Abstract

The concept of Shojinka, which is an important element of Just in Time production system, is attaining flexibility on the number of workers in a workshop due to demand variations.

Even though Just in Time production system adopts U-shaped line layout, traditional straight lines can be combined and balanced in an integrated manner to obtain the advantages of Shojinka. In this case, the problem, which is called Integrated Balancing of Multiple Straight Lines, arises.

On the other hand, the basic assumption of assembly line balancing is that every task’s time is fixed. However, in practice, different resource alternatives such as equipment or assistant worker may be available to process a task with different times. The problem in this case is to assign tasks and resources to stations that minimise total cost.

In this study, a binary integer mathematical model is presented for integrated balancing of multiple straight lines, assuming that task times are resource dependent. The proposed model is illustrated and validated using several examples. An experimental analysis is also conducted to emphasize the advantages of the integrated balancing concept, compared to the situation in which the lines are balanced independent from each other. The experimental results show that, when multiple straight assembly lines are balanced in an integrated manner with resource dependent task times, an average total cost improvement of 23.105% can be obtained compared to the independent balances of the lines. This is a significant improvement that emphasizes the importance of balancing multiple straight lines in an integrated manner, to take the advantages of shojinka and to adhere to the main philosophy of Just in Time.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

1 Introduction

Toyota Production System (TPS), which is also called as “lean manufacturing” or “lean production”, is known as one of the most flexible, efficient and productive production systems. TPS has emerged with the philosophy of Just-in-Time (JIT) in 1950s and pioneered the continuous development model. Several techniques such as level production, one piece flow, kanban system, shojinka etc. are used in accordance with the main purpose of JIT, which is producing the necessary products in the necessary quantities at the necessary time and eliminating all kinds of waste in the production environment (Monden 1993).

The concept of Shojinka, which was originally an important element of TPS, is easily to increase or decrease the number of workers in a production facility when the demand rate is increased or decreased. In a production facility, different types of products may be produced on different lines. The fluctuations in demands of products will probably require adding workers to some lines and removing from others (Monden 1993; Gökçen et al. 2010). In TPS, gaining the flexibility to adjust the number of workers in a workshop due to demand changes is called shojinka. Shojinka is one of the main components of JIT philosophy in the field of reducing workforce wastes. Monden (1993) states that three factors are prerequisite in order to realize shojinka: “proper design of machinery layout”, “multi-functional workers” and “continuous evaluation of standard operation routine”. TPS adopts U-shaped lines as the most proper machinery layout for realizing the concept of shojinka. U-shaped lines have more advantages compared to straight lines such as high communication between workers, easy problem solving, convenience for workers to be transformed into multi-functional workers and potential to utilize less number of stations (Miltenburg and Wijngaard 1994; Atasagun and Kara 2016).

On the other hand, for a given planning period, the number of workers required on a U-shaped line may be fractional. Since it is not possible to allocate a fractional number of workers, either the demand will not be met or at least one worker will be idle for a proportion of his/her available time. In order to make this idle time productive and eliminate the workforce waste, it is decided to combine several U-shaped lines into a single integrated line in Toyota. This way, a worker can perform operations from two or more neighbour U-shaped lines, and idle times can be eliminated or reduced (Monden 1993; Gökçen et al. 2010).

Even though JIT production system adopts U-shaped line layout, traditional straight lines can be combined and balanced in an integrated manner to obtain the advantages of shojinka. It should be noted that traditional straight assembly lines are still one of the most important elements and an important fact of today’s production systems. Therefore, if applicable, a company can combine its multiple straight assembly lines and obtain many advantages of shojinka more or less (Gökçen et al. 2010).

In the case of multiple straight assembly lines are combined, the problem, which is called as Integrated Balancing of Multiple Straight Lines (MSLB), arises. Essentially, MSLB is a generalized version of a well-known problem, simple assembly line balancing (SALB) which was first studied by Salveson (1955). Numerous studies have been published on SALB up to date. The literature on SALB is not practical to present here but interested researchers can refer to the review studies of Baybars (1986), Ghosh and Gagnon (1989), Erel and Sarin (1998), Becker and Scholl (2006), Scholl and Becker (2006) and Battaïa and Dolgui (2013).

The pioneering study on MSLB was performed by Gökçen et al. (2006). Gökçen et al. (2006) suggested that more than one assembly line can be located parallel and they can be balanced in an integrated manner. They proposed a binary integer mathematical model and a heuristic procedure for minimizing total number of stations, assuming that common stations can be utilized between two adjacent lines. The experimental study performed by Gökçen et al. (2006) revealed that integrated balancing approach utilized less number of stations for 65 out of 95 (68.4%) test problems compared to the independent balances of the lines.

In another study on MLSB, Gökçen et al. (2010) improved the work of Gökçen et al. (2006) considering not only parallel connectivity of the lines but also different connectivity opportunities such as consecutive and perpendicular connectivity. Gökçen et al. (2010) stated that if assembly lines are tightly related to each other and some supplier–customer relationships exist between these assembly lines then they may be connected to each other with consecutive or perpendicular connectivity.

The consecutive connectivity type can appear between an upstream line (supplier) and its downstream line (customer). If the output of an upstream line is the main input (part) of a downstream line, then assembly line managers may desire to locate these lines consecutively and close to each other (Gökçen et al. 2010). In this case, mentioned two lines can be connected to each other with a consecutive connectivity by utilizing a common station which includes tasks from the end of the upstream line and from the beginning of the downstream line.

The outputs of an upstream line may not always be the main part for a downstream line. In other words, the outputs of the upstream line may not be processed throughout most of the tasks on the downstream line. The outputs may be components that are attached to the main parts processed on the downstream line. This attachment can be performed at a stage (task) of assembly process. In this case, assembly line managers probably desire to locate the upstream line to the nearest point of use so as to minimise material handling from the upstream line to the downstream line. If such a location exists in a production system, two lines can be connected to each other with perpendicular connectivity (Gökçen et al. 2010).

One of the most important decision problems in assembly lines is assembly line balancing (ALB). ALB is the problem of assigning task to stations in such a way that precedence relations among tasks are not violated, sum of the processing times of the tasks in a station does not exceed cycle time and a performance measure is optimized. This performance measure is usually minimization of the number of utilized stations for a given cycle time. Cycle time is the time interval between two completed products. ALB problems with the objective of minimizing the number of stations is categorized as Type-I. Conversely, cycle time may also be minimized for a given number of stations in order to maximize the output. This type of ALB problems are known as Type-II.

In addition, the basic assumption in most of the studies of ALB literature is that every task’s time is fixed. However, in practice, different resource alternatives such as equipment or assistant worker may be available to process a task with different times. The problem in this case is to assign tasks and resources to stations that minimize total cost (Kara et al. 2011). Faaland et al. (1992) defined mentioned problem as Resource Dependent Assembly Line Balancing (RDALB). There are several studies in ALB literature dealing with resource dependency such as Pinto et al. (1983), Bukchin and Tzur (2000), Bukchin and Rubinovitz (2002) and Jayaswal and Agarwal (2014). Additionally, Corominas et al. (2008), Moon et al. (2009) and Corominas et al. (2011) implemented some resource restrictions to the ALB problem.

Kara et al. (2011) generalized the RDALB problem for straight and U-shaped assembly lines and proposed binary integer formulations considering both resource dependency and resource restrictions with practice oriented assumptions.

Kara and Atasagun (2013) adapted the RDALB approach of Kara et al. (2011) to the concept of parallel assembly lines and they obtained promising results in the case of parallel lines are balanced in an integrated manner instead of independent balancing.

In this chapter, RDALB approach proposed by Kara et al. (2011) is adapted to the problem of MSLB which was developed by Gökçen et al. (2010). The problem is called as integrated balancing of multiple straight assembly lines with resource dependent task times (RDMSLB). A binary integer mathematical model is presented with the objective of minimizing total equipment and operating costs of assembly lines for RDMSLB. An experimental analysis is also conducted to emphasize the advantages of the integrated balancing concept, compared to the situation in which the lines are balanced independent from each other. The remainder of the chapter is structured as follows. Notations and the proposed mathematical model are explained in Sect. 2. The proposed model is validated on an illustrative example in Sect. 3. Design and results of the experimental study are presented in Sect. 4. Finally, conclusion and some future research suggestions are given in Sect. 5.

2 Mathematical Model

In this section we propose binary integer programming formulations for RDMSLB by adhering to the assumptions of Kara et al. (2011) for RDALB and the assumptions of Gökçen et al. (2010) for the concept of MSLB.

2.1 Assumptions

The assumptions of the proposed model are as follows:

-

There are more than one assembly lines located close to each other with parallel, consecutive and perpendicular connectivity options.

-

Connectivity options of each line pair is predetermined and known.

-

Each assembly line in the facility is single model.

-

The precedence relationships among tasks of each line are known.

-

The processing time of a task is deterministic, but depends on the resources (equipment type and assistant) allocated to perform the task. The processing time of a task is independent of the station to which the task is assigned.

-

Some tasks cannot be completed by only one worker. If such a task is assigned to a station, an assistant should be assigned to this station as well.

-

The processing times of some tasks can be reduced by performing these tasks with the assistance of an assistant.

-

Some tasks should be performed using particular equipment. There may be alternate equipment types for a task. Some tasks can be performed with an equipment type or without equipment. Each equipment type is specified with a cost.

-

At most one equipment type can be allocated to perform a task. An equipment type can be used to perform more than one task in a station. In the case of two tasks from different lines require the same equipment type in a common station; it is assumed that those tasks can share the related equipment type.

-

Two or more equipment types can be assigned to a station for performing different tasks.

-

There is sufficient number of workers required to operate stations. But, the amounts of other resources (equipment types and assistants) are limited.

-

Employment cost of an assistant is independent of the station to which the assistant is assigned.

-

Utilization costs of the stations are assumed to be equal.

-

No work-in-process inventory is allowed between workstations.

-

It can also be worked each side of any line.

-

At most one common station can be utilized for a consecutive line pair, including tasks from the end of the upstream line and from the beginning of the downstream line.

-

At most one common station can be utilized for a perpendicular line pair, including tasks from the end of the upstream line and the task of the downstream line to which outputs of the upstream line are input.

-

Cycle times of the lines may differ. The cycle time for a common station among lines with different cycle times is the minimum of the cycle times of the lines that it spans.

2.2 Notation

The notations of the proposed model are as follows:

Indices | |

h, g, k, l, m, n: | Assembly line |

i, r, s, a, b, c, d: | Task |

j: | Station |

e: | Equipment |

Parameters and sets | |

\( {t}_{hie}^0 \): | Completion time of task i on line h with equipment e without assistant |

\( {t}_{hie}^1 \): | Completion time of task i on line h with equipment e with assistant |

N h: | Set of tasks on line h |

H: | Set of assembly lines |

E: | Set of equipment |

E hi: | Set of equipment which can be used to process task i on line h |

NE e: | Available number of equipment e |

NA: | Available number of assistants |

J: | Set of stations |

CT h: | Cycle time of line h |

PR h: | Set of precedence relations on line h |

(r, s) ∈ PR h: | A precedence relation on line h; task r is an immediate predecessor of task s |

\( {P}_{hi}^{\ast } \): | Set of predecessors of task i of line h |

\( {S}_{hi}^{\ast } \): | Set of successors of task i of line h |

F: | Set of disconnection relationships |

(h, g) ∈ F: | A disconnection relationship; common stations between lines h and g are not allowed |

CC: | Set of consecutive connectivity relationships |

(m, n) ∈ CC: | A consecutive connectivity relationship; upstream line m is connected to downstream line n with a consecutive connectivity |

c: | A task of upstream line m; S ∗ mc = Ø |

d: | A task of downstream line n; P ∗ mc = Ø |

PC: | Set of perpendicular connectivity relationships |

(k, l) ∈ PC: | A perpendicular connectivity relationship; upstream line k is connected to downstream line l with a perpendicular connectivity |

a: | The last task of the upstream line k |

b: | The task of downstream line l to which outputs of the upstream line k are input |

CW: | Annual utilization cost of a station (worker + fixed costs) |

CA: | Annual employment cost of an assistant |

c e: | Annual operating cost of equipment e |

K max: | Maximum number of stations |

M: | A big number |

Variables | |

x hij: | 1, if task i on line h is assigned to station j; 0, otherwise |

p hije: | 1, if task i on line h is assigned to station j with equipment e without assistant; 0, otherwise |

q hije: | 1, if task i on line h is assigned to station j with equipment e with assistant; 0, otherwise |

z je: | 1, if equipment e is assigned to station j; 0, otherwise |

u j: | 1, if station j is utilized; 0, otherwise |

t j: | 1, if an assistant is assigned to station j; 0, otherwise |

y hj: | 1, if station j is utilized on line h; 0, otherwise |

W (k,l)j: | 1, if station j includes tasks of both line k and line l and it is a common station; 0, otherwise |

V (k,l)j: | 1, if station j includes tasks of one of the line k and line l and it is not a common station; 0, otherwise |

2.3 Model

The objective function and constraints of the proposed model are as follows:

The objective function in Eq. (1) denotes the total cost associated with station utilization, assistant worker and equipment allocation. Equation (2) ensures that each task of each line is assigned to at least and at most one station. Equation (3) determines the resources (equipment type and assistant) allocated to a station. Equation (4) ensures that the workload of a station does not exceed the predetermined cycle time. This equation also ensures that the cycle time for a common station between two or more lines is the minimum of the cycle times of the lines that it spans. Precedence relationships among tasks are satisfied by the set of constraints given in Eq. (5). Equations (6) and (7) determines whether a station j is opened for line h or not. Equation (8) determines whether a station j is utilized or not. Equation (9) is used for disconnecting two assembly lines which cannot be connected with common stations. For a given (k, l) perpendicular connectivity relationship, Eq. (10) determines whether a station j is a common station between lines k and l, or not. Equation (11) ensures that at most one common station can be utilized between perpendicular connected lines k and l. If a common station is utilized between perpendicular connected lines k and l, Eq. (12) guarantees this station contains the last task (a) of the upstream line k and the task (b) of the downstream line l to which the outputs of upstream line k are the input. Note that, if there are two or more tasks with no successors in the precedence diagram of the upstream line k, a dummy task which succeeds all remaining tasks of the upstream line k with zero processing time should be added. For a given (m, n) consecutive connectivity relationship, Eq. (13) guarantees a common station between lines m and n includes tasks from the end of the upstream line m and from the beginning of the downstream line n. Equation (14) determines whether an equipment e is allocated to station j or not. Equation (15) restricts the allocated number of equipment e by the available number of this equipment type. Equation (16) determines whether an assistant worker is allocated to station j or not. Equation (17) ensures that the number of assistant workers assigned to stations does not exceed the available number of assistant workers. Finally, Equation (18) denotes that all variables in the model are binary variables.

3 Illustrative Example

The proposed mathematical model is validated on an illustrative problem in this section. The illustrative problem consists of four assembly lines each with 10 tasks. Information about task processing times in seconds and precedence relationships are given in Tables 1, 2, 3 and 4. Additionally, precedence diagrams of the lines are also given in Appendix.

Task time and precedence relationships information of Line 1 is given in Table 1. The IP i column of the table denotes the immediate predecessors of task i. It is seen in the table that task 1 of the Line 1 has a manual processing time of 21 s with one worker. Task 2 also has a manual processing time of 21 s with one worker but this task can alternatively be processed by Equipment 2 and 9 with processing times of 18 s and 13 s, respectively. Task 3 can be processed by one worker in 45 s manually but assistance of an assistant worker can reduce the task time to 27 s. Note that task 4 has three different processing alternatives each with assistant. This means that task 4 necessarily requires assistance of an assistant worker, and so on.

Similarly, task time and precedence relationships information of Lines 2, 3 and 4 are given in Tables 2, 3 and 4, respectively.

The connection relationships among lines for the illustrative problem are shown in Table 5.

Table 5 indicates that Lines 2 and 4 are connected to each other with a perpendicular connectivity. Note that, the last task of the line 2 is numbered as “10” and outputs of the upstream line 2 are input for the task 6 of the downstream line 4.

Available numbers and operating costs of different equipment types are given in Table 6.

Additional information about the illustrative example is as follows: utilization cost of a station (CW) is 100 cost units; employment cost of an assistant worker (CA) is 70 cost units and the number of available assistant workers (NA) is 10. The case “no equipment” is considered as an equipment type by labelling the equipment number “0”. Cycle time is 180 s and it is equal for all of the lines. K max is selected as nine and the problem is solved using CPLEX solver V12.5 on an Intel Xeon E5-1650 (6 Core) 3.20 GHz processor and 16 GB RAM workstation.

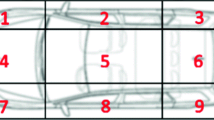

The optimal solution of the illustrative problem is obtained within 2 h and 2 min and 17 s with the objective function value of 899 cost units. Figure 1 illustrates the optimal solution of the problem.

Figure 1 shows that, optimal solution of the illustrative problem consists of six stations, three assistant workers and four different types of equipment such as equipment 2, 5, 8 and 10. Stations I and II are common stations between parallel connected lines 1 and 3. Station I includes tasks 1, 2, 3, 4, 5 and 6 of line 1 and task 1 of line 2 while station II includes tasks 7, 8, 9 and 10 of line 1 and tasks 2, 3, 4, 5 and 6 of line 2. Station III is a common station between consecutive connected lines 3 and 4, and it includes tasks from the end of line 3 and from the beginning of line 4. Similarly, Station V is a common station between perpendicular connected lines 2 and 4. This station includes the last task of line 2 (task 10) and the task of line 4 to which outputs of line 2 are input (task 6). Finally, stations IV and VI are single line stations and they are utilized for lines 2 and 4, respectively.

It is also seen in Fig. 1 that, additional resources allocated to stations are as follows: equipment 2 and an assistant to the station I, equipment 5 to the station II, an assistant to each of stations III and IV, and finally equipment 8 and equipment 10 to the station V.

4 Experimental Results

In this section an experimental study is conducted to compare integrated and independent balances of multiple straight lines in terms of total cost. A data set consists of 108 problems is generated and all those problems are solved using both integrated (RDMSLB) and independent (RDMSLB-independent) balancing approaches. Hence, a total of 216 solutions are obtained.

Assembly systems are generally characterised by three factors: problem size, strength of the precedence ordering relations among tasks, and the expected number of tasks per station (Aase et al. 2004; Kara et al. 2011). These factors can be defined by the number of tasks (NT), flexibility ratio (FR), and cycle time (CT) measures, respectively (Kara et al. 2011). FR is known as an indicator of the difficulty of the problem in ALB literature. A higher FR value indicates fewer precedence relations among tasks. This means more solution alternatives and a larger solution space. So, obtaining the optimal solution will be more difficult compared to an equivalent problem with a lower FR value.

It is assumed that there are four assembly lines in each test problem. Line 1 and Line 3 are located in parallel. Line 3 and Line 4 are connected to each other with a consecutive connectivity in which Lines 3 and 4 are upstream and downstream lines, respectively. Line 2 and Line 4 are connected to each other with a perpendicular connectivity in which outputs of Line 2 are inputs for Line 4. Finally, common stations are not allowed between line pairs (1, 2), (1, 4) and (2, 3).

Four levels of NT (20, 40, 60 and 80) are considered by assuming that each of the lines in the problem includes an equal number of tasks. For example, each line includes 5 tasks in a 20-task problem. Precedence relationships among tasks for each NT level are randomly generated and three different levels of FR (0.25, 0.50 and 0.75) are considered. In a NT–FR combination, it is assumed that all of the lines in the problem have precedence diagrams with the same level of FR. Hence, 12 assembly line systems are obtained.

In addition, it is assumed that all of the tasks in an assembly line system have a processing alternative without equipment (manual processing time). Processing times of the tasks without equipment are randomly generated following a discrete uniform distribution with U(10, 50). The numbers of different equipment types are selected as 6, 12, 18 and 24 for NT levels of 20, 40, 60 and 80, respectively. Annual operating costs of the equipment are randomly generated following a discrete uniform distribution with U(10, 50). Fifty percent of the tasks in each problem are considered to have processing alternatives with equipment while remaining 50% are assumed to be manual. The tasks with processing alternatives are also selected randomly. Processing times of the tasks with equipment are randomly generated in such a way that a task has a lesser processing time with equipment than its manual processing time. In the process of generating task times with equipment, it is assumed that task time reducing of a particular equipment type should be associated with the operating cost of that equipment type. For example, if the operating cost of equipment e is between 11 and 20, then this equipment reduces a task’s manual processing time with a random percentage between 11 and 20. If the operating cost of equipment e is between 21 and 30 then this equipment reduces a task’s manual processing time with a random percentage between 21 and 30, and so on. Percentages of task time reducing for equipment types are selected randomly in the related interval. In addition, it is assumed that a task can be processed using at most three different equipment alternatives. Available numbers of equipment types for all problems are restricted by 1 or 2 randomly.

Furthermore, 25% of the tasks in each problem are assumed to necessarily require assistance of an assistant worker. An additional 25% of the tasks can be processed by one worker but assistance of an assistant worker can reduce task processing time. Note that a task can be processed using both resource alternatives such as assistant worker and equipment. Percentages of task time reducing for assistant workers are randomly selected following a discrete uniform distribution with U(20, 50), for each related task. Available numbers of assistant workers are selected as 5, 10, 15 and 20 for NT levels of 20, 40, 60 and 80, respectively.

The process of generating resource dependent task times is repeated three times for each NT level. Each of these three task times is used together with each of NT–FR combination to construct a problem instance and hence 36 problem instances are obtained. For each problem instance, fixed station utilization and assistant worker costs are selected 100 and 70 cost units, respectively. Each problem instance is solved considering three levels of CT (180, 240 and 300) using the proposed mathematical model. That is, 108 solutions for RDMSLB are obtained. Additionally, 108 solutions for RDMSLB-independent are obtained using the proposed model by adding all of the line pairs to the set of disconnection relationships (F) and excluding the Eqs. (10–13). Note that, cycle times of the different assembly lines for each problem are assumed to be equal in the experimental study. All problems are solved using CPLEX solver V12.5 on an Intel Xeon E5-1650 (6 Core) 3.20 GHz processor and 16 GB RAM workstation. The CPU time limit of 3 h is used for all 216 solutions.

If the results of experimental study analysed, it is seen that 63 out of 108 (58.33%) RDMSLB solutions are optimal while 55 out of 108 (50.93%) RDMSLB-independent problems are optimally solved. In addition, all of the optimally solved 55 problems in RDMSLB-independent are also optimal in RDMSLB. Average of CPU times of optimally solved 63 RDMSLB problems is 21 min 54 s while average of CPU times of optimally solved 55 RDMSLB-independent problems is 20 min 45 s.

If the RDMSLB problems which have not been solved optimally are considered, it is seen that the average of optimality gaps is 14.99% while minimum and maximum of the optimality gaps are 0.55% and 28.83%, respectively. Similarly, for the RDMSLB-independent problems, minimum and maximum of the optimality gaps are 4.03% and 44.11%, respectively. The average of the optimality gaps for the RDMSLB-independent problems is 25.18%.

The effects of different NT, FR and CT values on the solution status are analysed in Tables 7, 8 and 9, respectively.

It can be seen in Table 7 that when NT increases, the number of optimal solutions decreases dramatically. This is an expected situation due to the increase of the numbers of decision variables and constraints depending on the problem size.

Table 8 presents that, different FR values has not a significant effect on the solution status for both RDMSLB and RDMSLB-independent cases.

It is seen in Table 9 that, the number of optimal solutions increases while CT increases for both RDMSLB and RDMSLB-independent cases.

In the experiment, the results of RDMSLB and RDMSLB-independent are also compared in terms of total cost using the solutions of above mentioned 55 problems which are optimal for both cases. Experimental results indicate that, integrated balancing concept provides an improvement in total cost compared to the concept of independent balancing for all of the 55 problems. A paired samples t-test is also performed to compare the total costs of RDMSLB and RDMSLB-independent. Results of the t-test are given in Table 10.

The results of paired samples t-test given in Table 10 indicates that, the difference between the total cost values of RDMSLB and RDMSLB-independent are significant at the level of 0.01 and mean total cost of integrated balancing approach is significantly lower than mean total cost of independent balancing approach.

In addition, by adhering to the study of Kara et al. (2011) the “percent improvement in total cost” (PI) is selected as the dependent variable for further statistical analysis. PI is calculated by Eq. (19). Table 11 summaries the mean values of PI obtained in the experiment.

Table 11 shows that, a total cost improvement of 23.105% is obtained when multiple straight lines are balanced in an integrated manner instead of independent balancing. It should be noted here that, the lack of NT = 80 in Table 11 is because none of the 80-task problems can be solved optimally. This situation can also be seen in Table 7.

An analysis of variance (ANOVA) and Duncan grouping test are also performed to analyse the results using IBM SPSS 20 statistical package. A three-way ANOVA is performed to examine the effects of three factors namely NT, FR, and CT on PI and the results are given in Table 12.

It is seen in Table 12 that, effects of NT, CT and two-way interaction of NT and CT are significant while the effects of FR, remaining two-way interactions and three-way interaction are not significant at the level of 0.01. These results indicate that, percent improvement in total cost is influenced by the number of tasks, cycle time and interaction of those factors. The results of Duncan groupings with the significance level of 0.01 are given in Table 13.

Duncan grouping results given in Table 13 indicates that; mean PI values for 20-task problems are significantly greater than that of 40-task problems. The difference of mean PI values for 60-task problems from that of 20-task and 40-task problems are not significant at the level of 0.01. Similarly, there is no significant difference between the mean PI values for different FR levels. Additionally, it can be seen in the Table 13 that, mean PI values for the cycle time levels of 300 and 240 are significantly greater than that of problems with the cycle time level of 180. The difference between the cycle time levels of 240 and 300 is not significant.

5 Conclusion

In this chapter, a binary integer mathematical model is proposed to adapt the resource dependent assembly line balancing approach to the problem of integrated balancing multiple straight assembly lines. The proposed model is validated on an illustrative example and an experimental study is conducted to compare the results of integrated and independent balancing approaches on the multiple straight assembly lines with resource dependent task times. The experimental results show that, when multiple straight assembly lines are balanced in an integrated manner an average total cost improvement of 23.105% can be obtained compared to the independent balances of the lines. This is a significant improvement that emphasizes the importance of balancing multiple straight lines in an integrated manner, to take the advantages of shojinka and to adhere to the main philosophy of JIT. The results also show that, above mentioned total cost improvement is influenced by the number of tasks, cycle time and interaction of those factors.

In further studies, goal programming approaches can also be applied to RDMSLB to provide flexibility for decision makers to balance their assembly lines based on their decision environments and preferred priorities. Efficient heuristics can be proposed for the RDMSLB due to NP-hard nature of the problem. Developing mathematical formulations for integrated balancing of multiple mixed model assembly lines with resource dependent task times can also be considered as a future research.

References

Aase, G. R., Olson, J. R., & Schniederjans, M. J. (2004). U-shaped assembly line layouts and their impact on labor productivity: An experimental study. European Journal of Operational Research, 156(3), 698–711.

Atasagun, Y., & Kara, Y. (2016). The multiple U line balancing problem: Recent developments and topics for future research. In International conference on natural science and engineering (ICNASE’16) (pp. 1471–1479). Kilis.

Battaïa, O., & Dolgui, A. (2013). A taxonomy of line balancing problems and their solutionapproaches. International Journal of Production Economics, 142(2), 259–277.

Baybars, I. (1986). Survey of exact algorithms for the simple assembly line balancing problem. Management Science, 32(8), 909–932.

Becker, C., & Scholl, A. (2006). A survey on problems and methods in generalized assembly line balancing. European Journal of Operational Research, 168(3), 694–715.

Bukchin, J., & Rubinovitz, J. (2002). A weighted approach for assembly line design with station paralleling and equipment selection. IIE Transactions, 35(1), 73–85.

Bukchin, J., & Tzur, M. (2000). Design of flexible assembly line to minimize equipment cost. IIE Transactions (Institute of Industrial Engineers), 32(7), 585–598.

Corominas, A., Ferrer, L., & Pastor, R. (2011). Assembly line balancing: General resource-constrained case. International Journal of Production Research, 49(12), 3527–3542.

Corominas, A., Pastor, R., & Plans, J. (2008). Balancing assembly line with skilled and unskilled workers. Omega, 36(6), 1126–1132.

Erel, E., & Sarin, S. C. (1998). A survey of the assembly line balancing procedures. Production Planning and Control, 9(5), 414–434.

Faaland, B. H., Klastorin, T. D., Schmitt, T. G., & Shtub, A. (1992). Assembly line balancing with resource dependent task times. Decision Sciences, 23(2), 343–364.

Ghosh, S., & Gagnon, R. J. (1989). A comprehensive literature review and analysis of the design, balancing and scheduling of assembly systems. International Journal of Production Research, 27(4), 637–670.

Gökçen, H., Ağpak, K., & Benzer, R. (2006). Balancing of parallel assembly lines. International Journal of Production Economics, 103(2), 600–609.

Gökçen, H., Kara, Y., & Atasagun, Y. (2010). Integrated line balancing to attain Shojinka in a multiple straight line facility. International Journal of Computer Integrated Manufacturing, 23(5), 402–411.

Jayaswal, S., & Agarwal, P. (2014). Balancing U-shaped assembly lines with resource dependent task times: A simulated annealing approach. Journal of Manufacturing Systems, 33(4), 522–534.

Kara, Y., & Atasagun, Y. (2013). Assembly line balancing with resource dependent task times: An application to parallel assembly lines. IFAC Proceedings Volumes, 46(9), 845–850.

Kara, Y., Özgüven, C., Yalçin, N., & Atasagun, Y. (2011). Balancing straight and U-shaped assembly lines with resource dependent task times. International Journal of Production Research, 49(21), 6387–6405.

Miltenburg, G. J., & Wijngaard, J. (1994). U-line line balancing problem. Management Science, 40(10), 1378–1388.

Monden, Y. (1993). Toyota production system. Norcross, GA: Engineering and Management Press.

Moon, I., Logendran, R., & Lee, J. (2009). Integrated assembly line balancing with resource restrictions. International Journal of Production Research, 47(19), 5525–5541.

Pinto, P. A., Dannenbring, D. G., & Khumawala, B. M. (1983). Assembly line balancing with processing alternatives: An application. Management Science, 29(7), 817–830.

Salveson, M. E. (1955). The assembly line balancing problem. Journal of Industrial Engineering, 6(3), 18–25.

Scholl, A., & Becker, C. (2006). State-of-the-art exact and heuristic solution procedures for simple assembly line balancing. European Journal of Operational Research, 168(3), 666–693.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2019 Springer Nature Switzerland AG

About this chapter

Cite this chapter

Atasagun, Y., Kara, Y., Can Atasagun, G. (2019). Achieving Shojinka by Integrated Balancing of Multiple Straight Lines with Resource Dependent Task Times. In: Paksoy, T., Weber, GW., Huber, S. (eds) Lean and Green Supply Chain Management. International Series in Operations Research & Management Science, vol 273. Springer, Cham. https://doi.org/10.1007/978-3-319-97511-5_9

Download citation

DOI: https://doi.org/10.1007/978-3-319-97511-5_9

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-97510-8

Online ISBN: 978-3-319-97511-5

eBook Packages: Business and ManagementBusiness and Management (R0)