Abstract

Silk-screen printing (also called screen processing or screen printing) consists of brushing ink onto a finemesh screen that carries the image to be printed and then squeezing it through the open parts of the screen. It is used to print decals, billboard posters, wallpaper designs, lettering on bottles and clothing, and printed circuit board images in the electronics industry, as well as for printing on glass, skis, surfing planks, and credit cards. Potential irritants, such as cleansing agents and inks, may cause irritant dermatitis. Organic solvents may cause neurotoxic and other adverse effects. The actual allergens described in silk-screen printers are acrylate components of the UV-curing compounds (the most frequent allergens), epoxy resin, diaminodiphenyl-methane, and triglycidyl isocyanurate.

Access provided by Autonomous University of Puebla. Download reference work entry PDF

Similar content being viewed by others

Keywords

1 Core Messages

-

Silk-screen printing (also called screen processing or screen printing) consists of brushing ink onto a fine-mesh screen that carries the image to be printed and then squeezing it through the open parts of the screen.

-

Silk-screen printing is used to print decals, billboard posters, wallpaper designs, lettering on bottles and clothing, and printed circuit board images in the electronics industry. It is also used for surfaces on which other kinds of printing are impossible, such as glass, skis, surfing planks, and credit cards.

-

Potential irritants, such as cleansing agents and inks, may cause irritant dermatitis.

-

Organic solvents may cause neurotoxic and other adverse effects.

-

The actual allergens described in silk-screen printers are acrylate components of the UV-curing compounds, epoxy resin, diaminodiphenylmethane, and triglycidyl isocyanurate.

-

Acrylate compounds have now become the most important allergens in this sector.

2 Introduction

Silk-screen printing (also called screen processing or screen printing) consists of brushing ink onto a fine-mesh screen that carries the image to be printed and then squeezing it through the open parts of the screen. This transfers the image to the printing stock or other surface (Nethercott and Nosal 1986; Jolanki et al. 1994). Silk is no longer used for the wire screens, as it has been replaced by nylon, Dacron, and polyester fabrics, which have very fine-mesh sizes (Adams 1983).

Previously, all the stencils were prepared manually, but, now, indirect photomechanical processing and photocomposition are widely used. The information is entered into a computer, which arranges it in an appropriate layout and exhibits it on a video display terminal from which it is photographed to make the stencils (Nethercott and Nosal 1986).

Silk-screen printing is used to print decals, billboard posters, wallpaper designs, lettering on bottles and clothing, and printed circuit board images in the electronics industry. It is used for surfaces on which other kinds of printing are impossible, such as glass, skis, surfing planks, and credit cards (Géraut 1995). Mechanical processes have replaced handwork so that contact with certain irritants – alkalis or acids (Géraut 1995), solvents, abrasive materials, and degreasers (Table 1) – and sensitizers (Table 2) has been reduced considerably. However, due to specific environmental factors (temperature and low humidity), outbreaks of dermatitis (itching and rashes) seem to be common in the microelectronics industry, such as has been reported, for example, in employees working in the silk-screening and kil-drying areas of a printed circuit board manufacturing facility in Portland (Rischitelli 2005).

The allergen spectrum seems also to have changed over the years (Adams 1983). Indeed, with the increasing environmental concern about volatile emissions, the printing industry has found that ultraviolet (UV)-cured inks are an attractive alternative to inks that require hydrocarbon solvents and oils, which release by-products when drying. Indeed, low-level chronic exposure (both via inhalation and dermal absorption) to organic solvents has been shown, also in silk-screen printing, to exert neurotoxic effects (Böckelmann et al. 2004), with a recent case caused by n-hexane in India (Pradhan and Tandon 2015). Moreover, with regard to ethylene glycol monomethyl ether and its acetate ester, which is converted to the former in the body, impairment of reproduction or hematopoiesis has been reported as well (Johanson 2000).

For this reason, these techniques are becoming more widespread (Isaac et al. 1992), and acrylate compounds have now become the most important allergens in this sector, which is illustrated here by means of a personal case and recent data from the literature.

3 Allergens Identified in Screen Making

A 40-year-old man consulted us because of an itching, dyshidrotic eczema on the palms of his hands, between his fingers, and on his wrists, which had persisted for 2 months. His lesions were clearly related to his work, which consisted of making stencils for printing athletic shirts. Doing this, he would come into contact with Saatigraf (Saati, Italy). This is a UV-curable aqueous emulsion of acrylate and methacrylate esters and resins that will polymerize upon radiation with UV light and affix to the screen. At the site of the image, the emulsion does not polymerize with UV light and is then rinsed off with water leaving the meshes open. In this way, a stencil is made that is subsequently printed on paper with a water-soluble ink (different stencils are used in turn to obtain different colors). The image drawing is then printed from the paper onto cloth from the paper by means of heat. The patient’s work consisted of rinsing off the UV-irradiated screens, which he had been doing with his bare hands and a rag for 2 years.

Upon epicutaneous testing with the Belgian standard series, the (meth)acrylate series (chemotechnique), and the patient’s own material, the patient reacted (after 2 days and 4 days, respectively) to epoxy resin (++, ++), ethylene glycol dimethacrylate (EGDMA) (++, +), and 2,2-bis(4-[2-hydroxy-3-methacryloxypropyl]-phenyl)-propane (bis-GMA; epoxy acrylate) (++, +). He also reacted to the Saatigraf emulsion tested as is in a semi-open test (++, ++).

The simplest formula for such a UV-curable emulsion consists of only three components although in practice, a typical industrial formula has many more ingredients. The three essential ingredients are:

-

1.

A UV-reactive prepolymer that gives the desired characteristics to the emulsion

-

2.

A thinner, which generally consists of multifunctional acrylate esters

-

3.

A photoinitiator

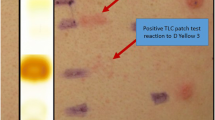

Our patient manifested a contact allergy to EGDMA and bis-GMA, as well as to epoxy resin. Saati informed us that the Saatigraf contained a tripropylene glycol diacrylate (TPGDA) and a bifunctional aromatic acrylate. This bifunctional aromatic acrylate turned out to correspond structurally to bis-GMA. Several dilutions of the TPGDA in petrolatum (1%, 0,1%, and 0,01%) also gave positive tests (Figs. 1 and 2).

The relevance of the reaction to EGDMA, which is commonly used in printing, is not certain. It is not possible to differentiate here between a cross-reaction and a concomitant reaction, neither could the presence of EGDMA in Saatigraf (Jolanki et al. 1994, who found other acrylated than those mentioned on the safety reports of 40 products) nor impurities in the test material be excluded.

The bifunctional aromatic acrylate used in Saatigraf strongly resembles bis-GMA, a well-known epoxy dimethacrylate, so a cross-reaction between these two structures is possible. However, the reaction to bis-GMA can also be explained as a cross-reaction to epoxy resins.

Our patient has had no more problems since he has been avoiding contact with Saatigraf. To do this, he wears Camatril Velours plastic gloves over cotton gloves, which turned out to be more practical than 4H gloves. He is also using a scraper instead of a rag.

4 Allergens Identified in Inks

The inks used in silk screening consist of multifunctional acrylics, which act as diluents until the reaction, and acrylated oligomers, which are cross-linked through UV light, which activates the photoinitiator in the ink. As far as we know, beside our case (Goossens et al. 1998), three other reports of contact dermatitis in silk-screen printers have been reported in the literature. The first case was published in 1986 by Nethercott and Nosal. Their female patient reacted to the UV-curable ink TPGDA, as did our patient, and also to pentaerythritol triacrylate (PETA).

Jolanki et al. (1994) reported the case of a woman who did silk screening in the manufacture of printed circuit boards with solder-resistant coatings. She developed lesions on the hands, wrists, forearms, face, and eyelids from handling UV-curable inks. She was allergic to triglycidyl isocyanurate (TGIC), diaminodiphenylmethane (DDM), and 2-hydroxyethyl methacrylate (2-HEMA) among other acrylics and several epoxy resins. TGIC is a solid trifunctional epoxy compound manufactured from epichlorohydrin and isocyanuric acid. This compound was present in an epoxy acrylate ink. DDM is a curing agent for epoxy resins and may cross-react with para-amino compounds; it was present in a DGEBA-type epoxy resin ink. 2-HEMA was present in a UV-curable epoxy acrylate ink.

The third case was reported by Isaac et al. (1992) and concerned a silk-screen printer who was allergic to butanediol diacrylate (BUDA), trimethylolpropane triacrylate (TMPTA), PETA, and the UV-curable ink. This woman worked in a pharmaceutical company. She printed labels in plastic bottles and so came in contact with UV-cured ink and developed a pruritic dermatitis involving the hands and eyelids. TMPTA and PETA were found in the UV-cured ink, but the relevance of BUDA could not be determined.

5 Conclusion

Besides the potential irritants, such as cleansing agents and inks, and the classic allergens, such as rubber chemicals, paraphenylenediamine and its derivatives, and preservatives (Adams 1983), new allergens have added to the spectrum of allergens in silk-screen printers. They are the acrylate components of the UV-curing compounds, epoxy resin, diaminodiphenylmethane, and triglycidyl isocyanurate.

6 Prevention

Wearing protective gloves (4H safety) and, as in our case, plastic gloves with cotton gloves underneath and using a scraper instead of a rag may prevent the recurrence of dermatitis. With regard to organic solvents, also the use of masks and adequate ventilation are needed in order to reduce both skin contact and inhalation.

On the basis of the literature and our own experience, besides the ubiquitous skin irritants (cleansing agents) and allergens (rubber components), the chemicals used in silk screening and mentioned in Tables 1 and 2 are at particular risk to the skin (for the allergens, the patch-test concentrations are also given).

References

Adams RM (1983) Silk-screening workers. In: Occupational skin disease. Grune and Stratton, New York, pp 438–439

Böckelmann I, Pfister EA, Peters B, Duchstein S (2004) Psychological effects of occupational exposure to organic solvent mixtures on printers. Disabil Rehabil 26:798–807

Géraut C (1995) Imprimeurs (Industrie du livre et du papier). In: L’essentiel des pathologies professionnelles. Edition Marketing, Paris, p 219

Goossens A, Coninx D, Rommens K, Verhamme B (1998) Occupational dermatitis in a silk-screen maker. Contact Dermatitis 39:40–41

Isaac MA, Thiboutot DM, Vasily DB, Marks J (1992) Contact dermatitis from printing inks. Am J Contact Dermat 3:142–144

Johanson G. (2000) Toxicity review of ethyleneglycol monomethylether and its acetate ester. Crit Rev Toxicol 30:307–45

Jolanki R, Kanerva L, Estlander T, Tarvainen K (1994) Concomitant sensitization to triglycidyl isocyanurate, diaminodiphenylmethane and 2-hydroxyethyl metacrylate from silk-screen printing coatings in the manufacture of circuit boards. Contact Dermatitis 30:12–15

Nethercott J, Nosal R (1986) Contact dermatitis in printing tradesmen. Contact Dermatitis 14:280–287

Pradhan S, Tandon R (2015) N-hexane neuropathy with vertigo and allodynia in a silk screen printer: a case study. Int J Occup Med Environ Health 28:915–919

Rischitelli G (2005) Dermatitis in a printed-circuit board manufacturing facility. Contact Dermatitis 52:78–81

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2020 Springer Nature Switzerland AG

About this entry

Cite this entry

Goossens, A. (2020). Silk-Screen Workers. In: John, S., Johansen, J., Rustemeyer, T., Elsner, P., Maibach, H. (eds) Kanerva’s Occupational Dermatology. Springer, Cham. https://doi.org/10.1007/978-3-319-68617-2_190

Download citation

DOI: https://doi.org/10.1007/978-3-319-68617-2_190

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-68615-8

Online ISBN: 978-3-319-68617-2

eBook Packages: MedicineReference Module Medicine