Abstract

Owing to their glassy nature, metallic glasses demonstrate a toughness that is extremely sensitive to the frozen-in configurational state. This sensitivity gives rise to the so-called “annealing embrittlement”, which is often severe and in many respects limits the technological advancement of these materials. Here, equilibrium configurations (i.e. “inherent states”) of a metallic glass are established around the glass transition, and the configurational properties along with the plane-strain fracture toughness are evaluated. An association between the intrinsic toughness and the inherent state properties is attempted in an effort to identify the fundamental origin of embrittlement of metallic glasses. The established correlations reveal a one-to-one correspondence between a decreasing toughness and an increasing shear modulus, which is robust and continuous over a broad range of inherent states. This annealing embrittlement sensitivity is shown to vary substantially between metallic glass compositions, and appears to correlate well with the fragility of the metallic glass.

Access provided by Autonomous University of Puebla. Download conference paper PDF

Similar content being viewed by others

Keywords

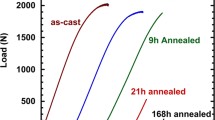

Unlike conventional oxide glasses, metallic glasses can be considerably tougher often approaching values typical of engineering metals. Specifically, the toughness of metallic glasses can vary from values as high as 150–200 MPa·m1/2, comparable to low carbon steels, to as low as 2–3 MPa·m1/2, which is more typical of oxide glasses. But like any glass, metallic glasses tend to embrittle when annealed around the glass transition, as evidenced by a measurable drop in their toughness and their capacity to deform plastically. This phenomenon, typically referred to as annealing embrittlement, has broad scientific and technological ramifications. From a technological perspective, annealing embrittlement is at least partly responsible for the large variability in toughness observed when the glass is quenched at different cooling rates, thereby limiting their mechanical performance and engineering reliability. From a physics perspective, the physical origin of annealing embrittlement is still a topic of debate and controversy that is far from being settled, as varying and contradictory theories have been proposed by various groups over the years.

Here, we seek to establish a fundamental correspondence between fracture toughness and the inherent state of the metallic glass that could reveal the underlying origin of embrittlement. High-purity fully-amorphous samples with size and geometry consistent with the E399 ASTM standard were produced in that work. The samples were fully relaxed at well-defined temperatures, TR, near the glass transition temperature, Tg, and are carefully characterized for “inherent-state” properties and plane-strain fracture toughness, KIC.

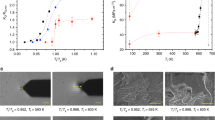

The “intrinsic” plane-strain fracture toughness KIC is found to follow exponentially decaying functions of the equilibrium isoconfigurational shear modulus G. This relation appears to be continuous over a broad range of equilibrium configurational states of the glass. Such correlation reveals that the plane-strain fracture toughness of samples equilibrated at different temperatures is linked uniquely to properties characterizing the inherent state of the glass (e.g. the shear modulus). It is interesting to examine how this sensitivity to annealing embrittlement varies among various metallic glasses. The annealing embrittlement sensitivity can be defined as the relative drop in fracture toughness KIC with respect to a relative drop in relaxation temperature.

Plotting fracture toughness vs. temperature data for metallic glass Zr35Ti30Cu8.25Be26.75 gathered in the present work, along with data for Pt57.5Ni5.3Cu14.7P22.5 and Zr44Ti11Cu10Ni10Be25 reveals that the three metallic glasses exhibit very different propensities for annealing embrittlement. Specifically, Pt57.5Ni5.3Cu14.7P22.5 and Zr44Ti11Cu10Ni10Be25 demonstrating the highest and lowest annealing embrittlement sensitivity respectively and Zr35Ti30Cu8.25Be26.75 falling in between.

Interestingly, the order of annealing embrittlement sensitivity actually follows the order of the fragility of the three glasses. The fragility, defined by Angell as the steepness of the viscosity temperature dependence at Tg, is often used as a parameter characterizing the potential energy landscape morphology of a glass/liquid. By plotting the annealing embrittlement sensitivity vs fragility for the three metallic glasses, a one-to-one correspondence is revealed. Since fragility is understood to be controlled by the decrease of the shear modulus with increasing temperature, and considering the one-to-one correspondence between KIC and G is demonstrated here, it is conceivable that fragility can be uniquely associated with the steepness of the fracture toughness drop with temperature, or equivalently with the annealing embrittlement sensitivity.

The outcome of this study could have significant scientific and technological implications. From a scientific perspective, this result suggests a thermodynamic origin of annealing embrittlement, but also a structural one. In Angell’s original conception, fragility quantifies how rapidly the “structure” (i.e. the local order) of an equilibrium liquid develops as the liquid cools towards Tg. As such, the present result suggests that annealing embrittlement should be associated with the degree of order established in each equilibrium state at which the atomic structure of the glass is relaxed to. From a technological perspective, the present result suggests that more fragile glasses are more prone to embrittlement than stronger glasses. Specifically, it suggests that fragile glasses would tend to embrittle at low fictive temperatures and toughen at high fictive temperatures, while stronger glasses would have a more constant toughness with varying fictive temperature.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2019 Springer International Publishing AG, part of Springer Nature

About this paper

Cite this paper

Demetriou, M.D., Garrett, G.R., Johnson, W.L. (2019). Origin of Embrittlement of Metallic Glasses. In: Gdoutos, E. (eds) Proceedings of the First International Conference on Theoretical, Applied and Experimental Mechanics. ICTAEM 2018. Structural Integrity, vol 5. Springer, Cham. https://doi.org/10.1007/978-3-319-91989-8_76

Download citation

DOI: https://doi.org/10.1007/978-3-319-91989-8_76

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-91988-1

Online ISBN: 978-3-319-91989-8

eBook Packages: EngineeringEngineering (R0)