.

Han L, Okiji T, Okawa S. Morphological and chemical analysis of different precipitates on mineral trioxide aggregate immersed in different fluids. Dent Mater J. 2010;29:512–7.

Hawley M, Webb TD, Goodell GG. Effect of varying water-to-powder ratios on the setting expansion of white and gray mineral trioxide aggregate. J Endod. 2010;36(8):1377–9.

Huffman BP, Mai S, Pinna L, Weller RN, Primus CM, Gutmann JL, Pashley DH, Tay FR. Dislocation resistance of ProRoot Endo Sealer, a calcium silicate-based root canal sealer, from radicular dentine. Int Endod J. 2009;42(1):34–46.

Jafarnia B, Jiang J, He J, Wang YH, Safavi KE, Zhu Q. Evaluation of cytotoxicity of MTA employing various additives. Oral Surg Oral Med Oral Pathol Oral Radiol Endod. 2009;107(5):739–44.

Ji DY, Wu HD, Hsieh SC, Teng NC, Chen CC, Ke ES, Lin YC, Lee SY, Yang JC. Effects of a novel hydration accelerant on the biological and mechanical properties of white mineral trioxide aggregate. J Endod. 2011;37(6):851–5.

Kai D, Li D, Zhu X, Zhang L, Fan H, Zhang X. Addition of sodium hyaluronate and the effect on performance of the injectable calcium phosphate cement. J Mater Sci Mater Med. 2009;20(8):1595–602.

Kogan P, He J, Glickman GN, Watanabe I. The effects of various additives on setting properties of MTA. J Endod. 2006;32(6):569–72.

Komabayashi T, Spångberg LS. Comparative analysis of the particle size and shape of commercially available mineral trioxide aggregates and Portland cement: a study with a flow particle image analyzer. J Endod. 2008;34(1):94–8.

Komabayashi T, Spångberg LS. Particle size and shape analysis of MTA finer fractions using Portland cement. J Endod. 2008;34(6):709–11.

Lee BN, Hwang YC, Jang JH, Chang HS, Hwang IN, Yang SY, Park YJ, Son HH, Oh WM. Improvement of the properties of mineral trioxide aggregate by mixing with hydration accelerators. J Endod. 2011;37(10):1433–6.

Lee SJ, Chung J, Na HS, Park EJ, Jeon HJ, Kim HC. Characteristics of novel root-end filling material using epoxy resin and Portland cement. Clin Oral Investig. 2013;17(3):1009–15.

Lin Q, Lan X, Li Y, Yu Y, Ni Y, Lu C, Xu Z. Anti-washout carboxymethyl chitosan modified tricalcium silicate bone cement: preparation, mechanical properties and in vitro bioactivity. J Mater Sci Mater Med. 2010;21(12):3065–76.

Massi S, Tanomaru-Filho M, Silva GF, Duarte MA, Grizzo LT, Buzalaf MA, Guerreiro-Tanomaru JM. pH, calcium ion release, and setting time of an experimental mineral trioxide aggregate-based root canal sealer. J Endod. 2011;37(6):844–6.

Matsunaga T, Tsujimoto M, Kawashima T, Tsujimoto Y, Fujiwara M, Ookubo A, Hayashi Y. Analysis of arsenic in gray and white mineral trioxide aggregates by using atomic absorption spectrometry. J Endod. 2010;36(12):1988–90.

Monteiro Bramante C, Demarchi AC, de Moraes IG, Bernadineli N, Garcia RB, Spångberg LS, Duarte MA. Presence of arsenic in different types of MTA and white and gray Portland cement. Oral Surg Oral Med Oral Pathol Oral Radiol Endod. 2008;106(6):909–13.

Nekoofar MH, Adusei G, Sheykhrezae MS, Hayes SJ, Bryant ST, Dummer PM. The effect of condensation pressure on selected physical properties of mineral trioxide aggregate. Int Endod J. 2007;40(6):453–61.

Nekoofar MH, Aseeley Z, Dummer PM. The effect of various mixing techniques on the surface microhardness of mineral trioxide aggregate. Int Endod J. 2010;43(4):312–20.

Neville AM, editor. Properties of concrete. 4th ed. Upper Saddle River: Prentice Hall; 2005. p. 2–8.

Paillere AM, Ben Bassat M, Akman S. Applications of admixtures for concrete. RILEM Technical Committees. New York: E & FN Spon, an imprint of Chapman & Hall; 1992.

Park JW, Hong SH, Kim JH, Lee SJ, Shin SJ. X-ray diffraction analysis of white ProRoot MTA and Diadent BioAggregate. Oral Surg Oral Med Oral Pathol Oral Radiol Endod. 2010;109(1):155–8.

Pelliccioni GA, Vellani CP, Gatto MR, Gandolfi MG, Marchetti C, Prati C. Proroot mineral trioxide aggregate cement used as a retrograde filling without addition of water: an in vitro evaluation of its microleakage. J Endod. 2007;33(9):1082–5.

Porter ML, Bertó A, Primus CM, Watanabe I. Physical and chemical properties of new-generation endodontic materials. J Endod. 2010;36(3):524–8.

Primus CM, inventor; DENTSPLY International, Inc., assignee. Dental material. United States Patent 7,892,342. 22 Feb 2011.

Profeta AC, Mannocci F, Foxton R, Watson TF, Feitosa VP, De Carlo B, Mongiorgi R, Valdré G, Sauro S. Experimental etch-and-rinse adhesives doped with bioactive calcium silicate-based micro-fillers to generate therapeutic resin-dentin interfaces. Dent Mater. 2013;29(7):729–41.

Rietveld HM. A profile refinement method for nuclear and magnetic structure. J Appl Cryst. 1967;2:65–71.

Schembri M, Peplow G, Camilleri J. Analyses of heavy metals in mineral trioxide aggregate and Portland cement. J Endod. 2010;36(7):1210–5.

Shahi S, Rahimi S, Yavari HR, Samiei M, Janani M, Bahari M, Abdolrahimi M, Pakdel F, Aghbali A. Effects of various mixing techniques on push-out bond strengths of white mineral trioxide aggregate. J Endod. 2012;38(4):501–4.

Shahravan A, Jalali SP, Torabi M, Haghdoost AA, Gorjestani H. A histological study of pulp reaction to various water/powder ratios of white mineral trioxide aggregate as pulp-capping material in human teeth: a double-blinded, randomized controlled trial. Int Endod J. 2011;44(11):1029–33.

Specification CRD-C 61-89ACRD-C 661-06. Specification for antiwashout admixtures for concrete, section 16, Test method for determining the resistance of freshly mixed concrete to washing out in water. Washington, DC: Chemical Research and Development Center, U.S. Army; 2006.

Taddei P, Tinti A, Gandolfi MG, Possi PML, Prati C. Ageing of calcium silicate cements for endodontic use in simulated body fluids: a micro-Raman study. J Raman Spectrosc. 2009;40:1858–66.

Tay FR, Pashley DH, Rueggeberg FA, Loushine RJ, Weller RN. Calcium phosphate phase transformation produced by the interaction of the Portland cement component of white mineral trioxide aggregate with a phosphate-containing fluid. J Endod. 2007;33(11):1347–51.

Torabinejad M, Hong CU, McDonald F, Pitt Ford TR. Physical and chemical properties of a new root-end filling material. J Endod. 1995;21(7):349–53.

Torabinejad M, White DJ, inventors; Loma Linda University, assignee. Tooth filling material and method of use. United States Patent 5,415,547. 16 May 1995.

Torabinejad M, White DJ, inventors; Loma Linda University, assignee. Tooth filling material and method of use. United States Patent 5,769,638. 23 June 1998.

Vanderweele RA, Schwartz SA, Beeson TJ. Effect of blood contamination on retention characteristics of MTA when mixed with different liquids. J Endod. 2006;32(5):421–4.

Wang X, Chen L, Xiang H, Ye J. Influence of anti-washout agents on the rheological properties and injectability of a calcium phosphate cement. J Biomed Mater Res B Appl Biomater. 2007;81(2):410–8.

Watts JD, Holt DM, Beeson TJ, Kirkpatrick TC, Rutledge RE. Effects of pH and mixing agents on the temporal setting of tooth-colored and gray mineral trioxide aggregate. J Endod. 2007;33(8):970–3.

Weller RN, Tay KC, Garrett LV, Mai S, Primus CM, Gutmann JL, Pashley DH, Tay FR. Microscopic appearance and apical seal of root canals filled with gutta-percha and ProRoot Endo Sealer after immersion in a phosphate-containing fluid. Int Endod J. 2008;41(11):977–86.

Wiltbank KB, Schwartz SA, Schindler WG. Effect of selected accelerants on the physical properties of mineral trioxide aggregate and Portland cement. J Endod. 2007;33(10):1235–8.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2014 Springer-Verlag Berlin Heidelberg

About this chapter

Cite this chapter

Camilleri, J. (2014). Composition and Setting Reaction. In: Camilleri, J. (eds) Mineral Trioxide Aggregate in Dentistry. Springer, Berlin, Heidelberg. https://doi.org/10.1007/978-3-642-55157-4_2

Download citation

DOI: https://doi.org/10.1007/978-3-642-55157-4_2

Published:

Publisher Name: Springer, Berlin, Heidelberg

Print ISBN: 978-3-642-55156-7

Online ISBN: 978-3-642-55157-4

eBook Packages: MedicineMedicine (R0)