Abstract

We modified a soft X-ray laser (SXRL) interferometer synchronized with a Ti:sapphire laser to observe a single-shot image of the nanoscale structure dynamics of materials induced by an optical laser pulse. The lateral resolution on the sample surface was improved to 0.7 μm using precise imaging optics. Using this system, we succeeded in observing thin film structures above the solid (or liquid) surface in the femtosecond laser ablation process of metals (Au). The thin film worked as soft X-ray beam splitter. This result shows a thin film was smooth and dense (with a roughness of a few nanometers and near sold density). Furthermore, it gave rise to the possibility of generating novel transient soft X-ray optics .

Access provided by CONRICYT-eBooks. Download conference paper PDF

Similar content being viewed by others

1 Introduction

The dynamical processes of the formation of unique structures, such as submicron scale ripple and bubble structures [1], by the irradiation of ultrashort pulse lasers have attracted much attention in the area of novel laser processing. In order to understand the femtosecond laser ablation process , direct observation of the surface dynamics is required. In previous works, we developed a soft X-ray laser (SXRL) interferometer synchronized with a Ti:sapphire laser pulse [2, 3]. The Ni-like silver SXRL at a wavelength of 13.9 nm [4] is suitable for probing the initial process of surface morphological changes, because it has a small attenuation length (<10 nm), short duration (<10 ps), large photon number (>1010 photons/shot), and can penetrate the surface plasma; the critical electron density is 1024 cm−3. The in-depth and lateral spatial resolutions on the sample surface were 1 nm and 2 μm, respectively. It was useful for the observation of the ablation process when the pump laser fluence was higher than the ablation threshold. However, it was insufficient to observe the dynamics of small structures around the ablation threshold such as the spallative ablation process predicted by molecular dynamics simulations [5].

In this study, we improved the lateral resolution of the system to 0.7 μm using precise imaging optics. Using this system, we succeeded in observing unique structures in the initial stage of the ablation process of Au pumped by an 80 fs Ti:sapphire laser pulse.

2 Improvement of the Optical Pump and Soft X-Ray Probe System

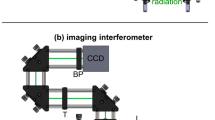

A schematic of the single-shot optical pump and SXRL probe system is shown in Fig. 40.1. This system consists of four parts: a Ni-like silver SXRL (13.9 nm, 7 ps), pump laser (795 nm, 80 fs), double time fiducial system, and soft X-ray imaging system with an interferometer. The timing accuracy between the SXRL and pump laser was 2 ps. The image of the illuminated area on the sample is transferred to the CCD surface by an imaging mirror. A double Lloyd’s mirror divides the soft X-ray into objective and reference light and generates an interference pattern on the CCD surface. A fringe shift of one period corresponds to a 20 nm depth. Moreover, the depth resolution was 1 nm in the current experiment. This system can be switched between interferometry and reflective imaging easily by modifying the relative incline angle of the double Lloyd’s mirror.

In this study, the lateral resolution was improved using a high precision imaging mirror with a short focal length (f = 125 mm). It was evaluated using grooves fabricated on a Pt film using a focused ion beam (FIB). Figure 40.2a is the image of the test pattern observed by a scanning electron microscope (SEM). The rectangular dark areas show the grooves. Each groove has a width of 0.5–8 μm and a depth of 6 nm. The intervals of groove pairs from one edge to the other edge of the groove were the same as the width of the groove. The single-shot soft X-ray image and cross section at the area enclosed by the dotted line are shown in Fig. 40.2b and c, respectively. The longitudinal scale was 0.35 μm/CCD pixel. A pair of grooves 1 μm wide was clearly observed and that with a 0.5 μm width was not clearly observed. Furthermore, the soft X-ray intensity decreased to 2 pixels at the edge of most of the grooves. Therefore, the lateral resolution was evaluated to be 0.7 μm. The lateral resolution was within the area of 400 μm × 400 μm, and was sufficient to measure the ablation process of the 100-μm spot size.

3 Observation of the Transient Thin Film Structure in the Femtosecond Laser Ablation Process

We observed the ablation dynamics of Au (100 nm thick), which was irradiated by a pump beam with a peak fluence of about 1.1 J/cm2. Figure 40.3a and b shows the temporal evolution of the interferogram of the ablated surface (= AF: ablation front). In Fig. 40.3a, 95 ps after the pump laser irradiation, the interference fringes were continuously smoothly. The height of the AF at the center was 20 nm. In Fig. 40.3b, at 389 ps, in addition to the interference fringes of the AF (height of ~40 nm), multiple concentric rings and thin interference fringes were observed around the dashed and solid arrows, respectively. Thin interference fringes imply the formation of another expanding structure above the AF. This is a thin film structure called an expansion front (EF). The height of the EF was over 100 nm. Figure 40.3c shows a schematic of (b). Because of the interference between the reflected SXRL from the AF and EF, multiple concentric rings (Newton’s rings) can be generated. The observation of Newton’s rings in the femtosecond laser ablation process has been reported using the visible probe beam [6]. The Newton’s rings in the soft X-ray region imply that the EF was dense (near solid density), thin (<10 nm), and smooth (a roughness of a few nanometers) so as to function as a soft X-ray beam splitter, because the reflectivity of soft X-rays is quite sensitive to surface conditions. Detailed analyses of these results are underway.

4 Summary

We modified the soft X-ray laser (SXRL) interferometer to observe the dynamics details of laser-induced materials. The lateral resolution on the sample surface was improved to 0.7 μm. Using this system, we succeeded in directly observing the expansion front (thin film structure) above the ablation front in the femtosecond laser ablation process of Au. The result indicated that the expansion front was dense (near solid density), thin (<10 nm), and smooth (with a roughness of a few nanometers). Further, it enables the possibility of developing novel transient soft X-ray optics .

References

Tomita, T., et al.: Effect of surface roughening on femtosecond laser-induced ripple structures. Appl. Phys. Lett. 90, 153115-1–153115-3 (2007)

Suemoto, T., et al.: Single-shot picosecond interferometry with one-nanometer resolution for dynamical surface morphology using a soft X-ray laser. Opt. Express 18, 14114–14122 (2010)

Hasegawa, N., et al.: Observation of the laser-induced surface dynamics by the single-shot X-ray laser interferometer. Proc. SPIE 8140, 81400G-1–81400G-18 (2011)

Nishikino, M., et al.: Characterization of a high-brilliance soft X-ray laser at 13.9 nm by use of an oscillator-amplifier configuration. Appl. Opt. 47(8), 1129–1134 (2008)

Perez D., Lewis L.J.: Molecular-dynamics study of ablation of solids under femtosecond laser pulses. Phys. Rev. B 67, 184102-1–184102-15 (2003)

Temnov, V., et al.: Femtosecond time-resolved interferometric microscopy. Appl. Phys. A 78, 483–489 (2004)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2018 Springer International Publishing AG

About this paper

Cite this paper

Hasegawa, N. et al. (2018). The Observation of Transient Thin Film Structures During the Femto-Second Laser Ablation Process by Using the Soft X-Ray Laser Probe. In: Kawachi, T., Bulanov, S., Daido, H., Kato, Y. (eds) X-Ray Lasers 2016. ICXRL 2016. Springer Proceedings in Physics, vol 202. Springer, Cham. https://doi.org/10.1007/978-3-319-73025-7_40

Download citation

DOI: https://doi.org/10.1007/978-3-319-73025-7_40

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-73024-0

Online ISBN: 978-3-319-73025-7

eBook Packages: Physics and AstronomyPhysics and Astronomy (R0)