Abstract

The Chemistry, Manufacturing and Controls (CMC) section of a regulatory submission details aspects of the drug’s chemical properties, its manufacturing process development and production, and control mechanisms, including analytical testing both in-process and of the finished drug, to show the process is controlled and reproducible. For a candidate biosimilar much is already understood about the chemistry and properties of the drug by thorough characterization of reference drug product. The challenge is to develop a manufacturing process with adequate controls to ensure that the biosimilar product closely matches the reference drug product and to demonstrate this biosimilarity with a strong analytical package.

Access provided by CONRICYT-eBooks. Download chapter PDF

Similar content being viewed by others

Keywords

The Chemistry, Manufacturing and Controls (CMC) section of a regulatory submission details aspects of the drug’s chemical properties, its manufacturing process development and production, and control mechanisms, including analytical testing both in-process and of the finished drug, to show the process is controlled and reproducible. For a candidate biosimilar much is already understood about the chemistry and properties of the drug by thorough characterization of reference drug product. The challenge is to develop a manufacturing process with adequate controls to ensure that the biosimilar product closely matches the reference drug product and to demonstrate this biosimilarity with a strong analytical package.

Understanding the Reference Drug

The first step in an effective biosimilar CMC strategy is to develop an extensive and sound understanding of the biochemical properties of the reference or innovator drug product, which for biosimilars we shall consider to be a recombinantly produced purified protein. The biosimilar developer lacks access to any proprietary information about the reference product, including for example development reports, batch records, and release specifications for the drug substance and product. Therefore, the developer must mine public sources of information, from information disclosed by the innovator through publication, presentation or information accessible from regulatory agencies. Additionally, a Certificate of Analysis is also available for some biologics reference drug products procured from certain geographical regions.

Generally, one can readily obtain basic aspects of the drug, such as the amino-acid sequence, type of product (IgG antibody, fusion protein, enzyme, etc), mechanism of action, dosage and formulation. Those with a background in development of similar types of protein products can identify likely Critical Quality Attributes (CQAs) that must closely match those of the reference product in order to avoid having any clinically meaningful differences from the reference product, the key test of biosimilarity. Some CQAs represent the protein functional aspects, such as an antibody binding to its target or an enzyme activity, which determine the mechanism of action of the protein. Others are structural, such as post-translational modifications (PTMs) like glycosylation, which can affect secondary aspects like effector function, as well as pharmacokinetic and pharmacodynamic (PK/PD) profiles. Other CQAs may represent the protein molecular state, for example aggregation or degradation, as well as secondary, tertiary or higher order structures that may impact biological activity. Aggregation and degradation are special concerns for protein therapeutics due to the higher immunogenicity of aggregated and certain degraded proteins.

Additionally, as with any biologic product, it is necessary to evaluate the process-related residual impurities such as host-cell proteins (HCP), host-cell DNA (HCDNA), and residual Protein A when Protein A chromatography is used in a process. HCP and Protein A impurities are generally detected by sensitive immunoassays (ELISA), while DNA is typically measured using the quantitative polymerase chain reaction (qPCR). In early development HCP can be detected using a standard assay for the HCP of a particular cell line, such as CHO cells. Later stage development needs to address the specific HCP produced by the cell line of interest. Such a cell-line specific ELISA is produced by generating detection antibodies against the non-transfected form of the cell line (sometimes called null-set cells) that had been used with transfection to produce the protein. These tests, together with the general safety assays (i.e. endotoxin, sterility) with appropriately selected acceptance criteria for the corresponding dose(s) and modes of administration will ensure the product safety of the biosimilar.

Any therapeutic protein represents a family of closely related variants, which all have the same amino-acid sequence but varying levels of modifications, either from variation within PTMs or due to degradations such as deamidation and oxidation. Thus, a typical monoclonal antibody shows at least 4–6 bands on isoelectric focusing, with each band representing a charge variant. All of these variants may have comparable activity such as target binding, but can vary in terms of effector function or PK/PD profiles (Schiestl et al. 2011). The biosimilar developer needs to understand the allowed range of these variants. This can be ascertained by extensive testing of many lots of the reference product, which will reveal the extent of variation for each CQA. How many lots? This is both a statistical and logistical question, and is addressed in more detail in Chap. 17. Recent approvals of some biosimilars suggest at least 20 lots should be assayed (Gray 2017), with more being better in terms of range setting. Testing of the originator lots may reveal considerable difference in one or more CQAs defining groups of lots with different profiles. This observation likely indicates that the innovator conducted a process changes(s), assessed comparability before and after the change(s), and obtained approval by the regulatory agencies for the new process/product. Furthermore, lots aged for varying lengths of time under the indicated storage conditions will reveal stability parameters.

Expression Systems and Clonal Selection

One has a choice of biological expression systems for production of a recombinant protein therapeutic, ranging from the simplest microbial systems to complex cellular systems such as mammalian cell lines. The simplest microbial cells, such as E. coli, can only express the protein without post-translational modifications (PTMs), such as glycosylation (see Table 8.1). For simpler proteins lacking such PTMs bacterial systems can be an attractive choice due to their rapid growth rate and productivity. They can present challenges in terms of recovery of the protein, which is typically produced in reduced, unfolded form in inclusion bodies. There are other bacterial systems that secrete the folded protein, such as that based on Corynebacteria (Ajinomoto), but again the protein would lack any PTMs. Higher order microbes such as yeast expression systems (i.e., P. Pastoris or S. cerevisia) will produce some PTMs, but usually in a more primitive form such as high-mannose glycosylation. For ready secretion of recombinant proteins with full PTMs, mammalian cell lines such as CHO, NS0 and PER.C6 have been the expression system of choice. Occasionally an alternative expression system such as one based on insect-cells (Protein Sciences) or even green plants (Medicago) is utilized for specialty products, such as vaccines (Fig. 8.1).

With these considerations in mind, the biosimilar developer would in most cases select a comparable system to what was used for the reference product. However, for simple proteins lacking PTMs, there could be economic advantages in going to a high-yielding microbial system. Secondly, in selecting a mammalian cell, attention should be given to subtle differences in some PTMs between types of cells, such as the type of sialic acid added (NANA vs. NGNA) or types of linkages between sugars (Ghaderi et al. 2012). The key focus is to produce PTMs as close as possible to those of the reference product. In this regard, the safest approach is to use the same type of expression system, even down to the specific strain of mammalian cell (i.e., CHO-DG44 vs. CHO-S), as used for the reference product.

In selecting clones for production of recombinant proteins following transduction, one generally seeks those with the highest productivity. Productivity is a function of both the specific expression rate, typically expressed as picograms/cell/day (pg/c/d), and the viable cell density (vcd). Thus, high productivity may be due to high specific productivity in spite of low cell density, or vice versa. The ideal would be for both pg/c/d and vcd to be high.

In development of a biosimilar, however, a new parameter enters into the selection process—how closely does the product from any given producing clone match that of the reference product? While this is mostly a function of PTMs, it may also be influenced by potential degradative processes in some clones, such as oxidation and deamidation. This new criterion supersedes productivity in terms of importance, since any biosimilar structural features must match as closely as possible to the reference product. Therefore, some highly productive clones may need to be passed over in favor of less productive ones that produce a protein more comparable to that of the reference product.

Finally, as with any development of clones for production of a recombinant protein, clonal stability needs to be assessed by repeatedly passaging the cells, typically for 20 passages or 50 generations, and measuring productivity and protein quality at selected time points during these passages. Some clones lose their ability to express a protein or alter their expression over time, and these need to be eliminated from consideration. With this consideration in mind it is recommended to select a primary clone and at least two back-ups for the clonal-stability study. Additionally, the product expressed by all selected clones should be evaluated and pass all criteria for the identified CQAs for the full culture period.

Development of Upstream and Downstream Processes and Scale-Up to Manufacturing

Biosimilar development follows the same path as new biopharmaceutical development in terms of upstream (culture) and downstream (purification) process development. Thus, following selection of a suitable clone, the goal is to develop consistent and high-yielding processes that produce protein with only trace levels of impurities. Upstream development is typically carried out in small bioreactors, ranging from multiple mini-bioreactors such as ambr® (Sartorius, see Fig. 8.2) or DasBox (Eppendorf) to 2–10 L benchtop bioreactors. By varying the culture media, feeds, and bioreactor parameters one seeks to produce the most protein in the shortest time. On the downstream side, the typical approach is to use a system of filters and chromatographic columns to purify the protein of interest by either binding/retaining it while impurities pass through, or vice versa.

However, there is one major difference for biosimilars—comparison to the reference product is needed throughout the upstream and downstream development program to ensure that the selected conditions produce protein highly similar to the reference product. Again, one may need to forego a high-yielding upstream process in favor of a lower-yielding one that produces protein more similar to the reference product. Similarly, some downstream process steps have the potential to induce structural changes in the protein, such as deamidation, which would produce acidic variants that may pull the protein outside of the isoelectric-point range of the reference product. Using newer charge-based techniques (Müller-Späth et al. 2015), it may be possible to separate charge variants in order to remove undesirable species in terms of biosimilarity. Such approaches, however, would add complexity and additional processing compared to tailoring the clone and production process to produce material similar to the reference product.

Of course, should the new process yield a higher purity in terms of lower residual host-cell proteins, or lower levels of aggregation or product-related degradants, that would be beneficial since such components of the reference product are undesirable. Indeed, as bioprocessing techniques improve, increasing lower levels of such impurities are expected, and it may well be that the reference product has already seen several process improvements over its lifetime to produce purer material. Finally, a full viral-clearance study is required for a biosimilar downstream process just as it is for a new biopharmaceutical.

Scale-up of biosimilars follows the same path as new biopharmaceuticals except that one is constantly assessing the effect of scale-up on the similarity of the biosimilar to the reference product. Some factors to assess as bioreactor scale increases are levels of oxygenation and carbon dioxide, pH and nutrients/waste products, as well as rate and efficiency of mixing. These effects need to be assessed over the range of bioreactors that could be used in production. Following the initial small-scale bioreactors, a series of increasingly larger bioreactors are used and the product quality assessed along the way. As with new biopharmaceutical development, consistency and robustness in production and purification is the goal.

While it is possible to selectively remove undesirable charge variants in the purification process by specialized techniques like charge-displacement cation-exchange chromatography (Zhang et al. 2011), this is challenging given the subtleness of the variations, which could be only a single-charge change on a large protein. Furthermore, such an additional step in the downstream process would likely reduce yields significantly due to the need to closely fractionate similar species. Therefore, it is much better to select a cell line and growth conditions that result in a protein with a highly similar profile to that of the reference product.

Regarding product process qualification, process characterization and validation, these areas of development are similar to those needed for a novel biopharmaceutical. However, for a biosimilar these steps can be easier since product and process knowledge is more advanced due to the learnings from the reference product. As for control strategies, these would be particularly strict for a biosimilar due to the need to maintain biosimilarity to the reference product at each step of the production and purification.

Effect of Raw Materials on Product Quality

Sometimes overlooked but very important is the assessment of critical raw materials, such as culture media components, process buffering chemicals, and excipients on the quality and hence biosimilarity of a protein. For example, some specific culture-media additives can alter post-translational modifications, such as the addition of N-acetyl neuraminic acid (NANA) to block production of NGNA sialic acid (D. Ghaderi et al. 2012). Furthermore, sugars such as glucose used in culture media, or sucrose and trehalose used in final formulations, can be contaminated with endotoxins, as sugars are biologically derived. This will vary from lot-to-lot and must be assayed, since endotoxins are a highly undesirable impurity. The careful consideration of critical raw materials continues through formulation development. For example, the effect of oxygen to produce peroxides in solutions of polyethers, such as polysorbates (Tween®) is well-known. Such peroxides are highly reactive and will degrade the protein. These can be controlled through a combination of sourcing ultra-high purity polysorbates meeting tight specifications for low-levels of peroxide, drawing only from previously unopened containers, and using fresh solutions. Furthermore, as with any new biopharmaceutical, one should seek to avoid animal-derived raw materials whenever possible, and if not, perform a risk-assessment on the potential for contamination from sources of transmissible spongiform encephalopathies (TSE). Other impurities in raw materials can include transition metal ions that can act as catalysts for the oxidation of sensitive amino acids such as methionine.

With the advent of single-use technologies utilizing plastics, a new potential source of impurities is present due to leachables and extractables from the plastics. This is particularly a concern with plastic bags used widely throughout the production process, from bags used to contain the cells and media of production to other bags for storage of buffers and both intermediates and bulk drug substances. The plastic materials must therefore be rigorously tested for leachables and extractables, and their effect evaluated. The United States Pharmacopeia has developed a rigorous series of tests for such materials for medical use to qualify for USP’s Type VI classification, which means that they are biologically compatible and suitable for even in vivo use in patients. Manufacturers of single-use systems have had to source very high purity plastics for their products, since previously these plastics were primarily used in industries not requiring such purity, such as the automobile industry. Customer of single-use materials should request leachable and extractable data from the supplies as well insist that they be made from USP Type VI materials.

Testing and control of residual process impurities such as host-cell proteins (HCP), host-cell DNA (HCDNA), and protein chromatographic ligands such as Protein A is the same for biosimilars as for novel biopharmaceutical. Levels of such residuals, which represent a potential safety concern, should be comparable to or lower than those of the reference drug since the biosimilar developer is relying on the positive safety history of the reference product.

Effect of Manufacturing Conditions on Product Quality and Control Strategy for Biosimilars

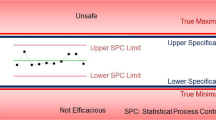

As described above, a tight control of the CQAs is required throughout the development of upstream and downstream processes to ensure that the selected conditions do not induce structural changes in the protein that may pull the target product outside of the range of the reference product. Many of the analytical methods ensuring the maintenance of biosimilarity continue to be used as in-process controls.

For biosimilars, as well as for any biologic, specifications need to be set following ICH Q6B. Some of the parameters tested and their acceptance criteria will reflect the specific process used for the manufacturing of the biosimilar product and as such differ from the originator (i.e. residuals from materials used in upstream media or downstream purification steps, HCP, residual host cell DNA, etc.).

The analytical comparability studies will guide the establishment of specifications for the CQAs. The principles discussed in Chaps. 11 and 17 can guide the decisions as to the acceptable ranges in the acceptance criteria set for each CQA to ensure biosimilarity.

Specifications will vary depending on the type of molecule (i.e. recombinant protein vs monoclonal antibody). For glycosylated molecules, understanding the impact of glycan composition on potency is important since variability is expected lot-to-lot. Variation on the level of sialylation can influence the PK profile of a molecule. For mAbs, oligosaccharide core-fucosylation impacts the Fc conformation and can lower the binding affinity of the molecule to Fc receptors. Therefore, it is important to monitor these structural features and ensure process controls are sufficient to maintain them within the acceptable range. For a monoclonal antibody, control of amino-acid modifications that may impact product potency may also be required (i.e. methionine oxidation, asparagine deamidation, etc.).

An important aspect of setting specifications is the evaluation of stability behavior for the biosimilar candidate in comparison to the reference material. Degradation profiles obtained during side-by-side, forced-degradation studies can uncover differences in behavior between the biosimilar candidate and reference material, such as oxidation due to metal catalysis from process residuals, requiring additional process controls. Typical forced-degradation conditions include exposure to high temperature, light, low and high pH, and oxidizing conditions. Their impact on the protein in terms of accumulation of low and high molecular weight species (SEC-HPLC; reducing and non-reducing CE-SDS), changes in charged species (CEX-HPLC), conformational changes (CD), potency and protein concentration (UV) should be evaluated for biosimilar candidate and reference material.

Additionally, the functional assays should be developed as early as possible to measure biological activity ensuring that biosimilar candidates are effective and suited for moving along the development process. As example, the functional assays used for testing monoclonal antibodies are described in Chap. 16. One or more of these assays will also become part of the specifications after appropriate validation to ensure assay performance.

A generic list of specifications for a biosimilar BDS is presented in Table 8.2.

As the number of lots manufactured using the same process increases, results for all the parameters included in the specifications as well as in-process and stability results, will create a database in support of process validation and enable to set robust specifications ranges for commercial lots.

Implementing a Successful CMC and Analytical Strategy fortheDevelopment of Biosimilars

The Analytical Strategy is the most critical component of planning a biosimilar development program. A chapter has been dedicated in this book (Chap. 11) to defining the principles of analytical biosimilarity that enable a carefully designed analytical plan. This section focuses on key factors to implement a successful CMC strategy fostering the constant collaboration between process development, manufacturing and analytical scientists throughout the development program of each biosimilar candidate.

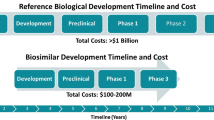

The development of a biosimilar product requires a complex set of CMC elements that need high level of expertise and investment. In particular, biosimilar development is heavily frontloaded on analytics. This shifts the traditional pattern of investment during the development of de novo biologics that delays to later stages the considerable costs of equipment/ expertise and/or outsourcing of state-of-the-art testing. Instead early investment in this area is critical for success when developing a biosimilar product. Analytical biosimilarity of the candidate to the reference product is the first layer of biosimilarity demonstration. It needs to be monitored and confirmed at every step of the development path to ensure success (Fig. 8.3).

A biosimilar protein is, by definition, related to the originator drug (reference product) by a common primary amino-acid sequence. Therefore, it is imperative to first ensure this condition is met by the biosimilar candidate. It is recommended that the biosimilar developer confirms the amino-acid sequence of the reference product by direct analysis to circumvent any potential misrepresentations in the public information.

In addition, all therapeutic proteins, including originator drugs, are a population of product variants. The key is to establish the characteristics of the API in the reference product to define the Quality Target Product Profile (QTPP) for the biosimilar (Bui et al. 2015). The QTPP is defined as a combination of Critical Quality Attributes (CQA’s). Based on ICH guidelines (Annex of ICH Q8), “A CQA is a physical, chemical, biological or microbiological property or characteristic that should be within an appropriate limit, range or distribution to ensure the desired product quality”.

The CQA’s, their values and ranges that define the biosimilar QTPP are established from testing of the reference product as indicated earlier. A thorough characterization of the API in the reference product using a panel of physicochemical methods (such as peptide mapping by LC-MS and including the analysis of PTMs) and biological assays (i.e. ADCC, CDC, others) originates a database to compare the biosimilar candidate. The surveillance of the reference product occurs continuously in order to form a full view of originator product variability in CQA’s. This includes variability derived from process changes incorporated by the originator and approved based on comparability exercises, as well as stability changes within the approved parameters. Since the reference product is only accessible to the biosimilar developer in its final formulation, testing requires methods that are not sensitive to the composition of the formulation or extraction of the API from the formulation avoiding changes to its structure and/or properties.

The assessment of CQA’s does not require a full validation of the analytical methods employed as per ICH Q2(R1). However, it is in the best interest of the biosimilar developer to use methods providing reproducible and reliable results from very early stage. It is recommended at a minimum to qualify the methods by evaluating the critical parameters for the intended purpose. Additionally, using orthogonal analytical methods based on different principles can typically aid in detecting small differences in molecular variants.

As indicated earlier, CQA’s need to be evaluated when selecting an expression system, even for the individual clones, to ensure that biosimilarity is attainable. Evaluating some of these parameters (i.e. glycosylation) at the clone level requires the adaptation of the methods typically used for the analysis of late-stage, highly purified samples to small quantities of cell culture supernatant. Additionally, testing of many samples in parallel (i.e. comparing clones, culture conditions, etc.) implies considerable dedication of resources.

Consider for example that evaluating the glycosylation produced by different clones implies obtaining the glycosylation pattern of major N- and O-glycan species and evaluating the differences observed in minor glycans present. This requires enzymatic or chemical release of oligosaccharides followed by fluorescent labeling and HPLC with fluorescence detection), identifying the individual oligosaccharides species i.e. by LC-MS of the released and tagged glycans, and estimating the glycosylation site occupancy (i.e. by CE-SDS and/or LC-MS). Once a clone(s) are selected, the effect of culture conditions and media additives, culture age, etc. should also be evaluated by testing the same glycosylation aspects. It is well known that glycosylation can be affected by these parameters and any changes may result in lack of biosimilarity.

Similarly, the assessment of biosimilarity at different steps in the development of the DSP purification needs to cover all the CQAs to ensure the biosimilar molecule obtained through the optimized USP is neither degraded nor the variant composition is changed (Chaudhari et al. 2017). As with any biologic product, a critical aspect of this evaluation is the assessment and control of aggregation.

The full comparability of the biosimilar candidate with the reference product should also include physico-chemical methods to evaluate the secondary, tertiary and higher order structures of the molecule that impact its biological functionality. A detailed evaluation of these methods can be found in Part IV of this book.

The dossier associated with a biosimilar regulatory filing requires a substantial analytical package—351(k), significantly larger than one supporting a new biologic filing—351(a) (Fig. 8.4; Ha and Kornbluth 2016). A solid analytical package demonstrating the candidate is highly similar to the reference product lowers the potential for clinical differences. The analytical similarity data is used to determine the extent and design of the non-clinical and clinical studies required.

As with the development of the bulk biosimilar, the analytical strategies for selecting the formulation and manufacturing process used for the drug product need to be supported by a strong analytical package. The closer the formulation chosen for the biosimilar matches the innovator formulation, the lower the chances of an impact on stability. However, changes in formulation may be preferred in order to generate IP and this is feasible as long as they come supported by a strong analytical package. More details on this topic can be found in Chap. 11 of this book.

The manufacturing of the final dosage form of a biosimilar does not differ from what is used for any biologic. Regularly, the selection of process steps, conditions such as temperature, time, holding times, etc. is done to ensure lack of impact on the characteristics of the product. Additionally, shipping conditions for bulk drug substances are controlled and testing of CQAs conducted at both ends to ensure no impact in biosimilarity (i.e. shear forces may impact aggregation). For biosimilar manufacturing, however, the level of control needs to ensure that no CQA is affected by the manufacturing and shipping selections beyond the acceptability ranges.

Conclusion

Development of a biosimilar is in some ways easier and other ways more challenging than a new biopharmaceutical. It is easier in that the reference drug is already well established and understood, and mechanism of action and indications known. It is more challenging in that at each step of the development program a biosimilar must be rigorously compared to the reference drug product. In a complex glycoprotein, multiple variants constitute any particular product and their ratios can vary from lot to lot. A thorough understanding of the range of this lot-to-lot variation, as well as the routes to degradation over time, is essential to developing a biosimilar that is indeed highly comparable to the reference product.

The constant collaboration between process development, manufacturing and analytical scientists throughout the development program of each biosimilar candidate is key to a successful outcome. Attaining the combination of quality attributes defining the targeted product requires constant verification as the candidate development progresses.

References

Bui LA, Hurst S, Finch GL, Ingram B, Jacobs IA, Kirchhoff CF, Ng C-K, Ryan AM. Key considerations in the preclinical development of biosimilars. Drug Discov Today. 2015;20(51):3–15.

Chaudhari PS, Nath R, Gupta SK. Opportunities and challenges in biosimilar development. Bioprocess Int. 2017;15(5):24–33.

Ghaderi D, Zhang M, Hurtado-Ziola N, Varki A. Production platforms for biotherapeutic glycoproteins. Occurrence, impact, and challenges of non-human sialylation. Biotechnol Genet Eng Rev. 2012;28:147–75.

Gray T. Biosimilar analytical similarity assessments: are you testing sufficient innovator lots? Biosimilar Dev. 2017. https://www.biosimilardevelopment.com/doc/biosimilar-analytical-similarity-assessments-are-you-testing-sufficient-innovator-lots-0001

Ha CY, Kornbluth A. A critical review of biosimilars in IBD: the confluence of biologic drug development, regulatory requirements, clinical outcomes and big business. Inflamm Bowel Dis. 2016;22(10):2513–26.

Müller-Späth T, Ulmer N, Aumann L, Bavand M. Twin-column cation-exchange chromatography for the purification of biomolecules. Biopharm Int. 2015;28(4):32–6.

Schiestl M, Stangler T, Torella C, Čepeljnk T, Toll H, Grau R. Acceptable changes in quality attributes of glycosylated pharmaceuticals. Nat Biotechnol. 2011;29(4):310–2.

Walsh G, Jefferis R. Post-translational modifications in the context of therapeutic proteins. Nature Biotech. 2006;24(10):1241--52.

Zhang T, Bourret J, Cano T. Isolation and characterization of therapeutic antibody charge variants using cation exchange displacement chromatography. J Chromatogr A. 2011;1218(31):5079–86.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2018 American Association of Pharmaceutical Scientists

About this chapter

Cite this chapter

Manzi, A.E., Ultee, M.E. (2018). Biosimilars Drug Substance Development and Manufacturing: Effective CMC Strategy. In: Gutka, H., Yang, H., Kakar, S. (eds) Biosimilars. AAPS Advances in the Pharmaceutical Sciences Series, vol 34. Springer, Cham. https://doi.org/10.1007/978-3-319-99680-6_8

Download citation

DOI: https://doi.org/10.1007/978-3-319-99680-6_8

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-99679-0

Online ISBN: 978-3-319-99680-6

eBook Packages: Biomedical and Life SciencesBiomedical and Life Sciences (R0)