Abstract

Crosslinking by gamma irradiation is a key technique employed in industrial and medical application of polymers to improve their mechanical and thermal properties. The objective of the present work is to investigate the effect of gamma irradiation on thermal properties of high density polyethylene (HDPE) reinforced with multiwalled carbon nanotubes (MWCNTs). The chemically treated MWCNTs were coated on HDPE pellets using nanofluid based deposition technique under continuous stirring, which were processed in an injection moulding machine to obtain nanocomposites having 0.25, 0.50, 0.75 and 1.0 wt% of MWCNTs. The nanocomposites thus obtained were exposed to γ-irradiation in the presence of air at 50 and 100 kGy doses. Thermal characterization of nanocomposites was studied using DSC, TGA and TMA techniques. The results obtained from the DSC studies revealed that the melting point of nanocomposites was not significantly influenced by the presence of MWCNTs, while γ-irradiation resulted a marginal change. The crystallinity of the nanocomposites was increased from 37.4 % for unirradiated HDPE to 55.8 % for 1.0 wt% and 100 kGy irradiated sample, which corresponds to 49 % enhancement. The onset temperature of degradation of nanocomposites was found to be influenced by both MWCNTs and irradiation dosage, which was increased by 16 °C for 100 kGy irradiated 1 wt% nanocomposite compared to unirradiated pure polymer. It is also found that the dimensional stability of the nanocomposites was increased by the reinforcement of MWCNTs. It is concluded from the above studies that thermal properties of nanocomposites are significantly influenced by the irradiation process and the concentration of MWCNTs.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

High density polyethylene (HDPE) is a semicrystalline polymer and ideal for industrial and medical applications because of its light weight, ease of processing, resistance to chemical corrosion, toughness and low cost of production. Due to biocompatible and bioinert nature of HDPE, it is explored in bone plates, bone screws, facial implants, orbital implants, artificial limbs and low load-bearing devices. Even though a wide variety of materials is being used as a cervical disc, HDPE has significant relevance due to its characteristics in addition to high cushioning effect [1].

During the last decade, researchers have attempted to improve physical, mechanical and thermal properties of HDPE for various applications. Different types of reinforcements such as carbon nanotubes (CNTs), graphite, hydroxyapatite (HA), calcium carbonate (CaCO3), wollastonite etc., have been used in order to improve the properties of HDPE [2–6]. Among the above mentioned reinforcements, CNTs are an ideal filler material due to their high Young’s modulus combined with low density, good electrical and thermal conductivity to prepare polymer nanocomposites [7]. Fouad et al. [8] prepared MWCNTs (up to 8 %) with HDPE via twin-screw extruder and injection moulding. It was observed that MWCNTs had no influence on melting temperature of nanocomposites; however, the crystallinity of the test material was reported to increase. Trujillo et al. [9] studied thermal properties of HDPE/MWCNTs/Al2O3 nanocomposites and reported that the onset temperature of degradation and melting temperature of nanocomposites were found to be decreased with an increase of concentration of reinforcement. Chrissafis et al. [10] studied fumed silica nanoparticles (SiO2)-HDPE composites filled with up to 5 wt% of reinforcement. Though the heat of fusion and the degree of crystallinity of composites were found to be decreased with filler content, no significant improvement on melting temperature was observed. Sahebian et al. [11] reported that the filler content had no influence on melting temperature of HDPE/CaCO3 composites but thermal expansion of them was restricted by the reinforcement of CaCO3. Kodjie et al. [12] prepared HPDE/SWCNTs (0.1, 0.25, 0.50 and 1.0 wt%) nanocomposites by solution blending technique and studied their characteristics. It showed that melting temperature of the nanocomposites was increased by 2 °C but the crystallinity was reduced by 4 % at 1.0 wt% of SWCNTs loading. In addition to that thermal stability of HDPE was also enhanced by 115 °C.

Gamma irradiation is widely used in industries for different purposes including medical sterilization and crosslinking of the polymers, which can be accomplished by chemically or irradiation [13]. As mechanical, thermal and thermo-physical properties of polymers are expected to be influenced by the crosslinking process [14], it is required to study the changes in the properties of polymeric material induced by the irradiation. The effects of gamma irradiation up to 1,000 kGy on HDPE have been studied by Puig et al. [15]. It was reported that the melting temperature of polymer was increased at low irradiation dose up to 150 kGy thereafter it was reduced gradually. Cataño et al. [16] reported that the onset temperature of degradation and melting temperature of HDPE/CaCO3 composites remained constant at different concentration of reinforcement and irradiation dose, however, the activation energy and degree of crystallinity was increased with filler content but not varied significantly with irradiation dose. Carmen et al. [17] studied the effect of gamma irradiation on HDPE/HA composites. It was noted that melting temperature of the composites was remained constant irrespective of concentration of the reinforcement. It was also observed that the crystallinity of composites was increased with filler concentration but it was decreased by 17 % when the test materials were exposed to γ-irradiation.

Though mechanical and thermal properties of MWCNTs reinforced HDPE have been reported, the influence of irradiation effect on thermal properties of the nanocomposites with varying concentration of MWCNTs have been not found in detail in the literature. Hence, the proposed study is focused on thermal characterization of irradiated HDPE/MWCNTs nanocomposites.

2 Materials and Methods

2.1 Materials

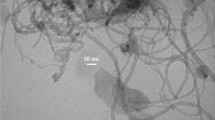

The nanocomposites with different concentrations, such as 0.25, 0.50, 0.75, 1.00 wt% of MWCNTs were received in the form of hemispherical cup representing a acetabular cup from Prof. Jose Simoes, University of Aveiro, Portugal. The materials used and processing techniques followed to prepare the nanocomposites were described in detail by Kanagaraj et al. [18].

2.2 Methods

The test materials were gamma irradiated with a 60cobalt source at room temperature in the presence of air at a dosage rate of 2.5 kGy/hr up to 50 and 100 kGy dosage level at M/s Microtrol sterilization Pvt. Ltd, Bangalore. Thermal analysis of the test sample was performed using a NETZSCH simultaneous thermal analyser (DSC & TGA, model STA 449F3). Samples (5.0 ± 0.1 mg) were heated in Argon atmosphere from room temperature to 550 °C. The thermo-mechanical analysis (TMA) of the nanocomposites was carried out using a Thermo-mechanical analyzer (TMA), Model Exstra 6000 (TMA/SS6000, Seiko Instruments Inc. Japan). The test sample was cylindrical in shape with 8 mm diameter and 2 mm thickness and it was heated from 35 to 85 °C in air under a static load of 10 mN applied on the sample through the expansion probe. All the experiments were performed at a heating rate of 10 °C/min. As recommended by ASTM F2625-10 standard.

3 Results and Discussion

3.1 Differential Scanning Calorimetry Analysis

Melting endotherms of unirradiated and irradiated nanocomposites were analyzed by Differential Scanning Calorimetry (DSC) thermograms and the results are presented in Fig. 1a and b, respectively.

It is observed from Fig. 1a that the melting temperature of unirradiated nanocomposites was found to be slightly varied for different concentrations of MWCNTs. Upon irradiation of the nanocomposites, the melting peak still shifted to higher values, as observed in Fig. 1b. It is observed that the melting temperature of HDPE was raised by increasing the concentration of MWNCTs and γ-irradiation doses. Typical parameters such as melting temperature and degree of crystallinity, were calculated from the DSC plots.

Figure 2a shows the variation of melting point of nanocomposites before and after irradiation. It is observed that the melting point of pure polymer was found to be 131.3 °C, which was increased to 133.8 °C by incorporation of 1.0 wt% MWCNTs corresponding to 1.8 % increase. When the nanocomposites were exposed to gamma irradiation at 100 kGy, the melting temperature of 1 wt% MWCNTs was raised 136.7 °C, which corresponds to a raise of 4 % compared to unirradiated pure polymer. The increase of melting temperature of nanocomposites with irradiation dosage confirmed that the melting process of the test samples was delayed due to the formation of crosslinks produced during the irradiation process, Premnath et al. [19, 20]. Furthermore, an increase of irradiation dose led to higher degree of crosslinking, which resulted in long branched molecules with infinite mass [21] and thus it is expected to demand higher heat input during the melting process resulting an increase of melting temperature of the nanocomposites.

The crystallinity of the nanocomposites was obtained by normalizing the heat of fusion of nanocomposites with that of a 100 % crystalline material, 289.4 J/g in this case [22]. Figure 2b shows the degree of crystallinity of test materials against irradiation dosage and MWCNTs concentration. The crystallinity of nanocomposites was found to be increased with concentration of MWCNTs and gamma irradiation. It was found to be increased from 37.4 to 51.8 % for 1 wt% MWNCTs in HDPE, which was then raised to 55.8 % at 100 kGy irradiation dose. The enhancement of crystallinity was 38.5 % for 1 wt% of HDPE/MWCNTs nanocomposites and 49 % for the same sample irradiated at 100 kGy dose. The increase of crystallinity of the test sample with irradiation dose was due to the fact that chain scission occurred in addition to crosslinking during the irradiation process and these two processes progressed to a higher degree with an increase of dosage level. It was reported by Bhateja et al. [22] that the broken chains formed by the chain scission process were rearranged into the existing crystals, thus an increase of the crystal perfection in an irradiated nanocomposite was occurred. According to Kanagaraj et al. [18], MWCNTs acted as sites for nucleation of crystallization and thus it enhanced the crystallinity of the nanocomposites.

3.2 Thermogravimetric Analysis

Thermal stability of nanocomposites before and after gamma irradiation was studied and it is shown in Fig. 3a and b.

It is observed from Fig. 3 that all unirradiated and irradiated nanocomposites showed higher thermal stability than pure HDPE. It is observed from the results that all nanocomposites are having relatively good thermal stability up to 325 °C at 0 kGy and it was increased to 400 °C at 100 kGy irradiated dose. It is observed from Fig. 4 that the onset temperature of decomposition of unirradiated nanocomposite at 1 wt% of MWNCTs was increased from 457.2 to 467.7 °C, while at 100 kGy the corresponding value was raised from 465 to 473.1 °C. It is due to high thermal stability of MWCNTs that restrict the thermal degradation effect of polymer chains.

3.3 Thermo-mechanical Analysis

In order to investigate the dimensional stability of nanocomposites, thermal expansion of the unirradiated and irradiated samples was studied in the temperature range of 35–85 °C and the results are shown in Fig. 5a and b.

It is observed from Fig. 5 that thermal expansion of both unirradiated and irradiated samples was decreased with an increase of MWCNTs and irradiation dosage but increased with temperature. Thermal expansion of pure HDPE was higher than that of nanocomposites at any concentration and irradiation dose. At 0 kGy, the linear strain of pure polymer was 5.87 × 10−3 m/m and it was reduced to 3.45 × 10−3 m/m at 1 wt% nanocomposite. When the nanocomposites were exposed to gamma irradiation at 100 kGy, the linear strain of 1.0 wt% nanocomposite was further reduced to 2.64 × 10−3 m/m whereas the same for pure HDPE was 3.90 × 10−3 m/m.

It is observed from Fig. 6 that thermal expansion of HDPE was decreased by 41.2 and 55 % for 1 wt% of MWNCTs and 100 kGy irradiation, respectively. In general, it is observed that the percentage decrease of linear strain of pure polymer is decreased by increasing the concentration of MWNCTs and the irradiation dosage level. The presence of MWCNTs and crosslinking induced by the irradiation resulted in long molecular chains with infinite mass restricting the mobility of polymer chains, which led to the reduction of linear thermal expansion of polymer and nanocomposites [23].

The coefficient of thermal expansion (CTE) of both unirradiated and irradiated nanocomposites was calculated in the temperature range of 40–80 °C at an interval of 10 °C, where the reference temperature was considered as 35 °C. Figure 7a and b show the CTE of nanocomposites at 0 and 100 kGy irradiation dose, respectively.

It is observed from Fig. 7a, b that (1) CTE of all test samples increased with temperature, (2) CTE of the sample was significantly restricted with an increase of the concentration of MWCNTs, (3) γ-irradiation also influenced to restrict CTE of test samples. It is observed that the CTE of unirradiated pure polymer at 40 and 80 °C was calculated to be 44.9 and 108.6 μm/m-K, respectively, whereas the same for 1 wt% nanocomposite, it was reduced by 62 and 41 %, respectively. Similarly at 100 kGy irradiation dose, the CTE for the pure polymer at same temperatures was noted to be 37.6 and 72.6 μm/m-K, and it was reduced by 57 and 35 %, respectively for 1 wt% nanocomposites. The reduction of CTE of nanocomposites could be attributed to very low intrinsic thermal expansion of nanotubes, which is 26 nm/m up to 800 K [24] and thus it is expected to restrict CTE of pure polymer. Moreover, MWCNTs have very high specific surface area and hence the interfacial area between MWCNTs and polymer matrix is of very high order resulting to the reduction of CTE of the composites.

4 Conclusions

Thermal characterization of gamma irradiated high density polyethylene reinforced with multiwalled carbon nanotube nanocomposites was studied and the following conclusions are drawn for nanocomposites having 1 wt% MWCNTs and irradiated at 100 kGy.

-

The melting temperature and crystallinity of HPDE was enhanced both by presence of MWCNTs and gamma irradiation as well. At 1 wt% MWCNTs in HDPE and 100 kGy irradiation dose, the melting temperature and crystallinity were increased by 5.4 °C and 49 % respectively.

-

The onset temperature of degradation of HDPE was delayed by MWCNT reinforcement and irradiation. At 1 wt% MWCNTs and 100 kGy irradiation dose, the degradation was delayed by about 75 °C.

-

Dimensional stability of HDPE greatly enhanced by the presence of MWCNTs. It was improved by 56 % upon irradiating 1 wt% nanocomposite at 100 kGy.

References

J.B. Park, R.S. Lakes, Biomaterials: An Introduction, 2nd edn. (Plenium press, New York, 1992)

S.-H. Yu, J.-T. Yeh, B.-C. Huang, K.-S. Huang, Preparation of HDPE/Carbon nanotube composite. Polym. Plast. Technol. Eng. 49, 15, 1534 (2010)

H. Fouad, R. Elleithy, High density polyethylene/graphite nano-composites for total hip joint replacements: Processing and in vitro characterization. J. Mech. Behav. Biomed. Mater. 4, 1376 (2011)

M. Wang, S. Deb, W. Bonfield, Chemically coupled hydroxyapatite-polyethylene composites: processing and characterization. Mater. Lett. 44, 119 (2000)

Z.H. Liu, K.W. Kwok, R.K.Y. Li, C.L. Choy, Effects of coupling agent and morphology on the impact strength of high density polyethylene/CaCO3 composites. Polymer 43, 2501(2002)

R. Yang, J. Yu, Y. Liu, K. Wang, Effects of inorganic fillers on the natural photo-oxidation of high-density polyethylene. Polym. Degrad. Stab. 88, 333 (2005)

P.M. Ajayan, O. Stephan, C. Colliex, D. Trauth, Aligned carbon nanotube arrays formed by cutting a polymer resin–nanotube composite. Science 265, 212 (1994)

H. Fouad, R. Elleithy, S.M. Al-Zahrani, M.A. Ali, Characterization and processing of high density polyethylene/carbon nano-composites. Mater. Des. 32, 1974 (2011)

M. Trujillo, M.L. Arnal, A.J. Müller, E. Laredo, Bredeau, D. Bonduel, Ph. Dubois, Thermal and morphological characterization of nanocomposites prepared by in situ polymerization of high-density polyethylene on carbon nanotubes. Macromolecules 40, 6268 (2007)

K. Chrissafis, K.M. Paraskevopoulos, E. Pavlidou, D. Bikiaris, Thermal degradation mechanism of HDPE nanocomposites containing fumed silica nanoparticles. Thermochim. Acta 485, 65 (2009)

S. Sahebian, S.M. Zebarjad, J.V. Khaki, S.A. Sajjadi, The effect of nano-sized calcium carbonate on thermodynamic parameters of HDPE. J. Mater. Process. Technol. 209, 1310 (2009)

S.L. Kodjie, L. Li, B. Li, W. Cai, C.Y. Li, M. Keating, Morphology and crystallization behavior of HDPE/CNT nanocomposite. J. Macromol. Sci., Part B 45, 2, 231 (2006)

M. Dole, Cross-linking and crystallinity in irradiated polyethylene. Polym. Plast. Technol. Eng. 13, 41 (1979)

S.K. Bhateja, E.H. Andrews, R.J. Young, Radiation-induced crystallinity changes in linear polyethylene. J. Polym. Sci. Part B 21, 523 (1983)

C.C. Puig, C. Albano, E. Laredo, E. Quero, A. Karam, Thermal characterization of the HDPE/LDPE blend (10/90) irradiated using γ-rays. Nucl. Instrum. Methods Phys. Res, Sect. B 268, 1466 (2010)

L. Cataño, C. Albano, A. Karam, N. Domĺnguez, Y. Sánchez, J. González, Effect of gamma irradiation on mechanical, thermal and rheological behavior of HDPE filled with seaweed residues. Nucl. Instrum. Methods Phys. Res., Sect. B 236, 348 (2005)

A. Carmen, K. Arquĺmedes, P. Rosestela, G. Gema, D. Nohemy, G. Jeanette, S. Yanixia, HDPE/HA composites obtained in solution: Effect of gamma radiation. Nucl. Instrum. Methods Phys. Res., Sect. B 247, 331 (2006)

S. Kanagaraj, F.R. Varanda, T.V. Zhil’tsova, M.S.A. Oliveira, J.A.O. Simões, Mechanical properties of high density polyethylene/carbon nanotube composites. Compos. Sci. Technol. 67, 3071 (2007)

V. Premnath, W.H. Harris, M. Jasty, E.W. Merrill, Gamma sterilization of UHMWPE articular implants: an analysis of the oxidation problem. Biomaterials 17, 1741 (1996)

V. Premnath, A. Bellare, E.W. Merrill, M. Jasty, W.H. Harris, Molecular rearrangements in ultra high molecular weight polyethylene after irradiation and long-term storage in air. Polymer 40, 2215 (1999)

P.C.P. Watts, P.K. Fearon, W.K. Hsu, N.C. Billingham, H.W. Kroto, D.R.M. Walton, Carbon nanotubes as polymer antioxidants. J. Mater. Chem. 13, 491 (2003)

S.K. Bhateja, R.W. Duerst, J.A. Martens, E.H. Andrews, Radiation-induced enhancement of crystallinity in polymers. J. Macromol. Sci. RMC 4, 581 (1995)

C.F. Deng, Y.X. Ma, P.Zhang, X.X. Zhang, D.Z. Wang (2008), Thermal expansion behaviors of aluminum composite reinforced with carbon nanotubes. Mater. Lett. 62, 2301 (2008)

M.N. Prakash, Master’s thesis, Department of mechanical engineering, College of engineering, The Florida State University (2005)

Acknowledgments

Authors gratefully acknowledge the Department of Science and Technology, India, for funding through a project IDP/MED/2009/04. Technical support given by M/s Microtrol sterilization Pvt. Ltd, Bangalore, Prof. J. A. O. Simoes, University of Aveiro, Portugal, staff from Central Institute Facility and Materials science laboratory at IITG is kindly acknowledged.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2013 Springer-Verlag Berlin Heidelberg

About this paper

Cite this paper

Kumar, N.N., Rama Sreekanth, P.S., Kanagaraj, S. (2013). Effect of γ-Irradiation on Thermal Properties of MWCNTs Reinforced HDPE. In: Giri, P.K., Goswami, D.K., Perumal, A. (eds) Advanced Nanomaterials and Nanotechnology. Springer Proceedings in Physics, vol 143. Springer, Berlin, Heidelberg. https://doi.org/10.1007/978-3-642-34216-5_40

Download citation

DOI: https://doi.org/10.1007/978-3-642-34216-5_40

Publisher Name: Springer, Berlin, Heidelberg

Print ISBN: 978-3-642-34215-8

Online ISBN: 978-3-642-34216-5

eBook Packages: Physics and AstronomyPhysics and Astronomy (R0)