Abstract

Bulk metallic glasses (BMGs) possess high strength, but their fracture toughness and fatigue crack growth resistance can vary widely. Fracture toughness and fatigue crack growth results for Zr-based BMGs show that fracture toughness is highly sensitive to the glassy micro- and/or nanostructure, while the fatigue crack growth resistance is relatively insensitive. Soft and heterogeneous glassy structures promote crack tip blunting and high fracture toughness, and can be promoted by thermo-mechanical treatments. During fatigue cycling, in-situ free volume generation occurs ahead of the crack tip that defines the local structure independent of the initial structural state. Accordingly, fatigue crack propagation rates depend little on the initial structure of the BMG. Finally, synchrotron XRD analysis of crack-tip strain fields revealed that the crack-tip deformation extends farther, and is more homogeneous, than visible shear bands suggest and the mechanism of fatigue crack propagation is identical to crystalline metals despite the different deformation mechanism.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Bulk metallic glasses (BMGs) have excellent high tensile yield strengths (~1–5 GPa is common) and large elastic strain limits (~2%). However, damage tolerance properties, such as fracture toughness and fatigue crack growth resistance, can vary widely from excellent to poor and the current understanding of how to control these properties is limited [1], thus motivating the present work.

2 Results

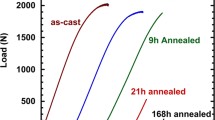

Fracture toughness studies on Zr63.78Cu14.72Ni10Al10Nb1.5 and Zr52.5Ti5Cu18Ni14.5Al10 (at.%) BMGs revealed cold deformation, e.g., cold rolling and imprinting, and thermal cycling 70 times to cryogenic temperatures (77 K) results in increased fracture toughness values [2, 3]. This affect is attributed to the softer and more heterogeneous glassy structures that result after these treatments, that in turn promote crack blunting. While annealing a Zr44Ti11Ni10Cu10Be25 BMG to reduce free volume in the glass structure severely lowers the fracture toughness, fatigue crack growth rates are unaffected [4]. This is attributed to a fatigue transformation zone of higher free volume that is formed in the cyclic plastic zone ahead of the crack tip, as revealed by positron annihilation spectroscopy (Fig. 1a) [5]. Furthermore, synchrotron x-ray studies of fatigue crack tips in a Zr52.5Ti5Cu18Ni14.5Al10 BMG reveal a crack tip strain field corresponds well with crystalline metals and that extends farther, and is more homogenous, than the visible shear bands suggest. Results confirm that the mechanism of fatigue crack growth in BMGs is alternating crack tip blunting and re-sharpening arising from compressive stresses that evolve in the cyclic plastic zone (Fig. 1b) [6].

3 Conclusions

Soft and heterogeneous glassy structures promoted by thermo-mechanical processing methods promote crack tip blunting and high fracture toughness in BMGs. In contrast, fatigue crack propagation rates depend little on the glassy structure of the BMG due to in-situ free volume generation that redefines the structure ahead of the crack tip during fatigue cycling. Finally, synchrotron XRD analysis of crack tip strain fields reveal that the mechanism of fatigue crack propagation is identical to crystalline metals.

References

Kruzic, J.J.: Bulk metallic glasses as structural materials: a review. Adv. Eng. Mater. 18, 1308–1331 (2016)

Li, B.S., et al.: Designed heterogeneities improve the fracture reliability of a Zr-based bulk metallic glass. Mater. Sci. Eng. A 646, 242–248 (2015)

Xie, S.H., Kruzic, J.J.: Cold rolling improves the fracture toughness of a Zr-based bulk metallic glass. J. Alloys Compd. 694, 1109–1120 (2017)

Launey, M.E., et al.: Effect of free volume changes and residual stresses on the fatigue and fracture behavior of a Zr-Ti-Ni-Cu-Be bulk metallic glass. Acta Mater. 56, 500–510 (2008)

Liu, M., et al.: Assessment of the fatigue transformation zone in bulk metallic glasses using positron annihilation spectroscopy. J. Appl. Phys. 105, 093501 (2009)

Scudino, S., et al.: Mapping the cyclic plastic zone to elucidate the mechanisms of crack tip deformation in bulk metallic glasses. Appl. Phys. Lett. 110, 081903 (2017)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2019 Springer International Publishing AG, part of Springer Nature

About this paper

Cite this paper

Kruzic, J.J. (2019). Crack Propagation in Bulk Metallic Glasses. In: Gdoutos, E. (eds) Proceedings of the First International Conference on Theoretical, Applied and Experimental Mechanics. ICTAEM 2018. Structural Integrity, vol 5. Springer, Cham. https://doi.org/10.1007/978-3-319-91989-8_77

Download citation

DOI: https://doi.org/10.1007/978-3-319-91989-8_77

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-91988-1

Online ISBN: 978-3-319-91989-8

eBook Packages: EngineeringEngineering (R0)