Abstract

Counter electrode selection has been a major challenge that directly affects the performance of dye sensitized solar cells. Platinum being a non-reactive metal is the most accepted material as counter-electrode, however, it has limitations due to its high cost and scarcity. In the present work, we have studied cost effective carbon based materials as alternate electrodes in dye sensitized solar cells.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

1 Introduction

Dye sensitized solar cells (DSSCs) have proven to be a low cost energy generation alternative to the conventional silicon solar cells. DSSCs show many unique advantages like ability to work in low light intensities and wide incident angles. These cells consist of a dye coated semiconductor oxide, redox electrolyte and a counter electrode (CE) [1, 2]. The working of DSSC is based on the photo excitation of the sensitizer (dye) which relaxes itself by transferring an electron to semiconductor oxide. The oxidized dye in this process gets regenerated by the redox electrolyte, usually an iodine-triiodide redox couple. At the counter electrode–electrolyte interface, electron is transferred from CE to electrolyte (liquid/solid/quasi solid). A thin layer of generally used platinum as a CE is responsible for catalyzing this electron transfer and is governed by the following reaction (1):

In this way, CE plays a significant role in regeneration of dye molecules by catalyzing the reduction process in electrolytic medium [3]. This reaction (49.1) has to be very fast as compared to recombination reaction at TiO2/electrolyte interface. Therefore, a counter electrode material should have high electrical conductivity as well as electrocatalytic activity. Figure 49.1 shows the desirable properties of a material to be used as an efficient CE.

Platinum (Pt) has generally been preferred as it possesses most of these qualities and functions well in DSSC. Nevertheless, its low electrochemical stability and high cost have been the main factor affecting efficiency and the device cost. Further, in practice, it has been quite challenging to replace expensive platinum based CE. A number of materials from carbon family [4] e.g. carbon nanotubes, graphite, carbon black, graphene, conductive polymers etc. have been investigated to function as CE in DSSCs. Specific carbon based materials provide almost all of the desirable properties to replace platinum. Particle aggregation, size, dispersion and solubility along with substrate adhesion are the key properties to be optimized for carbonaceous materials to be used as CE in DSSCs. Therefore, the selection of carbon based CE is made by taking into account the intrinsic properties of these carbonaceous materials.

2 Aim of Study

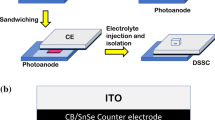

The present study is intended to study alternative counter electrode materials other than platinum for DSSCs. For the counter electrodes, carbon compounds such as poly (3, 4-ethylenedioxythiophene)poly(styrenesulfonate) (PEDOT:PSS), polyaniline (PANi), reduced Graphene Oxide (GO) and graphite paper were used. DSSCs have been fabricated with standard device structure using gel electrolyte medium and different counter electrode materials.

3 Methods

For the fabrication of devices, we used the previously reported methods [5]. Different counter electrode materials were deposited by spin coating and drop casting technique. The photovoltaic performance of the cells was measured using Keithley (model 2400) digital source meter at different light intensities. For the counter electrodes, carbon compounds such as poly (3, 4-ethylenedioxythiophene) poly(styrenesulfonate) (PEDOT: PSS), polyaniline (PANi), reduced graphene oxide (rGO) and graphite paper were used. Platinum counter electrode was also used as a reference.

4 Results

Figure 49.2 shows the current density-voltage characteristics of the DSSCs fabricated. The performance of PEDOT: PSS film as CE was found to better than rGO and PANi films. It can be seen from the graph that the device with graphite paper as a counter electrode exhibited open circuit voltage of 0.6 V and short circuit current density of 2.32 mA/cm2 comparable to that of platinum with lower fill factor.

Figure 49.3 shows the SEM image of the graphite paper depicting layered morphology with irregular grains forming a compact structure. Such layered and rough surface might be responsible for better electrolyte-CE interface and increased electrocatalytic activity of CE.

The lower fill factor for the devices based on graphite paper as CE can be improved by optimizing the device structure for compatibility of carbon based CE with the other components of the cell.

5 Conclusion

Platinum being a scarce and costly material is a major concern for cost effective dye sensitized solar cells. Carbon based materials are abundant and achieve nearly all properties needed to effectively function as a counter electrode in DSSC. Graphite paper has been used as counter electrode in the present studies; open circuit voltage and short circuit current are nearly the same as obtained using platinum as reference; however, the fill factor is comparatively low which may be improved by modifications in the device structure. Further, new carbon composites can be explored for a competent alternative to already known platinum as a counter electrode.

References

B.O. Regan, M. Gra¨tzel, A low-cost, high-efficiency solar cell based on dye-sensitized colloidal TiO2 films. Nature 353, 737–740 (1991)

S. Thomas, T.G. Deepak, G.S. Anjusree, T.A. Arun, S.V. Nair, A.S. Nair A review on counter electrode materials in dye sensitized solar cells. J. Mater. Chem. A 2, 4474–4490 (2014)

M. Ye, X. Wen, M. Wang, J. Iocozzia, N. Zhang, C. Lin, Z. Lin, Recent advances in dye sensitized solar cells: from photoanodes, sensitizers and electrolytes to counter electrodes. Mater. Today 18(3), 155–162 (2014)

K.S. Lee, H.K. Lee, D.H. Wang, N.G. Park, J.Y. Lee, O.O. Park, J.H. Park, Dye sensitized solar cell with Pt- and TCO- free counter electrodes. Chem. Commun. 46, 4505–4508 (2010)

H. Jauhari, R. Grover, O. Nanda, K. Saxena, Efficient quasi-solid state dye sensitized solar cell using succinonitrile: thiourea based electrolyte composition. RSC Adv. 6, 66788–66794 (2016)

Acknowledgements

The authors are thankful to Dr. Ashok K. Chauhan, Founder President, Amity University and Dr. V. K. Jain, Distinguished Scientist and Professor, Amity Institute of Advanced Research and Studies, Amity University, Noida for their continuous encouragements.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2019 Springer Nature Switzerland AG

About this paper

Cite this paper

Jauhari, H., Grover, R., Mehta, D.S., Saxena, K. (2019). Studies on Alternate Counter Electrode Materials for Pt—Free Dye Sensitized Solar Cells. In: Sharma, R., Rawal, D. (eds) The Physics of Semiconductor Devices. IWPSD 2017. Springer Proceedings in Physics, vol 215. Springer, Cham. https://doi.org/10.1007/978-3-319-97604-4_49

Download citation

DOI: https://doi.org/10.1007/978-3-319-97604-4_49

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-97603-7

Online ISBN: 978-3-319-97604-4

eBook Packages: Physics and AstronomyPhysics and Astronomy (R0)