Abstract

In this article, we firstly analyzed the development direction and trends of the information application of coal mine enterprise, and introduced the status of using 3DGIS into the mine information development. Secondly, we gave the principle of the coal mine comprehensive information system development, and put forward a framework of coal mine comprehensive information system platform based on this principle. This platform generates the 3D topography, mine tunnel stereoscopic drawing and excavated stereoscopic drawing based on the data of the geological survey and engineering, and shows the production information, real-time dynamic monitoring information by 3D on the mine excavated stereoscopic drawing, and the overall real perspective of the mine, including the ground and underground, will be spread out. Finally, we tried a pilot to develop and apply an information system platform based on this platform framework.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

139.1 Introduction

With the rapid development of the computer and network technology, the coal mine safety monitoring technology is constantly popularized and applied. The coal mine enterprise is gradually developing on the concentrated management schema by collectivization. So, to the coal mine production and safety monitor, we not only think monitor some side safety factor of the coal mine production, but also take the coal mine production as a whole to think and form the comprehensive safety monitor system (Lin 2010). The sub-systems of the safety monitor system are all separated, and every sub-system forms a system, then the system has the difficult maintenance, the poor reliability, the low sharing and utilization of the information resource, and it is difficult to be unified management (Qiao 2010; Wang et al. 2010). So, the high integration of the coal mine safety and production comprehensive information, 3D visualization of the safety production management and dispatching, and the digital coal mine development are the information development trends of the coal mine enterprise.

In the information management of the coal mine enterprise, the enterprise not only need to set up the digital coal mine, but also need to realize the 3D visual coal mine platform, which highly integrated the geological gauge information, the project information, the production information, the safety monitoring information, the mine worker positioning information, the comprehensive automation monitoring information and other office system information (Peng-fei and Jun 2009; Liang et al. 2010; Jun 2010; Han and Tian 2009). The relevant data, diagram and chart which are needed are indirectly queried by the visual and real dynamic 3D figure. So, the development trends of the coal mine informationization are digital, informationization and 3D visualization.

In this paper, according to the software, hardware and network of the coal mine enterprise, we designed the logical structure and system framework of the unified integrated software platform. This logical structure and system framework generates the 3D topography, mine tunnel stereoscopic drawing and excavated stereoscopic drawing based on the data of the geological survey and engineering. The data and information about the monitoring and production are showed by integration on the 3D stereoscopic drawing. We also tried a pilot to develop a system and put it to application according to this logical structure and system framework.

139.2 The Status of 3DGIS Research and Application

3DGIS technology can seamlessly integrate spatial data and its related attributes information, visualize graphs and images, and comprehensively analyze multi-source and heterogeneous data (Fan et al. 2010). At present, there are many commercial 3DGIS software firms which are already put forward the 3DGIS platform, such as Mapinfo and ArcGIS, etc. But these platforms mainly are used to the traditional survey domain (Wang 2010). The technology of synthesizing, integrating and showing of the 3D data and information of safety information is popular to focus on by the national coal mine research institutes, and this technology is rapidly developed (Yu 2011; Zhi-fan 2007). It is very difficult to develop the comprehensive platform of coal mine safety production data based on 3DGIS, and it need the developed members have the good mine profession knowledge and the rich experience of developing the enterprise software to integrate their data and information (Fu et al. 2003). The main member of all mine enterprise software development have the mine special background, and they are good at develop the profession software about the mine enterprise interior business flow and model, then their technology ability are not enough to integrate the safety information into an unified data comprehensive platform based on 3DGIS. The integrated software based on 3D lags the market needs.

139.3 The Principle of Developing the Coal Mine Comprehensive Information System Platform

The principles of developing the coal mine comprehensive information system platform are as follows (Gan et al. 2003; Sun et al. 2009).

139.3.1 Entirety

The coal mine informationization construction is the information system platform development, and it is not the sub-system development or the profession system development. The system platform development needs the platform have the more entire information and function, this avoid to cause new information islet. The system platform not only contents the safety and production management of the building mine and production mine, but also the coal mine manage itself.

139.3.2 Advancement

On the premise of contenting the entirety, the whole technology should be advanced in the internal, and it will not lag in 5–10 years. Advancement not only presents improving the mine safety production management and the enterprise production, but also expresses the enterprise management level and the enterprise image.

139.3.3 Maturity

The whole system platform has the mature function and technology, and the successful using example. This ensures the stability and reliability of running and using the system platform.

139.3.4 Extension

As a system platform, its extension ability shows whether it has the long using life or not. The system platform can join up the new system and make it perfected constantly according to the enterprise development demand.

139.4 The Design of the Logical Structure and System Framework of the Coal Mine Comprehensive System Platform

139.4.1 Logical Structure of Platform

The mine geological survey information, engineering information, production information, safety information, equipment working status information will be integrated into the comprehensive system platform. So, the centralized storage application, distributed management, unified data and sharing by authority should be as the goal of the system platform, and the hierarchical logical design is adopted, the system platform is divided three layer logic structures from top to bottom, that is the data layer, the business layer and the user layer. It shows in Fig. 139.1.

The data layer mainly includes the data organization, the data storage and the data management from many systems. The data to organize, store and manage includes the geological survey data, the production information, the safety monitoring information, the mineworker positioning information, the report forms, the tube bundle monitoring information and the video monitoring data, etc.

The business layer mainly processes the business logic and data. The business logic and data to process includes the geological data processing, the production data processing, the real monitoring data processing, the report form data analyzing and processing, the tube bundle monitoring data processing and the alarm data processing.

The application layer mainly expresses the information result. The expressing information result includes the information publishing, the information querying, the information browsing, the report form data inputting and the system maintaining.

The data layer, business layer, the application layer join and interrelate each other in the system.

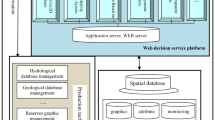

139.4.2 The System Framework

The geological information, information, production information, safety information, equipment running status information will be queried and showed in the system. The 3D visual technology can realize the visual showing, but the 3D showing needs a certain software to support. To the users, the developed system should be flexible and not be restricted by the platform. So, the whole system framework is based on the B/S and C/S model, and the users can feel the information management, the 2D and 3D image management and the information sharing in the B/S model. The system framework shows in Fig. 139.2.

The system framework includes the equipment layer, the controlling layer and the management layer.

The equipment layer mainly monitors the real-time and dynamic information of the mine by the sensors. Including the mine worker positioning information monitoring, the gas information monitoring, the belt controlling information monitoring, the hoisting system information monitoring, the main air exhausting machine information monitoring and the video controlling information monitoring.

The controlling layer mainly processes the real-time and dynamic information which is gathered by the comprehensively controlling system, manages and controls the equipments and workers. Including the person location system, the gas monitoring system, the belt controlling system, the hoisting system, the main air exhausting system, the video monitoring system process the monitoring data by gathering, manage and control the relevant equipment and workers.

The management layer mainly realizes the comprehensive querying the geological survey information, engineering information, production information, safety information, equipment working status information by the user-computer interface of the 3D visual system platform and the web production management system. The management layer supplies the advanced information supported platform, including showing on the dispatching screen and the industry TV, for the safety and production management of mine.

Where, the 3D visual system firstly automatic generates the 3D geological topography and the 3D stereoscopic diagram of the mine engineering based on the geological data and the engineering data. Secondly, it reads the real-time data from the safety monitoring system by the data gathering and processing procedure, and stores the data into the local database of the safety and production management system after the real-time data processing. Next, the 3D visual system shows the production information and the real-time dynamic monitoring information by 3D in the mine excavating stereoscopic diagram. The production information and the real-time dynamic monitoring information include the 3D distribution of the harmful gas, the 3D distribution of the workers, the 3D distribution and working status of the safety and production equipments, the video monitoring images of the underground and ground of the mine. The real overall perspective of the underground and ground of the mine will be showed.

The Web safety and production management system shows the production information and the real-time dynamic monitoring information in the mine excavating stereoscopic diagram. The production information and the real-time dynamic monitoring information include the distribution of the harmful gas, the distribution of the workers, the distribution and working status of the safety and production equipments, the video monitoring images of the underground and ground of the mine.

139.5 Pilot of Development and Application

Based on the above logical structure and system framework, we tried a pilot to develop an information platfom and apply in the Muchenjian coal mine of Beijing Haohua incorporation. The platform development project is started to survey and research in December 2010, and the system is worked in September, 2011. The system platform is working well now. The platform is based on the geological data and the engineering data of Muchenjian coal mine, and generates the 3D geological topography and the 3D stereoscopic diagram of the mine engineering by the 3D visual platform. The platform integrated the mine workers positioning system, the air supplying system and the water supplying system. The platform shows the mine workers positioning information, the air supplying information, and the water supplying information by 3D. The effect of the mine workers positioning information, the air supplying information and the water supplying information showed in the 3D excavating diagram is in the Figs. 139.3, 139.4, and 139.5 respectively. The web safety and productive management system is showed in Fig. 139.6.

139.6 Conclusion

In this article, according to the software, hardware and network of the coal mine enterprise, we designed a logical structure and a system framework of the coal mine integrated information software platform. We also tried a pilot to develop a system platform and put it to application by the logical structure and system framework. The integrated information software platform supplies the advanced information supporting to the safety and production management of the coal mine. In the future, the gas monitoring system, the controlling monitoring system and the video monitoring system are integrated and showed in this platform is our research content.

References

Fan C, Ming H, Lixin G (2010) Coal mine information system based on 3D geological roadways. In: Proceeding of 2010 international conference on computer application and system modeling (ICCASM 2010), pp 606–609

Fu C, Gui F, Dng-yu L (2003) Vitual real technology applied to mine gas explosion modeling. Coal Sci Technol 31(3):33–35 (in Chinese)

Gan Z, Li Z, Peng B (2003) Research on multi-heterogeneous integrated model. Appl Res Comput 10:16–17 (in Chinese)

Han X, Tian F (2009) Research on heterogeneous data integration of digitalized mine. Coal Sci Technol 37(3):87–89 (in Chinese)

Jun G (2010) Basic information platform of digital mine based on 3DGIS and its application. Ind Mine Autom 1:1–5 (in Chinese)

Liang X, Yuan Y, Zhang F, Xia W (2010) Studies on application and status quo of digital mine. China Min Mag 9(9):94–97 (in Chinese)

Lin C (2010) The current situation and typical case of the mine enterprise information building. In: Proceeding of the summit forum of development and information of the innovative coal enterprises, pp 338–343

Peng-fei L, Jun G (2009) Discussion on development situation and key technologies of digital mine in China. Ind Mine Autom 9(9):16–19 (in Chinese)

Qiao S (2010) Research on information integration architecture in coal enterprise. Coal Technol 29(1):58–60 (in Chinese)

Sun G, Sun K, Luo F et al (2009) Integrated architecture of information system in coal corporation. Colliery Mech Electr Technol 4:34–35 (in Chinese)

Wang CL (2010) Applied research on VRGIS 3D visualized mine safety data integration system. Coal Sci Technol 38(7):61–64 (in Chinese)

Wang L, Fang A, Chai S (2010) Design on integrated software platform of the mine comprehensive automation information system. Coal Eng 7:16–18 (in Chinese)

Yu N (2011) The research of 3DGIS technology. Technol Econ Area Commun 64(2):115–117 (in Chinese)

Zhi-fan G (2007) The technology and development of 3DGIS. Opemcast Min Technol 5:19

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2013 Springer-Verlag Berlin Heidelberg

About this paper

Cite this paper

Wen, B., Zhang, Rx., Lin, Cd., Wang, Ml., Ba, Qg. (2013). The Design and Application of the Framework of Coal Mine Comprehensive Information System Based on 3DGIS. In: Qi, E., Shen, J., Dou, R. (eds) The 19th International Conference on Industrial Engineering and Engineering Management. Springer, Berlin, Heidelberg. https://doi.org/10.1007/978-3-642-38427-1_139

Download citation

DOI: https://doi.org/10.1007/978-3-642-38427-1_139

Published:

Publisher Name: Springer, Berlin, Heidelberg

Print ISBN: 978-3-642-38426-4

Online ISBN: 978-3-642-38427-1

eBook Packages: Business and EconomicsBusiness and Management (R0)