Abstract

The study of hygrothermal behaviour is essential to evaluate the performance of construction components and building envelopes. Most building pathologies are related with temperature action. The use of non-destructive techniques to evaluate a building behaviour may be very useful as there is no need to destroy the building components, which would interfere with the user’s life. Infrared thermography is a non-destructive testing technology that can be applied to determine the surface temperature of objects. This technology has been applied to buildings for a couple of decades, to evaluate the building performance. It has been used to detect insulation defects, air leakages, heat losses through windows, moisture and different “hidden details”. This work evaluates the applicability of thermography to study the behaviour of building materials and building envelopes. A short literature review about thermography principles is presented. It is also showed the effect on the results of some factors that affect infrared thermography measurements. Several applications of infrared thermography to building diagnosis are listed, based on the work published by the scientific community. And finally, three test procedures are described in detailed to detect detachments on wall renderings, to evaluate the thermal comfort of floor coatings and to analyse the wetting and drying processes.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

1 Introduction

Infrared thermography (IRT) can be defined as the science of acquisition and analysis of data from non-contact thermal imaging devices. The process of thermal imaging was simplified over the years with the availability of efficient, high resolution infrared cameras that convert the infrared radiation emitted from bodies into thermal images [1], the thermograms, showing the body’s superficial temperature distribution [2]. In this process, each shade expresses a specific temperature range (see Fig. 1).

Thermography has a long history, although its use has increased dramatically with the commercial and industrial applications of the past fifty years. Infrared rays were discovered in 1,800 by Sir William Herschel and approximately thirty years later the first infrared detector was developed. For a long period, infrared detectors were only used by the scientific community and for military purposes. In the end of the 60s the first commercial infrared cameras appeared and in the 90s a new generation of equipment emerged, which increased its applicability in several fields including building diagnosis.

Infrared thermography is now a useful tool for engineers, architects and consultants allowing the evaluation of existing buildings and the identification of potential problems. It is a non-contact and non-destructive technique, which is able to identify surface temperature differences [3].

Most pathologies are related with temperature action. The use of non-destructive techniques to test a building material or component may be very useful by making it possible to evaluate its behaviour without destroying it and without interfering with the users’ life [4–6].

Despite thermography’s potential uses in buildings, its application has not been greatly standardized. The parameters that may affect measurements aren’t completely understood and interpreting the results becomes difficult and confusing.

The main objective of this work was to evaluate the applicability of thermography to study the behaviour of building materials and building envelopes. On the other hand, based on some simple experiments that were carried out at the Building Physics Laboratory (LFC) of Faculty of Engineering of Porto University (FEUP), an attempt of systematizing test procedures is made hoping that it may be valuable for future users of this technology.

2 Infrared Thermography

2.1 Principles

Infrared energy is part of the electromagnetic spectrum. It travels through space at the speed of light and can be reflected, absorbed and emitted. The wavelength (λ) of infrared energy is between 0.75 and 1,000 μm. It can be divided into three parts: near-infrared, from 0.75 to 1.5 μm, mid-infrared, from 1.5 to 20 μm and far-infrared, from 20 to 1,000 μm (see Fig. 2).

The Stefan-Boltzmann law calculates the total amount of radiation emitted by the blackbody at a certain temperature T, in every direction and over all wavelength [7].

where R t is the total blackbody spectral radiance (W/m2), σ is the Stefan-Boltzmann constant (\( \sigma \, = \,5.67\, \times \,10^{ - 8} \;{\text{W/m}}^{ 2} {\text{K}}^{ 4} \)) and T is the temperature (K).

Normally real surfaces don’t behave like a blackbody. The property that traduces the emissive capacity of a real surface is emissivity (ε) that can be defined as the ratio of the radiation emitted by the surface to the radiation emitted by a blackbody at the same temperature [7].

When the spectral component of the radiant energy interacts with a semitransparent surface, part of the radiation may be reflected, absorbed and transmitted. The reflectivity (ρ) is a property that determines the fraction of the incident radiation that is reflected by the surface, the absorptance (α) is a property that determines the fraction of the radiation absorbed by the surface and the transmissivity (τ) is the property that determines the fraction of the radiation that is transmitted through the surface. The sum of these three parameters is equal to one [8].

According to the Kirchhoff Law, at thermal equilibrium, the emissivity of a surface equals its absorptance [7].

Considering Kirchhoff Law, Eq. (3) can be rewritten as:

The non-blackbody emitters for which the emissivity is constant regardless of the wavelength are called grey bodies. The total amount of radiation emitted by the grey body can be calculated using the Stefan-Boltzmann law and considering the emissivity of the surface, ε.

2.2 Factors Affecting Infrared Thermography Measurements

It is well known that several parameters affect thermographic measurements, namely, emissivity, reflectivity, absorptance and others [3, 9]. To evaluate the influence of some of these parameters, simple tests were carried out using the LFC’s thermographic equipment, both in laboratory and “in situ”.

2.2.1 Emissivity

Emissivity is one the most important parameters in thermographic measurements, especially when a quantitative study is intended (measurement of real values of surface temperature and not only of the surface temperature differences). To assess the influence of emissivity two laboratory tests were carried out.

One of the laboratory test consisted of partially immersing a specimen of cellular concrete in water followed by a drying period. The test was performed under steady state conditions, inside a climatic chamber. Thermal images were obtained using four different values of emissivity: 0.62, 0.85, 0.91 and 0.95.

As expected [3, 9–11], the results showed that emissivity variation induced changes in the thermal images, during absorption (see Fig. 3). By looking at the thermal images it was possible to say that the images obtained with emissivity 0.62 were quite different from the remaining ones. The differences between the other thermograms (emissivity’s 0.85, 0.91 and 0.95) were not very significant [12].

Another laboratory test consisted of measuring the surface temperature of a lime stone sample in hygrothermal equilibrium with the environment. Thermal images were obtained using three different values of emissivity: 0.60, 0.80 and 1.00. The surface temperatures measured at the same point on the specimen vary considerably according with the emissivity (see Fig. 4). For the lower values of emissivity, the changes in surface temperature of the lime stone specimen were greater than 1.5 °C: with emissivity of 0.60, the obtained surface temperature was 12.2 °C; with emissivity of 0.80, the surface temperature obtained was 13.9 °C and with emissivity of 1.00, the surface temperature obtained was 14.9 °C.

These tests showed that if a quantitative evaluation is intended, the emissivity values must be precisely determined. However, if the study aims for a qualitative evaluation of the results, the selected emissivity value is not very important. Nevertheless, a judiciously selected emissivity value may simplify the interpretation of the thermal image.

2.2.2 Reflectivity

The material reflectivity may cause some problems in infrared radiation measurements. The energy captured by the camera results from the sum of two parcels, if the body is not transparent to infrared radiation:

-

The body reflects a fraction of the energy emitted by the atmosphere and surrounding objects;

-

The body emits radiation as a function of its surface temperature.

Several examples of reflection are presented in Fig. 5: (a) effect of reflectivity on the thermal image of a ceramic floor - the hotter area in the bottom left of the image results from the ceramic surface’s thermal reflection [13]; (b) reflection of the operator on a metallic surface; (c) reflection of a light bulb in a window.

2.2.3 Absorptance

To assess the influence of colour/absorptance of the surface on thermographic measurements two "in situ" tests were performed. One of them consisted in obtaining thermal images of the Carmo Church, in Porto, Portugal. The Carmo Church’s east façade is covered with hand-painted ceramic tiles. The colouring varies between white and several shades of blue (see Fig. 1). The thermal image shows remarkable temperature differences caused by the colour variation [14].

The other test that was performed consisted on painting a lime stone sample using different colours and assessing the effect of absorptance (see Fig. 6: (a) black (b) white, (c) dark blue, (d) green, (e) red, (f) yellow). Thermograms were taken with the sample in thermal equilibrium with the environment and no temperature differences were detected in the thermal image. However, after the exposure of the sample to solar radiation, the surface temperatures measured on different colours were quite different. Black and dark blue presented the highest temperatures, followed by green and red, yellow and, finally, white.

The effect of absorptance on different colours of the surface: a black, T(after solar radiation) = 30.4º C. b white, t(after solar radiation) = 27.3º C. c dark blue, T(after solar radiation) = 29.3º C. d green, T(after solar radiation) = 28.6º C. e red, T(after solar radiation) = 28.6º C. f yellow, T(after solar radiation) = 27.9º C

When the façade is painted with different colours, especially if there is a small colour pattern, the effect of the sun can conceal completely the results obtained. Even on a cloudy day, the diffuse solar radiation can affect the thermal patterns on the exterior of the building. Of course, on a plain façade solar radiation can be very useful to detect anomalies using thermography.

2.2.4 Other Factors

The existence of heat sources near the measurement area, such as radiators and artificial lights may affect the results. The severity of the interference from these sources depends on their radiation power and reflection from the surface under study (see Fig. 7).

The existence of shadows on the building, resulting from the presence of other buildings, trees or other neighbouring elements can lead to wrong conclusions (see Fig. 8). Also moist surfaces, after rain fall, may affect the interpretation of the results if not taken into account (see Fig. 9). Moreover, thermography is hardly applied when objects are in thermal equilibrium and without any thermal gradient (see Fig. 10).

3 Infrared Thermography Applications to Building Assessment

Infrared thermography has been applied since 1960 in many fields for several purposes. To the building assessment, it is commonly used since the 1990s. However, during the past few years, interest in the use of thermography for building inspections has increased, mostly due to lower infrared equipment costs. This technology enables the analysis of building structure, assemblies and materials. It is possible to identify missing insulation areas, air infiltration/exfiltration, poor window seals, areas of moisture infiltration, HVAC systems, plumbing or electrical components, construction details, etc. In the following sections a brief state-of-the-art of infrared thermography applications’ to building assessment is presented.

3.1 Thermal Comfort of Floor Coatings

The comfort of interior floor coatings is very important for the well-being of building users, especially in bedrooms and bathrooms where people commonly walk barefoot. Although comfort depends on floor and environmental temperatures, it is also determined by the material’s thermal characteristics, namely, thermal diffusivity and effusivity. Infrared thermography can be used to evaluate the comfort of interior floor coatings by comparing effects from barefoot contact with different materials [12,15,16] (see Fig. 11).

3.2 Detachments

Tests performed by Chew[10] pointed out the thermography potential to evaluate detachments on tile facades. The laboratory evaluation consisted on using samples composed by: concrete slab, cement sand screed with detachments of different diameters of hollowness and exterior ceramic wall tiles adhered with epoxy. After immersing the samples in water, thermograms were taken under controlled air temperature, with artificial lighting switched off and with no heat sources nearby. The test sample surface was heated up to acquire cross-sectional temperature gradient with four infrared lamps. It was possible to conclude that thermography was effective in locating the simulated detachments, especially for detachments with greater diameter.

Sakagami et al. [17] showed that using infrared thermography under microwave heating is a useful testing technique to detect superficial cracks in concrete structures. The work developed showed that applying microwave heating to the concrete structure with wet cracks, water in the cracks can be selectively heated, which leads to a specific temperature distribution around the crack enabling an easier detection. Preliminary experimental investigation was carried out for mortar-block specimens with artificial cracks using a microwave oven.

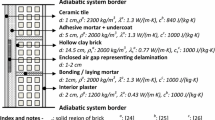

Studies made by Cerdeira et al. [18] focused on stone panel defects. Laboratory tests under controlled conditions were performed in scale models reproducing a real building envelope. The front face of the models was coated with stone panels with different thickness. In the mortar existing between the brick layer and the stone panels, a series of detachments with different size and shape were introduced to simulate the lack of adherence. A hot air generator was placed inside the models to set up the thermal gradient. The areas with defects were detected with lower temperatures than the surrounding areas as the air gap increased the thermal resistance of the wall. Higher thermal gradients between the interior and the exterior of the models lead to higher temperature differences between the defect and the surroundings. In the thinner stone panels the defects were detected more clearly. It was concluded that infrared thermography can be a valuable maintenance technique to detect detachments.

The latest study was made by Simões et al. [19] in which two set of experiments were carried out with four models of direct adhered ceramic tiles to simulate different defects and inappropriate adhesion of the adhesive layer using lock-in thermography. The tests were arranged with two halogen lamps of 2,000 W turned on for 30s and followed by a cooling phase of 60s. The results obtained showed that this technique allowed the identification of the defects, especially for those with larger dimension, but the induced detachment was not identified.

The detection of detachments in real building façades is also possible using the solar radiation as a heat source (see Fig. 12).

3.3 Moisture Anomalies

Dampness or changes in moisture content can also be detected by thermography, as surface temperature changes occur due to evaporative cooling [20], decrease of thermal resistance and increase of heat storage capacity of the moist material [21].

Balaras and Argiriou [22] made some recommendations for detecting water damage on roofs. They stated that inspections should be performed at night when the roof surface is still dry. Day-time surveys must be avoided once direct solar radiation can cover-up potential differences caused by the wet insulation. The moisture damage was detected by exploiting the thermal properties of water. As water has higher specific heat than other materials used on roofs, water loses or gains heat are much slower than other materials under similar conditions. A wet area retains the absorbed heat for a longer period than a dry mass and therefore takes longer to radiate heat during the night. Hence, it is detected by higher temperatures.

Avdelidis et al. [23] analysed the infrared thermography applicability in the detection of water movement and concentration in porous stones.

Grinzato and Cadelano [24] monitored the moisture content of a wall. The tests were carried out on a church fresco without applying thermal stress by artificial heat sources. The testing procedure consisted on increasing the evaporation rate of the surface by enhancing the air speed and recording, at the same time, a sequence of thermograms (before, during and after the increasing of the air speed). The results showed that it is possible to quantify the evaporation of a surface based on decreasing temperature, due to evaporation, as the intensity of the evaporation rate is related to the speed of temperature change.

Lerma et al. [25] also evaluated the detection of moisture on a building façade by making a qualitatively map of the surface moisture based on multi-temporal thermal analysis. This analysis is based on the different thermal behaviour of wet masses compared to dry masses over time due to temperature variations.

Rajewski and Devine [26] showed that thermal anomalies can be detected during the winter as building heat is conducted through wet insulation more rapidly than through dry insulation, thus, creating a warmer surface over the wet insulation. Moisture leaks and roof water damages were identified as areas with a higher temperature since damp insulation has a different overall heat transfer coefficient.

Rising damp on walls can also be detected by infrared thermography. The water level in the wall is detected due to superficial temperature variation, which is a result of evaporation at the wetted surface (see Fig. 13).

3.4 Thermal Bridges

Infrared thermography can be used to locate the position and to assess the magnitude of thermal bridges in existing buildings, as thermal bridges increase significantly heat loss through buildings components, especially with higher insulation levels (see Fig. 14).

As showed by Balaras and Argiriou [22], taking an outdoor thermogram of the structural component during winter, thermal bridges appear as light coloured areas because the heat losses from the indoor heated space cause a temperature increase. An indoor thermogram of the component during summer will show a similar image as a result of the absorbed solar heat gains from the external surface that are conducted through the building materials.

Asdrubali et al. [27] proposed an analytical methodology to quantitatively analyse some types of thermal bridges, which was validated by experimental and numerical analysis.

3.5 Air Leakage

Air leakage through windows and doors allows unwanted outdoor air to enter inside the building (infiltration) or indoor air to escape (exfiltration). Outdoor air increases heat losses in winter and heat gains in summer, thus, increasing both heating and cooling loads. A common location for air infiltration is around a window or a door frame. Infrared thermography is commonly used with a blower door test running. The blower door helps exaggerate air leaking through defects in the building shell and such air leaks are detected by the infrared camera (see Fig. 15).

3.6 Missing or Damaged Insulation

Infrared thermography allows checking the effectiveness of insulation in a building [3,28]. Thermal insulation reduces heat losses by conduction through the building envelope (i.e. walls, roofs) during winter and heat gains during summer. Missing or damaged insulation can be located by infrared cameras (see Fig. 16). According to Balaras and Argiriou [22] when the thermogram indicates a temperature difference of about 11 °C between the internal and external surface temperature that could indicate problems with the thermal insulation.

3.7 Hidden Details

Infrared thermography can be used to detect “hidden details”, as subsurface pips, ducts, wall ties, thermal resistances from radiant floors, etc. (see Fig. 17).

4 Detailed of Test Procedures

The guarantee of accurate assessment of building components using infrared thermography can only be achieved if inspection methodologies are available. This section provides detailed information about three test procedures to assess comfort of floor coatings (see Table 1), to detect detachments (see Table 2) and to evaluate wetting and drying processes of building materials (see Table 3). These tables, in a summarized and systematized manner, give particular emphasis to the objectives, procedures and obtained results. A critical analysis is presented at the end.

5 Conclusions

Thermography is a non-destructive testing technology with much potential to be applied to building diagnosis. Research studies developed at the Building Physics Laboratory (LFC) revealed that emissivity is an essential parameter, since it greatly influences thermographic measurements and may restrict the application of this technology to buildings. However, if the study aims for a qualitative analysis of the results, the selected emissivity value is not very important. It was also possible to confirm the influence of the material reflectivity on the results obtained. Colour or absorptance to solar radiation must also be considered during thermographic testing, as it may mask the results and cause misinterpretation, especially if the façade is painted with different colours and there is a specific small colour pattern. Other tests carried out emphasise the effect of heat sources near the measurement area, shadows on the building and moist surfaces after rain fall. On the other hand, it was also concluded that thermography cannot be used to study objects in thermal or hygroscopic equilibrium, as temperature differences between the object and the environment must be significant.

Infrared thermography is a useful technology to study the behaviour of buildings and building components. Examples of its application are presented, namely, to assess the comfort of interior floor coatings and to detect detachments of walls coatings, moisture anomalies, thermal bridges, air leakage and missing or damaged insulation.

Finally, detailed information about three test procedures is provided, summarized and systematized in the form of tables. These tables include information about the objectives of the study, test procedures, obtained results, equipment that was used and, at the end, a critical analysis of the applicability of thermography to the study carried out. The information is related with:

-

Evaluation of the comfort of interior floor coatings. Thermal images were obtained from the sole of a barefoot after having been in contact with different floor materials. Since the superficial temperature variation, after contact between the foot and the material, is related with discomfort, a comparison of thermograms revealed the various material comfort levels.

-

Detection of detachments of wall rendering. The detachment creates an air layer and thermal resistance to heat flows, which enables the temperature differential to be assessed. Two phases can clearly be distinguished, both in laboratory and "in situ". In the heating phase, the thermal resistance caused by detachment impedes the absorbed heat from reaching the interior, which means that the surface temperature is higher in the detachment. In contrast, in the cooling phase, the heat absorbed by the façade is prevented from reaching the surface, which means that surface temperatures are lower in the detachment, due to the reduction in thermal capacity.

-

Assessment of the wetting and drying process of building materials. Temperature differences due to superficial water evaporation provided a mean of recognising “wet” and “dry” areas. It was also possible to evaluate the material’s approximate drying time since small superficial temperature variations indicate that moisture is rather significant. Thermography, however, detects only superficial moisture.

References

Rao, P.: Infrared thermography and its applications in civil engineering. The Indian Concrete Journal, 82(5), 41–50 (2008)

NEC San-ei Instruments, Ltd.: TH1 101 Thermo Tracer—Operation Manual, Japan (1991)

Hart, J.M.: A Practical Guide to Infra-red Thermography for Building Surveys. Garston, Watford (1991)

Avdelidis, N.P., Moropoulou, A.: Applications of infrared thermography for the investigation of historic structures. J. Cultural Heritage. 5(1), 119–127 (2004)

Grinzato, E., Vavilovb, V., Kauppinen, T.: Quantitative infrared thermography in buildings. Energ. Build., 29(1), 1–9 (1998)

Haralambopoulos, D.A., Paparsenos, G.F.: Assessing the thermal insulation of old buildings—The need for in situ spot measurements of thermal resistance and planar infrared thermography. Energy Convers. Manage., 39(1–2), 65–79 (1998)

Incropera, F.P., Witt, D.P.: Fundamentals of Heat and Mass Transfer- 4th ed. John Wiley & Sons ed. , New York (1996)

Hagentoft, C.: Introduction to Building Physics. Student Litteratur, Sweden (2001)

Chown, G.A., Burn, K. N.: Thermographic identification of buildings enclosure defects and deficiencies. Canadian building digest 229, Canada, NRC–IRC (1983)

Chew, M.Y.L.: Assessing building facades using infra-red thermography. Struct. Survey, 16(2), 81–86 (1998)

Gaussorgues, G.: La thermographie infrarouge—Principles, Technologies, Applications. 4th edn. TEC & DOC, Paris, France (1999)

Barreira, E.: Thermography applications in the study of buildings hygrothermal behaviour. M.Sc. Thesis, Porto, FEUP, Portugal (in Portuguese) (2004)

Barreira, E., de Freitas, V.P.: Thermal images obtained from different solutions of radiant floor. Internal Report LFC/IC 134.2003, LFC, FEUP, Porto, Portugal (in Portuguese) (2003)

Barreira, E., de Freitas, V.P., Delgado, J.M.P.Q., Ramos, N.: Thermography applications in the study of buildings hygrothermal behaviour. Chapter published in infrared thermography. In: Prakash, R.V. (ed.) Intech, Croatia (2012)

Barreira, E., de Freitas, V.P.: Evaluation of building materials using infrared thermography. Constr. Build. Mater., 21(1), 218–224 (2007)

Barreira, E., de Freitas, V.P.: Thermal comfort evaluation of floor coatings using infrared thermography. Construlink Int. J. 3(8), 30–38 (2004). (in Portuguese)

Sakagami, T., Komiyama, T., Suzuki, H.: Proposal for a new thermographic non-destructive testing technique using microwave heating, In: Proceedings of the thermosense XXI, International society for optical engineering (SPIE), Orlando, pp. 99–103 (1999)

Cerdeira, F., Vázquez, M.E., Collazo, J., Granada, E. Applicability of infrared thermography to the study of the behaviour of stone panels as building envelopes. Energ. Build., 43(8), 1845–185 (2011)

Simões, N., Simões, I., Tadeu, A., Serra, C.: Evaluation of adhesive bonding of ceramic tiles using active thermography. In: Proceedings of the 11th international conference on quantitative infrared thermography, Naples, Italy (2012)

Rosina, E., Ludwig, N.: Optimal thermographic procedures for moisture analysis in building materials. In: Proceedings of society of photographic instrumentation engineers (SPIE), 3827, pp. 22–33 (1999)

ASTM.: ASTM C1153—10 Standard practices for location of wet insulation in roofing systems using infrared imaging. American Society for Testing and Materials (ASTM) International (2010)

Balaras, C.A., Argiriou, A.A.: Infrared thermography for building diagnostics. Energ. Build. 34(2), 171–183 (2002)

Avdelidis, N.P., Moropoulou, A., Theoulakis, P.: Detection of water deposits and movement in porous materials by infrared imaging. Infrared Phys. Technol. 44(3), 183–190 (2003)

Grinzato, B., Cadelano, G., Bison, P.: Moisture map by IR thermography. J. Modern Optics, 57(18), 1770–1778 (2010)

Lerma, J.L., Cabrelles, M., Portalés, C.: Multitemporal thermal analysis to detect moisture on a building façade. Construction and Building Materials, 25(5), 2190–2197 (2011)

Rajewski, G., Devine, G.: Building Envelope—infrared thermography, preventative roof maintenance workshop, Building operator association (1996)

Asdrubali, F., Baldinelli, G., Bianchi, F.: A quantitative methodology to evaluate thermal bridges in buildings. Appl. Energy 97, 365–373 (2012)

Ocaña, S.M.; Guerrero, I.C.; Requena, I.G. (2004). Thermographic survey of two rural buildings in Spain. Energy and Buildings, 36(6), 515–523

de Freitas, S.S., de Freitas, V.P., Barreira, E.: Application of infrared thermography to the diagnosis of façade rendering detachment, A state of the art report on building pathology—CIB W086, CIB Edition (in Press) (2013)

Barreira, E., de Freitas, V.P.: Infrared thermography applications in the study of building hygrothermal behaviour. CIB W40 Meeting, Caledonian University, Glasgow (2004a)

Barreira, E., de Freitas, V.P.: Importance of thermography in the study of ETICS finishing coatings degradation due to algae and mildew growth. In: Proceedings of the 10th international conference on durability of building materials and components (10DBMC), CSTB, Lyon (2005)

Acknowledgments

The research work presented herein was supported by FEDER funds through the Operational Programme for Competitiveness Factors—COMPETE and by national funds through the FCT—Portuguese Foundation for Science and Technology, under research project PTDC/ECM/114189/2009. J.M.P.Q. Delgado would like to thank Fundação para a Ciência e a Tecnologia (FCT) for financial support through the grant SFRH/BPD/84377/2012.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2013 Springer-Verlag Berlin Heidelberg

About this chapter

Cite this chapter

Barreira, E., de Freitas, S.S., de Freitas, V.P., Delgado, J.M.P.Q. (2013). Infrared Thermography Application in Buildings Diagnosis: A Proposal for Test Procedures. In: Delgado, J. (eds) Industrial and Technological Applications of Transport in Porous Materials. Advanced Structured Materials, vol 36. Springer, Berlin, Heidelberg. https://doi.org/10.1007/978-3-642-37469-2_4

Download citation

DOI: https://doi.org/10.1007/978-3-642-37469-2_4

Published:

Publisher Name: Springer, Berlin, Heidelberg

Print ISBN: 978-3-642-37468-5

Online ISBN: 978-3-642-37469-2

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)