Abstract

The methods of fission-track (FT) thermochronology, based on a combination of the external detector method, zeta calibration against independent age standards and measurements of horizontal confined track lengths, have undergone relatively little change over the last 25 years. This conventional approach has been highly successful and the foundation for important thermal history inversion methods, supporting an expanding range of geological applications. Several important new technologies have emerged in recent years, however, that are likely to have a disruptive effect on this relatively stable approach, including LA-ICP-MS analysis for 238U concentrations, new motorised digital microscopes and new software systems for microscope control, digital imaging and image analysis. These technologies allow for new image-based and highly automated approaches to FT dating and eliminate the need for neutron irradiations. Together they are likely to have a major influence on the future of FT analysis and gradually replace the older, highly laborious manual methods. Automation will facilitate the acquisition of larger and more comprehensive data sets than was previously possible, assist with standardisation and have important implications for training and distributed analysis based on image sharing. Track length measurements have been more difficult to automate, but 3D measurements and automated semi-track length measurements are likely to become part of future FT methods. Other important trends suggest that FT analysis will increasingly be combined with other isotopic dating methods on the same grains, and multi-system methods on coexisting minerals, to give much more comprehensive accounts of the thermal evolution of rocks. There are still a range of important fundamental issues in FT analysis that are poorly understood, such as a full understanding of the effects of composition and radiation damage on the annealing properties of different minerals, which are likely to be fruitful areas for future research in this field.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

- Laser Ablation Inductively Coupled Plasma Mass Spectrometry (LA-ICP-MS)

- Confined Track Lengths

- Zeta Calibration

- Fission Track (FT)

- External Detector Method (EDM)

These keywords were added by machine and not by the authors. This process is experimental and the keywords may be updated as the learning algorithm improves.

1 Introduction

A variety of experimental methods emerged during the early development of FT dating to measure the essential ratio of the 238U spontaneous fission track density to the parent uranium concentration. Mostly the uranium concentration could not be measured explicitly, but rather the track density of induced 235U fission tracks resulting from a thermal neutron irradiation was used as a proxy (Fleischer et al. 1975). By the end of the 1980s, just one of these experimental methods, the external detector method (EDM) (e.g. Naeser and Dodge 1969; Gleadow 1981; see Chap. 2, Kohn et al. 2018) had come to dominate the practice of FT analysis. As discussed below, there were several reasons for the success of this method, but by far the most significant was that it provided age information on individual ~100–200 µm mineral grains, the first of any geochronological technique to routinely do so.

The EDM has become central to what we may now describe as conventional FT analysis, a combination of procedures that has progressively become the standard, and almost universally adopted, approach to FT dating in laboratories around the world. In this approach, FT ages are determined by the EDM using the empirical ‘zeta’ calibration against a set of independent age standards (Fleischer and Hart 1972; Hurford and Green 1983), combined with measurements of horizontal confined track lengths (Gleadow et al. 1986) usually measured using a microscope drawing tube and digitising tablet. In essence, these two complementary data sets comprising the FT grain-age distribution and the FT length distribution, contain, respectively, the time information and the temperature information that are required by forward modelling schemes to reconstruct the thermal history of a particular sample (Fig. 4.1). This approach has been widely applied to the common uranium-bearing accessory minerals apatite, titanite and zircon, of which apatite has been by far the most important, because of its common occurrence, its simple and consistent etching behaviour and its well-documented annealing properties relative to other minerals. Apatite will therefore be the principal focus in the rest of this chapter, although most of the discussion would apply equally to other minerals.

Analytical sequence required for the reconstruction of thermal histories from primary measurements of a, the number, and b, the lengths of fission tracks in a mineral sample, together with the 238U concentration, here indicated by a circular laser ablation pit in (a). Image a includes a region of interest outlining the area to be counted and an internal grid to assist in counting. Image b shows a confined fission track and its measured length. In the centre, a radial plot shows the distribution all of grain ages, and a histogram the distribution of all lengths measured in a sample. These results can be thought of as primarily reflecting the time component, and the temperature component of the underlying thermal history, respectively. The thermal history reconstructed from such data is shown in the temperature–time plot, c, on the right. In practice, this FT analytical sequence is currently fully developed only for apatite and is the basis of the conventional approach described here. Future developments in FT thermochronology, however, are likely to follow a similar sequence, but will include new technologies for collecting the data, greater use of automation, richer data sets and routine integration of the results with other thermochronometers

There has been little change in this conventional approach to FT thermochronology over a period now approaching 25 years, although important advances have been made in understanding FT annealing and in the development of multi-compositional annealing models over this time, accompanied by a comprehensive description of the statistics of FT analysis (Galbraith 2005; see Chap. 6, Vermeesch 2018). Together, these advances are applied in the inverse modelling techniques used for thermal history reconstruction from FT data (Ketcham 2005; Gallagher 2012). The recognition that apatite FT annealing properties vary with composition (e.g. Green et al. 1985; Barbarand et al. 2003) means that measurement of some specific ‘kinetic parameter’ for each grain is now also required. The two kinetic parameters in common use are the average diameter of track etch pits parallel to the c-axis, Dpar (Donelick 1993; Donelick et al. 2005) and/or the chlorine concentration of the apatite, usually measured by electron probe micro-analysis (EPMA, Green et al. 1985). With these additional refinements, the conventional approach has provided a stable platform that has underpinned major growth in the field, and a widening diversity of applications.

Following the general adoption of this standardised approach, the dominant emphasis of most FT studies over the past decade or more has been, appropriately, on geological applications, rather than on ongoing development of the methods themselves, or probing remaining areas of uncertainty. There is a danger in this state of affairs, however, that FT analysis may be applied in a formulaic way with little understanding of some of the more fundamental assumptions and unresolved issues that underlie the technique. To continue in this mode would be to invite stagnation, but, fortunately, important new trends have been emerging over the last decade, which are likely to have a disruptive influence on FT analysis as it is now practiced. Ultimately, these changes have the potential to improve the quality and consistency of FT data and thereby provide new insights into the thermochronology of the continental crust.

The early part of the twenty-first century has seen the emergence of several important new technologies including (i) laser ablation inductively coupled plasma mass spectrometry (LA-ICP-MS), (ii) fully motorised digital microscopes that allow all microscopy functions to be placed under computer control and (iii) practical image analysis techniques based on captured and stored digital images obtained using (ii). Underlying all of these, of course, is the steady advance of desktop computing power and, crucially, the availability of abundant, cheap disc storage for captured digital images. These developments are likely to have a major impact, and indeed come to dominate, the foreseeable future of FT analysis, and are the central subject of this chapter. A number of other important trends, in the way that FT data are used and combined with other thermochronometers, will also be discussed below.

2 The Current State of FT Analysis

The stability and practical convenience of the conventional approach to FT analysis have had some important advantages, particularly in providing single grain-age information and the ability to statistically test the coherence of the sampled age populations (Galbraith 1990). The induced tracks could be measured over exactly the same area counted for spontaneous tracks, and the zeta calibration largely settled, or at least avoided, earlier disputes about the 238U spontaneous fission decay constant, and neutron dosimetry calibrations. Horizontal confined track lengths were shown by Laslett et al. (1982) to give the closest approximation to the true underlying distribution of unetched fission-track lengths. The widespread adoption of this approach has also aided consistency in data production, although the degree to which this has been universally achieved is doubtful.

There are also a number of disadvantages to the conventional approach, however. The most significant of these include the very long sample turnaround times, typically months, necessitated by neutron irradiation, and the accompanying laboratory safety issues arising from handling radioactive materials. Moreover, the procedure is highly laborious, with long hours needed at the microscope to measure the three track densities and confined track lengths required for each sample. Even then, the number of counts and lengths are relatively limited, thereby reducing the precision of the measurements. The method also requires a major commitment to operator training, typically over a period of months, in order to develop the appropriate levels of expertise. In addition, the quality of measurements is significantly dependent on operator experience and requires an individual calibration. Finally, the zeta calibration means the technique is dependent on other methods and therefore is not an absolute dating method in its own right.

Reference to widely available age standards has brought a measure of consistency to FT age determinations between individual researchers, but recent inter-laboratory comparison experiments have shown an alarming lack of similar consistency when it comes to track length measurements (Ketcham et al. 2015). There are a variety of factors contributing to this situation, but one crucial issue is the lack of any comparable ‘length standards’, and indeed it is currently hard to see how an independent reference value for FT lengths could be obtained. A resolution is urgently needed to this problem so that track length measurements, and the thermal history models based on them, can be accepted with confidence. This must be a major short-term goal for the future of FT analysis.

3 LA-ICP-MS Analysis of Uranium Concentrations

The progressive refinement and decreasing costs of access to LA-ICP-MS technologies during the 1990s has led to their increasingly widespread availability to researchers in the twenty-first century. This technology provides an alternative to neutron irradiation for analysing the uranium concentrations of mineral grains with ppm sensitivity and a spatial resolution comparable to fission-track dimensions. The first significant adaptations of this technology to FT analysis (Hasebe et al. 2004, 2013) showed this to be a practical and highly effective approach, and, as a result, it is now being progressively adopted by an increasing number of FT groups. The major advantages of this method include the speed of analysis, direct analysis of parent 238U, rather than using 235U as a proxy, at least comparable precision and accuracy to the conventional approach, and elimination of the need to handle irradiated materials. There can be no doubt that LA-ICP-MS will be an important part of the future of FT thermochronology, a change being accelerated by the increasing difficulty of access to suitable neutron irradiation facilities, following closure of many research reactors around the world.

One of the most important features of using the LA-ICP-MS method is that only a single track density measurement (spontaneous track density, ρs) is required, compared to three for the EDM, which, given the relatively large uncertainties associated with most track density measurements, has the potential to improve the precision of measurements using the new approach. So far, it appears that comparable precision is being obtained using either method (e.g. Seiler et al. 2014), although this has not yet been rigorously tested and further developments in LA-ICP-MS technology are likely to see the precision from this method exceeding that from conventional analyses.

An important issue raised by the adoption of LA-ICP-MS in FT analysis is that it requires rethinking of how the FT age equation is applied (Hasebe et al. 2004; Donelick et al. 2005; Gleadow et al. 2015; see also Chap. 2, Kohn et al. 2018). As with most new technologies the initial adoption of this approach has tended to follow earlier practices and most reported measurements have used a ‘modified zeta’ calibration based on reference to age standards (Hasebe et al. 2013; Gleadow and Seiler 2015). However, from the beginning it has been clear that the emergence of this new technology gives an important opportunity to revisit the question of using an absolute calibration, based on explicit use of the constituent constants making up this ‘modified zeta’ (e.g. Hurford 1998; Soares et al. 2014; Gleadow et al. 2015).

Many of these constituent constants, such as Avogadro’s number, or the density of apatite are well known, but other, such as the FT detection efficiency in different materials, and indeed, the spontaneous 238U decay constant, are not. The near future of FT analysis is therefore likely to include renewed experimental efforts to ascertain precise values for these constants (e.g. Jonckheere and van den Haute 2002; Soares et al. 2014). Another important consideration that will be essential for the future evolution of this method will be the development of a series of widely accessible, matrix-matched compositional standards for the analysis of apatite and other FT minerals.

Interestingly, this version of the FT age equation (see Chap. 6, Vermeesch 2018, Eq. 6.25) also explicitly requires the average etchable range of a single fission fragment, which can be approximated by half the confined track length. This is the key geometric parameter required to relate the planar, 2D, spontaneous fission track density to the 3D volume concentration of 238U atoms in the mineral. We might then ask which value should be used for this length factor. If one is using a modified zeta calibration, then this factor is implicitly assumed to be the characteristic track length in the age standards used, typically around 14.5–15.0 µm. Used this way the results obtained are directly comparable to those from the conventional, zeta calibrated EDM, which also makes the same implicit assumption about the track length component.

The question then arises about what is the significance of the FT age calculated in the conventional way when applied to samples that have a mean track length that is quite different to the age standards used for the zeta calibration. In such cases, the FT age calculated with the conventional approach is in fact a kind of ‘model age’, rather than the ‘true’ FT age anticipated in the derivation of the FT age equation. This model age is the FT age that would be obtained for a sample, if it had the same length distribution as the age standards used. In the great majority of samples, however, this assumption is invalid as the average track length is mostly shorter, sometimes significantly so, than in the age standards. In almost all samples, therefore, if the actual etchable fission fragment range was used in the equation, a significantly older age will result because this length factor occurs on the denominator of the age equation. In the conventional, or the ‘modified zeta’ LA-ICP-MS approach, the importance of the length component is obscured by the zeta calibration, and the calculated ‘model’ age will be nearly always younger than the ‘true’ FT ages based on the actual mean track length.

This is an important question and one that is likely to be debated in ongoing discussions about FT thermochronology, especially as fission track results are increasingly integrated with other thermochronometers, where comparable assumptions and ‘model age’ calculations do not apply. At one level, this is not a major issue for reconstructed thermal histories, because these histories are derived from the actual length distributions. However, there can be no doubt this ‘model age’ calculation is also responsible for many of the apparent inversions observed in the expected relative sequence of apatite FT and apatite (U–Th)/He ages, because the two ages are not being calculated in the same way. One of the benefits that may come from more widespread adoption of the LA-ICP-MS approach will be a clearer understanding of what we actually mean by a ‘FT age’.

The adoption of LA-ICP-MS, of course, raises a range of new practical considerations and calibration issues of its own, which are still being worked through. As was the case with the conventional approach, the development of standard analytical protocols and appropriate reference materials for U analysis will take time and is likely to be a fertile research field in the near future. At present, this is largely being pursued on a laboratory-by-laboratory basis, but there are important opportunities for greater inter-laboratory standardisation and adoption of a more unified approach. Such issues as the optimum ablation parameters (e.g. power levels, pulse rate and ablation pattern), potential heterogeneous ablation, controlling ablation pit depth, and detecting and monitoring compositional zoning, have not yet been fully explored for their potential influence on FT ages derived by this method compared to other applications of LA-ICP-MS. Similarly, the statistics of FT dating using LA-ICP-MS has lagged behind that of the EDM but is now receiving much needed attention (Chap. 6, Vermeesch 2018).

The number of direct comparisons between the conventional and LA-ICP-MS approaches is still quite limited although the concordance between the two is generally excellent (e.g. Hasebe et al. 2004; Seiler et al. 2014; Gleadow et al. 2015). LA-ICP-MS can analyse for many elements simultaneously, so that this new method could progressively build an analytical database on apatite compositions and etching properties that could be of significant value to future annealing models for apatite and other minerals. The issue of well-calibrated, homogeneous and matrix-matched standards for LA-ICP-MS is another area that is currently limiting the more effective utilisation of this approach.

One exciting possibility might be to measure the concentration of chlorine and other elements that might influence annealing kinetics in apatites simultaneously with the measurement of 238U. Chlorine has an extremely high ionisation potential and therefore has a much higher detection limit in apatite (Chew and Donelick 2012), but early experiments (Chew et al. 2014) show great promise for this to become a standard procedure in future. This would have the great advantage for FT analysis of eliminating an entire analytical procedure, electron probe micro-analysis (EPMA) that is currently required to measure the halogen content in apatite. EPMA for fluorine and, to a lesser extent, chlorine can be problematic, and very careful analytical protocols are required to produce satisfactory results (e.g. Goldoff et al. 2012). It is not hard to imagine this cumbersome additional analytical step being replaced by LA-ICP-MS in the near future. With either method, well-calibrated compositional standards are required to produce satisfactory results, but the method still lacks suitable international reference materials (e.g. Chew et al. 2016).

4 Computer-Controlled Digital Microscopy

The emergence of a new generation of fully motor-driven research microscopes over the past decade is a major advance that has the potential to put all aspects of FT microscopy under computer control. For the first time, the most advanced research microscopes can assist the operator with virtually all routine microscope tasks. Coupled with high-quality digital imaging and appropriate control software, these instruments can provide fully autonomous microscopy and multiple slide-handling capabilities that largely eliminate the long periods at the microscope, previously required for the conventional approach. Such motorised microscopes are also allowing new kinds of track measurements to be made that were not practical, or even possible, using earlier manual systems (e.g. Jonckheere et al. 2017).

This trend towards automated microscopy actually began with the development by Gleadow et al. (1982) of a computer-controlled three-axis stage system that substantially improved the efficiency of mirror-image matching between grain mounts and muscovite track detectors in the external detector method. Alternative manual solutions to the mirror-image matching problem in the EDM have also been found, including laying out grains in a grid pattern prior to mounting, and the precise relocation of the etched detector over the grain mount and counting the two sets of tracks at two different focal levels—the so-called sandwich technique (Jonckheere et al. 2003). Both require considerable manual dexterity and patience by the analyst, and neither has been widely adopted. In most laboratories, various versions and generations of either two-, or three-axis motorised stage systems have become part of the conventional EDM approach (Smith and Leigh-Jones 1985; Dumitru 1993).

The capabilities of modern digital microscopes, however, provide a fundamental change in the opportunities for precise computer control, and image-based analysis that can transform the way FT microscopy is conducted. These capabilities include motor-driven objective nosepieces, reflector turrets, diaphragms, filter wheels, illumination shutters, condenser components, stage movements and focusing. The focus motors are particularly important as they now give control on the vertical or z-axis with a precision of a few tens of nanometres, enabling the capture of vertical stacks of images (z-stacks) spaced at a fraction of a micrometre. In this way, it is possible to image the full 3D structure of etched fission tracks in transmitted light and of the etched surface in reflected light at very high magnification. Essentially all of the information available to the operator in conventional microscopy can now be permanently captured in digital form for display on a high-resolution monitor, or subsequent digital image analysis.

Precise control of the vertical movement of the microscope stage is of fundamental importance for automatic focusing and for digital imaging of fission tracks. The ability to capture images in multiple image planes at sub-micron spacing of typically 100–300 nm means that the full 3D character of etched tracks can be captured conveniently and quickly at high magnification for the first time. In this, it is vital that the microscope is stable against both vibrations of the bench and thermal expansion of the microscope body. In some locations, it may be necessary to isolate the microscope from building vibrations using some form of damping table or tablet, although this is mostly not required.

Thermal expansion of the microscope body can be a significant problem for precise, sub-micron, focus control. Large research microscopes, especially as more and more electronics and powerful incandescent light sources have been added to the basic frame, can show substantial thermal expansion over the temperature range typically encountered in the operating environment. If this factor is not controlled, then the distance between the specimen on a stage and the objective can change by up to 20 µm over time in larger format microscopes, simply due to expansion of the microscope frame, as illustrated in Fig. 4.2. The most advanced microscopes now compensate for this thermal expansion and remain stable during an imaging session, but analysts need to be aware that not all motorised microscopes have successfully controlled this problem. High-intensity LED lamps are now appearing that greatly reduce the amount of heat generated close to the microscope and also have the advantage of exhibiting a constant colour temperature over their entire power range, giving a constant white-balance in the captured images.

Thermal expansion in three motor-driven, large-format research microscopes that have been used for FT analysis. The upper group of square symbols shows how the temperature of the microscope stand, measured using an infrared non-contact thermometer, is observed to change as a function of elapsed time since the microscope was switched on. Perhaps surprisingly, all three microscopes follow a very similar temperature increase from a room temperature of ~20 °C to eventually reach a stable operating temperature of nearly 30 °C after about 4 h. For each of the three microscopes, a specimen was set in focus at the start and then the z-axis adjustment in µm required to bring the specimen back into focus was recorded at different times up to 300–550 min. The lower three curves show the amount of adjustment required due to this thermal expansion of the microscope stand. The early 1990s Axiotron microscope shows an expansion of over 20 µm, consistent with the thermal expansion expected in the aluminium microscope body over this temperature range. In contrast, the two modern motorised microscopes (DM6000 and Axio Imager) show only a small, or negligible degree of expansion as temperature increases, although both have some initial instability, before stabilizing. This, along with vibrational stability, is an important consideration for reliably capturing image stacks at sub-micron spacing for automated FT analysis

In addition to motorised control of the microscope itself, there have been key improvements in digital cameras for microscope use over the last few years. Most microscope cameras over the past decade have used CCD sensors that produced images of excellent quality and resolution, but had very slow frame rates of only a few frames per second. This has been an important limitation on the speed at which functions such as autofocus and digital imaging could be carried out, and has been the rate-limiting step in autonomous image capture for FT analysis. In the last few years, however, this has changed significantly with the emergence of a new generation of CMOS sensors with similar image quality and resolution, but very high frame rates of tens to even hundreds of frames per second, and making use of faster data transfer protocols, such as USB3 and GigE. This technological advance has greatly reduced the time required for digital image acquisition in FT analysis.

5 Automation in FT Analysis

The goal of automating FT analysis has had an enduring appeal, and the highly labour-intensive and operator-dependent nature of the required microscopy makes the automation of routine tasks particularly desirable. The potential benefits of an automated system, in addition to relieving the operator of the need for long periods at the microscope, include advantages in providing more consistent data collection, in reducing the dependence on operator experience, and accelerated training for new practitioners. Another factor driving the need for change is that microscope drawing tubes, a key hardware component for conventional track length measurements, are now obsolete and no longer available. Ultimately, the goal of any automated system must be to significantly increase the efficiency of analysis and improve the quality of the data obtained. Many thermochronology studies are also demanding larger quantities of data than can easily be met with traditional analytical approaches.

Until recently, however, the goal of comprehensive automation of FT analysis has remained difficult and impractical, not least because the necessary hardware was not yet available. Early attempts at developing automated systems therefore required specially constructed hardware for the task (e.g. Wadatsumi et al. 1988; Wadatsumi and Masumoto 1990) and principally for this reason have had very little subsequent impact on the field. This situation has now changed with new digital microscopes and computing resources, leading to significant progress in the development of automated analysis systems over the past decade. Important conceptual and software advances are now also being made (e.g. Gleadow et al. 2009a, 2015) that allow these hardware developments to be fully utilised. Importantly, both hardware and software continue to develop rapidly and it is almost certain that automated FT analysis will play a major role in the future of the field.

Several research groups are now pursuing the goal of FT automation including automatic track counting (Gleadow et al. 2009a, 2015; Kumar 2015), automatic or assisted location of suitable grains for counting (Gleadow et al. 2009b; Booth et al. 2015), determination of crystallographic orientation of grains (Peternell et al. 2009; Gleadow et al. 2009b, 2015) and the characterisation of fission track etch pits (Reed et al. 2014; Gleadow et al. 2015). A novel alternative to these automated methods (Vermeesch and He 2016) seeks to use crowdsourcing for counting tracks in captured digital images to average interpersonal differences in fission track counts, while also generating larger data sets than would be possible by a single analyst alone. Many of these approaches are still at an early, experimental stage of development, and the only one now fully operational as an integrated FT analytical system is that developed at the University of Melbourne, which will be detailed here as a case study.

The approach developed in Melbourne is divided into two components. The first is a microscope control system (TrackWorks) that autonomously captures a comprehensive set of digital images on previously marked mineral grains, and the second is an image analysis and review system (FastTracks) that processes the captured and stored images offline on a computer. The operator is required mainly to supervise a brief setting up routine at the microscope, and finally to review the results obtained from the image analysis on a computer and make any corrections or adjustments required.

In this system, the automated track counting is achieved by an image analysis routine called ‘coincidence mapping’, described in detail by Gleadow et al. (2009a), based on a digital superimposition of transmitted and reflected light images. After applying a fast Fourier transform bandpass filter to flatten background variations, the two images are segmented by applying an automatic threshold value to produce a binary image separating ‘features’ from ‘background’. These images include both track and non-track features, but the ‘coincidence’ between the transmitted and reflected images, derived by extracting only those elements that are common to both, is almost entirely fission tracks. Spurious non-track features, such as dust particles, polishing scratches and inclusions, are rarely observed equally in both reflected and transmitted light images, and the few that may be erroneously counted can easily be removed during a rapid manual review of the results.

The best results are obtained with this image analysis technique when careful attention is given to consistent sample preparation. The most suitable mounts have flat polished surfaces with little grain relief, obtained by using diamond, rather than alumina, polishing compounds. A more significant factor is that polished apatite grains commonly show strong internal reflections when observed in incident light, due to their very low surface reflectivity, which degrades the reflected light image required for coincidence mapping. Applying a thin metal coating, typically by depositing a thin (~10 nm) layer of gold onto the etched surface, eliminates these internal reflections. This coating step is most important for apatite, but reflected light imaging of zircon, titanite and muscovite external detectors, are all improved by a reflective coating. Applying the metal coating is easily implemented using either a sputter coater or vacuum-evaporation unit and greatly improves automatic track counting without being dependent on operator skill or experience.

The current Melbourne system is designed to work with either the conventional EDM or the LA-ICP-MS methods, but has particular advantages when coupled with laser ablation because it produces a permanent digital replica of the etched grain surfaces, which are otherwise partially destroyed at the ablation step. The optical information in both transmitted and reflected light, previously accessible only in real time at the microscope, is still available for later observation and analysis through the stored images. The locations of coordination markers and analysed grains can also be exported to a laser ablation or electron microprobe stage, so that further geochemical analysis is streamlined.

As was typical in earlier microscope stage systems (Gleadow et al. 1982; Smith and Leigh-Jones 1985; Dumitru 1993), grain coordinates need to be related to an internal reference frame defined by coordination markers attached to or engraved in the surface of each slide or grain mount. In the Melbourne system, three Cu electron microscope grids are usually attached to each slide for this purpose. The process of locating and accurately centring these markers can itself be automated, so that multiple slides can be loaded on the microscope stage and coordinated automatically (Fig. 4.3).

Upper image a shows a microscope stage with multiple slide insert from Autoscan Systems to carry three fission track mounts for automatic slide coordination, automatic grain detection and autonomous grain imaging. This insert is fitted to a piezo-motor stage on a Zeiss Axio Imager microscope. b is an enlarged view of the same three apatite grain mounts showing the three Cu electron microscope grids attached to each that are used as coordination markers. The grey band across each is a thin (~10 nm) gold coating deposited on the surface using a sputter coater to enhance the surface reflectivity, while still allowing for observation and imaging in transmitted light (Gleadow et al. 2009a). These custom microscope slides have dimensions of 25 × 30 mm, a size that better allows for multiple slide handling and imaging on a normal sized stage. Later versions of this stage insert will carry six slides of this size at one time

The task of locating optimally oriented grains (c-axis parallel) of a suitable size for FT analysis can be automated using digital imaging of grains under circular polarised light (Gleadow et al. 2009b) where the brightness of similarly sized grains is controlled by their orientation. In this observation mode, the brightest grains will be those with their c-axes parallel to the polished surface. A particular advantage of automatic grain detection is that it provides an unbiased selection of grains for analysis, independent of where tracks are located, or whether a particular grain contains any tracks at all. This factor is especially important for low track densities where inappropriate grain selection can significantly bias an age determination. Once a suitable set of grains have been selected for analysis, an automatic image capture sequence can be run autonomously over perhaps 40–80 grains with no further need for operator supervision. The digital image sets captured over a batch of several slides can then be then archived to disc for later retrieval and image analysis.

5.1 Automatic FT Counting

An advantage of any automated image analysis system working on captured images is that the processing can be done independently of the microscope on a different computer. In the Melbourne system, image analysis is typically an interactive process that starts with running the automatic coincidence mapping routine for track counts, adjusting measurement parameters and filter settings as necessary, and reviewing the results. A typical workflow involved in using the FastTracks system for a complete analysis of all parameters is shown schematically in Fig. 4.4, and representative results are shown overlaid on some transmitted light images for a Durango apatite sample in Fig. 4.5.

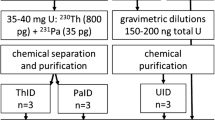

Flow chart showing the sequence of steps involved in conducting a typical automatic FT analysis session using the FastTracks image processing system. The system operates on a set of images captured autonomously using a motorised digital microscope in transmitted and reflected light using the TrackWorks control package. Even though most of the analysis is made automatically, some input or review from the operator is usually required at various steps, as indicated in the left side column. Outputs are shown on the right, and a–d correspond to results in the image overlays in Fig. 4.5. The procedure is essentially the same if the EDM is used, with the addition that tracks are also counted over the paired mica external detector images. Confined FT lengths can be measured at any time though this sequence using 3D measurement tools but are usually measured on a separate set of captured images, either with or without implantation of 252Cf fission tracks to enhance the yield

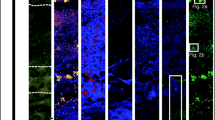

Typical sequence of images with overlaid results obtained using the automated steps in Fig. 4.4. Each image shows a different step in the procedure and the enlarged circle in each frame shows more detail of the lower right area. a shows etched spontaneous fission tracks in a surface transmitted light image in a sample of Durango apatite. The white box is the region of interest (ROI) that defines the area within which the analysis is carried out. b shows the automatically counted tracks from the coincidence mapping algorithm with their surface intersections highlighted. c shows the automatically detected c-axis azimuth direction highlighted by the dark blue parallel lines, and a small bar on each track etch pit shows the automatically determined Dpar values. d shows the results of a prototype automated semi-track length measurement tool, the overlaid lines being the surface projection of the semi-track lengths that are determined in 3D. For each of these semi-tracks, the system determines the true length from the centroid of the surface etch pit to the end of the track, the true angle to the c-axis, the projected length, the depth to the end and the true dip angle below the surface (corrected for refractive index). This image also shows the length of a single horizontal confined track near the centre that has been manually measured by clicking on each end of the track at high magnification. None of the automated measurements in b–d have had any manual correction, although this is often required for a small fraction of the tracks

In this sequence, the first step would involve setting a region of interest (ROI) on each grain (Fig. 4.5a), to define the area for analysis and exclude areas that are unsuitable for counting such as regions outside the grain boundary, areas that are poorly illuminated, or with fractures, inclusions, etc. In a departure from the simple rectangular shapes dictated by eyepiece grids used in conventional microscopy, an automated system can use a ROI of any arbitrary size or shape, or even multiple ROIs within a particular field of view to avoid interference from features such as fractures or inclusions. The area of the ROI can be simply determined from the number of pixels contained so that an accurate track density can be calculated for each grain.

Once image analysis for automatic track counting is complete (Fig. 4.5b), typically taking less than one minute for 30–40 grains using FastTracks, the results may be reviewed and corrected if necessary by the operator for any misidentified features or uncounted tracks (Gleadow et al. 2009a). Such features typically make up only a few per cent of the total, and the manual review can be carried out quite quickly. A worthwhile focus for future research will be to develop additional image analysis routines to correctly identify the small proportion of tracks, mostly very shallow dipping tracks, which may be overlooked or misidentified. Machine learning techniques (Kumar 2015, Donelick and Donelick 2015) may be useful in this regard. After an automatic count has been completed, further automatic image analysis routines can be used to determine other parameters from the stored image sets, such as the c-axis direction and Dpar values (Fig. 4.5c). This secondary analysis typically takes only seconds once the initial image processing has been carried out, and, since the c-axis direction is known within the selected prismatic grain surfaces, the orientation of all other features can be automatically referred to that direction.

5.2 Confined FT Length Measurements

The most time-consuming part of measuring the lengths of confined tracks is not actually the length measurement as such, but the location of suitable horizontal confined tracks. It is this location task that makes automation of length measurements significantly more difficult than automatic counting. Measuring the positions of track ends is relatively trivial to do manually, but can be carried out much more precisely on greatly enlarged digital images than on a live microscope image using a drawing tube and digitiser. An automated microscopy system can greatly assist in this process, but so far no fully automated system has emerged. One partial solution is for the operator to locate suitable confined tracks for length measurement and simply mark their positions during inspection of the grain mount. It is then straightforward to autonomously capture cropped image stacks locally around these locations for later measurement by manually clicking the cursor on each end of the confined track in the on-screen 3D image stack (Gleadow et al. 2015). The length, angle to the c-axis and dip angle can then be automatically recorded (Fig. 4.5d). Although not completely automated, such an image-based system has advantages in that a permanent record is made of the tracks measured, and much greater precision and consistency are possible, relative to a manual measurement under the microscope.

With this system, length measurements can be made accurately over a greater range of dip angles, compared to traditional ‘horizontal’ confined tracks, by recording both the position and the depth plane of the track ends in a transmitted light image stack. The depth component of the true length may be automatically corrected for the refractive index of apatite (Laslett et al. 1982; Gleadow et al. 2015). Such 3D lengths potentially introduce an additional source of sampling bias that still needs further investigation, because dipping tracks are more likely to intersect the surface, and therefore become disqualified as confined tracks if they are long than if they are short. However, the likely increase in sample size from 3D measurements makes understanding this potential bias a worthwhile objective. Even restricting the true dip angles to the usual ‘horizontal’ criterion of <10–15° (Ketcham et al. 2009; Laslett et al. 1982) will make the measurements more precise by correcting for that dip, thereby improving data quality and consistency. Indeed, because the actual dips of conventional ‘horizontal’ track lengths are poorly constrained, and greater than they appear due to the refractive index, the projected lengths recorded without reference to dip may include errors of up to several per cent, or even more.

An important goal for the future of track length measurements will be to find ways to automatically locate confined tracks for measurement, and to develop fully automated measurement tools. This is certainly the most challenging image analysis problem encountered in the automation of FT analysis so far, but there are no fundamental reasons why a solution should not be found.

5.3 Automated Semi-track Length Measurements

Recently, a possible alternative pathway to the automated collection of track length data has emerged, building on the theoretical understanding of the true lengths of ‘semi-tracks’ developed by Laslett and Galbraith (1996) and Galbraith (2005). Semi-tracks are those tracks intersecting the etched surface, the same features that are counted for the spontaneous track density measurement (Chap. 1, Hurford 2018). These tracks have the great advantage that, unlike confined tracks, their locations are already known from the automatic counting result, and the etch pit marking the counted feature also precisely defines the surface end of the track. The termination of the track can then be located by digital analysis of the captured image stack starting from the surface etch pit and tracing the feature until the end of the track is reached. Current attempts at automating this procedure are extremely promising (Fig. 4.5d). The number of semi-tracks available for measurement vastly exceeds the number of the inherently rare confined tracks by a factor of about 50–100, so that much larger length data sets could be collected automatically. Another advantage of semi-tracks is that they are all etched to the same degree, unlike confined tracks that usually show significant variation in the degree of etching because of the variable geometry of their etching access pathways.

Laslett and Galbraith (1996) have shown that, although semi-track lengths are less useful than confined track lengths, they nonetheless show distinctly different length distributions for different thermal history styles and are significantly more informative than ‘projected’ track lengths. This new source of track length information could therefore potentially be used for thermal history modelling. The statistical assessment of Laslett and Galbraith (1996) and Galbraith (2005) allows the semi-track length distribution corresponding to any particular confined length distribution to be calculated, opening the possibility that the inverse procedure can also be achieved by a Monte Carlo modelling approach. The ability to model the underlying confined track length distribution would also mean that, in principle, the results of both confined and semi-track length measurements could be combined in reconstructing a thermal history.

5.4 Other Benefits of Automated FT Analysis

So far, this discussion has been concerned with automation of measurements that have previously been made manually, albeit in a much less convenient way. Other measurements could be made by an automated system, however, that go beyond what has been done before. One such possibility would be the routine assessment of the widths and other dimensions of confined tracks and the semi-tracks from which they are etched. In principle, this might allow for a correction to be applied for the degree of etching of each individual track, and then calculating the etchable range of the latent track before etching began. Such ‘unetched’ lengths of confined tracks might give a more precise representation of the true underlying track length distribution and remove the effects of variable degrees of etching that currently blur the detail of confined track length distributions, and by implication the thermal histories derived from them.

Other significant benefits flow from a digital image-based system, most importantly in the area of training. Previously processed image sets provide a novel and highly efficient way for new analysts to be exposed to the detailed results from an experienced observer. The latest release of the FastTracks system, for example, includes a ‘Training Extension’ that allows a new analyst to import and overlay the results of a previous analysis of the same image set. This system makes a digital comparison with the previous results and highlights any discrepancies for consideration, correction or discussion. Experience in the Melbourne laboratory has shown that this image-based automated system substantially reduces the training time for new students and other novice analysts to a matter of just weeks. Previously, using manual methods, it took many months for a new analyst to achieve a similar level of competence. Widespread sharing of such processed digital image sets between laboratories could therefore play a key role in training a new generation of FT analysts and, importantly, in standardisation between individuals and groups. Indeed, common measurements on the same track length images could provide widely distributed standard reference materials for track lengths that have so far been so conspicuously lacking in FT measurements (Ketcham et al. 2015).

The ability to rapidly transfer digital FT image sets over the Internet also means that completely new modes of distributed analysis can be imagined. In this way, a single centralised digital microscopic imaging facility could support a number of different analysts dispersed at remote locations. One well-equipped laboratory could thus potentially support a number of individual researchers and groups around the world who would only need an Internet connection and a computer with the appropriate software tools to undertake FT analysis on the downloaded image sets. The size of the comprehensive digital image packages currently in use is quite large, typically 5–10 GB per sample, which has implications for how easily these can be transferred. However, files of comparable size are already routinely downloaded today, so such transfers are unlikely to be a significant problem. Some image compression techniques are available to reduce the file sizes, and future implementation of high efficiency ‘lossless’ image compression techniques might further reduce the size of files for transfer. The so-called lossy compression formats, such as jpeg, are best avoided as they can introduce image artefacts and loss of detail during image processing. Of course, continuing improvements in network bandwidth will also assist in the process of efficient transfer of large files.

6 Future Technological Developments

New approaches in FT thermochronology such as those described here have often followed or coincided with the arrival of significant new technologies. Important ongoing developments can be anticipated in all the hardware components relevant to FT analysis, including digital microscopy, imaging systems, computational power, communications, and mass spectrometry for trace element and isotopic analysis. Such ongoing technological advances are likely to significantly influence the future evolution of FT analysis.

Continuing developments in automated digital microscopy are moving rapidly at the present time and likely to lead to a new generation of powerful autonomous instruments that will require less and less supervision by a human operator. One important trend already underway is the emergence of a new generation of ‘headless’ microscopes that are designed for fully automated scanning of large numbers of slides for later offline inspection and analysis. Several major microscope manufacturers are already producing digital microscopy systems that are entirely directed at on-screen examination and image capture. Some are designed to automatically scan up to 100 slides at a time and capture high-resolution digital images for biomedical and even petrographic applications. These systems are designed to operate without human intervention and therefore make no provision for a binocular head and eyepieces, greatly simplifying the design. The microscope systems of the future are likely to look very different to those now in use, and one can imagine a dedicated digital microscopic imaging system constructed specifically for the requirements of FT analysis. Such a system would need many fewer components and options compared to the general purpose instruments of today, potentially reducing costs and increasing the imaging capacity.

An intermediate step with current generation digital microscopes is the ability to automatically scan and image apatite grains over multiple slides, with substantial savings in operator time. Once set up, the present TrackWorks microscope control system can automatically locate slide coordination markers, detect suitable grains and autonomously capture image sets over three FT slides at a time. Increasing camera speeds, however, have meant that this capture time is now reduced from several hours, previously run overnight, to less than one hour for such a batch. A new generation of larger format motorised stages mean it should soon be possible to increase this autonomous capture capacity to six slides at a time, and further increases can be foreseen beyond that.

One other area where new developments in microscopy could have an impact on FT analysis is the emergence of various so-called super-resolution imaging techniques. These techniques are able to exceed the normal diffraction-limited resolution of conventional optics and could potentially provide more sharply resolved images for FT analysis. There are several such systems currently available, directed almost exclusively at biomedical applications and particularly fluorescence microscopy. None of these appear at present to be suitable for imaging fission tracks, but this is a very active area of innovation at present, and it is possible that a suitable technology might appear in future.

Developments in computing power and display technologies continue at a rapid pace so that even greater computational capacity will be available to replace current desktop and laptop computers, allowing ever more powerful image analysis procedures. Other opportunities for advanced image analysis could arise by utilising the massively parallel processing power of graphics processor cards to greatly accelerate performance, and also from unconventional computing architectures, such as neural networks and even quantum computing. The point here is not so much that greater speed of analysis is urgently needed, as it is already very fast, but these new technologies are likely to substantially expand the kinds and quality of data that can be collected and processed automatically. For example, higher-resolution imagery and more closely spaced image stacks could be captured and analysed. This has significant implications for the necessary image storage, but the capacity of computer storage is also continually increasing and becoming cheaper—essentially following ‘Moore’s Law’. Similarly, the capacity and speed of global communications capable of transferring very large data sets between laboratories will continue to increase. These developments will accelerate the opportunities for inter-laboratory collaboration, standardisation, training and distributed analysis.

The accuracy of uranium concentration measurements with current generation laser ablation ICP-MS instruments is typically limited to a few per cent. However, looking at the rapid development of this technology over the last 20 years gives confidence that it, and potentially other kinds of mass spectrometry systems, such as ICP time-of-flight (TOF) mass spectrometers, will continue to evolve, leading to increased precision and sensitivity for future applications in FT analysis. Such methods for the direct, rapid measurement of 238U for FT analysis is also likely to be accompanied by greater levels of automation, faster analysis, better software integration, simultaneous multi-element capabilities and multi-system dating, all with many fewer demands on operator time.

One final comment here is that all of these developments at the most advanced level of FT analysis still depend on the basic requirement of crushing rock samples and separating their constituent minerals. These are still mostly carried out using quite primitive mechanical crushing, heavy liquid and magnetic separation techniques that are dirty, slow and potentially dangerous. Despite some developments in the emergence of non-toxic heavy liquids, these methods for the most part have changed little over the last century. One important new technology is the electrodynamic disaggregation of rocks with the Selfrag devices (Giese et al. 2010), which are starting to appear in some larger groups, but at a cost that puts them well out of reach for most laboratories. It is possible that this kind of disaggregation device could find a more widespread application as part of a centralised FT sample preparation and digital imaging facility as discussed above. Even so, the ongoing necessity of large-scale mineral separation suggests that a substantial research effort to develop new, innovative and highly automated approaches to this laborious task would surely be of great benefit to the analytical community.

7 Other Trends in FT Analysis

A number of other important trends can be discerned in the wider field of FT thermochronology that go beyond the technical data acquisition advances that have been the main emphasis here. An example is the increasing integration of FT analysis of apatite and zircon in thermochronology studies with other systems such as 40Ar/39Ar dating of co-genetic mineral phases (e.g. Carrapa et al. 2009; see Chap. 5, Danišík 2018). Another is the simultaneous modelling of multiple FT samples that have a known spatial relationship to each other, such as in a borehole or in a vertical sampling profile across topographic relief. The thermal history inversion will be much more powerfully constrained in such cases, and this approach is now being facilitated by the addition of multi-sample capabilities to modelling codes (e.g. Gallagher 2012). Beyond this, there are many exciting applications for thermochronology emerging through the integration of thermal history modelling with thermokinematic and surface process models through software such as PECUBE (Braun et al. 2012) to provide better-constrained and mutually consistent solutions to geological problems.

Similarly, FT analysis can be combined with other U-decay schemes applied to the same mineral grains in the so-called double dating (e.g. FT and U–Pb, or (U–Th)/He and U–Pb) or ‘triple dating’ (e.g. FT, (U–Th)/He and U–Pb) (see Chap. 5, Danišík 2018). This is another important trend that is likely to accelerate in coming years with the wider adoption of LA-ICP-MS techniques, which allows the measurement of multiple isotopic systems simultaneously with the measurement of 238U for FT analysis (e.g. Carrapa et al. 2009; Shen et al. 2012). With advances in mass spectrometry, it is even possible to imagine a system that could simultaneously, or sequentially make in situ measurements of FT, (U–Th)/He, U–Th–Pb and even U–Xe ages in a single grain.

Within FT thermochronology itself, another trend is towards analysis of significantly larger numbers of grains in a sample, particularly for detrital applications (~100 grains, Bernet and Garver 2005; Carrapa et al. 2009). For this trend to continue requires greater analytical efficiency and sample throughput which would be greatly facilitated by the application of automation. Automatic grain detection, in particular, might help to ensure representative sampling of different age populations in a detrital suite and reduce the potential for operator bias in grain selection. The adoption of LA-ICP-MS for uranium measurements also gives the opportunity to analyse for a range of additional trace elements simultaneously, such as the REEs, which could help in fingerprinting different detrital sources and characterising their petrogenetic origins. Another possible trend, after several decades where FT analysis has been dominated by apatite, is an renewed interest in multi-mineral FT studies, including titanite, zircon and other previously studied minerals, and exploration of the potential of additional minerals, such as monazite which has potential for ultra-low temperature thermochronometry (Gleadow et al. 2002, 2005).

The development of new approaches and new technologies gives an opportunity for many fundamental issues in FT analysis to be revisited, new calibrations undertaken and new modelling strategies developed to take advantage of alternative kinds of data. New measurements of the track detection efficiency of apatite and other minerals are needed if FT analysis is to move away from a purely empirical calibration and become an independent absolute dating method (e.g. Jonckheere and van den Haute 2002; Soares et al. 2014). New statistical studies are needed to fully understand the implications of 3D track length measurements. If automated measurements of semi-track lengths become a routine option, as is highly likely, then new FT annealing models based directly on such measurements need to be developed, or alternatively, robust inversion methods to derive confined track length distributions from semi-track data. The influence of radiation damage on the annealing properties of zircon, titanite and other minerals is another area that requires further study. While this factor is increasingly being recognised as a significant influence in thermochronology, it is nonetheless very poorly understood.

There are also many aspects of the effects of mineral composition on FT annealing that have received almost no attention, and are worthy of further exploration. These include the potential influence of OH substitution in fluorapatites. The difficulty in measuring this anion has meant that it has been largely ignored to date, and the annealing properties of hydroxyapatites are almost unknown. One important observation, however, is that etching rates in diagenetic hydroxyapatites are comparable to those in chlorapatites, so it may be that some OH substitution could be responsible for the observed tendency for Dpar values to increase towards the fluorapatite end of the compositional spectrum (Green et al. 2005; Spiegel et al. 2007). Although anion substitutions, especially Cl, in apatite clearly have a dominant control on the annealing properties, various cation substitutions might also have an influence, such as REE, Sr and Mn (Carlson et al. 1999; Barbarand et al. 2003), which need to be investigated further. In other minerals, such as zircon and titanite we have scarcely begun to assess the influence of compositional factors on their annealing properties, and how these might interact with accumulating radiation damage. Some studies (Haack 1972; Dahl 1997; Carlson et al. 1999) have provided evidence of a systematic relationship between annealing properties and the underlying crystal chemistry of FT minerals reflected in such parameters as the ionic porosity. In principle, such relationships, if adequately understood, could allow the annealing properties of an unknown mineral to be predicted from its composition, which would be of great benefit. Current knowledge of the underlying mechanisms falls far short of such a capability, but further research into some of these fundamental questions is clearly warranted and could significantly influence the future of FT studies.

Another area that remains poorly understood is the relationship between the fundamental mechanisms of FT annealing at the atomic scale and the empirically observed behaviour of etched tracks. Several recent investigations are providing important new insights into the annealing behaviour of unetched fission tracks (Li et al. 2011, 2012; Afra et al. 2011) that are now starting to close this gap in our understanding. A complete convergence between studies of the properties of latent fission tracks and the properties of etched tracks is still some way off, but must surely be an important research goal for the future of FT thermochronology.

8 Conclusions

After a long period of relative stability in the widely used methods of FT thermochronology, a number of disruptive developments are now occurring that will have a formative effect on future practice in this field. Importantly, these have the potential for much more rapid analysis and improved data quality, which should in turn propagate through to more reliable thermal history reconstructions. These changes include the gradual adoption of LA-ICP-MS analysis for the direct determination of 238U concentrations in mineral grains, rather than using induced 235U fission tracks as a proxy, and the adoption of automated analytical methods based on digital images captured with a new generation of computer-controlled, motor-driven microscopes. Image analysis of captured image sets can provide automatic counting of fission tracks and a range of support features including automatic slide coordination, automatic grain detection and batch processing of multiple grain mounts at one time. The c-axis direction in uniaxial minerals such as apatite and zircon can also be determined automatically, as can the track etch pit size parameters Dpar and Dper. 3D confined track length measurements can then be automatically related to crystallographic orientation. New approaches to the automatic measurement of track lengths are now under development that will complete the analytical sequence required for automatic FT analysis. Significant improvements in all these methods can be anticipated, as is the involvement of an increasing number of groups in their development. This trend towards increasingly effective automation is likely to be a major component of future developments in FT analysis.

Importantly, these new approaches are not simply new ways of doing the same thing as before, but include opportunities for obtaining new and much richer data sets that were not previously practical to measure manually. This is likely to lead to more robust, consistent and better-standardised analyses than were previously possible, and much improved training procedures for new analysts. Sharing of digital image sets also means that much greater inter-laboratory standardisation will be possible, as will new distributed modes of analysis where one well-equipped laboratory could provide captured images for a number of other analysts in different places. Working with captured digital images of etched mineral grains has particular advantages when combined with laser ablation analysis, which is destructive of the grain surfaces on a micro-scale. LA-ICP-MS also enables a range of other isotopes to be analysed simultaneously with 238U, including 232Th, Pb isotopes and potentially 35Cl as a kinetic parameter in apatite, which allows not only for more rapid and streamlined analytical methods, but also for multiple dating systems to be applied to single grains at the same time. Thus, the current trend towards so-called double and triple dating in apatite and zircon is likely to become a major part of the future of FT thermochronology.

Continued technical development in instrumentation, computational power and software can be expected to lead to further enhancements and new opportunities across all of these current trends in FT thermochronology. The outcome is expected to be a future FT analysis based on more comprehensive data sets, better standardisation and more robust thermal history inversions, as part of a broader multi-mineral, multi-system approach to thermochronology.

References

Afra B, Lang M, Rodriguez MD, Zhang J, Giulian JR, Kirby N, Ewing RC, Trautmann C, Toulemonde M, Kluth P (2011) Annealing kinetics of latent particle tracks in Durango apatite. Phys Rev B 83:064116

Barbarand J, Carter A, Hurford AJ (2003) Compositional and structural control of fission-track annealing in apatite. Chem Geol 198:107–137

Bernet M, Garver JI (2005) Fission-track analysis of detrital zircon. Rev Mineral Geochem 58:205–238

Booth JT, Jones J, Schaeffer K, Woodall K, Kumar R, Dodds Z, Donelick R (2015) Mapping for microscopes: automating apatite-image handling. Goldschmidt Abstr 2015:341

Braun J, van der Beek P, Valla P, Robert X, Herman F, Glotzbach C, Pedersen V, Perry C, Simon-Labric T, Prigent C (2012) Quantifying rates of landscape evolution and tectonic processes by thermochronology and numerical modeling of crustal heat transport using PECUBE. Tectonophysics 524–525:1–28

Carlson WD, Donelick RA, Ketcham RA (1999) Variability of apatite fission-track annealing kinetics: I. Experimental results. Am Mineral 84:1213–1223

Carrapa B, DeCelles PG, Reiners PW, Gehrels GE, Sudo M (2009) Apatite triple dating and white mica 40Ar/39Ar thermochronology of syntectonic detritus in the Central Andes: a multiphase tectonothermal history. Geology 37:407–410

Chew DM, Donelick RA (2012) Combined apatite fission track and U-Pb dating by LA-ICP-MS and its application in apatite provenance studies. Mineral Assoc Canada Short Course 42:219–247 (St Johns, NL)

Chew D, Donelick RA, Donelick MB, Kamber BS, Stock MJ (2014) Apatite chlorine concentration measurements by LA-ICP-MS. Geostand Geoanal Res 38:23–35

Chew D, Babechuk MG, Cogné N, Mark C, O’Sullivan GJ, Henrichs IA, Doepke D, McKenna CA (2016) (LA, Q)-ICPMS trace-element analyses of Durango and McClure Mountain apatite and implications for making natural LA-ICPMS mineral standards. Chem Geol 435:35–48

Dahl PS (1997) A crystal-chemical basis for Pb retention and fission-track annealing systematics in U-bearing minerals, with implications for geochronology. Ear Planet Sci Lett 150:277–290

Danišík M (2018) Chapter 5. Integration of fission-track thermochronology with other geochronologic methods on single crystals. In: Malusà MG, Fitzgerald PG (eds) Fission-track thermochronology and its application to geology. Springer, Berlin

Donelick RA (1993) Apatite etching characteristics versus chemical composition. Nucl Tracks Radiat Meas 21:604

Donelick A, Donelick R (2015) Machine learning applied to finding and characterizing the tips of etched fission tracks. Goldschmidt Abstr 2015:759

Donelick RA, O’Sullivan PB, Ketcham RA (2005) Apatite fission-track analysis. Rev Mineral Geochem 58:49–94

Dumitru TA (1993) A new computer-automated microscope stage system for fission-track analysis. Nucl Tracks Radiat Meas 21:575–580

Fleischer RL, Hart HR (1972) Fission track dating: techniques and problems. In: Bishop WW, Miller DA, Cole S (eds) Calibration of hominid evolution. Scottish Academic Press, Edinburgh, pp 135–170

Fleischer RL, Price PB, Walker RM (1975) Nuclear tracks in solids. University of California Press, Berkeley, p 605

Galbraith RF (1990) The radial plot; graphical assessment of spread in ages. Nucl Tracks Radiat Meas 17:207–214

Galbraith RF (2005) Statistics for fission track analysis. Chapman & Hall, Boca Raton, p 219

Gallagher K (2012) Transdimensional inverse thermal history modeling for quantitative thermochronology. J Geophys Res 117:B02408

Giese J, Seward D, Stuart FM, Wüthrich E, Gnos E, Kurz D, Eggenberger U, Schruers G (2010) Electrodynamic disaggregation: does it affect apatite fission-track and (U-Th)/He analyses? Geostand Geoanal Res 34:39–48

Gleadow AJW (1981) Fission-track dating methods: what are the real alternatives? Nucl Tracks 5:3–14

Gleadow AJW, Seiler C (2015) Fission track dating and thermochronology. In: Rink WJ, Thompson JW (eds) Encyclopedia of scientific dating methods. Springer, Dordrecht, pp 285–296

Gleadow AJW, Leigh-Jones P, Duddy IR, Lovering JF (1982) An automated microscope stage system for fission track dating and particle track mapping. In: Workshop on fission track dating. Fifth international conference on geochronology, cosmochronology and isotope geology, Nikko Japan, Abstract, pp 22–23

Gleadow AJW, Duddy IR, Green PF, Lovering JF (1986) Confined fission track lengths in apatite: a diagnostic tool for thermal history analysis. Contrib Mineral Petrol 94:405–415

Gleadow AJW, Belton DX, Kohn BP, Brown RW (2002) Fission track dating of phosphate minerals and the thermochronology of apatite. Rev Mineral Geochem 48:579–630

Gleadow AJW, Raza A, Kohn BP, Spencer SAS (2005) The potential of monazite for fission-track dating. Geochim Cosmochim Acta 69(Supp 1):A21

Gleadow AJW, Gleadow SJ, Belton DX, Kohn, BP, Krochmal MS (2009a) Coincidence Mapping, a key strategy for automated counting in fission track dating. In: Ventura B, Lisker F, Glasmacher UA (eds) Thermochronological methods: from palaeotemperature constraints to landscape evolution models, vol 324. Geological Society of London Special Publication, pp 25–36

Gleadow AJW, Gleadow SJ, Frei S, Kohlmann F, Kohn, BP (2009b) Automated analytical techniques for fission track thermochronology. Geochim Cosmochim Acta 73(Suppl):A441

Gleadow A, Harrison M, Kohn B, Lugo-Zazueta R, Phillips D (2015) The Fish Canyon Tuff: a new look at an old low-temperature thermochronology standard. Ear Planet Sci Lett 424:95–108

Goldoff B, Webster JD, Harlov DE (2012) Characterization of fluor-chlorapatites by electron probe microanalysis with a focus on time-dependent intensity variation in halogens. Am Mineral 97:1103–1115

Green PF, Duddy IR, Gleadow AJW, Tingate PR, Laslett GM (1985) Fission track annealing in apatite: track length measurements and the form of the Arrhenius plot. Nucl Tracks 10:323–328

Green PF, Duddy IR, Hegarty KA (2005) Comment on compositional and structural control of fission track annealing in apatite by Barbarand J, Carter A, Wood I, and Hurford AJ. Chem Geol 214:351–358

Haack U (1972) Systematics in the fission track annealing of minerals. Contrib Mineral Petrol 35:303–312

Hasebe N, Barberand J, Jarvis K, Carter A, Hurford AJ (2004) Apatite fission-track chronometry using laser ablation ICP-MS. Chem Geol 207:135–145

Hasebe N, Tamura A, Arai S (2013) Zeta equivalent fission-track dating using LA-ICP-MS and examples with simultaneous U-Pb dating. Island Arc 22:280–291

Hurford AJ (1998) Zeta: the ultimate solution to fission-track analysis calibration or just an interim measure? In: van den Haute P, De Corte F (eds) Advances in fission-track geochronology. Kluwer Academic Publishers, pp 19–32

Hurford AJ (2018) Chapter 1. An historical perspective on fission-track thermochronology. In: Malusà MG, Fitzgerald PG (eds) Fission-track thermochronology and its application to geology. Springer, Berlin

Hurford AJ, Green PF (1983) The zeta age calibration of fission track dating. Chem Geol (Isot Geosci Sect) 1:285–317

Jonckheere R, van den Haute P (2002) On the efficiency of fission-track counts in an internal and external apatite surface and in a muscovite external detector. Radiat Meas 35:29–40

Jonckheere R, Ratschbacher L, Wagner GA (2003) A repositioning technique for counting induced fission tracks in muscovite external detectors in single-grain dating of minerals with low and inhomogeneous uranium concentrations. Radiat Meas 37:217–219

Jonckheere R, Tamer M, Wauschkuhn F, Wauschkuhn B, Ratschbacher L (2017) Single-track length measurements of step-etched fission tracks in Durango apatite: Vorsprung durch Technik. Am Mineral (in press)

Ketcham RA (2005) Forward and inverse modeling of low-temperature thermochronometry data. Rev Mineral Geochem 58:275–314

Ketcham RA, Donelick RA, Balestrieri ML, Zattin M (2009) Reproducibility of apatite fission-track length data and thermal history reconstruction. Ear Planet Sci Lett 284:504–515

Ketcham RA, Carter A, Hurford AJ (2015) Inter-laboratory comparison of fission track confined length and etch figure measurements in apatite. Am Mineral 100:1452–1468

Kohn B, Chung L, Gleadow A (2018) Chapter 2. Fission-track analysis: field collection, sample preparation and data acquisition. In: Malusà MG, Fitzgerald PG (eds) Fission-track thermochronology and its application to geology. Springer, Berlin

Kumar R (2015) Machine learning applied to autonomous identification of fission tracks in apatite. Goldschmidt Abstr 2015:1712

Laslett GM, Galbraith RF (1996) Statistical properties of semi-tracks in fission track analysis. Radiat Meas 26:565–576

Laslett GM, Kendall WS, Gleadow AJW, Duddy IR (1982) Bias in measurement of fission track length distributions. Nucl Tracks 6:79–85

Li W, Wang L, Lang M, Trautmann C, Ewing RC (2011) Thermal annealing mechanisms of latent fission tracks: apatite vs. zircon. Ear Planet Sci Lett 302:227–235

Li W, Lang M, Gleadow AJW, Zdorovets MV, Ewing RC (2012) Thermal annealing of unetched fission tracks in apatite. Ear Planet Sci Lett 321–322:121–127

Naeser C, Dodge FCW (1969) Fission-track ages of accessory minerals from granitic rocks of the central Sierra Nevada Batholith, California. Geol Soc Am Bull 80:2201–2212

Peternell F, Kohlmann F, Wilson CJL, Gleadow AJW (2009) A new approach to crystallographic orientation measurement for apatite fission track analysis: effects of crystal morphology and implications for automation. Chem Geol 265:527–539

Reed L, Vigue K, Kumar R, Ndefo-Dahl A, Dodds Z, Donelick R (2014) Automated fission track and etch figure characterisation in apatite crystals (Abstract). In: 14th International conference on thermochronology, Chamonix, September 2014, p 23

Seiler C, Kohn B, Gleadow A (2014) Apatite fission track analysis by LA-ICP-MS: an evaluation of the absolute dating approach. In: 14th International conference on thermochronology, Chamonix, September 2014, pp 11–12

Shen CB, Donelick RA, O’Sullivan PB, Jonckheere R, Yang Z, She ZB, Miu XL, Ge X (2012) Provenance and hinterland exhumation from LA-ICP-MS zircon U-Pb and fission-track double dating of Cretaceous sediments in the Jianghan Basin, Yangtze block, central China. Sed Geol 281:194–207

Smith MJ, Leigh-Jones P (1985) An automated microscope scanning stage for fission track dating. Nucl Tracks 10:395–400

Soares CJ, Guedes S, Hadler JC, Mertz-Kraus R, Zack T, Iunes PJ (2014) Novel calibration for LA-ICP-MS-based fission-track thermochronology. Phys Chem Mineral 41:65–73