Abstract

This paper presents a novel nanoindentation technique that obtains massive data on the basis of large volume to extract the mechanical properties of both the individual mineral phases of shales and its bulk rock. Massive data collected on a given surface but extended to a depth of 8–10 μm with the statistical or grid indentation method were processed to extract the mechanical properties of individual mineral phases as well as the dependence of the mechanical behavior upon indentation depth. Large volume-based indentation was then applied at varying depths by the sacrificial removal of the previously indented surface layer. This method is now being implemented as a screening and optimization protocol for various chemical stimulants and additives used in hydraulic fracturing and oil/gas production operations.

Access provided by CONRICYT-eBooks. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Oil and gas shales are a type of multi-scale, multi-phase, hybrid inorganic-organic composite materials that possess both frictional and cohesive behavior, and hence it is very challenging to characterize and interpret their engineering behavior. The recovery and extraction of oil and gas from shale reservoirs and other tight formations require hydraulic fracturing, usually assisted or enhanced by other stimulation techniques, to create fracture network or channels for the flow of oil and gas. The aqueous hydrofracking fluids are usually loaded with various chemical stimulants and additives (e.g., proppants) to enhance and improve oil/gas recovery, maintain the wellbore stability, and minimize deterioration and damage to the formation. Sufficient data obtained from past and existing operations have suggested that some physical and chemical reactions between the constituent mineralogy (e.g., clay, carbonate, pyrite) of shales and the hydrofracking fluids may take place during and after the hydrofracking processes, and such interactions can alter the mechanical properties of individual phases and hence the bulk rock, which may become significant or even severe under the environment of elevated temperatures and pressures. For instance, a widely recognized hypothesis for the rapid drop of gas production rate in shale formations after 6–12 months production is that the clay minerals in fine-grained shales can interact with water via such processes as hydration, absorption, and adsorption, among others, leading to the swelling and softening of the clay matrix as well as the bulk rock, which in turn causes significant proppant embedment and further reduction in fracture conductivity. As a result, the fracture network is negatively impacted. Therefore, understanding how the mechanical properties of individual phases change upon interactions with hydrofracking fluids plays a key role in suppressing shale softening and maximizing the long-term production of hydrocarbons in shale reservoirs. However, traditional macroscopic mechanical testing can yield the mechanical properties of the rock mass as a composite, but no insights can be obtained into the behavior of individual mineralogical phases of shales that may undergo dynamic changes prior to and during the oil/gas extraction process (e.g., hydraulic fracturing, injection of stimulants, rock-fluid interactions). In the past two decades, nanoindentation testing, a non-destructive technique, has been widely used to characterize the mechanical properties of various materials at the micro- to nano-meter scales (Oliver and Pharr 2004). This paper presents a novel big data and large volume (BDLV)-based nanoindentation technique that provides a useful, viable way to accurately characterize the softening behavior of individual phases of shales as well as the bulk rocks at the micron to nanometer scale.

2 Materials and Methods

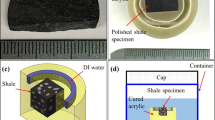

The studied shale sample was recovered from Longmaxi shale formation of Sichuan basin, China. X-ray powder diffraction (XRPD) results show that clay minerals, quartz, and calcite are the major constituents of the bulk rock. Two adjacent small pieces were first cut from the core sample in the direction parallel to the bedding plane, and then were glued onto a cylindrical sample holder for subsequent sample preparation. Each tested surface with dimensions of 15 × 10 mm was carefully ground and finely polished with abrasive papers in the order of increasing fineness. To simulate the underground hydrothermal environment during the hydrofracking process and the subsequent oil/gas production, one piece of the shale samples was placed for 24 h in a hydrothermal reactor filled with deionized (DI) water at a temperature of 120 °C and pressure of 2 MPa once a flat and smooth surface was obtained in the previous step, while the other piece was used as a non-treated sample to obtain the baseline data. Nanoindentation experiments were conducted in a G200 nanoindenter (Keysight Technologies, Inc., Santa Rosa, CA) using a Berkovich diamond indenter tip. Indentation loading usually involves pushing the indenter tip into the sample surface, during which the applied load F and the penetration depth h were recorded during the loading and unloading processes, and the mechanical properties (e.g., Young’s modulus E and hardness H) can be derived from the load-displacement loading and unloading curves. For highly heterogeneous materials, such as shales and concretes, a grid indentation method was proposed by Constantinides et al. (2006) to probe the mechanical properties of individual constituent phases, from which the statistical methodology is adopted in this study. The newly developed BDLV-nanoindentation technique described in this paper mainly includes two steps, consisting of a big data-based analytics to extract the meaningful results from a massive dataset and a large volume-based experimental approach to obtain more data at different surfaces with varying depths. To employ the big data-based analysis of the nanoindentation results, indentation testing was performed using a continuous stiffness measurement (CSM) method at 500 spots on each sample surface. The mechanical properties in the direction perpendicular to the bedding plane were continuously characterized as a function of indentation depth. Statistical deconvolution was applied to the experimental results (i.e., the Young’s modulus) calculated from the E-h curves at different indentation depths. The large volume-based processing was achieved by sequentially removing the softened surface layers of the tested shale sample via polishing and then conducting the big data-based nanoindentation analysis on each of the subsequently prepared, freshly polished surfaces. With such a method, a series of sacrificially removed surfaces can be analyzed to estimate the rate of softening for shales.

3 Results and Discussion

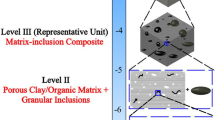

Figure 1 shows the baseline results obtained from the big data-based nanoindentation testing on the untreated sample. Five mechanically distinct phases are determined at the relatively shallow indentation depth (e.g., h = 0.25 µm), and they are respectively assigned as organic matter (e.g., kerogen in voids), clay matrix (not individual clay particles), interface between hard-soft minerals (e.g., clay-quartz interface), calcite or other carbonates, and quartz in the order of increasing Young’s modulus. With increasing depth, the Young’s moduli of all these phases gradually change and eventually converge into one single value at large indentation depth (e.g., h > 5 µm). Such depth-dependent elasticity can be affected by several factors. Generally, a 10% rule of thumb, which states that the ratio of maximum indentation depth to characteristic size of the indented phase needs to be smaller than 1/10, can be followed when the mechanical properties of individual phases are of interest in a multi-phase composite. Microscopic observations reveal that coarser and harder silt-size particles are embedded in the layered clay matrix. Therefore, thin film-substrate analogy is applied to interpret the mechanical response of shales that contain solid inclusions and pores within a clay matrix. The data of each mineral phase, except for the interface, were fitted using the model proposed by Wei et al. (2009):

where t is the characteristic size of the individual phases; Y and β1 are two constants that can be determined by the curve fitting for each phase; Ep and Ec are the fitted Young’s moduli of individual phases and bulk rock, respectively. The results obtained from the big data-based nanoindentation analysis for the pre-treated sample are presented in Fig. 2. Due to the fact that clay minerals tend to become hydrated when they are in contact with water, particularly in a hydrothermal environment with high pressure and temperature, the Young’s modulus of clay matrix decreases from 18.8 GPa to 16.3 GPa after a 24-h treatment. In addition, for the Young’s modulus of calcite, a reduction from 66.2 GPa to 57.9 GPa is observed, which is caused by partial dissolution of calcite in water under the hydrothermal condition.

4 Conclusions

In this paper, the shale-softening behavior is quantitatively characterized using a newly develop big data-based nanoindentation technique. Results obtained from the non-treated sample and DI water-treated sample show that interactions between shale and water significantly weaken the mechanical response of the clay matrix. Since clay matrix usually acts as the major supporting skeleton in shales, the reduction of its Young’s modulus increases the potential of proppant embedment. The rate of such a softening process is proposed to be determined by performing the big data and large volume-based nanoindentation analysis after removing the tested surface layers that have been softened, which warrants further investigation in future study.

References

Constantinides, G., Ravi Chandran, K.S., Ulm, F.-J., Van Vliet, K.J.: Grid indentation analysis of composite microstructure and mechanics: principles and validation. Mater. Sci. Eng., A 430, 189–202 (2006). https://doi.org/10.1016/j.msea.2006.05.125

Oliver, W.C., Pharr, G.M.: Measurement of hardness and elastic modulus by instrumented indentation: advances in understanding and refinements to methodology. Mater. Res. Soc. 19, 3–20 (2004)

Wei, Z., Zhang, G., Chen, H., Luo, J., Liu, R., Guo, S.: A simple method for evaluating elastic modulus of thin films by nanoindentation. J. Mater. Res. 24, 816–822 (2009). https://doi.org/10.1557/jmr.2009.0109

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2018 Springer Nature Switzerland AG

About this paper

Cite this paper

Luo, S., Li, Y., Wu, Y., Yu, Y., Zhang, G. (2018). Big Data and Large Volume (BDLV)-Based Nanoindentation Characterization of Shales. In: Wu, W., Yu, HS. (eds) Proceedings of China-Europe Conference on Geotechnical Engineering. Springer Series in Geomechanics and Geoengineering. Springer, Cham. https://doi.org/10.1007/978-3-319-97112-4_127

Download citation

DOI: https://doi.org/10.1007/978-3-319-97112-4_127

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-97111-7

Online ISBN: 978-3-319-97112-4

eBook Packages: EngineeringEngineering (R0)