Abstract

Fossil fuels use reduction and waste recycling are two great challenges facing our society nowadays. A concept intended to solve both problems is Waste-to-Energy (WtE) approach (Brunner and Rechberger in Waste Manag 37: 3–12, 2015). The routes to the energy recovery can be grouped as thermo-chemical and biochemical approaches and the selection of the WtE technologies also depends on the waste composition. Waste sources can be industrial and agricultural production and urban regions but growing attention is paid to municipal solid waste in OECD countries (Hoornweg and Bhada-Tata in What a waste: a global review of solid waste management. World Bank, Washington, DC 2012) consisting dominantly of organic materials (27%), paper (32%), plastic 11%, glass, metal and other components. Most widespread technologies for MSW thermal conversion are: (1) MSW incineration; (2) co-combustion with other fuels; (3) gasification; (4) pyrolysis (Astrup et al. in Waste Manage 37: 104–115 2015).

Access provided by CONRICYT-eBooks. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

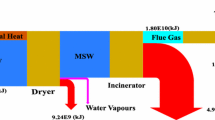

Fossil fuels use reduction and waste recycling are two great challenges facing our society nowadays. A concept intended to solve both problems is Waste-to-Energy (WtE) approach (Brunner and Rechberger 2015). The routes to the energy recovery can be grouped as thermo-chemical and biochemical approaches and the selection of the WtE technologies also depends on the waste composition. Waste sources can be industrial and agricultural production and urban regions but growing attention is paid to municipal solid waste in OECD countries (Hoornweg and Bhada-Tata 2012) consisting dominantly of organic materials (27%), paper (32%), plastic 11%, glass, metal and other components. Most widespread technologies for MSW thermal conversion are: (1) MSW incineration; (2) co-combustion with other fuels; (3) gasification; (4) pyrolysis (Astrup et al. 2015). Further, the selection of the most appropriate technology depends also on the wastes amounts and their logistics. MSW incineration is a relatively widely used robust approach, however requiring extensive purification of flue gases and creating a problem of the combustion waste utilisation. Incineration technologies cannot deliver cost effective small scale solutions needed for distributed waste management systems. As a prospective, the gasification approach can be considered, especially when pre-treated urban wastes are used (refuse derived fuels RDF) and local (decentralised) waste processing options are actual. Gasification of solid recovered fuels can make a difference if coupled with efficient gas cleaning and energy recovery. The efficiency of the system lies at the integrated feedstock preparation, gasification process and gas cleaning for a final product—carbonized solids, syngas and condensable liquids.

The aim of the study was to evaluate RDF gasification and development possibilities, and validate the gas cleaning system in conditions of feedstock variability of solid recovered fuel applicable for small-scale installations.

2 Materials and Methods

Refuse derived fuel samples were collected from Latvia and neighbouring countries: Lithuania and Estonia and were characterised by elemental composition (C, H, N, O, S, Cl), ash amount as well as heating value. The thermal decomposition process of RDF was studied using thermo-gravimetrical analysis. A laboratory scale set up was developed to test the RDF samples gasification characteristics and efficiencies. In gasification tests, the RDF samples were pyrolysed in an electrically heated quartz batch reactor. Composition of syngas was monitored and the process was studied at differing temperature regimes with RDF and with RDF + lime additions. Further, metals and trace elements in RDF and in the formed ashes were analysed using dissolution in Aqua regia with a following analysis by ICP-OES.

3 Results and Discussion

Refuse derived fuel samples from Latvia and other Baltic countries in general in respect to their elemental composition are similar to RDF samples from UK, Netherlands, Sweden and Germany, however a significant variability has been found if compared samples obtained from large cities and countryside at first in respect to presence of metals and proportion of plastics and wood residues. As some problems might be considered like wastes disinfection, some limitations to further processing might be created.

RDF samples calorific values on dry basis are close to thse of coal and are sufficient to use only the RDF samples in the pyrolysis process. The tudy of thermal decomposition using thermo-gravimetrical analysis helps to reveal thermal decomposition stages and support the selection of the thermal decomposition process regime.

As challenges for pyrolysis application of the RDF can be considered: (1) optimisation of the thermal decomposition process; (2) reduction of the organochlorine formation; (3) formation and removal of tars; (4) development of methods for utilisation of ashes formed during the pyrolysis process. To solve these problems, the following approaches were suggested: (1) lime admixtures; (2) the pyrolysis process optimisation (thermal regime, RDF loading rate); (3) syngas plasma post-treatment. The suggested approaches provided possibilities to obtain high-quality syngas with achieve good energy efficiency of the pyrolysis process. The above mentioned process is used to design the RDF gasification unit using fluidised bed for small—medium scale RDF processing.

Further, the bottom ash and fly ash composition were analysed and metal and chlorine concentrations were determined. Metal speciation analysis has been achieved, to study not only the total, but also the biologically available metal fractions. Ash utilisation possibilities were studied and potential use in building industry applications was demonstrated.

4 Conclusion

The results of this study have shown that calorific values of RDF samples are close to those of coal and are sufficient to use of sole RDF samples in the pyrolysis process. However: (1) lime admixtures; (2) pyrolysis process optimisation (thermal regime, RDF loading rate); (3) syngas plasma post-treatment can help to achieve high quality syngas and utilise the formed wastes (ash). Optimised gasification conditions are used to design fluidised bed RDF gasification unit for small—medium scale RDF processing.

References

Astrup FH, Tonini D, Turconi R, Boldrin A. Life cycle assessment of thermal waste-to-energy Technologies: review and recommendations. Waste Manag. 2015;37:104–15.

Brunner PH, Recherberger H. Waste to energy—a key for sustainable waste management. Waste Manag. 2015;37:3–12.

Hoornweg D, Bhada-Tata P. What a waste: a global review of solid waste management. Urban development series. Knowledge papers no. 15. Washington, DC: World Bank; 2012 http://documents.worldbank.org/curated/en/2012/03/16537275/waste-global-review-solid-waste-management.

Acknowledgements

This work has been supported by the European Regional Development Fund within the project No. 1.1.1.1/16/A/050 “Variable fuel gasification for municipal solid waste recovery”.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2018 Springer International Publishing AG

About this paper

Cite this paper

Klavins, M., Porsnov, D., Bisters, V., Kalviss, J., Damkevics, R. (2018). Refuse Derived Fuel Gasification Possibilities in Small Scale Units. In: Kallel, A., Ksibi, M., Ben Dhia, H., Khélifi, N. (eds) Recent Advances in Environmental Science from the Euro-Mediterranean and Surrounding Regions. EMCEI 2017. Advances in Science, Technology & Innovation. Springer, Cham. https://doi.org/10.1007/978-3-319-70548-4_274

Download citation

DOI: https://doi.org/10.1007/978-3-319-70548-4_274

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-70547-7

Online ISBN: 978-3-319-70548-4

eBook Packages: Earth and Environmental ScienceEarth and Environmental Science (R0)