Abstract

The aim of this chapter is to compare collaborative new product development (CNPD) established by industrial companies with their suppliers and customers, according to their size and the type of innovation generated. To do so, eight in-depth case studies were analyzed, based on semi-structured interviews. The findings show that CNPD with suppliers in more active than with clients. The results also show that firm size is important in CNPD activities namely when product differentiation and large scale production activities are at stake. From another perspective, the results show that the development of processes and management methodologies in upstream activities are not extensively used. The chapter contributes to knowledge about CNPD by comparing how upstream and downstream are affected based on firm size and the type of innovation generated.

Access provided by CONRICYT-eBooks. Download chapter PDF

Similar content being viewed by others

Keywords

1 Introduction

The competitiveness of the global market, the complexity of products and the need for specialization promote collaborative new product development (CNPD) in upstream as well in downstream activities in the supply chain (Hoegl and Wagner 2005; Nieto and Santamaria 2010; Moreira and Karachun 2014; Tuli and Shankar 2015; Un and Azakawa 2015). Therefore, firms’ involvement in value creation in CNPD represents a competitive advantage (Soosay et al. 2008; Nieto and Santamaria 2010; Büyüközkan and Arsenyan 2012; Un and Azakawa 2015; Lager 2016).

New product development activities have been the primary objective of many firms. After reviewing 461 articles Moreira and Karachun (2014) found that cooperative strategies are heavily dependent on knowledge transfer and management in order to integrate innovation, supplier integration, user involvement, new product and new process development processes, the management of internal and external teams and the launch of new products. In this context, the literature highlights the importance of CNPD in firms’ positioning in the market leading to the debate about collaboration with both suppliers and customers (Faems et al. 2005; Soosay et al. 2008; Van de Vrande et al. 2009; Brettel and Cleven 2011; Theyel 2012). For example, Powell et al. (1996), Soosay et al. (2008), Wynarczyk et al. (2013) and Tuli and Shankar (2015) mention that collaboration refers to activities carried out between firms to conceive new products, manufacturing processes and management methodologies. Other authors address the subject of collaboration between firms to analyze its effect on CNPD (Nieto and Santamaria 2007; Parida et al. 2012; Tuli and Shankar 2015; Hossain and Karaunen 2016). Finally, most of studies on CNPD do not compare the involvement between industries of different technological intensity, namely involving small and medium-sized firms (SMEs) operating in low-tech industries (Silva and Moreira 2017).

The dynamics of CNPD emphasizes the characteristics of firms in their collaborative activities upstream and downstream in the supply chain, which enables the understanding and the determination of what their differences are and how they are operationalized. Clearly, most of the studies analyze CNPD based on supplier-client relationships; however, there is a lack of empirical evidence in what pertains to the comparison of upstream and downstream activities involving large firms vis-à-vis SMEs.

The aim of this research is to compare firms’ involvement in CNPD in upstream and downstream activities of the supply chain, based on firm size and the innovation generated, and determine the differences according to those characteristics. For this purpose, a framework was developed serving to study firms’ involvement in CNPD in various circumstances. The study aims to answer the following questions: How is CNPD operationalized between industrial firms and their suppliers and customers? How do firms intervene in CNPD according to their size and the innovation created?

The chapter is divided in five sections. After this introduction, that comprises the first section, the theory on CNPD is depicted in the second section, when collaboration in upstream and downstream activities are explored. Section 3 addresses the method and data used throughout the article. Section 4 discusses the results. Finally, Sect. 5 presents the main conclusions of the chapter.

2 Theory on Collaborative New Product Development

2.1 Involvement Between Firms in CNPD

CNPD is based on sharing information, risks and rewards (Takeishi 2001; Emden et al. 2006; Wagner and Hoegl 2006; Inauen and Schenker-Wicki 2012; Un and Azakawa 2015), being common practice in high-tech industries, as is the case of the pharmaceutical, electronics and auto industries (Powell et al. 1996; Takeishi 2001; Inauen and Schenker-Wicki 2012), and subsequently spreading to other industries. Chesbrough (2003) studied this collaborative practice in large firms in high-tech industries, calling it open innovation. Various authors conclude that CNPD is operationalized by large firms, because they are highly specialized and able to make major investments (Lecocq and Demil 2006; Lichtenthaler 2008; Ferrary 2011; Gay 2014). However, SMEs also participate in CNPD, despite their limitations regarding R&D investment and production capacity (Laursen and Salter 2006; Van de Vrande et al. 2009; Lee et al. 2010; Theyel 2012; Silva and Moreira 2017). Other studies claim that collaboration between companies promotes the development of new products, manufacturing processes or management methodologies according to firms’ size and the innovation generated in CNPD (Laursen and Salter 2006; Nieto and Santamaria 2007; Parida et al. 2012; Theyel 2012; Hossain 2015). Nevertheless, there is no literature concerning the comparison between CNPD carried out by SMEs and large firms in upstream and downstream activities.

2.1.1 Objectives in Resorting to External Technology

CNPD has been analyzed to distinguish objectives when resorting to external technology (Freel 2003; Lecocq and Demil 2006; Van de Vrande et al. 2009; Lee et al. 2010; Hossain 2015). Large firms operationalize CNPD aiming to develop differentiated products and processes, contributing to the externalization of more fruitful results from their activity (Chesbrough and Crowther 2006; Gassmann 2006; Ferrary 2011). In the case of SMEs, the aim is to diversify their product portfolio (Lecocq and Demil 2006; Van de Vrande et al. 2009; Wynarczyk et al. 2013; Hossain 2015) and extend their network of partners to access diversified markets (Lichtenthaler 2008; Lee et al. 2010). In the view of Freel (2003), Madrid-Guijarro et al. (2009) and Parida et al. (2012), the CNPD undertaken by SMEs aims to increase the efficiency of their resources, mainly in relation to manufacturing processes. The above studies reveal it is large firms that involve suppliers in CNPD with the aim of creating differentiated products. However, there are differences in the interaction between firms in CNPD, according to the characteristics of those involved and the innovation created (Nieto and Santamaria 2007; Theyel 2012; Spithoven et al. 2013; Hossain and Karaunen 2016). Consequently, firm size and the innovation created in CNPD can be expected to lead to different results regarding their influence on the objectives of resorting to external technology.

2.1.2 CNPD Operationalized According to Its Innovation Nature

Various studies classify innovation according to its radical nature in order to understand its influence on CNPD (Van de Vrande et al. 2009; Parida et al. 2012; Inauen and Schenker-Wicki 2012; Hossain 2015). Radical innovation, understood as the development of new products and processes, is created through collaboration between firms operating in high-tech industries to promote differentiation (Garcia and Calantone 2002; Koberg et al. 2003; Diedericks and Hoonhout 2007; Inauen and Schenker-Wicki 2012), whereas incremental innovation, understood as the development of improved products and processes, emerges from collaboration between firms to reposition their products or increase the efficiency of their activity (Inauen and Schenker-Wicki 2012; Parida et al. 2012). Other studies claim that radical innovation is created in CNPD between large firms, because they have major technological resources, whereas incremental innovation is created by SMEs (Koberg et al. 2003; Van de Vrande et al. 2009; Inauen and Schenker-Wicki 2012). However, the literature is controversial, because SMEs also have the capacity to develop new products, despite their limited resources (Lee et al. 2010; Hossain 2015). From another perspective, radical innovation emerges from upstream CNPD activities among large firms and between those large firms and consultancy firms and academic institutions, due to their capacity to develop emerging technologies (Gassmann 2006; Ferrary 2011; Un and Azakawa 2015), while incremental innovation emerges from the downstream collaboration undertaken by SMEs (Bonner and Walker 2004; Faems et al. 2005; Roy and Sivakumar 2010). However, these approaches do not compare the circumstances in which CNPD occurs in relation to the industries in which firms operate.

2.2 Vertical Collaboration

2.2.1 CNPD Operationalized Upstream

CNPD undertaken upstream corresponds to suppliers’ involvement with firms (Powell et al. 1996; Hoegl and Wagner 2005; Laursen and Salter 2006; Brunswicker and Vanhaverbeke 2014; Tuli and Shankar 2015), through participation in B2B networks, outsourcing contracts and acquiring patents (Gomes-Casseres 1997; Laursen and Salter 2006; Van de Vrande et al. 2009). The involvement of universities and consultants in CNPD activities is another form of collaboration upstream, when firms need to incorporate emerging technologies (Tether 2002; Freel 2003; Faems et al. 2005; Fontana et al. 2006; Bruneel et al. 2010; Brunswicker and Vanhaverbeke 2014). According to Cohen and Levinthal (1990), Tether (2002) and Inauen and Schenker-Wicki (2012), suppliers’ specialization is crucial for CNPD dynamics upstream.

Frequent Versus Occasional Collaboration

Frequent collaboration occurs with regular industrial suppliers operating in high-tech industries (Peng et al. 2014). However, the great complexity of CNPD favors collaboration between firms and new suppliers (Croom 2001; Bueno and Balestrin 2012), principally in the case of large firms (Boehe 2007). New suppliers’ collaboration in CNPD, which can occur occasionally, is due to firms’ need for specialization in differentiated products (Phillips et al. 2006; Bueno and Balestrin 2012; Raluca 2013). In general, firms collaborate frequently with regular suppliers, involving competences which are specific and complementary to the diversity of requirements for new products (Tidd et al. 2001; Bueno and Balestrin 2012).

Objectives of the Innovation Generated

Collaboration between suppliers and industrial firms contributes to the development of products and processes (Fritsch and Lukas 2001; Lager 2016) when firms need to incorporate, simultaneously, specialized material, manufactured technologies or management methodologies (Clark and Fujimoto 1991; Knudsen 2007; Faems et al. 2005; Soosay et al. 2008; Brettel and Cleven 2011). In addition, universities collaborate with large firms to develop new processes (Faems et al. 2005; Laursen and Salter 2006; Un and Azakawa 2015) for more agile development of new-to-the-market differentiated products (Tether 2002). However, CNPD undertaken upstream, mainly by SMEs, creates improved products and processes (Verhees and Meulenberg 2004; Faems et al. 2005; Soosay et al. 2008; Lager and Frishammar 2012; Theyel 2012) to increase the efficiency of their activity (Soosay et al. 2008). The facts described reveal that radical innovation promotes collaboration between service suppliers and large firms for the development of new processes. From another perspective, the innovation created in CNPD is more significant in firms operating in high-tech industries (Faems et al. 2005; Tether 2002). However, Schiele (2010) defends that suppliers’ specialization is what matters the most, which underpins radical innovation. Most studies claim that the radical innovation is created mainly in the CNPD undertaken by large firms, when compared to the less radical nature of products developed by SMEs (Clark and Fujimoto 1991; Laursen and Salter 2006; Un and Azakawa 2015). However, these views are limited because they do not compare the innovation created in CNPD according to the industries in which firms operate.

Typology of Firms Involved

The literature states that large firms are more active in CNPD than SMEs (Chesbrough 2003; Spithoven et al. 2013; Hossain and Karaunen 2016). Upstream CNPD is mostly carried out by large industrial firms operating in high-tech industries (Wynstra et al. 2010; Gay 2014). Another perspective claims that firm size does not affect upstream collaboration in CNPD (Lee et al. 2010; Parida et al. 2012; Wynarczyk et al. 2013) and that SMEs intervene in CNPD with firms of varying sizes (Parida et al. 2012; Theyel 2012) due to their flexibility and capacity to adapt to the market (Lecocq and Demil 2006; Lee et al. 2010), despite their limitations regarding major R&D investment and production capacity (Van de Vrande et al. 2009; Lee et al. 2010).

Although SMEs develop new products in collaboration with industrial suppliers (Nieto and Santamaria 2010; Hossain 2015; Hossain and Karaunen 2016), the need for SME specialization encourages collaboration with small and medium-sized service suppliers, mainly when they operate in specific niche markets (Verhees and Meulenberg 2004; Tether and Tajar 2008; Hossain 2015). In addition, growing technological development has led to firms acquiring academic knowledge about new materials and manufacturing processes (Faems et al. 2005; Nieto and Santamaria 2010; Un and Azakawa 2015). In this context, university and consultant involvement upstream in CNPD with large firms promotes the development of new processes and management methodologies (Cohen and Levinthal 1990; Tether 2002; Faems et al. 2005; Un and Azakawa 2015; Brettel and Cleven 2011). These facts show the importance of the contribution of service suppliers to CNPD when companies need to develop new processes (Faems et al. 2005; Laursen and Salter 2006; Un et al. 2010; Nieto and Santamaria 2010).

2.2.2 CNPD Operationalized Downstream

Downstream CNPD (Powell et al. 1996; Brockhoff 2003; Lagrosen 2005; Theyel 2012) has been undertaken through agreements (Gomes-Casseres 1997; Laursen and Salter 2006; Lager and Frishammar 2012), granting rights to use technology (Powell et al. 1996, Wynarczyk et al. 2013) and collaboration between companies (Van de Vrande et al. 2009; Lee et al. 2010; Gay 2014). Downstream collaboration has been addressed in various studies due to customers’ importance in spreading the innovation created upstream (Freel 2003; Knudsen 2007; Lee et al. 2010; Un and Azakawa 2015). However, the literature on CNPD involving customers is controversial and needs a deeper analysis.

Frequent Versus Occasional Collaboration

When the main objective is the creation of customized products, frequent relations involving SMEs and customers in CNPD are more common than those involving large firms and customers (Lee et al. 2010). For Tether (2002) and Knudsen (2007), frequent relations in CNPD occur between companies and customers operating in high-tech industries when developing new products. Stephanie and Shulman (2011) and Peng et al. (2014) add that it is clients’ need for specialization in manufacturing processes that stimulates firms’ frequent involvement in CNPD, due to product differentiation. Therefore, frequent relations between SMEs and clients operating in high-tech industries are due to the radical nature of CNPD.

Objectives of the Innovation Generated

The aim of collaboration is to respond with differentiation to market needs (Tether 2002; Van de Vrande et al. 2009; Inauen and Schenker-Wicki 2012; Lager 2016). In this context, CNPD involving SMEs generates disruptive outcomes (Parida et al. 2012), although Brockhoff (2003), Bonner and Walker (2004), Faems et al. (2005) and Roy and Sivakumar (2010) conclude that collaboration between companies and clients creates new products based on incremental innovation when the collaboration occurs with SMEs. These approaches reveal that downstream collaboration is affected by the technological intensity of the industries in which firms operate and by the innovation created in CNPD.

Typology of Firms Involved

In upstream interaction, clients normally involve large industrial firms in CNPD, due to their technological specialization and production capacity (Tether 2002; Lichtenthaler 2008). In turn, large firms promote more active collaboration downstream, because they have technology and experience, resulting from the frequent interaction with clients (Lagrosen 2005; Lee et al. 2010; Moghaddam and Tarokh 2012). In addition, large firms operating in high-tech industries are more likely to be involved by industrial clients because they introduce greater specialization in their activity (Tether 2002). Therefore, downstream CNPD is mostly undertaken between large firms operating in high-tech industries (Lichtenthaler 2008). On the contrary, other studies conclude that SMEs are also involved with clients in CNPD because their technical know-how and market knowledge upstream stimulate innovation (Verhees and Meulenberg 2004; Van de Vrande et al. 2009; Lee et al. 2010; Nieto and Santamaria 2010; Silva and Moreira 2017). Consequently, firm size is not necessarily a limitation for collaboration with clients (Johnsen and Ford 2006; Van de Vrande et al. 2009; Lee et al. 2010), when CNPD does not require a large production scale.

3 Methodology

The particularities of CNPD allow the exploration of several research areas, due to its diversity of analysis. This fact leads to a comparative study of the collaboration carried out by firms in upstream and downstream activities, by SMEs and large firms, to identify the asymmetries found in interaction with suppliers and customers and the circumstances in which they occur.

This research is an exploratory study, based on qualitative research to describe the situation studied, from an inductive perspective (Yin 2003; Baxter and Jack 2008; Heath and Tynan 2010). The methodology used here is similar to that used in other studies on similar subjects (Lagrosen 2005; Emden et al. 2006; Eslami and Lakemond 2016; Silva and Moreira 2017).

The field research was carried out in three stages. The first relates to collecting data from industrial firms undertaking CNPD. The next stage corresponds to the analysis, treatment and description of the information gathered. The third involves joining the information in cases, according to a set of variables analyzed during the literature review. The case study is used to describe the situation observed, in accordance with the methodology of this research (Miles and Huberman 1994; Yin 2003; Baxter and Jack 2008) and with the study’s objective. Cases are analyzed individually to describe the situation of each firm. Then the cases are compared to determine the differences in the study variables portraying each firm (Yin 2003; Baxter and Jack 2008). The information about the cases is subsequently summarized in tables to analyze the results, provide the “big picture” of the situation studied and answer the research questions (Miles and Huberman 1994; Yin 2003).

Based on the characterization of CNPD carried out by firms, this research used purposive sampling whose elements were chosen from a number of previously selected industrial firms to ensure maximum information about the topics of analysis in the study (Malhotra 2007; Black 2010). Purposive sampling was constructed based on the information gathered about firms’ innovation activities. The sample is composed of four SMEs and four large industrial companies that carry out CNPD with suppliers and clients, the European Commission (2002) criterion having been used to classify firms according to number of employees. This classification lets us describe and compare the situation of SMEs and large firms. Table 1 presents the firms selected for this study, which will be designated as focal firms.

The diagnosis of firms’ situation was made through holding semi-structured interviews with the leaders of the focal firms, according to their structure and lines of command, as shown in Table 1. Interviews allow us to determine how focal firms undertake CNPD regarding the objectives of resorting to external technology upstream, the innovation created and the typology of firms involved in CNPD both upstream and downstream. The semi-structured interviews were carried out using a script, aiming to guide the central themes of the study (Malhotra 2007). They lasted between a minimum of 1 h 5 min and a maximum of 2 h 15 min. They were recorded and then transcribed to paper to be treated individually as case studies. Subsequently, the cases are compared (Yin 2003; Baxter and Jack 2008), in order to distinguish the difference in CNPD carried out by the focal firms upstream and downstream according to firm size. The confidentiality of the information gathered was assured by the identity of the firms interviewed remaining anonymous (being designated as C1–C8). The interviews took place on the firms’ premises, allowing the situation and innovative practices implemented to be checked. Additional information about the firms’ activity was also supplied, such as catalogues of their product portfolio, company profile, information on the technology used, markets, sources of supply, and manufacturing bases and process, among others. During the interviews, themes related to the innovative projects developed by the focal firms in the last 2 years were dealt with, to understand the innovation created in CNPD with their suppliers and clients. Additional contacts were also made with the focal firms by e-mail and telephone to complement and confirm the information collected.

The unit of analysis is the dyadic relationship in focal firms’ CNPD with suppliers and customers.

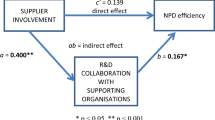

A framework was drawn up to analyze the collaboration carried out between firms and their suppliers and clients in CNPD, as shown in Fig. 1.

The results of the cases studied regarding firms’ objectives when resorting to external technology upstream are presented in Table 2. The results shown in Tables 3 and 4 describe the CNPD undertaken with upstream and downstream partners, according to firm size and the innovation generated.

4 Discussion

4.1 Collaboration Between Suppliers and Firms in CNPD

Firms’ Objective in Resorting to External Technology

The diversification of firms’ activity is the main reason for collaborating with suppliers, as shown by cases C3 and C8 in relation to large firms, and cases C4 and C7 in the case of SMEs. In addition, SMEs’ need to increase the efficiency of their activity promotes involvement with suppliers, as shown by cases C1 and C5. In the case of large firms operating in high-tech industries, it is differentiation that stimulates collaboration with suppliers in NPD, as revealed by case C2. The cases studied show that more radical product innovation is created in the CNPD undertaken upstream by large firms.

Frequent Versus Occasional Collaboration Upstream

In most cases, regular suppliers collaborate frequently in the CNPD carried out by firms. However, case C5 shows that SMEs could involve regular suppliers in CNPD. These results complement other studies (Hartley et al. 1997; Wasti and Liker 1999; Peng et al. 2014), showing that CNPD may result from the occasional involvement of suppliers. This difference in suppliers’ frequent/occasional collaboration in NPD is due to the different technological evolution of the industries and the slower pace of CNPD. Another perspective reveals that large firms frequently collaborate with regular suppliers, as shown by cases C2, C3, C6 and C8, and also occasionally with new suppliers to develop differentiated products or implement diversification, as shown by cases C6 and C8. These results complement prior research (Phillips et al. 2006; Bueno and Balestrin 2012; Raluca 2013) as beyond differentiated products there are cases of collaboration with suppliers to diversify product portfolio. In particular, cases C3 and C6 also show that frequent collaboration occurs between focal firms and small and medium-sized suppliers.

Focus of CNPD Upstream

Collaboration between suppliers and firms in CNPD creates new products (as cases C3, C5 and C6 exemplify) and also new processes (C2, C2, C6 and C8). In this respect, the cases studied reveal that the upstream CNPD undertaken by both SMEs and large firms is not limited to the physical development of products. These results complement several studies (Clark and Fujimoto 1991; Tether 2002; Lager 2016) showing that upstream collaboration is not affected by firm size. In particular, cases C1, C4, C5 and C7 show that SMEs have competences to intervene in CNPD upstream, and complement some studies about SMEs’ tendency to engage in CNPD downstream (Theyel 2012; Hossain 2015).

Then again, large firms’ need to conceive new product concepts and management methodologies in the form of new business models, as exemplified by case C6, favors upstream collaboration with consultants and universities, as referred in prior studies (Faems et al. 2005; Laursen and Salter 2006; Un and Azakawa 2015). This collaboration results from large firms’ need for specialization in the conception of differentiated products, as referred by Tether (2002). Therefore, the differentiation of activity in large firms favors collaboration with service suppliers to develop new manufacturing processes and management methodologies that go towards conceiving radical new products, as exemplified by cases C2 and C6. On the other hand, the less radical nature of manufacturing processes created in CNPD results from the diversification of the activity of SMEs operating in low-tech industries, of which cases C4 and C7 are examples. However, case C1 shows that SMEs also develop new production processes in collaboration with suppliers to increase the efficiency of their activity. Therefore, comparing cases C1 and C2 with the other cases shows that development of new manufacturing processes is due to the radical nature of CNPD and the high-tech industries of activity in which firms operate. These results differ from previous research (Clark and Fujimoto 1991; Laursen and Salter 2006; Un and Azakawa 2015) and show that firm size does not condition CNPD.

Typology of Suppliers Involved

The involvement of SMEs and large firms in upstream activities is quite widespread. From this point of view, firms’ need of specialization promotes upstream collaboration with medium-sized service suppliers. This interaction generated upstream is due to large firms’ differentiation activity (case C6), increased efficiency of SME activity (cases C1 and C5) and also the high-tech industries in which companies operate (cases C1 and C6). In this context, case C6 differs from the others concerning the type of supplier and the specialization required at the initial stage of CNPD. In this respect, C6 involves consultants and research centers in CNPD to idealize differentiated products and develop the business model adapted to its target. These facts show that, in general, CNPD between industrial companies and their suppliers is not affected by their size, but rather by their specialization, as referred in other studies (Laursen and Salter 2006; Lee et al. 2010). These results complement prior research (Chesbrough and Crowther 2006; Bianchi et al. 2011; Ferrary 2011; Gay 2014) about the influence of firm size in upstream CNPD. Nevertheless, some large firms collaborate with suppliers of a similar size because of the type of industry they operate and their manufacturing process requires a high scale of production, and only large firms have such processes, as referred in prior studies that analyzed large firms (Chesbrough 2003; Christensen et al. 2005; Wynstra et al. 2010), and quoted from cases C2 and C8: “we involve large firms because they are more able to respond with the specialization and capacity for our demands” (case C2), “the suppliers operating in this industry and involved in the CNPD are large firms operating in high-tech industries” (case C8). So the difference between cases C2 and C8 and the others shows that supplier size affects their collaboration when a high specialization and scale of production is required by the CNPD.

4.2 Collaboration Between Firms and Clients in CNPD

Frequent Versus Occasional Collaboration Downstream

Frequent downstream collaboration in CNPD occurs between industrial companies, as shown by cases C1, C2, C3, C4 and C6. In this respect, cases C1 and C4 show that SMEs also collaborate with industrial customers because of their capacity to develop disruptive products, as previous studies has mentioned (Tether 2002; Knudsen 2007). Thus, these results complement the studies of Brockhoff (2003), Bonner and Walker (2004), Faems et al. (2005) and Roy and Sivakumar (2010) about the innovation generated downstream in the CNPD involving SMEs. On the other hand, cases C5, C7 and C8 show that occasional downstream collaboration in NPD occurs between industrial and commercial companies. Comparison between cases shows that frequent downstream collaboration results from more active involvement between industrial firms, as opposed to involvement between industrial and commercial firms, and that firm size does not affect CNPD interaction.

Focus of Downstream CNPD

In collaboration between large firms (cases C2, C3, C6 and C8) firms’ need for specialization downstream is limited to the physical development of products. However, some SMEs also collaborate with clients to develop new processes, case C1 being an example. In this case, collaboration arises from the fact that the firms operate in high-tech industries, as referred by Parida et al. (2012), and use similar technology, and not due to their size. Furthermore, SME specialization favors collaboration with medium-sized clients operating in the same industry to develop new processes, as in case C4, as mentioned in prior research (Brockhoff 2003; Bonner and Walker 2004; Faems et al. 2005; Roy and Sivakumar 2010). Comparing cases C1 and C4 with the others shows, in the first place, that collaborative development of new processes downstream is carried out between firms and clients operating in the same industry and that firm size does not affect that collaboration, and secondly, that SMEs also have competences to develop products and processes in collaboration with clients, complementing previous studies (Lagrosen 2005; Un and Azakawa 2015; Eslami and Lakemond 2016).

Objective of Downstream CNPD

Collaboration with clients is not affected by size or by the industry type, as shown by cases C1, C4 and C5. These results confirm previous studies (Tether 2002; Lee et al. 2010; Parida et al. 2012) and complement the literature (Bjerke and Johansson 2015; Eslami and Lakemond 2016) about how SMEs intervene in downstream CNPD. Moreover, the collaborative atmosphere generated between SMEs and clients operating in the industry favors the development of manufacturing processes, as shown by cases C1 and C4. Here, the more radical nature of manufacturing processes conceived by focal firms C1 and C4 is due to the collaborative development of new products with large clients operating in the same industry, as in the quote from C1: “because the complexity of the new products idealized by our clients in the electronics industry requires the development of new programming with specific functions”. From another perspective, the development of improved manufacturing processes between SMEs and medium-sized clients operating in the same industry is due to the less radical nature of the products developed, as is quoted from case C4: “we improved that product’s finishing process to reposition it”. Finally, the cases show that firms involved in downstream CNPD do not develop any management methodology, because their objective concerns the physical conception of products.

5 Conclusions

This study concluded that CNPD between industrial firms and suppliers is more frequent and active than that with clients, giving rise to asymmetry in upstream and downstream collaboration, and that fact is due to the innovation created in CNPD and those taking part in it. This phenomenon has various implications for theory. Firstly, it shows that asymmetry is the result of greater upstream collaboration between industrial companies, and between these and service suppliers, compared to downstream collaboration. From another perspective, it reveals that collaboration between SMEs and suppliers is more active than that with clients. Consequently, more active collaboration in upstream CNPD is due above all to the frequent interaction between industrial companies and between these and service suppliers to develop new products, manufacturing processes and management methodologies, when compared to the less active downstream collaboration between industrial companies and the occasional collaboration between these and commercial firms for physical development of products. These facts complement the literature on CNPD by showing that more active collaboration between firms upstream in the supply chain is the result of extending the range of suppliers involved in CNPD to service firms, due to the need for specialization at the early stages of CNPD.

Generally speaking, industrial companies involve suppliers of different types in CNPD, mainly when they aim to diversify their product portfolio. However, in certain cases, differentiation is generated by collaboration between large firms operating in the same high-tech industry, to create new products, as exemplified by case C2. These facts corroborate the view of large industrial firms’ tendency to collaborate, motivated by great specialization, available technology and high production capacity, and show that the more radical nature of CNPD stimulates collaboration between suppliers and large clients operating in the same industry. In addition, this study shows that differentiation in the activity of large industrial firms also promotes upstream collaboration with SMEs. This argument contradicts the perspective of collaboration restricted to large firms, allowing the conclusion that SMEs collaborate with large firms, when the latter turn to specialization in other industries and a high scale of production is not required. Another view infers that SMEs involve suppliers of varying sizes in CNPD when they aim to increase the efficiency of their activity. So the various interactions generated between industrial companies and suppliers in CNPD let us conclude that firs size does not limit their intervention in CNPD when the aim is to diversify their product portfolio or increase the efficiency of their activity, while sustained differentiation in great specialization and production capacity is generated between large firms.

Collaboration between firms and suppliers to develop new processes is more active than that carried out with clients. This phenomenon is due to the limited collaboration between industrial firms and clients to develop new manufacturing processes, which is non-existent in developing new management methodologies, and allows the conclusion that downstream collaboration is focused mostly on the physical development of new products. So the asymmetry found in upstream and downstream collaboration in NPD is due to more active collaboration between large firms and suppliers to develop new manufacturing processes and management methodologies. Nevertheless, the results show that SMEs take part in CNPD, but more actively in upstream activities to develop new manufacturing processes.

The asymmetry found in collaboration between companies according to their industry is due to the innovation generated in CNPD. In general, differentiation is created through collaboration between firms operating in the same industry, whereas CNPD carried out between firms operating in different industries creates diversified products or promotes increased efficiency in firms’ activity. However, the interaction between firms is not formed linearly, because collaboration between firms and service suppliers to develop new processes is more active upstream than downstream. The situation studied revealed that downstream collaboration between industrial firms and service suppliers is more limited, because in most cases it is restricted to physical development of products. On the other hand, industrial firms collaborate more actively with service suppliers in upstream CNPD. In this context, upstream collaboration between large firms and research centers is due to the more radical nature of the CNPD. This goes against the view of some authors regarding service suppliers’ collaboration only in post-production activities and shows the importance of their collaboration in the early stages of the NPD undertaken by industrial companies.

From another perspective, this study concludes that CNPD is carried out between large firms operating in high-tech industries and generating large production scales (as in case C2). However, this study also reveals that SMEs operating in high-tech industries (exemplified in case C1) involve other large firms in CNPD. These facts show, in the first place, that upstream and downstream CNPD is influenced by the technological intensity of firms’ operating industries, and secondly, that firm size affects their intervention in CNPD only when a high scale of production is required.

Then again, the asymmetry of upstream and downstream collaboration between firms is due to the diversity of specialization required by CNPD, particularly service suppliers’ upstream collaboration to create manufacturing processes and management methodology adapted to new product concepts. In turn, the differentiation in large firms’ activity and the specialization of the industry in which they operate promotes collaboration between specialist firms (case C2 being an example). Therefore, greater symmetry in upstream and downstream collaboration between firms occurs when those taking part in the CNPD are specialist firms operating with similar technology in the same industry.

The framework developed in this study explains the possible interactions between firms and their suppliers and clients, according to their size and the innovation created. Generally speaking, the CNPD undertaken by industrial companies aims to diversify their activity or increase their efficiency. However, large industrial firms operating in specific niche markets undertake CNPD to differentiate their portfolio. In this context, firm size affects their intervention in CNPD, when differentiation requires great specialization and large-scale production. These facts have implications for defining firms’ innovation strategy and the strategic options adapted to their business environment. In this context, firms’ strategy should consider their competences and the objectives of innovation to occupy a favorable position in CNPD. Study of the collaboration between firms and their suppliers and clients reveals that collaborative development of manufacturing processes and management methodologies are little explored areas of business, particularly in downstream activities of the supply chain. The framework developed explains the interactions firms can establish in CNPD to expand their activity.

References

Baxter P, Jack S (2008) Qualitative case study methodology: study design and implementation for novice researchers. Qual Rep 13(4):544–559

Bianchi M, Cavaliere A, Chiaroni D, Frattini F, Chiesa V (2011) Organizational modes for open innovation in bio-pharmaceutical industry: an exploratory analysis. Technovation 31(1):22–33

Bjerke L, Johansson S (2015) Patterns of innovation and collaboration in small and large firms. Ann Reg Sci 55(1):221–247

Black K (2010) Business statistics: contemporary decision making. Wiley, Chichester

Boehe DM (2007) Os papéis de subsidiárias brasileiras na estratégia de inovação de empresa multinacionais estrangeiras. RAUSP Rev Admin 42(1):5–18

Bonner JM, Walker OC (2004) Selecting influential business-to-business customers in new product development: relational embeddedness and knowledge heterogeneity considerations. J Prod Innov Manag 21(3):155–169

Brettel M, Cleven NJ (2011) Innovation culture, collaboration with external partners and NPD performance. Creat Innov Manag 20(4):253–272

Brockhoff K (2003) Customers’ perspectives of involvement in new product development. Int J Technol Manage 26(5–6):464–481

Bruneel J, D’Este P, Salter A (2010) Investigating the facts that diminish the barriers to university-industry collaboration. Res Policy 39(7):858–868

Brunswicker S, Vanhaverbeke W (2014) Open innovation in small and medium-sized enterprises (SMEs): external knowledge sourcing strategies and internal organizational facilitators. J Small Bus Manag 53(4):1241–1263

Bueno B, Balestrin A (2012) Inovação colaborativa: uma abordagem aberta no DNP. ERA Rev Admin Empres 52(5):517–530

Büyüközkan G, Arsenyan J (2012) Collaborative product development: a literature overview. Prod Plan Control 23(1):47–66

Chesbrough H (2003) The era of open innovation. Sloan Manage Rev 44(3):35–41

Chesbrough H, Crowther AK (2006) Beyond high-tech: early adopters of open innovation in other industries. R&D Manag 36(3):229–236

Christensen JF, Olesen MH, Kjaer JS (2005) The industrial dynamics of open innovation: evidence from the transformation of consumer electronics. Res Policy 34(10):1533–1549

Clark KB, Fujimoto T (1991) Product development strategy, organization, and management in the world auto industry. Harvard Business School Press, Boston

Cohen WM, Levinthal DA (1990) Absorptive capacity: a new perspective on learning and innovation. Adm Sci Q 35(1):128–152

Croom SR (2001) The dyadic capabilities concept: examining the process of key supplier involvement in collaborative product development. Eur J Purch Supply Manag 7(1):29–37

Diedericks E, Hoonhout H (2007) Radical innovation and end-user involvement: the ambilight case. Knowl Technol Policy 20(1):31–38

Emden Z, Calantone RJ, Droge C (2006) Collaborating for new product development: selecting the partner with the maximum potential to create value. J Prod Innov Manag 23(4):330–341

Eslami MH, Lakemond N (2016) Knowledge integration with customers in collaborative product development projects. J Bus Ind Mark 31(7):889–900

European Commission (2002) Observatory of European SMEs: European Committee

Faems D, Van Looy B, Debackere K (2005) Interorganizational collaboration and innovation: toward a portfolio approach. J Prod Innov Manag 22(3):238–250

Ferrary M (2011) Specialized organizations and ambidextrous clusters in the open innovation paradigm. Eur Manag J 29(3):181–192

Fontana R, Geuna A, Matt M (2006) Factors affecting university-industry R&D projects: the importance of searching and signalling. Res Policy 35(2):309–323

Freel MS (2003) Sectoral patterns of small firm innovation, networking and proximity. Res Policy 32(5):751–770

Fritsch M, Lukas R (2001) Who cooperates in R&D? Res Policy 30(2):297–312

Garcia R, Calantone R (2002) A critical look at technology innovation typology and innovativeness terminology: a literature review. J Prod Innov Manag 19(2):110–132

Gassmann O (2006) Opening up the innovation process: towards an agenda. R&D Manag 36(3):223–228

Gay B (2014) Open innovation, networking, and business model dynamics: the two sides. J Innov Entrep 3:2. https://doi.org/10.1186/2192-5372-3-2

Gomes-Casseres B (1997) Alliance strategies of small firms. Small Bus Econ 9(1):33–44

Hartley JL, Zinger BJ, Kamath RR (1997) Managing the buyer-supplier interface for on-time performance in product development. J Oper Manag 15(1):57–70

Heath T, Tynan C (2010) Crafting a research proposal. Mark Rev 10(2):147–168

Hoegl M, Wagner SM (2005) Buyer-supplier collaboration in product development projects. J Manag 31(4):530–548

Hossain M (2015) A review of literature on open innovation in small and medium-size enterprises. J Glob Entrep Res 5(6). https://doi.org/10.1186/s40497-015-0022-y

Hossain M, Karaunen I (2016) Open innovation in SMEs: a systematic literature review. J Strateg Manag 9(1):58–73

Inauen M, Schenker-Wicki A (2012) Fostering radical innovations with open innovation. Eur J Innov Manag 15(2):212–231

Johnsen RE, Ford D (2006) Interaction capability development of small suppliers in relationships with larger customers. Ind Mark Manag 35(8):1002–1015

Knudsen (2007) The relative importance of interfirm relationships and knowledge transfer for new product development success. J Prod Innov Manag 24(2):117–138

Koberg CS, Detienne DR, Heppard KA (2003) An empirical test of environmental, organizational and process factors affecting radical innovation. J High Technol Manag Res 14(1):21–45

Lager T (2016) Managing innovation and technology in the process industries: current practices and future perspectives. Proc Eng 138:459–471

Lager T, Frishammar J (2012) Collaborative development of new process technology/equipment in the process industries: in search of enhanced innovation performance. J Bus Chem 9(2):67–84

Lagrosen S (2005) Customer involvement in new product development: a relationship marketing perspective. Eur J Innov Manag 8(4):424–436

Laursen K, Salter A (2006) Open for innovation: the role of openness in explaining innovation performance among U.K. manufacturing firms. Strateg Manag J 27(2):131–150

Lecocq X, Demil B (2006) Strategizing industry structure: the case of open systems in a low-tech industry. Strateg Manag J 27(9):891–899

Lee S, Park G, Yoon B, Park J (2010) Open innovation in SMEs: an intermediated network model. Res Policy 39(2):290–300

Lichtenthaler U (2008) Open innovation in practice: an analysis of strategic approaches to technology transactions. IEEE Trans Eng Manag 55(1):148–157

Madrid-Guijarro A, Garcia D, Van Auken H (2009) Barriers to innovation among Spanish manufacturing SMEs. J Small Bus Manag 47(4):465–488

Malhotra N (2007) Marketing research – an applied orientation. Person Prentice Hall, New Jersey

Miles MB, Huberman AM (1994) Qualitative data analysis: an expanded source book. Sage, Thousand Oaks, CA

Moghaddam P, Tarokh MJ (2012) Customer involvement in innovation process based on open innovation concepts. Int J Res Ind Eng 1(2):1–9

Moreira AC, Karachun HL (2014) Uma revisão interpretativa sobre o desenvolvimento de novos produtos. Cuad Admin 27(49):155–182

Nieto MJ, Santamaria L (2007) The importance of diverse collaborative networks for the novelty of product innovation. Technovation 27(6–7):367–377

Nieto MJ, Santamaria L (2010) Technological collaboration: bridging the innovation gap between small and large firms. J Small Bus Manag 48(1):44–69

Parida V, Westerberg M, Frishammar J (2012) Inbound open innovation activities in high-tech SMES: the impact on innovation performance. J Small Bus Manag 50(2):283–309

Peng DX, Heim GR, Mallick DN (2014) Collaborative product development: project complexity on the use of information technology tools and new product development practices. Prod Oper Manag 23(8):1421–1438

Phillips W, Lamming R, Bessant J, Noke H (2006) Discontinuous innovation and supply relationships: strategic alliances. R&D Manag 36(4):451–461

Powell WW, Koput KW, Smith-Doerr L (1996) Interorganizational collaboration and the locus of innovation: networks of learning in biotechnology. Adm Sci Q 41(1):116–145

Raluca B (2013) Trust, partner selection and innovation outcome in collaborative new product development. Prod Plan Control 24(2–3):145–157

Roy S, Sivakumar K (2010) Innovation generation in upstream and downstream business relationships. J Bus Res 63(12):1356–1363

Schiele H (2010) How to distinguish innovative suppliers? Identifying innovative suppliers as new task for purchasing. Ind Mark Manag 35(8):925–935

Silva LF, Moreira AC (2017) Collaborative new product development and the supplier/client relationship: cases form the furniture industry. In: Garcia Alcaraz JL, Alor-Hernández G, Maldonado Macias AA, Sanchez-Ramírez C (eds) New perspectives on applied industrial tools and techniques. Springer International Publishing, Heidelberg, pp 175–195

Soosay CA, Hyland PW, Ferrer M (2008) Supply chain collaboration: capabilities for continuous innovation. Supply Chain Manag 13(2):160–169

Spithoven A, Vanhaverbeke W, Royjakkers N (2013) Open innovation practices in SMES and large enterprises. Small Bus Econ 41(3):537–562

Stephanie CS, Shulman AD (2011) A comparison of new services versus new product development: configurations of collaborative intensity as predictors of performance. J Prod Innov Manag 28(4):521–535

Takeishi A (2001) Bridging inter-and intra-firm boundaries: management of supplier involvement in automobile product development. Strateg Manag J 22(5):403–433

Tether BS (2002) Who Co-operates for innovation, and why. An empirical analysis. Res Policy 31(6):847–967

Tether BS, Tajar A (2008) Beyond industry-university links: sourcing knowledge for innovation from consultants, private research organizations and public science-base. Res Policy 37(6/7):1079–1095

Theyel N (2012) Extending open innovation throughout the value chain by small and medium-sized manufacturers. Int Small Bus J 31(3):256–274

Tidd J, Bessant J, Pavitt K (2001) Managing innovation: integrating technological, market and organizational change. Wiley, Chichester

Tuli P, Shankar R (2015) Collaborative and lean new product development approach: a case study in the automotive product design. Int J Prod Res 53(8):2457–2471

Un CA, Azakawa K (2015) Types of R&D collaborations and process innovation: the benefit of collaborating upstream in the knowledge chain. J Prod Innov Manag 32(1):138–153

Un CA, Cuervo-Cazurra A, Azakawa K (2010) R&D collaborations and product innovation. J Prod Innov Manag 27(5):673–689

Van de Vrande V, de Jong JPJ, Vanhaverbeke W, de Rochement M (2009) Open innovation in smes: trends, motives and management challenges. Technovation 29(6/7):423–437

Verhees F, Meulenberg M (2004) Market orientation, innovativeness, product innovation, and performance in small firms. J Small Bus Manag 42(2):134–154

Wagner SM, Hoegl M (2006) Involving suppliers in product development: insights from R&D directors and project managers. Ind Mark Manag 35(8):936–943

Wasti NS, Liker JK (1999) Collaborating with suppliers in product development: a U.S. and Japan comparative study. IEEE Trans Eng Manag 46(4):444–461

Wynarczyk P, Piperopoulos P, McAdam M (2013) Open innovation in small and medium-size enterprises. An overview. Int Small Bus J 31(3):240–255

Wynstra F, von Corswant F, Wetzels M (2010) In Chains? An empirical study of antecedents of supplier product development activity in the automotive industry. J Prod Innov Manag 27(5):625–639

Yin RK (2003) Case study research: design and methods. Sage, Thousand Oaks, CA

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2018 Springer International Publishing AG, part of Springer Nature

About this chapter

Cite this chapter

Silva, F., Moreira, A.C. (2018). Collaborative New Product Development in SMEs and Large Industrial Firms: Relationships Upstream and Downstream in the Supply Chain. In: Moreira, A., Ferreira, L., Zimmermann, R. (eds) Innovation and Supply Chain Management. Contributions to Management Science. Springer, Cham. https://doi.org/10.1007/978-3-319-74304-2_5

Download citation

DOI: https://doi.org/10.1007/978-3-319-74304-2_5

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-74303-5

Online ISBN: 978-3-319-74304-2

eBook Packages: Business and ManagementBusiness and Management (R0)