Abstract

The need to record directly the sensing target of interest in the vicinity of where a physiological and clinically relevant event takes place, rather than indirectly or through surrogate measures, has led to the need for implantable monitoring devices. In addition to ensuring the sensitivity and specificity of sensor responses, issues related to sensor fouling, drift , biocompatibility , and hermeticity of the packaging are important considerations. This chapter examines the current state of the art of sensing techniques, focusing on electrochemical methods (potentiometry , amperometry , and voltammetry ), due to their simplicity in design and fabrication [1], as well as low-power operation .

Access provided by CONRICYT-eBooks. Download chapter PDF

Similar content being viewed by others

Keywords

These keywords were added by machine and not by the authors. This process is experimental and the keywords may be updated as the learning algorithm improves.

2.1 Introduction

The need to record directly the sensing target of interest in the vicinity of where a physiological and clinically relevant event takes place, rather than indirectly or through surrogate measures, has led to the need for implantable monitoring devices. In addition to ensuring the sensitivity and specificity of sensor responses, issues related to sensor fouling, drift , biocompatibility , and hermeticity of the packaging are important considerations. This chapter examines the current state of the art of sensing techniques, focusing on electrochemical methods (potentiometry , amperometry , and voltammetry ), due to their simplicity in design and fabrication [1], as well as low-power operation . The basic principles of sensor operation and fabrication, with due consideration of these sensors when embodied as an implantable system, will be discussed.

2.2 Potentiometric Ionic Sensing

Potentiometric sensors represent an important family of sensors typically used for the detection of ions. Monitoring of various ion concentrations can provide valuable insights into the state of tissue and the underlying biochemical processes. Here we will discuss different potential ionic targets and the basic theory of potentiometric sensing , as well as clinical examples.

2.2.1 Ionic Targets

The most common application of ion sensors is their use in the clinical analysis for example in blood. Electrolytes such as Na+, K+, Cl−, Ca2+, Mg2+ and pH are routinely measured using ion sensors in clinical analyzers (HTA) and point-of-care (POC) discrete instruments [2]. Magnesium (Mg2+) is the eleventh most common element, the fourth most common cation in the human body, and the second most common intracellular cation [3]. It is essential to all cells, as more than 300 enzymes need magnesium ions for their catalytic action (including all enzymes synthesizing or utilizing ATP, or those that synthesize DNA or RNA). Intracellular Mg2+ correlates with intracellular potassium (K+), which is also essential for the function of all living cells. Figure 2.1 illustrates the intracellular and extracellular ions, their concentrations and ionic shifts taking place.

Reprinted from [4], © 2001 with permission from Elsevier

Intracellular and extracellular ions and shifts.

Another common element in the human body is K+. It is the main intracellular cation and is essential in neuronal function and in the osmotic balance between cells and the extracellular fluid. K+ is the predominant ion inside a cell (typically 140 mM [4]), being one to several orders of magnitude higher than Na+, Ca2+, and Cl−. Thus, intracellular K+ essentially determines cytoplasm volume. The extracellular space, however, contains low levels of K+ [5, 6]. Cellular loss of K+, leading to its extracellular accumulation, is one of the most prominent ionic shifts in early ischemia [7]. In general, cellular loss of K+ takes place in three distinct phases: (1) an initial rapid increase of extracellular K+ is followed by (2) a plateau and (3) a secondary increase. The latter is only partially reversible and hence marks the beginning of irreversible ischemic damage [7]. Thus, extracellular K+ increases due to the loss of the intracellular K+. According to [8], dysfunction of the sodium–potassium pumps due to ATP reduction and activation of potassium channels where the intracellular compartments are filled with water are key factors for the increase of K+ in extracellular space during ischemia . According to [9], in cellular cultures, potassium leaks out of dying cells, leading to elevated extracellular potassium ranging between 1 and 150 mM K+.

On the other hand, Na+ is the main extracellular cation. The concentration difference between K+ and Na+ leads to a potential difference, known as the membrane potential . Na+ regulates blood volume, pressure, osmotic equilibrium, and pH . “ Cellular and whole body Na:K ratios are crucial to the maintenance of normal blood pressure” [3]. The Na:K ratio may become too high via high Na+ or low K+, or indirectly by Mg2+ deficiency, leading to hypertension.

Extracellular Ca2+ concentration increases at sites of infection from its typical baseline, which ranges between 0.9 and 1.2 mM [10]. In addition, calcifications at sites of chronic inflammation or ischemic necrosis have led to the conclusion that extracellular Ca2+ concentrations also increase in sterile inflammation in addition to infectious inflammation [10]. According to [10], increased extracellular Ca2+ concentration can lead to the amplification of the inflammatory response .

Monitoring of tissue pH can be used as a means of assessing the ischemic state of tissues, especially since its value follows cell metabolism, and it can thus be considered as a direct method for monitoring ischemia [11,12,13,14]. A lack of oxygen delivery to the tissue , due to ischemia , can lead to a decrease of intracellular pH . This is due to glycolytic lactate acid generation and ATP depletion processes [8]. The tissue acid–base balance is maintained by the release of energy by ATP (which releases protons) and the re-synthesis of ATP (which consumes protons). When oxygen delivery to the tissue is inadequate and fails to synthesize the amount of ATP to address the metabolic needs of the tissue , the rate of proton release exceeds the rate of proton consumption. As a result, the pH decreases proportionally. A significant blood loss induced by trauma, for example, can lead to a reduced perfusion of tissue . This reduced supply of blood to tissue has as a consequence the increase of CO2 and lactic acid , leading inevitably to a pH decrease. Measurement of tissue pH provides localized assessment of metabolic and blood flow abnormalities. If the body pH is significantly reduced below 7.4, acidosis takes place. Many chemical reactions taking place in the human body, especially those related to proteins, are pH dependent. If the pH decreases below 6.8 or increases above 7.9, cell death occurs. As discussed in [15], once the tissue becomes acidotic, pH cannot offer any more information regarding the progression of ischemic injury. According to [8], it is the end of the active metabolic processes (glycolytic lactate acid generation and the ATP depletion ) that gives rise to the decrease in pH that leads to a plateau in the measured pH value. Measurements of pH are regularly used to monitor tissue hypoxia [8], while low pH values have also been found in tumor tissue . Nevertheless, it is affected by other parameters, such as temperature, and its application is further restricted as it provides information only for the area in contact with the pH sensor. From the above, it is evident that human health is closely related to pH homeostasis, and its fluctuations, in addition to indicating ischemia , are also related to atherosclerotic plaque development, inflammation , and tumor growth [16]. Ionic sensors are therefore an important class of sensors for providing valuable information regarding the state of tissues and patients.

2.2.2 Basic Theory of Ion Sensing

The first significant commercial contribution in the field of potentiometric sensing was in 1932, when Arnold Beckman developed the pH glass-based liquid electrode [17]. pH provides a measure of the amount of hydrogen ions (H+) and hydroxide ions (OH−) in an aqueous solution. A solution is defined as being neutral when the hydrogen ion concentration is equal to the hydroxide ion concentration. When this is the case, the pH is equal to 7. This is the case for water at 25 °C, where the concentrations of hydrogen and hydroxide ions are both 1 × 10−7 mol l−1. If the H+ ion concentration increases, pH decreases and when the concentration of OH− ions increases pH increases. A low pH value (between 0 and 7) describes an acidic solution, while a high pH describes an alkaline solution (between 7 and 14). pH is given by the decimal logarithm of the reciprocal of the hydrogen ion activity, aH+, in a solution.

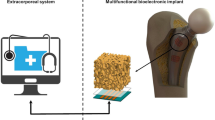

A standard pH potentiometric system consists of a reference electrode (RE) and a working electrode (WE). The former generates a constant potential irrespective of the ionic composition of the solution, while the latter generates a voltage which is a function of the hydrogen activity of the solution. Thus, a pH sensor can be considered as a voltage source, i.e. a battery. The series resistance of the source depends on the electrodes composition and configuration. The lower the pH , the larger the potential difference measured between the two electrodes and vice versa.

When equilibrium has been reached, the expressions for the ion-selective membrane phase (usually organic) and electrochemical potential in the aqueous phase are equal, so the phase-boundary potential (EPB) can be expressed as:

and when \( \mu_{\text{org}}^{0} = \mu_{\text{aq}}^{0} \)

where µ is the chemical potential (µ0 under standard conditions), kI desctribes the phase transfer energy, zI is the charge , and αI is the activity of ion I, ϕ is the electrical potential , T is the temperature, F = 96,485 C mol−1 is the Faraday constant, R = 8.314 J (K mol)−1 is the gas constant and kI is the phase transfer energy. The Nernst equation is expressed as:

E0 includes all the constant contributions, where the phase boundary potential is proportional to the logarithmic value of the activity ideally with a slope of 59.154 mV per decade for monovalent ions and for divalent ions 29.6 mV per decade at 25 °C. The modified Nernst equation is usually called the Nicolskii–Eisenman equation , and it is given by

where, αI,(IJ) and αJ,(IJ) are the activities of the primary (I) and interfering ions (J), \( K_{\text{IJ}}^{\text{pot}} \) represents the selectivity coefficient . The activity of αI,(I) is related to the mixed ion activity αI,(IJ) according to

The smaller the coefficient, the better the selectivity of the sensor is. When \( K_{\text{IJ}}^{\text{pot}} \) is very small, the part on the right-hand side of the equation approaches the primary ion activity αI,(I) without interfering ions, and therefore interference is negligible. If there is more than one interfering ion in the solution, the sum of the selectivity coefficients \( \left( {\mathop \sum \nolimits_{\text{J}} K_{\text{IJ}}^{\text{pot}} \alpha_{\text{J}} } \right) \) must be used. In mixed solutions, the potential response of an electrode obtained according to the Nicolskii–Eisenman equation will be different depending on the charges of primary and interfering ions [18].

If we consider pH sensors according to the Nernst equation , a pH sensor generates an ideal 59.154 mV pH −1 slope at 25 °C

where E is the voltage of the hydrogen electrode and pH is the hydrogen ion concentration being measured. E0 is the standard electrode potential . In metal –metal -oxide (MMO) electrodes, E0 is a constant that lumps together the standard potentials, the metal oxide solubility product, and the water ionization product [19]. Generally speaking, it is a constant potential difference that is independent of the sample composition, but depends on the temperature and the type of the reference electrode [20]. According to [21], in the case of a standard hydrogen electrode (SHE) E0 has a value of 926 mV and in case of using a Ag/AgCl RE has a value of 577 mV [22]. The intercept of the mV versus pH curve of the sensors response with the y-axis for pH of zero indicates the value of E0. Variations in E0 can in the case of IrO x electrodes, for example, be “due to variations in the stoichiometry of oxide compounds and the difference in oxidation states of iridium oxides” [22]. Additional factors related to the mechanical and chemical properties of the films as well as the hydrodynamics related to the redox processes taking place will influence the response of the sensors and lead to deviations between identical sensors [22]. The slope of the measured response is calculated by

where V1 is the potential difference measured with a solution with pH 1 and V2 is the potential difference measured with a solution of pH 2. The intercept for a temperature (T) in kelvin is found by:

where V″ is the potential difference measured in the solution being characterized.

According to the Nernst equation , at T = 25 °C, where the sensitivity of the sensor is equal to ±59.14 mV pH −1, for pH between 0 and 14, the voltage measurement can range between ±414 mV, and at T = 80 °C, where the sensitivity of the probe is ±70 mV pH −1, between ±490 mV. A typical pH measurement system produces at pH = 7 a zero voltage, has an accuracy of 0.05 pH between T = 20–25 °C, a resolution of 0.01 pH (=>0.1 mV) and a reaction time less than 1 s for 95% of the final value [23]. The pH sensitivity of −59 mV pH −1 at room temperature is well known as a Nernstian slope . However, depending on the surface and the formed microstructures and oxidation states of the ion -sensitive films and membranes, and thus the fabrication process, this slope may vary. Therefore, in [21] a sensitivity of −49.7 mV pH −1 was demonstrated, while, as will be discussed in following sections, certain films such as IrO x produce super-Nernstian responses.

All interfaces in the galvanic cell must be dominated by fast, reversible , and well-established faradaic charge transfer [2]. A practical potentiometric measurement of the potential difference across a galvanic cell requires an open circuit potential (OCP) measurement. Potentiometric measurements are performed with a zero faradaic current. Thus, high input impedance is mandatory for the measurement. This is in contrast with the amperometric , conductimetric, and impedimetric type of sensors.

The definition of the response time of a pH sensor is given as the time needed for the potential change induced by a pH unit change to reach 90% of its final equilibrium value. Issues regarding stability and repeatability in the measurements are related to potential fluctuation (∆V), potential deviation (δV) and potential drift (V′) and hysteresis (dV) as discussed in [22]. These are illustrated in Fig. 2.2. ∆V is a small non-random voltage fluctuation caused by electronic noise or interference and motion artifacts such as liquid motion. This can be in the range of ±0.3 mV and ±1 mV. δV is defined as the difference in measured potential responses between different tests when using the same electrode in the same solution. Reported values are less than 5 mV [22]. For recorded potentials varying between −0.07 and 0.46 V for pH between 1.5 and 12.1, the proposed ideal resolution is 0.02 pH mV−1. Nevertheless, due to a δV = 5 mV, the minimum pH sensing resolution is 0.1 unit of pH . The difference between the peak recorded potential and the 90% value of the saturated recorded potential is defined as the V′. This can range between 3 and 10 mV, with the potential stabilizing within 5 s. Hysteresis , is defined as the dV obtained when comparing measurements obtained from solutions with the same value of pH within the same experiment. Reported values range from 0.3 mV and can be as large as 23.7 mV [22]. In iridium-based pH sensors, dV can be minimized by creating high-quality IrO x films in terms of thickness, amorphousness and porosity [22]. The theoretical temperature dependence of potentiometric pH sensors is 0.3, 0.8, 1.3, and 2 mV °C−1 for pH of 2, 4, 7, and 10, respectively. Drift is a change in baseline potential over time, while the loss of sensitivity has a decreasing slope [20].

Reprinted from [22], © 2011, with permission from Elsevier

a Potential fluctuation (δV), deviation (ΔV) and drift (V′) are characteristics defining stability and repeatability, while b hysteresis (dV) a defines the reversibility of the sensor.

2.2.3 Ion Selective Electrodes

There are many different ways to develop an ion sensor. The classical pH electrode is the glass-based electrode sensor, which, however, has a number of drawbacks when considering its use for biomedical applications. These include slow response times, instability in fluoride, hydrofluoric acid, and silane solutions, the need for recalibration, and their susceptibility to membrane fouling, leading to loss of precision and accuracy. In physiological measurements, rapid pH measurements are of interest, as is the steady state value. Because of the very high impedance of these electrodes (multiple GΩs), these sensors require a high impedance meter [24], complicating the recording electronics. Due to their mechanical fragility, large size, and lack of deformability [22], they are unsuitable for in vivo and implantable applications.

Ion Selective Electrodes (ISEs) were first described by Cremer [25]. The discovery of antibiotics and selective binding cations gave a push to the field of ISEs. In the last two decades, solid state pH sensors have been developed in an effort to tackle the issues associated with glass-based electrodes [26]. The ionic markers discussed earlier can be monitored using solid contact ISE sensors instead of glass-based ones. Similarly to standard glass-based sensors, these are transducers , which produce a change in their equilibrium d.c. electrical potential , which is related to the activity of a specific ion in the solution. The potential is measured as the difference between an RE of constant potential and a working electrode , the surface of which is modified by an ion -specific membrane , since this process has to be selective. ISEs are very simple, robust sensors, which can be easily miniaturized. In addition, they are very sensitive, reaching sensing limits as low as parts-per-billion (ppb) [20]. They are based on the ion transfer processes taking place between the solution and the ion -sensitive membrane . The interaction of the analyte with the membrane leads to a non-uniform charge distribution, which gives rise to a change in electrode potential . As discussed in [27], the response of potentiometric sensors, i.e. the recorded signal , does not depend on the size of the active area of the sensor. Thus, due to their size independence, the response of these sensors will not change as their dimensions are reduced to micro and nano scales. It is important to note that when multiple ISEs are used there is a need for only one reference electrode . Nevertheless, each ISE will have its own baseline and slope [20].

Noble metals with stable oxides and reasonable conductance are one possible implementation of the ion-selective membrane , forming what are known as metal /metal -oxide and metal -oxide /metal -oxide electrodes [28]. They have an intrinsic mechanical stability and they can be easily miniaturized using semiconductor fabrication technology, making them CMOS compatible. Metal oxides absorb hydrogen atoms at the surface sites, changing the valency of the oxygen atom. This leads to the formation of an OCP difference between the two electrodes, the magnitude of which is proportional to the solutions pH [24]. Iridium oxide is a well-documented material [28,29,30,31,32,33], which can be formed hydrated or unhydrated [28, 30], with the hydrated form exhibiting super-Nernstian responses.

An alternative to MMO electrodes is solid-contact conductive polymer electrodes. These have been extensively reviewed in [34, 35]. Functional polymers (such as conductive polymers like polyaniline and polypyrrole) can be designed to selectively swell and shrink so that, depending on the analyte’s concentration. They can change their mass and elasticity. Polymer pH sensors react to these changes due to the protonation and deprotonation of nitrogen atoms in the polymer film. In conductive polymers , protons added to the material make them more conductive. Linear polyethylenimine (L-PEI) and linear polypropylenimine (L-PPI) polymers are particularly suitable for biosensing applications due to their strong bonding to electrode surfaces [24].

For the detection of K+, Na+ and ammonium (NH4+), valinomycin, monensin and nonactin are respectively used [17, 36,37,38]. In comparison to glass electrodes, in ionophore-based ISEs the chemical structure of the ionophore can be tailored such that a very high selectivity is achieved [39, 40]. Today there are ISEs for more than 60 different ions. ISEs can be used for the measurement of polyions, such as heparin and protamine, inorganic ions [41, 42], and also neutral species such as CO2, O2, SO2 [43,44,45], water, ammonia, organic amines, alcohol and non-ionic surfactants [41]. Advances in the host–guest chemistry for ISEs and the understanding of their theoretical response mechanisms led to the development of the first clinical analyser and its commercialization in 1972. Nowadays ISEs are almost irreplaceable in clinical analysis for detection of ions of clinical relevance, such as K+, Na+, Ca2+, Mg2+, and Cl−. ISEs determine the concentration of free ions in comparison with other methods, such as atomic absorption spectrophotometry (AAS) or inductively coupled plasma mass spectrometry (ICP-MS) techniques used to determine total ion concentration.

Lipophilicity of the ISE’s membrane is defined as p = log k, with k being the distribution coefficient of the different species between water and normal octanol [46]. Ionophores and ion -exchangers of low lipophilicity (p < 6), e.g. unsubstituted tetrakis(phenyl)borates, can leach from the ISE membranes relatively fast, so that the bulk resistance of the membranes increases 2–3 times within a few days, even at room temperature. Most of the used ionophores (charged or neutral), as well as ion exchangers, are highly lipophilic, with p = 8.

No matter what technique is used for the functionalization of the electrodes, deposited ion -sensitive membranes should have good adhesion to the sensor substrate. An issue with ISEs is the membrane lifetime. Membrane failure is mainly caused by partial detachment of the sensing membrane from the conductive surface or by the loss of the ionophore, plasticizer or carrier from the polymeric membrane film used due to leaching of some of the components into the surround solution. Leaching of the ionophore from its polymer matrix can influence the lifetime of a selective membrane . Insufficient lipophilicity of the membrane components is a dominant reason for the limited lifetime of ISEs; the more lipophilic the ionophore, the longer the lifetime of an ISE. Several approaches to how to improve it are discussed in [47]. For example, in the application of ISEs having a minimum lifetime of one month in clinical analysis, it requires a lipophilicity (log Pc) in regular 200 µm thick membranes of 11.3 and greater. It is possible to increase the lipophilicity with attachment of longer alkyl chains to the ionophore’s body. The attachment of an ionophore to a plasticizer -free polymer matrix has also been reported with minimal or no loss of the ionophore’s functionality [48,49,50]. The lower detection limit is dictated by the presence of the complexed primary ions in the membrane , where the upper limit is determined from the fact that the counterions must not enter from the sample side. When simultaneous extraction of a primary ion and its counterion (coextraction) occurs, the response slope is changed [51].

Ion exchangers allow for a proper electrode response and also have another important role. Membranes containing only ionic sites in a polymer matrix will still exhibit some selectivity based on the lipophilicity of ions due to their ion exchange properties. The more lipophilic ions have a lower hydration energy and partition more easily into the organic membrane phase from the aqueous solution [52, 53]. The physical and chemical properties, such as the polarity, and lipophilicity can have a significant effect on the ion -selective electrode selectivity and response time [54, 55]. Apolar and polar plasticizers can be distinguished based on the dielectric constant. Apolar plasticizers, such as bis(2-ethylhexyl)sebacate (DOS), promote the formation of ion pairs within the membrane [56].

The formation of ion pairs can significantly influence the slope of the response . If a divalent ion M2+ forms ion pairs with a monovalent ion A−, the phase transfer equilibria are dictated by MA+ as the predominant species, and the slope , characteristic for monovalent ion , can be obtained [57]. A polar membrane containing 2-nitrophenyloctyl ether (o-NPOE) shows an increase in selectivity for alkali ions due to decreasing coordinating ability [58], which is the reason for improvement of the detection limit [59]. There are several problems associated with using plasticized PVC. Some disadvantages are related to the possible leaching of the plasticizer from the membrane into the sample. While it shortens the lifetime of an electrode , it can significantly affect in vivo measurements due to inflammation and toxicity to the surrounding tissue [60]. In the case of microelectrodes, the specific resistance of the membrane can be increased, which can affect the electrode response [61]. The adhesion towards the matrix is important because the formation of an aqueous layer between the ion -selective solid-based membrane and metallic conductor can significantly impair the response [62]. The development of polymers that are self-plasticizing, such as polyurethanes [63], polysiloxanes [64], and polyacrylates [65], is a significant and active area of research. Other plasticizer -free polymers, prepared by one-step polymerization, are methacrylate and methacrilate–acrilate copolymers [66].

Nowadays ISEs are miniaturized, robust, and solid state and use integrated solid state REs. The main sensors developed for use in clinical environments are H+, Na+, K+, Ca2+, and Cl−; also used are Li+, Mg2+, NH4+, trace metal ion detection, and organic ion detection. Improved selectivity and sensitivity are achieved with new affinity ligands [67].

Another important family of potentiometric sensors are ion -sensitive field effect transistors (ISFETs). As discussed in [68], the line separating ISFETs (and thus also ChemFETs) from ISEs with integrated electronics is very thin. In an ISE, there is a conductor between the selective sensing membrane and the transistor gate (similarly to an extended gate ISFET), and an operational amplifier-based voltage follower is used instead of a single transistor . Active ISEs demonstrate improved thermal stability and reduced photo-induced junction currents. ISE membrane deposition is performed following the CMOS fabrication process. Active ISEs demonstrate an improved response time to chemical changes in contrast to passive ones. CMOS ISEs have been reported with a lifetime in excess of 120 days, with response time within 5% of the ideal and a 10 µM detection limit .

2.2.3.1 Iridium Oxide MMO pH Sensors

In vivo pH sensing is an important target for implantable systems. In general, pH sensing can be achieved by using iridium oxide metal –metal -oxide (MMO) sensors or polymer-based pH sensors. The ideal characteristics of these MMOs are discussed in [19]. According to [16, 19, 69], the advantages of IrO x films over other pH -sensitive oxides include a wide response range , fast response time, high pH sensitivity (a super Nernstian response , i.e. greater than 59 mV pH −1), minimal potential drift , low sensitivity to redox pair interference (thus high chemical selectivity), and finally high durability. IrO x has also demonstrated an outstanding stability over wide pH ranges and in different solutions. They are also characterized by a low impedance and low temperature dependence [33]. Thus far, there are many methods for the fabrication of IrO x functionalized electrodes for pH sensing . Sputtered IrO x (SIROF) is costly and the fabrication protocol is hard to optimize. Thermal oxidation requires very high temperatures (500–800 °C) and the film may crack if it is incompatible with a CMOS process. Anodic deposition based on electrolysis is an economic solution; however, process parameters can easily affect the deposition efficiency. Electroplating allows the formation of hydrous (electrochemical growth in aqueous solutions) IrO x on target planar microelectrodes selectively, using relatively inexpensive compounds of iridium. Hydrous IrO x leads to higher sensitivities [16]. According to [69], the above make IrO x “one of the best choices as sensitive material for pH electrodes”. Its use has also been discussed within the context of muscle and nerve electrical stimulation. Another advantage of (electrochemically generated, AIROF, not thermally) iridium-based pH sensing is the compatibility of the material with CMOS processes.

The authors in [70] discuss in detail how different applied potentials for the oxidation and formation of the IrO x film change the oxidation state of the film. At a constant pH the change is reflected in the OCP. A higher OCP corresponds to an oxide with higher valence and leads to higher sensitivity . Thus, the OCP at pH 0 increased from 490 to 825 mV and the slope from 62 mV pH −1 to 73.6 mV pH −1. In this way, the OCP recorded can be fine-tuned, e.g., for a specific power supply, so that the sensor response can be compatible with the output swing of the pH recording amplifier. In addition, the thicker the oxide the slower the response of the sensor to a pH change (350 vs. 40 ms), while in terms of drift the sensors are characterized as electrochemically stable, with a drift less than 300 µV h−1 [70].

The characteristics of these devices and the variety of different fabrication methods of IrO x pH sensors are discussed and summarized in [71]. As discussed in this paper, the potential drift , which causes errors in the measurement of pH , depends on the oxidation state and hydration of the oxide film and the preparation method used for the film. The fabricated sensor exhibited OCP changes between 700 and −100 mV for pH 0 to pH 14 and thus a slope of 59 mV pH −1, with no hysteresis and no changes in sensitivity , but a small 5 mV drift within 100 days. During a two-day continuous experiment at a pH of 6.6 the sensor demonstrated a relatively constant potential of 321.2 mV with a deviation of less than ±0.2 mV. Part of this could be due to temperature variations. The response time of the sensor to a pH change was considered to be less than 0.2 s. In [72] a drift of ±0.03 pH h−1 was reported for AEIROF and responses of −71 mV pH −1 and −61 mV pH −1 varying from 700 to 120 mV between pH of 3 and 10.

Sol-gel is a simpler and economical approach. Sol-gel based IrO x has low temperature dependence, low interference and low voltage drifts. Potential differences from 500 to −100 mV between pH 0 and 12 and a 58.5 mV pH −1 sensitivity is demonstrated. However, both AIROF and SIROF films are more sensitive due to their higher porosity. In [22, 73], response times from 2 to 60 s were reported for flexible iridium oxide fabricated with a sol-gel process. The response time is mainly affected by the porosity of the sensing membrane . The sol-gel process results in a lower porosity (reduced response time). Lower porosity, however, means lower sensitivity . The measured potential differences ranged from about 500 to −200 mV and sensitivities from 57 mV pH −1 to 63.4 mV pH −1.

In [74], the authors again used an IrO x pH electrode and a Ag/AgCl reference with sensitivities of 69–71 mV pH −1 and OCP varying between 500 mV and 0 V. In order to protect the electrode from corrosion by physiological electrolytes a biocompatible ionophoric coating was used (Nafion). In [75], implanted pH sensors were used to assess in vivo tissue trauma in the brain . Following characterization, the sensors were dipped in Nafion. AIROF electrodes were also coated with Nafion in [19] in order to stabilize the response of the sensors and to protect them from chloride and protein adsorption. Nafion coatings were also used in [76] and once again improved the stability and selectivity of the sensor. IrO x was once again used with a 80–90 mV pH −1 sensitivity and an E0 from 800 to 400 mV. Nafion was also used in [77] in AIROF electrodes. According to [78], most metal oxides, such as IrO x , are electronic conductors and thus they will respond to solution redox species. This will lead to large measurement errors. Many of these interferences can be eliminated or attenuated by coating the electrode with Nafion. There is, however, a tradeoff. The thicker the Nafion coating is, the greater the attenuation and thus elimination of the effect of interference, but the slower the response time of the electrode will be to a change in pH . This equilibration time was found to be a function of pH and it can reach a maximum value of 2 min [78].

The cytotoxicity of IrO x has been examined and has been found not to be toxic, with cells adhering and surviving on Ir surfaces. Table 2.1 compares and summarizes the published literature in terms of MMO pH sensor characteristics and fabrication methodology. Different methods are used, such as electrochemical growth (AIROF), electrodeposition, sputtered coating (SIROF), thermal, and printing methods.

2.2.3.2 Polymer-Based pH Sensing

Polyvinylchloride (PVC) is the most used polymer for solid state ISEs. Immobilization of the PVS membrane is via adsorption through Van der Waals interactions; thus adhesion to the surface is poor. In this case, stability and reproducibility could be a problem [91]. Leaching of components from the membrane will lead to a short lifetime and a loss of functionality. Leaching from covalently linked benzo-18-crown-6 with multi-walled carbon nanotubes (MWCNT) was studied in [92]. It is known that PVC is not haemocompatible [93]. Possible rejection and passivation of the sensor can be observed during blood fouling [94]. Thick PVC layers can hinder ion diffusion through the membrane . The thermal stability of these is low; thus one must consider the application they are intended to be used for [90].

Modification of the ISE surface is discussed in [95]. Poly(ethylene glycol) (PEG) and phosphorylcholine [96, 97] are used as hydrophilic materials so as to improve the sensor biocompatibility . Phosphorylcholine mimics the zwitterion nature of phospholipid moieties which is observed on the cell membrane surface [98]. PEG binds water molecules and creates a hydrophilic barrier which prevents protein adsorption.

It is evident from the above discussions that the field of polymeric pH sensors is an active research field. In [83], a Nernstian slope of 59.9 mV pH −1 was achieved between pH 2 and 9 with a measured potential difference between 200 and −150 mV. In [20], a conductive polymer pH sensor had a response time of t90% = 45 s and slopes between 59.8 and 62 mV pH −1. In [84], a pH sensor was developed using a metal Pt electrode electropolymerized by a pyrrole conductive polymer and a drop-cast PVC neutral carrier membrane . This sensor exhibited a Nernstian response , a response time less than 1 s, an impedance of 10 MΩ (the measurements are performed without sophisticated shielding and integrated amplifiers ), and a potential drift of less than 250 µV d−1, corresponding to a pH drift of 5/1000 pH units day−1.

2.2.3.3 In Vivo pH Sensing

There is significant interest in the use of pH sensing for tissue ischemia , as pH can be used as a marker for ischemia . In [13], tissue pH due to ischemia changes from about 7 to 6.5 within an hour of induced ischemia . In [99], within 45 min of induced ischemia , the measured pH changed by 0.8 (from 7.4 to 6.6) and K+ by 30 mM. Measurements were performed using commercially available ion -selective electrodes. In [8], pH changed from 7.4 to 6.4 within 40 min of induced ischemia . In a number of papers (e.g. [8, 15, 99]), the measured tissue pH initially decreased rapidly on the onset of ischemia and it subsequently stabilized to a constant value. This is presumably due to the tissue becoming acidic, marking the end of all metabolic processes giving rise to the pH decrease. This was argued to be a disadvantage of pH measurement when compared to tissue bio-impedance . Intracellular pH falls by 0.5–1 pH units during cerebral ischemia and the extracellular space becomes more acidic within 20 s of ischemia . According to [100,101,102], one of the main problems with tissue pH measurements is that they are not sufficiently stable during long-term measurements. Drifts, which have been described as unacceptable, greater than 0.48 pH units per 100 h were reported in [101]. According to [101, 103], the deposition of proteins on the surface of glass pH sensors during tissue pH measurements leads to measurement errors, producing a rise in measured pH . This protein deposition potentially creates an additional junction potential , which in turn leads to this pH increase. Other sources of drift are temperature variations, patient movement, and RE junction potential variation. A second pH sensor was used to simultaneously measure the pH of healthy muscle tissue (pH between 7.38 and 7.44) in order to compare this with ischemic muscle tissue pH . The pH measured from the healthy site remained somewhat constant throughout the experiment, between pH 7 and 7.2. The pH of the compromised tissue was initially at a lower pH value of 6.9. At the moment of occlusion, the pH started to decrease. Within one hour of occlusion, the pH dropped to 6.5. Within minutes from the release of occlusion, the pH increased to 6.9. In [101], 120 h of pH measurements from a patient with good post-operative recovery remained essentially constant and averaged a pH of 7.4, which is within healthy levels. Results obtained from a patient with an ischemic episode indicated a pH decrease 5 h following surgery. During this period, pH decreased by 0.4 pH units. Paper [104] reports pH changes of pH 0.73 between pH 7.08 to pH 6.35 within three hours (i.e. −0.0041 pH min−1) of tourniquet on canine hind limbs, a drop of pH 0.66 within an hour (i.e. −0.011 pH min−1) via arterial occlusion, a drop of pH 0.27 within an hour (i.e. −0.0045 pH min−1) via venous occlusion and a drop of pH 0.55 within an hour (i.e. −0.0092 pH min−1) via total occlusion of rat anterior thigh flaps. Other reported values are a drop of pH 0.80 in tissue pH within 240 min (i.e. 0.0033 pH min−1) in an amputated rat hind limb and a decrease of pH 0.35 from pH 7.4 to pH 7.05 (i.e. −0.0058 pH min−1) following occlusion of the femoral artery of a rabbit hind limb. An average decline of −0.00677 pH min−1 was also reported using a similar setup. An average per minute change of muscle tissue pH ranging between pH −0.33 to pH −0.11 is possible. In [105], the pH probe used exhibited a drift of less than 0.01 pH units over a six-hour period.

Of interest is the intestinal luminal pH of the normal healthy gastrointestinal (GI) tract. The colonic mucosa is covered by a surface of mucus with a thickness of 100–800 µm [106]. As discussed in [107], the colonic epithelium maintains a constant pH up to 840 µm above the cell lining. Failure of the anastomosis in the GI tract following colorectal resection, for example, leads to anastomotic leakage , which is considered one of the most challenging complications in GI surgery. Intramucosal pH at the anastomosis was found to be an independent factor for leakage development [108]. In patients with an anastomotic intramucosal pH which was less than 7.28 units within the first 24 h after surgery a 22 times higher risk of leakage is reported [108]. Patients with anastomotic leak had a mean pH of 7.05, while patients without a leak had a pH of 7.32 in the first 24 h [108]. In [105], the threshold value of intramural pH for ischemia and thus failure in the anastomosis was found to be less than pH 7. Compared to laser Doppler velocimetry, which correctly predicted the outcome of the anastomosis by 70%, tissue pH measurements succeeded in 93% of the cases [105]. It is, however, important to note that normal intestinal mucosal pH levels are not constant throughout the length of the intestines. In [107] the authors assessed the pH in different areas of the colon leading to what they termed as “the closest approximation of pH values of superficial colonic epithelium”. The measurements follow luminal colonic measurements (such as those obtained with pH sensing capsules), which nevertheless are more acidic in all colonic segments. It was found that the rectum (pH 7.15 ± 0.44) and the right colon (pH 7.05 ± 0.32) were relatively acidic, while the transverse (pH 7.42 ± 0.51), left (pH 7.46 ± 0.60), and sigmoid (pH 7.38 ± 0.59) colon were more alkaline. According to [107], the colonic mucosa tends to be more alkaline relative to the luminal colonic pH . In [15], pH in the intestine significantly dropped after ischemia , from 7.6 to 6.8 within 180 min of induced ischemia . Arterial pH followed a similar trend (7.44–6.95). According to [108], a pH less than 7.28 in the first 24 h following surgery is associated with a 22 times higher risk of anastomotic leakage .

In addition, continuous pH measurements provide an important parameter in detection of gastroesophageal reflux disease (GERD) [109] and also drug activity, which depend on saliva pH [110]. In [85], a system for GERD employing both impedance and pH measurements was demonstrated. The pH sensor was based on [22], which provided a slope of 51 mV pH −1, a voltage ranged between 0.5, and −0.1 V for pH values between 1 and 12. A second example of an ingestible capsule incorporating both impedance and pH for GERD is presented in [111]. The pH sensor had a sensitivity of 33.3 mV pH −1 and recorded voltages of 350 mV for pH 7 and 250 mV for pH 4. The combination of multichannel impedance with pH monitoring helps to detect nonacid reflux.

2.2.4 K+ Sensors

As discussed earlier, K+ is an important ion in biomedical applications. The cellular K+ level is a clinically important parameter for assessing cellular function. In ischemic myocardium for example, K+ loss is observed [112]. A connection between the cellular K+ loss and the balance in the charge during lactate transport has been hypothesized [113]. Passive movement of K+ in response to cellular loading of Na+ may enhance the loss of cellular potassium ions [114]. Cellular K+ loss in the ischemic heart is also related to the pH level [115].

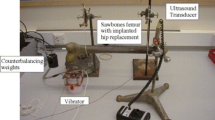

An enhanced selectivity to K+ was achieved using a solid state-based internal electrolyte, such as polypyrrole stabilized with cobalt organic counterion and using calyx[4]arene ester [116]. In [117], micromolar detection was achieved where the silicon atom is part of the ether ring. In [91], the use of valinomycin for highly selective measurements of K+ is discussed, where different changes in the internal layer can give an extended sensitivity limit. Another internal solid contact electrode is based on the use of poly(3-octylthiophene) [118]. Using a lipophilic ion conductor avoids the drift related to the development of a water layer between the ionophore layer and the substrate. Graphene has also been proposed as the solid contact material [119]. An example of early multiparametric chemical tissue sensing is shown in Fig. 2.3.

Reprinted from [82], © 2002, with permission from Elsevier

Isolated rabbit papillary muscle, which was arterially perfused, with lactate , pH , K+ sensors and with both the reference and counter electrodes positioned at the septum.

In [120], a K+ solid contact microelectrode is described. The sensor is based on a neutral carrier and demonstrated operation within a pH range of 3–11, detection limit of 1.8 × 10−6 M, and working range between 6 × 10−6 to 1 × 10−1 M with a Nernstian slope of 52 mV decade−1. Valinomycin-based electrodes for online detection of intravascular and myocardial K+ ions was described in [91]. In [82], K+ sensitive electrodes were presented with a slope of 51 mV per decade (potential differences between 0 and 250 mV) for concentrations between 6 µM and 100 mM, a life time exceeding 40 days and a response time of t95% = 14.2 s.

2.2.5 Na+ Sensors

Na+ selective electrodes were traditionally made using variant glass electrodes. However, nowadays one uses PVC-based membranes loaded with ionophores like monensin, an antibiotic, or its derivatives. Urine can be tested for Na+ in the case that a nonpolar pre-extraction is done, because the lipophilic PVC membrane can extract nonpolar species that interfere with the response towards the primary ion , which leads to a drift and loss of selectivity [91].

2.2.6 In Vivo Ionic Sensing Using ISEs

In the last few decades, extensive progress has been made through the development of portable blood-gas and electrolyte devices. However, these remain unsuitable for continuous in vivo measurements and thus unable to provide real-time diagnostic information for rapid therapeutic decisions. Current ambulatory pH recordings require the passing of the sensor transanally or transnasally using a catheter. These are uncomfortable and conspicuous, thus affecting the daily life of patients. The Medtronic Bravo pH monitoring system is a solution which is attached to the mucosal wall to measure its pH and transmits data wirelessly to an external receiving device [121, 122]. Its dimensions are 6 mm × 5.5 mm × 25 mm and has an antimony pH sensor and a RE. The entire system is contained within epoxy.

A number of flexible implantable ion -sensitive electrode arrays mainly based on polymeric membranes have also been fabricated for myocardial measurements. In [79], flexible arrays of eight ion -sensitive 250 µm diameter electrodes were presented. The electrodes were functionalized such that they are sensitive to pH (55 mV pH −1), K+ (58.1 mV/K+) and Ca2+ (28.9 mV/Ca2+). The sensors demonstrated a reduced lifetime when used in serum and whole blood measurements. According to the authors, interferences in living tissue are more complex due to the inflammatory response . Protein adsorption and other effects in tissues can reduce the sensitivity of the sensors. In vivo experiments were performed in rabbits.

In [80], in vivo experiments were performed in porcine models. pH sensors with 500 µm diameter electrodes demonstrated linear responses between pH 4 and 12, with a slope of 58.5 mV pH −1. The reported lifetime of the electrodes was about 3 months while the reported drift was equal to 0.12 mV h−1. The authors reported a myocardial pH decrease during induced ischemia from pH 7.4 to 7.25 and from 7.4 to 7.05 (at a second site closer to the ischemic region). In [81], the same authors reported results from a similar electrode array for pH and K+ sensing (Fig. 2.4b, c). A slope of 58.9 mV pH −1 with a drift of 0.25 mV h−1 and 58.3 mV/K+ with a drift of 0.08 mV h−1 were reported and the electrodes exhibited equivalent resistances of less than 10 MΩ. The platform was used to detect acute ischemia in several sites of the heart. During an 18 min experiment in porcine hearts, pH changed from about 7.3 to 6.25 and K+ from 3 to 12 mM. Once again, electrodes closer to the ischemic region demonstrated a greater change in tissue pH . The same group reported on the use of metal –metal -oxide (MMO) anodic electrodeposited iridium oxide film (AIROF) pH electrodes which exhibited a super-Nernstian response of −63.5 mV pH −1, linear between pH of 2–10, a lifetime of one month, a fast response and an accuracy of 0.02 pH units [77] (Fig. 2.4a). The measured potentials varied between about 300 mV for pH 2 to −100 mV for pH 10. During ischemia , a significant increase of CO2 takes place. This can diffuse through the polymeric membrane to the inner hydrogel layer of polymeric pH sensors leading to pH measurement errors. This is potentially eliminated by MMO pH sensors. Generally, during ischemia , pH may decline from 7.2 to 6.3 and even as low as 5.7 [77, 82]. Simultaneously, extracellular K+ may vary between 3.5 and 9 mM [77, 82]. In [8, 99, 125,126,127,128] the authors built upon previous work by incorporating in their system impedance measurements in addition to pH and K+. Nevertheless, the ionic and impedance sensors were on two different substrates. The ionic sensors were realized with ISFET-based structures (Fig. 2.4e).

a A flexible IrO x pH sensor for measurements at the myocardium. Reprinted with permission from [77], © American Chemical Society 1998. b Top: illustration of a flexible platform for pH and K+ measurements with a common reference electrode for in vivo measurements. Bottom: Sensor cross-section. Reprinted with permission from [123], © American Chemical Society 2001 and c its realization, with connecting wires. Reprinted with permission from [81], © American Chemical Society 1995. The sensors of (a–c) are some examples of the first generation of flexible sensors for in vivo measurements developed by R. Buck’s group in the late 1990s for heart ischemia monitoring. d Ionic sensor array-enabled endoscopic probe developed for measurements in the upper GI tract. Reprinted from [124], © 2014, with permission from Elsevier. e A pH and K+ ISFET and temperature sensor array probe for ischemia monitoring from the early 2000s. Reprinted from [125], © 2001, with permission from Elsevier. f A flexible and stretchable array of IrO x pH sensors developed by J. Rogers’ group for heart ischemia monitoring. Reprinted with permission from [16], © Wiley 2013

Rogers’ group [16, 129] also uses IrO x , for pH measurements. They reported super-Nernstian sensitivities of 68.9 mV pH −1 in [129] (Fig. 2.5) and 69.9 mV pH −1 in [16] (Fig. 2.4f) and a temperature dependence of −1.6 mV °C−1, corresponding to a change of pH of 0.02 for a 1 °C change in temperature. Thus temperature changes within typical physiological temperature variations will not affect pH measurements significantly. Measurements on a rabbit heart gave a baseline pH of 7.4 and 7.32 in [129] and [16] respectively. During induced ischemia , this dropped to 6.22 in [129] and to 5.6 in [16] within 30 min. A significant advance in the field is presented in Fig. 2.5 [129], where an array employing a variety of sensing methodologies from electrical, chemical, and optical was developed for cardiac monitoring.

Multisensor array for monitoring of the epicardium for ischemia and other applications from Rogers’ group. Reprinted with permission from [129]. © Wiley 2015

An endoscopic sensor array (Fig. 2.5d) for use with a laparoscopic teleoperated robot gastroendoscope was presented in [90, 124, 130] for the detection of ischemia in the gastrointestinal system. The electrodes used were commercially available 3 mm long, 600 µm diameter beryllium copper alloy pins. For the RE the pin was covered by a carbon ink and subsequently by Ag/AgCl and finally by Nafion. The authors studied the interference of K+ and Na+ and the adhesion of the sensing films to the substrate at low pH . In in vivo applications, membrane stability and leaching of membrane constituents are important issues which must be addressed. A response time of about 18 s and a maximum sensitivity of 60 mV pH −1 were reported in [130], while sensitivities of 13.07 mV pH −1 and 17.8 mV/K+ were reported in [124] and 43.23 mV pH −1, 52.62 mV pH −1 and 53.88 mV pH −1 in [90]. Polymeric sensing films were used in all of these ISEs using PVC, PEDOT, and PEDOT-PEG [90] membranes and the authors report that the eletropolymerized PEDOT membranes exhibit a significantly smaller impedance (about 100 times less, 1.3 × 106 Ω vs. 1.4 × 104 Ω). PEDOT is strongly attached on Au surfaces used as a substrate through the dative binding of the sulfur groups in the PEDOT molecule [90], making the membrane very stable. In another approach the authors used as a crosslinker poly (ethylene glycol) diglycidilether (PEG) mixed with PEDOT.

2.2.7 ISFETs

An extension to potentiometric sensors, such as those discussed in previous sections, is the ISFET. This was first proposed in the 1970s by Piet Bergveld as a MOSFET without a gate metallization [131], as shown in Fig. 2.6. The exposed oxide is then placed in direct contact with the solution/sample under test. Charge accumulates at the exposed oxide insulator of the ISFET via the specific adsorption of hydrogen ions available in the solution [132]. This build-up of charge is a function of ionic concentration (pH or others depending on the sensing membrane ) and leads to the formation of an electrical double layer capacitance at the oxide /solution interface due to charge separation and polarization . Because of this, a potential difference is established across the interface and thus at the transistor’s gate oxide . The ISFET equivalent circuit will hence include a number of different capacitances and voltage sources.

a Simplified schematic of a MOSFET. b The ISFET structure. Reprinted from [131], © 2003, with permission from Elsevier

CMOS transistors can be operated in two modes. In strong inversion the device is operated above its threshold voltage, and its operation is characterized by the drift of electrons across an electric field established in the transistor channel. Its current-voltage characteristic when the device is operated in saturation is defined by the classic square law equation:

If it is operated in the strong inversion triode region, then it is characterized by

In weak inversion, the operation of the device is characterized by the diffusion of electrons across an electric field established in the transistor channel due to the very low gate voltage (e.g. VGS < VT). The drain current in this regime is typically in the nano-ampere scale or lower and the transconductance to current ratio is maximized and a constant for a given current, leading to a maximum intrinsic voltage gain for the device . Due to the low currents, this regime is unsuitable for high-frequency application, but for potentiometric sensing , which involves the recording of d.c. voltages, it is ideal, leading to ultra-low-power instrumentation. The low terminal voltage required for operation in weak inversion and the gate capacitance being minimized in this regime leads to a minimum input noise density for a given drain current and a minimum input offset voltage due to low voltage mismatch [133]. However, the output noise current is maximized and so is the current mismatch, which is mainly due to VT mismatch between identical devices. The current-voltage characteristic follows an exponential relationship similarly to bipolar transistors, thus allowing translinear and log domain processing circuit techniques to be employed. If the transistor source is tied to the bulk, the current-voltage characteristic of a MOS operated in weak inversion is approximated by [134]

and if VDS > 4Ut, the transistor is in saturation and the last term is ignored since e−4 = 0.018, leading to

where I0 is also known as the specific current (Is or Ispec), defined as the current when VGS = VT. This is equal to

Parameter \( I_{\text{spec}}^{\prime} \) is the specific current of a square device and is technology dependent, and n is known as the slope or substrate factor or gate coupling coefficient, and is typically considered to be constant. It represents the loss of “coupling efficiency between gate and channel caused by the substrate or body, which act as a back gate ” [134]. The slope factor in weak inversion corresponds to the capacitive division between the gate voltage and the silicon surface potential resulting from the gate oxide (Cox), the depletion below the channel (Cd) and the interface state (Cint) capacitances, with the effect of the latter being negligible; thus, this is expressed as [134]

Its value can vary between 1 and 1.5 depending on the technology used. Parameter Cox is the oxide capacitance per unit area, which is transistor (as a process may have transistors with different gate oxide thicknesses) and process-dependent; thus the gate capacitance is defined by

where \( \varepsilon_{{{\text{SiO}}_{2} }} \) is the SiO2 permittivity , ε0 is the permittivity of free space and tox is the thickness of the gate oxide SiO2 layer ; µn,p is the carrier mobility (electrons for NMOS and holes for PMOS, µn > µp), W and L are the width and length of the transistor , respectively, VGS is the transistor gate-to-source voltage, VDS the drain to source voltage and VTn,p is the transistor’s threshold voltage. The subscript n, p indicates that these parameters will be different for NMOS and PMOS devices. Cox and µn,p are typically provided by the CMOS foundry for a specific process as is VTn,p for a regular MOSFET. The product \( \mu_{{{\text{n}},{\text{p}}}} C_{\text{ox}} \) is known as the transistor gain factor and is typically given as Kn,p or as βn,p. All other variables are design parameters. If VDS is kept constant by circuit design techniques, the only device input variable is VGS. It has thus been debated whether the sensitivity of the device to ionic changes should be defined as an additional variable changing VGS or VT [131]. The measurement is performed against a RE, such that a two electrode potentiometric cell is formed. Typically, a non-polarizable RE is used, such as Ag/AgCl, in order to form a stable potential difference at its interface with the solution in contact. If the RE biasing the otherwise floating solution, is defined as a remote transistor gate connected to the gate oxide via the intermediate ionic solution, then the ionic sensitivity of the device can be described as a change in VT, changing as a function of the concentration of a target ion [131]. The perception that the device threshold modulation leads to detectable changes in the I-V characteristic of the device has been the dominant method to describe the device operation. The RE voltage is capacitively coupled thought the electrolyte to the ion sensitive passivation surface. The ion -dependent charge separation of this interface modulates the threshold voltage of the device . A MOSFET’s VT (VT_MOS) is defined by [131]

The first term defines the difference between the gate metal (ΦM) and silicon (ΦSi) work functions, with q being the electron charge . The second term is due to the total semiconductor charge density (QTot), which is equal to the sum of the accumulated charge in the oxide insulator (Qox), the trapped charge in the oxide -silicon interface (QSS) and the depletion charge in the silicon bulk (QB), i.e. QTot = Qox + QSS + QB. The final term determines the onset of inversion depending on the silicon doping level [131, 135]. In the ISFET structure, however, the VT expression is defined by [133]

where Vref is the constant potential formed at the RE/solution interface , Ψ is the chemical potential across the electrolyte/passivation interface , which is a function of pH and χSol is the surface dipole potential of the electrolyte in contact with the sensing passivation layer , a constant. Thus, Ψ is the only pH dependent term modeled by the combination of the site binding theory and the Gouy–Chapman–Stern double-layer model. According to the former, the insulator surface becomes charged once an equilibrium is reached between the insulator surface binding sites and the bulk solution hydrogen ions. The charge on both sides of the interface is matched and on the solution side it spreads across the double layer . According to the double layer model, there is a tightly packed compact layer close to the interface . This is known as the Helmholtz layer , the potential across which rises linearly. This is followed by a diffuse outer layer of charge which follows a Boltzmann distribution. This is known as the Gouy–Chapman layer , the potential across which rises exponentially. This eventually is replaced by an even distribution of charge in the bulk of the electrolyte. The double layer can thus be modeled by a linear constant capacitance CHelm and a nonlinear capacitance CGouy-Chap, as shown in the ISFET macro-model of Fig. 2.7. Following the above, it can be shown [131, 136] that Ψ is given by

where pHpzc is the pH value with which the oxide surface is electrically neutral, Ut is the thermal voltage (Ut = kT/q ≈ 25.85 mV at room temperature), while α is related to the intrinsic surface proton buffer capacity and the double layer capacity and can take a value between 0 and 1 [136]. Parameter α is a dimensionless sensitivity parameter describing the reduction of sensitivity by relating the ISFET sensitivity (SISFET) to the ideal Nernstian response (SNernst = 2.303Ut ≈ 59.2 mV pH −1 at 25 °C).

For α = 1, the device has the ideal Nernstian sensitivity , while for α = 0, the device is insensitive to pH changes. Using the above, VChem can be simplified by introducing the term γ, which groups all the pH -independent terms [133, 136], leading to

According to which, if α is considered a constant, VT and pH are linearly related. The temperature dependence of this should not be overlooked.

As mentioned previously, the sensitivity of the device to ionic changes can also be defined as an additional variable changing VGS instead of a change in VT [131, 135]. This can be performed by considering the ISFET as a floating -gate MOS (FG-MOS) device with a single input capacitively coupled through the passivation and defined by the passivation interface chemistry to the floating gate and considering VT as a process-dependent constant; thus, in this scenario VT = \( V_{{{\text{T}}_{\text{MOS}} }} \). An ISFET macro-model is shown in Fig. 2.7. There is a potential applied to the RE (VR). The RE/solution interface is characterized by a double layer model. Depending on the electrode material used (polarizable , e.g. Pt, or non-polarizable , e.g. Ag/AgCl), different elements of the electrode’s equivalent circuit model may dominate. A polarizable electrode is characterized by charge storage, demonstrating a high resistance to charge transfer through the interface ; thus the model is described by the double layer capacitance. In a non-polarizable electrode , charge transfer dominates, in which the interface is characterized by a small resistance . In either case, a potential drop across the interface will be developed, and in the case of a non-polarizable electrode , an (ideally) constant potential difference with the solution (Vref) is formed across the interface , unaffected by changes in solution composition, temperature or other factors. At the interface between the solution and the ISFET sensing membrane , there is a second double layer capacitive interface , elements of which, however, are pH dependent, leading to a pH dependent potential formed at this interface (VSense, which we termed earlier as Ψ), i.e. across the interfacial capacitances CHelm and CGouy-Chap. The series combination of these two capacitances (CChem) is estimated to be equal to 0.14 pF µm−2 [133] and 1 pF µm−2 [137]. Subsequently, there is the passivation capacitance (CPass) coupling the latter potential to the floating gate . There are trapped charges both in the passivation (VPass-TC) and in the floating gate structure (VFG-TC) due to the fabrication process. Additional parasitic capacitances exist between the transistor’s electrical gate and its other nodes (body, CFGB, substrate, CFGSub, drain, CFGD, and source, CFGS) due to the overlap of conductive areas between the gate and these nodes and the operating region of the device [138], as well as between the chemical gate passivation and these same nodes (CPassB, CPassSub, CPassD, CPassS), which are all process and device geometry dependent. Finally, there is also Cox and the bias dependent depletion capacitance (Cd) of the device (which is a constant in the deep weak inversion region of operation) [133, 137]. Taking into account the above, it leads to the equivalent circuit of Fig. 2.7. All these capacitances collectively influence the sensor performance nonlinearly [137]. The passivation capacitance couples the chemical dependent interface potential to the floating gate and influences the chemical response of the sensor. This leads to a capacitive division of the chemical dependent voltage developed at the interface and explains the reduced transconductance of ISFETs when compared to a MOSFET with the same dimensions [133, 137]. This capacitance depends on the top metal layer geometry which defines the chemical sensing area of the device , i.e., the chemical gate . It can be modeled, to a first level approximation, as a series of capacitances due to the two dielectrics (e.g. SiO2 and Si3N4), using (2.22), however, the fringing field at the edges will essentially modify the geometric factor of the equation and can be more accurately modeled using finite element analysis (FEM) [137]. This fringing field effect is modeled by the δ power factor (2.22) and it was experimentally found to be in agreement with FEM simulations which indicated that it is equal to 0.7. Approximate values for CPass given in [138] are 100 aF for 0.35 and 0.18 µm and 200 aF for 0.13 and 0.09 µm CMOS processes. The value of CPass can be in the region of 22.65 µF m−2 for a standard 0.35 µm process according to [139, 140], giving for a WS = LS = 2 µm a capacitance of 90.6 aF. Thus, since capacitance is defined by \( C_{x} = \varepsilon_{0} \varepsilon_{x} W_{\text{s}} L_{\text{s}} /t_{x} \), where ε x the permittivity of the x dielectric layer , t is the thickness of the x dielectric layer , with x being either SiO2 or Si3N4, and WS and LS are the width and length of the top metal layer defining the chemical gate [133, 137, 138]. CPass is given by

Cd is given by [139]

From the above discussion and the equivalent model, we can calculate the voltage at the interface as [139]

As mentioned previously, there are trapped charges in the passivation and in the floating gate [137]. If these are modeled as a single voltage source (\( V_{{{\text{TC}} - {\text{total}}}} \)) prior to the passivation capacitance, then from [133] we have

From the simple equivalent model, the potential formed at the floating gate (VFG) can be deduced from the following, if the total capacitance (Ctotal) seen between the nodes is defined as Ctotal–1:

For more discussions regarding the term ζ, refer to [139, 140]. The model can become increasingly complex if the intrinsic parasitics of the MOSFET are considered. In this case Ctotal is equal to Ctotal–2 below

In which case VFG becomes [135]

Typically, the last two terms in the numerator are ignored, as they may be grounded, while CFGSub may be one and the same with CFGB if the device is not on a separate well. An additional capacitive term, CP, was introduced in [137] to account for the increase in floating gate capacitance due to the larger top metal layer defining the chemical gate of the device . The ratio of CPass to Ctotal (the total capacitance seen by the floating gate ) scales down the effect of VChem, and thus the device’s pH sensitivity [135]. Maximizing this ratio by increasing the chemical gate area formed by the top metal layer (WSLS) and making it much larger than the transistor’s electrical gate area (WL) improves the pH sensitivity . In this case, the ISFET characteristics will approach those of the underlying MOSFET, since VFG will become equal to VPass [133]. This is one of the reasons for the sub-Nernstian pH sensitivity of unmodified CMOS process-compatible ISFETs [135]. This capacitive division due to passivation thus leads to a reduction of the device transconductance when referred to the remote gate (i.e. the RE). Increasing CPass will increase it and will also decrease VT [140]. In addition, the subthreshold slope will also be affected, shown to be inversely proportional to the dimensions of the chemical gate and thus CPass [133, 137]. In [137], this was found to be larger in ISFETs than in MOSFETs with the same electrical dimensions. Thus, a smaller WSLS will lead to a larger linear voltage operating range , requiring larger voltages to generate the same drain current [133]. The factor n is modified due to the additional capacitances present and thus according to [133] it becomes

The first two terms of Ceff are several orders of magnitude smaller than the other two associated with the chemically sensitive interface , and thus they dominate.

The noise of an ISFET is considered to be the same as that of a MOSFET in terms of the intrinsic device properties. Chemical noise, which is attributed to electrode degradation over time and surface chemical noise, will add up to this, as reported in [137, 138]. This additional noise contribution was defined as K/f, where f is the frequency and K was found experimentally to be equal to 1 nV2 Hz. The ISFET noise was found thus to be an order of magnitude larger than that of a MOSFET. Increasing the chemical gate dimensions was suggested as a means of reducing the random offset associated with trapped charge in [137]. The interested reader may refer to [137, 138] for further analysis, discussion, and equations, while the effect of the capacitances between passivation and all transistor nodes to VFG are also taken into account in [137]. When silicon nitride is expose in an aqueous solution, a thin hydrated surface layer is formed as hydrogen ions diffuse into the material. This changes the effective layer of the passivation and thus also the potential drop across it. Changes of this over time lead to drift in the recorded signal . In [137], it was found that drift had a negligible dimensional relationship to physical dimensions, ranging between 1 and 1.4 µV s−1, three orders of magnitude larger than that of fabricated MOSFETs of the same dimensions, while it exhibited a relaxed exponential characteristic.

2.2.7.1 CMOS-Compatible ISFETs

In [141], ISFET structures where developed using an unmodified standard commercial CMOS process. The polysilicon gate was not removed and it formed a floating gate electrode together with the two metal layers of the process on top of the gate as in Fig. 2.8. Above the top metal layer , the insulating pH sensitive oxynitride layer was located [131, 141]. In this way, the top layer nitride passivation was connected to the gate oxide through the stack of the process’s metal layers. The top metal layer essentially defines the chemical sensing area of the device . Thus two gates may be defined; one is the electrical gate , defined by the transistor polysilicon gate and the other is the chemical sensing gate defined by the top metal layer [135]. This separation allows the two to be dimensionally different [135]. The top passivation layer , which is typically silicon nitride on top of silicon oxynitride in commercially available CMOS processes, is used to protect the silicon chip from the environment [132]. It is deposited using low-temperature (300–400 °C) chemical vapor deposition (PECVD) [142]. Non-CMOS-compatible ISFETs typically use low-pressure chemical vapor deposition (LPCVD) to deposit the silicon nitride pH sensing film. This process allows a higher deposition rate and leads to dense films with superior purity and uniformity and few pinholes. However, it is incompatible with film deposition on metals as a result of the high temperatures required (700–800 °C). Si3N4 films deposited with PECVD, on the other hand, lead to films with lower oxynitride content, i.e. low density and consequently fewer hydrogen ion binding sites, and thus a sub-Nernstian pH sensitivity [133], while they also contain pinholes. Silicon nitride provides a linear response with pH with a sensitivity typically within 45–56 mV pH −1, with the sensitivity as a function of the oxide’s stoichiometry [142]. These led to a linear sub-Nernstian surface potential /pH slope (less than 59 mV pH −1) [143]. This structure is essentially an ISE with FET detection via an electrically floating transistor polysilicon gate [141]. Another advantage of keeping the polysilicon gate is reduced light sensitivity [141]. A structure where the chemically sensitive layer is deposited on a metal , which is located at a distance from the MOS structure and is connected to the transistor gate through a metal line, is known as an extended gate ISFET [141]. However, if the length of this wire is reduced and is connected vertically to the transistor gate the compact device of Fig. 2.8 is obtained. The use of the passivation opening mask typically used in standard CMOS processes to define bond-pad openings in the top passivation layer was proposed in [144]. This was used as a means of minimizing the use of a full stack of metals and inter-metal insulators in a technology. In this way, the ISFET consisted of the gate oxide , the polysilicon gate , the first aluminum metal layer and the first inter-metal silicon dioxide dielectric, and thus the second and third metal and their intermediate inter-metal dielectric as well as the top layer insulation were removed without additional fabrication steps. This led to ISFETs with similar chemical sensitivity , improved effective transconductance (approximately three times larger), and reduced threshold voltage (approximately a third smaller). Classic CMOS compatible ISFETs exhibit a low transconductance due to the capacitive voltage divider formed by the stack of capacitances between the gate and the sensing membrane . In [144], this was reduced by reducing the sensing membrane by 5–11%. Nevertheless, the device noise was increased by two orders of magnitude, but still within acceptable levels for chemical sensing application according to [144], while the drift was dramatically increased, making the device inappropriate for absolute concentration measurements and limiting its usefulness for detecting the occurrence of an event (such as ssDNA binding).

Another issue with CMOS-compatible ISFETs is related to the low-temperature PECVD process used in CMOS for the deposition of the passivation sensing layers. While the quality of the deposited passivation may be adequate for typical CMOS device and circuit performance, it may potentially fall short in chemical sensing applications. This is due to the low density and the porosity of the resulting sensing film. Because of these characteristics, the passivation layer may over time “absorb and become saturated with analytes or other substances in the solution, which may in turn cause an undesirable time-varying drift in the chemFETs” VT [145, 146]. Consequently, this may lead to a loss of accuracy in the measurement and monitoring of the target analyte .

2.2.7.2 ReFETs and Differential Measurements

An ISFET insensitive to any ions is known as a reference FET, i.e. a ReFET, and such a device offers important advantages. Identical ISFET and ReFET pairs can allow differential measurements to be performed, leading to common mode errors, such as drift and temperature effects, to be eliminated while also relaxing the RE specifications. Thus pseudo-reference electrodes, i.e. polarizable electrodes, made out of noble materials such as Au or Pt, can be used and the non-constant interface potential formed at their interface with the solution/sample under test will also be a common mode signal that can be removed by the instrumentation. One such circuit is shown in Fig. 2.10a. A ReFET must be as similar as possible to the ISFET it is being used with; it should thus have the same electrical and chemical gate dimensions and it should be laid out similarly, such that common mode interferences influence the devices similarly. The challenge is in making it insensitive to ions. Many methods have been proposed. One option is to apply a membrane on top of the chemical gate such that the device’s pH sensitivity is reduced ideally to zero. Hydrophobic membranes with very low buffer capacity, such that α = 0, have been proposed [131]. Examples of such membranes are parylene and Teflon. Another approach is to add a diffusion barrier, such that the ISFET illustrates a delayed response [131]. According to [132], a polymer membrane must be used which prevents hydrogen ions from reaching the pH -sensitive membrane . However, this should not block any other ions to “preserve the electrical characteristics of the underlying ISFET” [132], such that there is no potential drop across this additional membrane . In [132] a PVC-based membrane was used which has a very low sensitivity to H+, Na+, and K+. The ISFET and the device to be used as a ReFET were matched through UV exposure; however, a VT mismatch between the two was established once the PVC membrane was deposited. Another approach used to perform differential measurements is to have two ISFETs with different sensitivities. In [147] for example, the first ISFET had a Ta2O5/SiO2 gate with a sensitivity of 58–59 mV pH −1 and the second one used a SiO x N y /Si3N4/SiO2 gate with a sensitivity of 18–20 mV pH −1. Each of the two devices was used as one of the input transistors in the differential pair of an operational amplifier configured as a source follower and their outputs were subsequently subtracted by a differential amplifier resulting in an overall sensitivity of 40–43 mV pH −1. Another approach is to use the same ISFETs, with the same sensitivity and sensing films , but to use circuit techniques to decrease the sensitivity of one of the two devices. This was implemented in [148], where the authors used different gains for two ISFET amplifiers by controlling the width of the ISFET pMOS load. The two topologies resulted in sensitivities of 50 and 30 mV pH −1. Similarly to [147], a differential amplifier subtracted the signals from the two ISFET amplifiers and amplified the resulting signal leading to an overall sensitivity of 40–45 mV pH −1. These techniques are not ideal; they may relax the specifications of the RE, but since the devices are not identical and their sensitivities different [147] or because their response is scaled [148], the effect of common mode interferences will not be completely eliminated.

2.2.7.3 Sensing Oxides