Abstract

A novel silicon nanowire field effect transistor (SiNW-FET) was fabricated using complementary metal oxide semiconductor (CMOS) compatible technology. The shrank nanowire with high surface-to-volume ratio and individual back gate were achieved by the local-oxidation of silicon (LOCOS) process. The width of nanowire by this technique can be shrank down to sub 100 nm. The drain current versus gate voltage (Id-Vg) characteristic of the SiNW-FET exhibits about five orders of magnitude of Ion/Ioff current ratio, and the threshold voltage shifts positively after hybridization of 1fM concentrations of HBV X gene DNA fragments and 3 ng/mL concentrations of the cancer marker, respectively. The results show that the back-gated nanowire device has the capability of acting as a real-time, label-free, highly sensitivity and excellent selectivity SiNW-FET biosensor in detecting biomolecules.

Access provided by CONRICYT-eBooks. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Ultrasensitive detection of biological and chemical species is essential to the screening and detection of disease, discovery and screening of drugs, as well as gas detection and biomolecular analysis. There are various researches in detecting biomolecules by using optical, spectrometric, electrochemical, or SPR methods. However, those methods, unfortunately, have drawbacks of time-consuming, fail sensitive, less selective, and complex processes that are expensive and unsuitable for diseases monitoring [1].

One-dimensional nanostructures have been demonstrated as good candidates for ultrasensitive, miniaturized molecule sensors in the biosensing applications. Among the variety of systems explored, the sensors based upon semiconductor nanostructures, such as semiconductor single-wall carbon nanotubes [2,3,4], silicon nanowires [5,6,7], SnO2 nanowires [8], and In2O3 nanowires [9], could be generally understood in terms of change of surface charge of the nanostructures with the presence or absence of molecular species. Because of the high surface-to-volume ratio of the nanostructures, their electronic conductance may be sensitive enough to the surface species that single molecule detection becomes possible. However, most of the existing studies based on “bottom-up” nanostructures are limited by complex integration, requiring transfer and positioning of an individual nanostructure and making reliable ohmic contacts. Furthermore, the control of doping concentrations in self-assembled semiconducting nanostructures remains a challenge, and the fabrication of high-density sensor arrays is also very difficult.

Recently, many papers have reported that biosensors based upon semiconductor field effect transistor (FET) demonstrated ultrahigh sensitive performance [10,11,12,13]. FET is a type of transistor that relies on an electric field to control the conductivity of channel by modulating the charge carrier in a semiconductor material. Bio-FET combines the FET and some particular biomolecular like DNA or protein, utilize the characterize of FET and the specific recognized binding force of biomolecular to sense and detect the desired target molecular [14]. FET fabrication uses the commercial CMOS technology, therefore the device can be made by mass production. However, the fabrication cost is relatively high because precise and expensive manufacturing tools like advanced lithography are necessary if a nanoscale dimension device is needed.

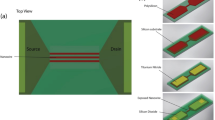

In this paper, we proposed a novel method to fabricate NWFETs whereas prevents using the expensive lithography tool. We used in situ-grown local oxidation of silicon (LOCOS) process to form nanowire, and combine the standard manufacturing process of CMOS to fabricate a local silicon side-gated NWFET. By patterning the doped silicon film to form local gates, an individual gate for every NWFET is realized. The shrinking nanowire with higher surface-to-volume ratio and individual side gate for integration are achieved by the LOCOS process. The detection sensitivity is therefore greatly enhanced as the signal can be effectively transduced because of large surface-to-volume ratio.

2 Material and Method

A NWFET was fabricated by using commercially available 6-in. (100) silicon-on-insulator (SOI) wafers as the device substrate. The stacked films of TEOS-oxide and silicon nitride were deposited sequentially as the masking layer for LOCOS process. The underlying layer of TEOS-oxide is used to cushion the transition of stresses be-tween the silicon and the nitride film. The active region and gate were then defined by the optical lithography system (Canon FPA-3000i5 stepper). The composed ox-ide/nitride stack layers were then plasma-etched, followed by the oxidation process was thermally grown. The patterned silicon nitride prevented the underlying silicon from oxidation and left the exposed silicon to be oxidized. The active region including nanowire, source, drain, and gate were defined due to the silicon nitride capped on top of the regions. The linewidth of nanowires was shrunk due to oxidant diffused laterally during the oxidation process.

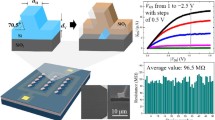

As+ ion implant and rapid thermal anneal were carried out to form the source, drain, and gate region. Before contact pad defining and etching, the stacked Al-Si-Cu alloy onto titanium nitride metal film was formed by sputter system. The silicon dioxide and silicon nitride layers were deposited to passivate the surface. The detection region of the NWFET was then etched back for the purpose of DNA immobilization. A schematic diagram of the fabricated back-gated NBFET biosensor is depicted in Fig. 1. The device after fabrication was stored in the clean room.

3 Results and Discussion

The top-view images by scanning electron microscope (SEM) is shown in Fig. 2. The images display the crossover view of side-gated field effect transistor structure and the enlarge view of the silicon nanowire. The length of nanowires is 1 μm and the width ranges from 80 to 300 nm.

Like general metal oxide semiconductor field effect transistors (MOSFETs), the gate is used to control the electric field from gate to nanowire, and hence control the on/off state of the device. As a n channel FET, the gate voltage (VG) is applied from negative to positive direction to induce negative charges in the channel. When the gate voltage is low, the high-quality junction can guarantee the very low leakage current (Ioff) at pico-ampere (pA) level. When the gate voltage is high up to threshold voltage (Vth), the conducting inversion layer is constructed and the channel is “opened”, the drain-to-source current (IDS) increases obviously. Finally, the currents (ION) reach different saturations with different drain-to-source voltages (VDS). The electrical characteristics of the side-gated NWFET is shown in Figs. 3(a) and (b).

The Vth of a MOSFET is usually defined as the gate voltage where an inversion region forms in the substrate of the transistor. The substrate of the nMOSFET is composed of p-type silicon which has more positively charged electron holes compared to electrons. When a voltage is applied on the gate, an electric field causes the electrons in the substrate to become concentrated at the region of the substrate nearest the gate causing the concentration of electrons to be equal to that of the electron holes, creating a depletion region. If the gate voltage is below Vth, the transistor is turned off and ideally no current flows from the drain to the source. If the value of gate voltage is more than Vth, the transistor is turned on, which is caused more electrons at the NW surface, and hence creates a channel which current can flow, at this step it is called strong inversion.

Figure 4 illustrates the energy band diagram of NWFET at different situations. The original energy band is shown in Fig. 4(a), which the energy band of channel is bended down due to the work function difference of gate and channel. When applying a positive gate voltage, the work function of gate is making lower and hence the energy band of channel is more bend down, causing an inversion layer is created at the channel surface, as shown in Fig. 4(b). When the NWFET is serving as a biosensor, it is most likely another gate provided at the nanowire surface. Therefore, a charging molecular binds to the surface provides extra voltage to the channel, and changes the energy band of channel. If a molecule with electrical charge adsorbed onto the nanowire surface, it causes electric field either to accumulate or to be depleted within the channel surface [Fig. 4(c)]. For example, DNA, which is bearing negative charge, binds to the nanowire will cause the threshold voltage shifted right. Thus, we can measure the threshold voltage shift to make sure the binding of the target DNA and capture DNA for the purpose of detection.

The NWFET was used to serve as the biosensor device for DNA detection. Here we design a specific DNA sequence as the probe DNA. The sequence of probe DNA is fully complementary to that of target DNA. For the purpose of biosening, the nanowire surface has to modify to attach DNA. At first, samples were rinsed with D.I. water. Then, cleaning the patterned wafer with fresh-prepared piranha solution (H2O2/H2SO4 = 1:3) for 1 h at 85 °C. The samples were immersed to 5% APTES (3-amino-propyl-triethoxy-silane) aqueous solution for 75 min at room temperature which were titrated to pH3.5 by HCl, followed by rinse with D.I. water and dry with hot baking at 120 °C. After baking, sample was immersed in the linker solution, 2.5% glutaraldehyde, for 1 h at room temperature.

After that, covalent immobilization was used to bind the terminal 5’ amine group of the oligonuclcotide to the carbonyl group on the surface. The procedure was preparing a solution of water-soluble 10 mM HEPES (4-(2-hydroxyethyl)-1-piperazineethanesulfonic acid, J.T. Baker Chem. Co.) and 5 mM EDTA buffer (Ethylene-Diamine-Tetra-Acetate) to adjust the above solution to pH 6.6 (i.e., HEPES buffer). Mixing the solution with 10 nM single stranded DNA named capture-DNA, and devices were immersed in the mixture solution for 16 h to ensure the complete bonding. After immobilization, DI water was used to wash the chip, purged with N2 and dried with hot baking.

The ID-VG curves of the NWFET at each step is measured and recorded. Figure 5 shows the I-V curves of the devices at different steps. At firstly, the electrical characteristic of NWFET without any modification process was recorded and denoted as “bare” in Fig. 5. After surface modification by using APTES, the curve shifts toward left slightly because APTES modification on nanowire affects the surface of nanowire toward positive charge rich and the depletion of positive charge in silicon nanowire. Upon capture DNA attached, the curve becomes right shift. In this step, single strand DNA which is negative charged immobilized onto the sensor surface and hence induces repelling effect of electron in the NW, which is similar to the manner of applying negative voltage at gate. The nanowire can be a good negative molecular indicator because of the high surface-to-volume ratio of the nanostructures, their electronic I-V curve is sensitive enough to the surface species that single-molecule detection becomes possible.

The target DNA which is complementary to capture DNA was applied to hybridize to capture DNA, and the IV curve continues to right shift. This result is reasonable because target DNA also bears negative charge, and more negative charges induce the curve a right-shift. The shift of threshold voltage is about 0.86 V.

We can also control the dehybridization of target DNA. A denaturation process is tested using hot DI water. From calculation, the melting temperature for the double-strand DNA to be de-hybridized is to be ~70 °C. That means it is possible to separate the target DNA from capture DNA only if the temperature of DI water is above 70 °C. To verify the calculation, a 60 °C hot water is injected to the NW surface first to wash the DNA, and the electrical characteristic is recorded. As seen in Fig. 5, the curve after 60 °C washing is almost the same with complementary DNA data, implying the 60 °C water is insufficient to de-hybridize the target DNA. On the other hand, when increasing the water temperature to 72 °C, the curve shifts left and becomes almost the same level with the data of capture DNA. This result indicates that 72 °C water is able to dehybridize the target DNA and wash out from the NW.

4 Conclusion

A novel side-gated Si NWFET for sensing DNA with specific sequence was fabricated by integrating the top-down complementary metal oxide semiconductor (CMOS) field effect transistor compatible technology. The shrinking nanowire with higher surface-to-volume ratio and individual side gate for integration are achieved by the LOCOS process. The device exhibits low leakage current at off state and excellent field effect properties. The width of shrinking nano-channel by the LOCOS can be down to 80 nm. The ID-VG characteristic of the NWFETs exhibits five orders of magnitude on Ion/Ioff, and the threshold voltage shifts positively to 0.86 V after hybridizing target DNA. The results show that the nanowire-based device acts as a label-free, highly sensitive and selective biosensor for mutation gene sensing. In addition, our approach offers the possibility of highly parallel detection of multiple chemical and biological species with local control of individual elements in a single integrated chip in the future.

References

Presnova, G., Presnov, D., Krupenin, V., Grigorenko, V., Trifonov, A., Andreeva, I., et al.: Biosensor based on a silicon nanowire field-effect transistor functionalized by gold nanoparticles for the highly sensitive determination of prostate specific antigen. Biosens. Bioelectron. 88, 283–289 (2017)

Wasik, D., Mulchandani, A., Yates, M.V.: A heparin-functionalized carbon nanotube-based affinity biosensor for dengue virus. Biosens. Bioelectron. 91, 811–816 (2017)

Yoo, S.M., Baek, Y.K., Shin, S., Kim, J.H., Jung, H.T., Choi, Y.K., et al.: Single walled carbon nanotube-based electrical biosensor for the label-free detection of pathogenic bacteria. J. Nanosci. Nanotechnol. 16, 6520–6525 (2016)

Yamada, K., Kim, C.T., Kim, J.H., Chung, J.H., Lee, H.G., Jun, S.: Single walled carbon nanotube-based junction biosensor for detection of Escherichia coli. PLoS ONE 9, e105767 (2014)

Noor, M.O., Krull, U.J.: Silicon nanowires as field-effect transducers for biosensor development: a review. Anal. Chim. Acta 825, 1–25 (2014)

Gao, A., Zou, N., Dai, P., Lu, N., Li, T., Wang, Y., et al.: Signal-to-noise ratio enhancement of silicon nanowires biosensor with rolling circle amplification. Nano Lett. 13, 4123–4130 (2013)

Gao, N., Zhou, W., Jiang, X., Hong, G., Fu, T.M., Lieber, C.M.: General strategy for biodetection in high ionic strength solutions using transistor-based nanoelectronic sensors. Nano Lett. 15, 2143–2148 (2015)

Jakob, M.H., Dong, B., Gutsch, S., Chatelle, C., Krishnaraja, A., Weber, W., et al.: Label-free SnO2 nanowire FET biosensor for protein detection. Nanotechnology 28, 245503 (2017)

Kim, J., Rim, Y.S., Chen, H., Cao, H.H., Nakatsuka, N., Hinton, H.L., et al.: Fabrication of high-performance ultrathin In2O3 film field-effect transistors and biosensors using chemical lift-off lithography. ACS Nano 9, 4572–4582 (2015)

He, J., Zhu, J., Jiang, B., Zhao, Y.: Label-free direct detection of MiRNAs with poly-silicon nanowire biosensors. Methods Mol. Biol. 1580, 297–302 (2017)

Namdari, P., Daraee, H., Eatemadi, A.: Recent advances in silicon nanowire biosensors: synthesis methods, properties, and applications. Nanoscale Res. Lett. 11, 406 (2016)

Shen, M.Y., Li, B.R., Li, Y.K.: Silicon nanowire field-effect-transistor based biosensors: from sensitive to ultra-sensitive. Biosens. Bioelectron. 60, 101–111 (2014)

Wu, C.-Y., Cheng, H.-Y., Ou, K.-L., Wu, C.-C.: Real-time sensing of hepatitis B virus X gene using an ultrasensitive nanowire field effect transistor. J. Polym. Eng. 34, 273 (2014)

Wu, C.C., Ko, F.H., Yang, Y.S., Hsia, D.L., Lee, B.S., Su, T.S.: Label-free biosensing of a gene mutation using a silicon nanowire field-effect transistor. Biosens. Bioelectron. 25, 820–825 (2009)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2018 Springer International Publishing AG

About this paper

Cite this paper

Wu, CC., Manga, Y.B., Hung, JY., Yang, WL. (2018). A Novel Approach to Fabricate Silicon Nanowire Field Effect Transistor for Biomolecule Sensing. In: Duy, V., Dao, T., Zelinka, I., Kim, S., Phuong, T. (eds) AETA 2017 - Recent Advances in Electrical Engineering and Related Sciences: Theory and Application. AETA 2017. Lecture Notes in Electrical Engineering, vol 465. Springer, Cham. https://doi.org/10.1007/978-3-319-69814-4_25

Download citation

DOI: https://doi.org/10.1007/978-3-319-69814-4_25

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-69813-7

Online ISBN: 978-3-319-69814-4

eBook Packages: EngineeringEngineering (R0)