Abstract

Ultrasound imaging is a well-established, noninvasive imaging modality used in many clinical procedures. New developments in high-resolution microultrasound are well suited to biosensing, including applications such as material characterisation, biometrics and chemical sensing. Electronic system design for ultrasound and microultrasound is most commonly associated with the use of piezoelectric transducers to generate and sense the ultrasonic pressure waves. This chapter covers the basics of ultrasound physics and piezoelectric transducers as well as their context within the larger field of biosensing. An example of an ultrasound imaging system is presented, and the availability and suitability of commercial solutions are discussed in comparison to individual approaches seen in the research domain. Finally, possible variations in ultrasound device characteristics are discussed, and the impact of these and overall system concerns on ASIC development is considered.

Access provided by CONRICYT-eBooks. Download chapter PDF

Similar content being viewed by others

Keywords

1 Introduction

Ultrasound (US) imaging has a long history in medical applications, with documented use dating back to the 1940s [52]. As it is noninvasive, inexpensive and relatively portable, it has become a recognised technique in the clinical sector. More recent research has expanded the range of frequencies used for medical imaging above 20 MHz, allowing the creation of higher-resolution microultrasound (μUS) images. μUS is an imaging modality with resolution in the range 10s–100s of microns, allowing imaging of thin layers of tissue and tissue structure which cannot be resolved using traditional frequencies. This has led to its adoption in small animal imaging, intravascular imaging, optical and ophthalmic applications and other situations which require fine detail for diagnosis and interpretation.

The higher resolution of μUS comes at a cost in penetration depth because of the frequency-dependent attenuation present in biological tissue. While the general system structure of μUS electronics is the same as in the standard US, the higher loss factors, higher frequencies and other application-specific considerations introduce specific challenges to the development of the necessary support electronics.

The first section of this chapter reviews the basics of US imaging and places it in context in biosensing. The second section explores the current uses of μUS in biosensing, and the third section establishes the electronic system specifications for a medical US system, reviewing existing hardware and describing the necessary IP blocks. The fourth section describes an application-specific integrated circuit (ASIC) implementing these blocks, and the final section reviews existing applications of similar circuits.

1.1 The Nature of Ultrasound

US imaging uses sound waves above the range of human hearing to map the mechanical properties of a target object and displays them in the form of an image. The strength of the resultant echoes is dependent on the intensity of the initial pressure wave, the attenuation of the propagating media (caused by both absorption and scattering) and the changes in acoustic impedance encountered. Acoustic impedance, Z, is related to the density, ρ, and the phase speed of sound in the material, v:

Z allows calculation of transmission and reflection coefficients with the same equations as electrical transmission lines [45].

Conventional medical US operates in the range 1–20 MHz, with μUS systems operating at frequencies f c > 20 MHz. While acoustic propagation in biological tissue is nonlinear to various degrees, this can be neglected when performing conventional US imaging, so received US signals can be assumed to have the same bandwidth characteristics as the original transmitted signal [26], with amplitude and phase modulation introduced by the propagation path and the reflection coefficient:

In Eq. (8.2), V(t) is the voltage output from the system, A(t) and θ are, respectively, the amplitude and phase characteristics combining the original signal and its passage through tissue, and sin(2πft) is the original signal.

US waves are generated using ultrasonic transducers operating under the direct and converse piezoelectric effects. In medical systems, they are predominantly operated in the pulse-echo mode in which the same transducer transmits and receives the pressure signals [10]. From a system’s point of view, the most important parameter of these devices is their capacitance. Most devices use parallel plate electrode configurations to induce and sense the internal electric fields, resulting in a dominant capacitive term which can have a large impact on system loading and must be modelled in any electronics design [25].

In US imaging, the main incentive for increasing the transducer’s centre frequency, f c, is to achieve a corresponding increase in spatial resolution of the final image. This can be separated into two components: the axial resolution, measured on the axis normal to the face of the US transducer, and the lateral resolution, measured on the axis parallel to the face of the transducer. The axial resolution is primarily a function of the temporal length of the initial ultrasonic pressure wave, which is related both to f c and the impulse response of the device. The lateral resolution is a function of the width of the active area of the transducer, its aperture, the US wavelength, λ, and the depth of the focal point of the beam. The ideal lateral resolution, L, can be expressed as:

where the ratio of the focal depth to the aperture size is called the f-number, f #. Increasing f c and the bandwidth of the transducer will thus improve both the axial and lateral resolutions, resulting in the ability to distinguish smaller features [33].

λ can be calculated from the speed of sound, v, divided by the frequency of the signal, f. The speed of sound in most biological tissues lies between v = 1484 m/s (water) and v = 1590 m/s (liver) [3]. When calculating values, it is common to use v = 1500 m/s as a convenient approximation. Based on this, λ = 1 mm at f = 1.5 MHz and λ = 0.1 mm at f = 15 MHz. This tenfold increase in resolution allows the detection of structures of interest to radiologists, corresponding with the limit of viewing with the naked eye [62]. Further increases in f provide resolutions of 10s of microns, which allow imaging of discrete layers with thicknesses <1 mm and identification of small changes in tissue structure characteristic of early-stage disease progression [13].

1.2 Relevance to Biosensing

1.2.1 Sensing in the Body

The most familiar uses of medical US feature relatively large external probes intended for imaging large fields of view, e.g. in obstetrics, but there is also extensive application of US imaging in minimally invasive devices in current clinical use and as subjects of active research and development. Current clinical standards recognise and encourage the use of US in endoscopic imaging to supplement optical instruments for imaging subsurface tissues and previously identified areas of disease which have not yet penetrated to the surface. This can allow earlier diagnosis and treatment, improving patient outcomes [22]. While some work has been done in the μUS domain, standard probes for oesophageal imaging operate in the range 7.5< f <12 MHz, balancing resolution and penetration depth (“EUS Imaging” [12]). Lower-frequency probes can also be used for transoesophageal echocardiography (TEE) imaging of the heart (“Transoesophageal Echocardiography (TEE)” [57]).

Another established clinical application of minimally invasive US imaging is in catheter probes for intravascular imaging (IVUS). Because of the small size of the probes and the shallow imaging depth, μUS in the range 20–30 MHz is commonly used in these catheters [5].

Research into further applications of US in biosensing is currently under way, including the use of US transducers integrated into needles to assist surgical vision [21], biomonitoring of implants with Doppler US [60] and integration of μUS and other biosensing technologies into capsule endoscopy [29].

1.2.2 Need for CMOS Circuits and Systems

Reviewing current and future applications of US and μUS in biosensing, it is clear that circuit and system approaches are heavily influenced by the form factor and limited access to the probes. Any relevant probe must be hermetically sealed, with all required power and signal wires/antennas within packages small enough to introduce into narrow access channels such as the throat or rectum or through surgical channels less than 5 mm in diameter. These tight physical restraints mandate miniaturisation and integration, particularly the use of custom CMOS circuits, and careful system partitioning to achieve adequate system performance within a viable device envelope. Hence, later sections of this chapter explore current developments in μUS CMOS and interconnection technologies.

2 Microultrasound for Biosensing

2.1 Ultrasound in SAW Chemical Sensors

Current research into the manipulation, testing and analysis of chemical samples has led to multiple developments in the lab-on-a-chip (LOAC) domain. LOACs are favoured for their ability to allow miniaturisation and automation of many of the tasks required for the development of new proteins and peptides, amongst other chemical research [18]. While there has been significant research into the use of optical tweezers for sample manipulation, optical devices are limited by the need for expensive and bulky optics and lasers and by relatively small working volumes. A proposed alternative is the use of ultrasonic surface acoustic waves (SAW) to manipulate samples noninvasively on devices which can be easily miniaturised and offer a path to large-scale manufacturing [31].

SAW transducers manipulate microfluidic samples by inducing travelling surface waves which couple into droplets placed on the surface of the device. Microstreaming is induced in the droplets, causing internal mixing and patterning, translation of the droplets or, at very high power, jetting and atomisation [31]. This allows LOAC sensing without the use of external fluid manipulation devices, opening a pathway to full system miniaturisation.

2.2 Biosensing with Ultrasonic Biomarkers

An interesting issue in US imaging for the detection of biomarkers is that it is not a true imaging modality but rather a mapping of relative changes in the mechanical properties of the material and its response to pressure waves. Because of this, multiple layers of information about the tissue properties are encoded into the returned echoes. These can be extracted with appropriate analytical techniques and reference materials in a technique known as quantitative ultrasound (QUS). Depending on the homogeneity of the tissue and the degree to which the imaging parameters are understood, properties such as the acoustic impedance, attenuation and backscattering coefficient can be calculated and compared against reference values to determine tissue health and disease progression [27, 61].

QUS processing is particularly valuable in biological environments where clinicians look for differences in subsurface tissues which are difficult to determine from greyscale US images. IVUS imaging has proven a natural focus for this approach as the properties of plaques developing in the circulatory system have important impacts on long-term patient outcomes. Research with commercial 20 MHz IVUS catheters (Volcano Corporation, San Diego, USA) used QUS to explore the relationship between various biomarkers and tissue characteristics in patients with coronary disease and showed statistical significance between various pharmaceuticals and associated biomarkers [16].

US sensors have also found applications in biometrics due to their mechanical imaging properties. Fingerprints can be detected with US either through capacitive detection of loading by the fingerprint ridges [47] or by pulse-echo imaging of the surface layer of the skin [53]. As both types of detection depend on the fingertip ridges having the correct material properties and physical contours, these sensors are resistant to many spoofing approaches possible with optical sensors. 3D approaches have also been used to image skin pores [35], allowing multiple biometrics to be collected with a single device.

2.3 Parameters of Microultrasound

The difference in f c between conventional US and μUS is small when compared with contemporary radiofrequency (RF) standards in the 10s–100s of GHz range. However, the strong influence of frequency on the behaviour of US in biological tissues leads to key differences in the design and performance of μUS systems which must be considered, but which also make μUS useful for biosensing and health monitoring.

One major consequence of moving to μUS is the increased attenuation in all biological tissues, noted previously. Attenuation in dB can be assumed to be linear with respect to frequency, as a first approximation, with variations between different tissue types. As an example, the human liver has an attenuation coefficient α ≈ 0.8 dB/cm at 1 MHz, 15 dB/cm at 10 MHz and 200 dB/cm at 100 MHz [10]. This relationship is well understood, and the loss of penetration depth with frequency is appreciated; there remains a need for an increased emphasis on system gain and noise performance in μUS systems to maximise imaging performance within the unavoidable physical limitations of the approach.

Recalling Eq. 8.3, f # for a transducer is a function of the ratio between the focal depth and the aperture. Hence, as the focal length is reduced in correspondence with the increased attenuation, the aperture must also be reduced to maintain f #, resulting in comparatively smaller devices. For array systems, the individual elements must also be reduced, as US transducer elements are constrained by the same grating lobe considerations as in antenna design [10]. For linear arrays, this mandates elements no more than λ in width and approximately λ/2 for arrays steered off-axis. This results in much more difficult manufacturing and can impact electrical connectivity, a topic discussed further in Sect. 3.

3 Electronic Systems for Ultrasound

3.1 Overall System Architecture

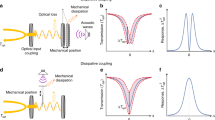

Full electronic modelling of ultrasound transducers can be quite difficult, due to the mechanical loading effects of the acoustic elements of the system, and different models have been developed depending on the aspects of the transducer being assessed in a given engineering situation. Two commonly used models are Mason’s model and the KLM model [20]. Mason’s model (Fig. 8.1a) in its simpler form models the transducer as a modified tank circuit with a dominant capacitive term and is well suited for analysis centred on the fundamental resonance frequencies and impedance loading effects. However, the component terms can be difficult to calculate for a given configuration without analytical measurements.

Simplified electrical circuit approximations for ultrasound transducers. (a) Mason’s model is a modified tank circuit suitable for SPICE-based modelling at or near a resonance. (b) The KLM model is conceptually closer to the physical components of the system and provides both loss and acoustical data and electrical impedance data

The KLM model (Fig. 8.1b) models the electrical and mechanical components more explicitly and can be more easily related intuitively to material properties. It is a better model for calculating loss factors and the full electrical impedance curve of a device. However, the loss terms appear in the form of complex impedances [25], which are incompatible with most SPICE-based circuit models, making it poorly suited to interfacing with extended circuit models. Full system analysis commonly uses a combination of these two models and/or finite element analysis to obtain all the required specifications. Both circuit models in Fig. 8.1 also include a simple diode-based amplifier protection circuit used to prevent overvoltage at the input to the receive amplifiers, but other transmit/receive switching configurations are possible [32].

The standard architecture used in US and μUS systems is well established, with most innovation occurring in the specifics of individual system blocks or in the addition of compatible functionality on top of the accepted standards. Base US systems can be separated into transmit and receive subsystems, with some functional overlap but significant differences in specification which require separate treatment. A typical block diagram of a clinical US system is shown in Fig. 8.2.

The first fundamental decomposition of the electronics is into the transmitting (TX) and receiving (RX) circuits. This separation owes its existence to the significant difference in operating voltage between the two halves of the system, caused by the efficiency loss inherent in the converse and direct piezoelectric conversions in the ultrasonic transducer, ultrasonic attenuation within the imaged medium and electrical, mechanical and ultrasonic losses within the physical components of the system [10].

The TX circuit is designed to generate a sequence of high-voltage pulses of given duration and frequency with intervening time delays (Fig. 8.3). These pulses are applied successively to the ultrasonic array to set up a corresponding pressure wave propagating into the medium. The pulse length can vary from one to multiple cycles at f c, depending on the specification for power delivery and spatial resolution. The pulse amplitude is on the order of 50–200 V at frequencies >50 MHz for μUS [49]. While such frequencies are no longer considered difficult in electronics design, the combination of frequency and amplitude driving highly capacitive devices presents a significant design challenge with limited off-the-shelf solutions. Commercially available solutions will be addressed in more detail in the next section.

The complexity of the TX electronics in a particular system is dependent on not only the operating frequency and voltage but also the focusing requirements and the number of elements in the array. In a system with a single element either unfocused or physically focused, it is sufficient to supply a single drive signal. For array systems with electronic focusing, however, a separate drive signal is needed for each array element, requiring replication of the drive circuitry by a factor equal to the number of elements operated together in the array. Commercial systems can have element counts greater than 512 [2], making reduction of the electronic footprint critical to overall system size.

For electronic focusing, the TX pulses must also be delayed with respect to each other to allow shaping of the output acoustic pulse. These electronic delays mimic the path length variance seen in a mechanical lens and are small with respect to the period of the pulses [55]. As exact implementation of the required delays would often demand a system clock frequency many times greater than fc, many systems either compromise focal accuracy or use analogue delay components to achieve the final delay resolution [7, 54].

US RX electronics share many of the same challenges as the TX electronics with respect to the frequency, channel count and need for fine focussing delays if hardware beamforming is performed. However, the >60 dB reduction in voltage compared with the TX side requires several additional components in the signal chain (Fig. 8.2).

The standard RX signal chain is identical across all channels and features protection circuitry preceding a series of amplification stages, beginning with a low-noise amplifier (LNA) followed by one or more variable- (VGA) and fixed-gain amplifiers. The protection circuitry is extremely important to protect the vulnerable LNA inputs from the high-voltage TX pulses [32]. The specification of the amplification stages varies between systems, depending on the attenuation and desired penetration depth of the image, and additional filtering and matching networks may be included to maximise signal integrity. The full signal chain up to the digitisation phase is referred to as the analogue front end.

The analogue components of the receive network then lead into the analogue-to-digital converters (ADCs), whose specification should be based not only on the Nyquist conditions of the received signals and the desired voltage resolution but should also consider the intended focal delay resolution. While post-sampling interpolation is often used to increase delay resolution, its accuracy is dependent on the linearity of ultrasonic propagation, so higher sampling rates are needed when imaging highly nonlinear media such as biological tissue.

There are multiple approaches to handling the digital processing required to create greyscale images from the RF RX signals. Most systems deal with the initial focal delays and summation (delay-and-sum architecture) [55] in the same circuits as the analogue processing before passing data to the main processor. This can be achieved using digital signal processing (DSP) chips, but it is far more efficient to use either field-programmable gate arrays (FPGAs) or ASICs due to the natural parallelism of the signal chain. Performing the first stage beamforming on the system boards is time efficient and also allows a reduction in the bandwidth of the data connection to the processor on the order of the number of channels in the active focal aperture. With data sampling rates greater than 20 megasamples per second (MSPS) per channel, this can make the difference between the need for a 100 MB/s data channel and a 1–10 GB/s channel.

Final image formation, i.e. scan conversion, is conventionally performed in the main processor of the US scanner, though there has been an increase in GPU-based implementations in recent years with the rise of affordable chipsets driven by the PC gaming market.

3.2 Chipset Implementation

The commonality in the basic signal flow in the US RX system has been addressed by commercial chips integrating the main analogue stages with suitable ADCs in a single package. Featuring up to eight channels/chip, these can be effective in developing a full US system rapidly. However, they are less space and power efficient than the ASIC solution and do not always address DSP requirements, so they are not suitable for all applications. Complementary TX chips are also sometimes available. There are currently three major suppliers of chipsets for the medical US market: Analog Devices Inc. (Norwood, USA), Texas Instruments Inc. (TI, Dallas, USA) and Maxim Integrated (San Jose, USA).

Analog Devices (“Ultrasound | Analog Devices” [58]) currently offers only analogue RX front-end chips, but parts are available integrating different components, allowing better design control and power consumption through the absence of unnecessary features. All Analog Devices chipsets offer eight parallel channels and sampling rates up to 125 MSPS with all chips supplied in 10 × 10 mm2 ball-grid array (BGA) packages.

TI offers both TX and RX chipsets (“AFE5807 | Ultrasound | Medical Analog Front End | Description & parametrics” [1]), with up to eight channels on RX. The sampling frequency is limited to 80 MSPS, with most chips functioning only up to 65 MSPS. Chips are packaged in 15 × 9 mm2 and 9 × 9 mm2 FBGA (fine-pitch BGA) packages. Compromise may be required on TX as eight-channel TI chips can produce only 15 MHz transmit pulses, and the higher frequency, 50 MHz chips are available only with two channels. The 15 MHz chip comes in a 12 × 12 mm2 very thin quad flat no-lead (WQFN) package and the 50 MHz one in a 13 × 13 mm2 new FBGA (nFBGA) package.

Maxim Integrated offers TX, RX and TX-RX chips for US (“Ultrasound Imaging – Maxim” [59]), but with a lower frequency range than other suppliers. Their eight-channel RX chips allow up to 50 MSPS in a 10 × 10 mm2 package. The eight-channel TX chip has a 20 MHz analogue signal bandwidth in the same package. The TX-RX chip integrates TX and RX chips with the same performance in a single die, but it is packaged in a relatively large 10 × 23 mm2 chip-scale BGA (CSBGA) package, the size potentially presenting a barrier to integration into smaller, more portable applications.

There has been substantial improvement in the specifications offered by all three companies in the last two decades, so a system designer must reassess them regularly when developing analogue front-end circuits over multiyear timescales.

3.3 CMOS Mismatch with μUS Frequencies and Form Factors

By reviewing the specifications of the current commercial chipsets, certain common trends become apparent which make US electronics design at high frequencies particularly difficult. The highest sampling frequency is 125 MSPS, with 80 MSPS or less more common. Given the Nyquist sampling criterion, the highest value results in a system bandwidth limit of 62 MHz. However, US system design typically allows up to 100% bandwidth on all signals, based on high-performance transducer impulse responses. This reduces f c to a maximum of 40 MHz. The figure is still lower in many systems as the amplitude-modulated nature of US signal interpretation means that quadrature sampling is desirable for envelope detection without the use of Hilbert transforms or other calculations which are difficult to implement with reduced instruction set computing (RISC) hardware [44]. With quadrature sampling, 125 MSPS limits the f c to just over 30 MHz, accommodating only the lower end of μUS applications.

The other major factor to consider with commercial chipsets is the size when packaged. The chips discussed in the previous section range from 9 to 15 mm on a side, discounting the large TX-RX chip, and have a maximum of eight channels. Assuming a 128-channel system with both TX and RX capabilities, and using 10 × 10 mm2 chips as an average size, this results in 3200 mm2 of circuit board space just to mount the packages, with a much larger area required to house other components including decoupling, routing, FPGA/DSP chips and supporting power and ground planes. While μUS systems have been successfully developed based on the use of chipsets, they are by necessity either limited in channel count [28] or large enough that they are not functionally portable [8]. With this in mind, the next logical step is to consider the development of ASICs integrating the necessary analogue and digital components into a single chip.

In academic research, there has been only limited development of ASICs for US systems at any frequency. Work has focused on ASICs to integrate with micromachined US transducers, rather than the bulk ceramic used in current clinical systems. This follows from the original design intent of micromachined transducers, which is to maximise system integration by using foundry processes for sensor fabrication, and aligns with the expertise of the research groups involved, which lies in the domain of silicon-level device development.

Most research to date has focused on transducer designs which are compatible with existing foundry processes, requiring only additional layers of standard materials. Examples have been reported at standard US frequencies [17, 46] and for μUS [48]; there are many other examples for f c ≤100 MHz. However, many approaches are limited to the main analogue components, requiring additional hardware to support the digital circuitry. Hybrid approaches introducing thin piezoelectric films into the micromachined device stack have had some success in research and development but are far less common, with only a handful at 8–9 MHz [34, 56] and >50 MHz [24, 37]. In this case, the implementations at μUS frequencies include integrated digital circuits, further reducing overall circuit complexity.

Apart from ASICs reported in the public domain, it can be assumed that major commercial clinical system suppliers develop ASICs in-house. However, the specifications and technical details of these chips are not publically available, so their characteristics can be inferred only from the overall system performance, and they are thus not discussed further here.

4 Integrated Circuits for Microultrasound

The specific performance metrics for a μUS system make it particularly difficult to implement using existing hardware, as outlined in the previous section. While discrete components are available which can meet some of the requirements, the consequences of their use on the system as a whole, particularly the large physical dimensions and interconnections, make them impractical, and the development of ASICs is thus effectively mandatory for systems intended for clinical use.

A fully integrated system is, by necessity, a mixed signal implementation, with high-voltage CMOS required for the drive circuits for most types of μUS transducer. The particular impact of μUS system requirements on integrated circuit (IC) design is reviewed in this section.

4.1 Key Factors

4.1.1 Physical Dimensions

As discussed previously, many potential uses for μUS feature miniaturised probes inserted through surgical channels or natural orifices. These probes usually measure 4–10 mm in outer diameter, placing strict limits on the size of the ASIC floor plan. There is also a strong preference for bare die solutions, as the extra area taken up by packaging is often prohibitive.

When calculating estimated die area for a given application and system partitioning, it is important to keep in mind the large number of channels/interconnects required for a system with large array element count. For a 128-channel system with full TX and analogue circuitry integrated in the ASIC, a minimum of 256 pins are needed just for input and output signals, with control, bias and power pins requiring, e.g. 50 more. Not only can this place limits on the minimum perimeter of the die, but the resulting 300+ pin fan-out is demanding of space, expanding the footprint of the supporting printed circuit board (PCB).

Difficulties with pinout and fan-out caused by the high channel counts in μUS applications are an example of a more general interconnection problem. Connections to US transducers are usually made with soldered cable connections or wire bonds like those used in IC packaging [6]. With the smaller pitch required by μUS wavelengths, current research into US and μUS interconnection emphasises flip-chip technologies and high-density flexible circuits to maximise density and robustness [4, 14].

4.1.2 Frequency

f c for an US system affects both the analogue and digital parts of an ASIC design. The RX amplifier chain must have sufficient bandwidth to avoid signal distortion prior to digitisation. To simulate the final bandwidth correctly during the design phase, it is critical to model the large capacitance presented by the transducer load. While impedance matching is possible externally to reduce loading effects, integration of matching inductors for high channel count systems is not practical in most μUS applications.

μUS frequency requirements have two major impacts on digital design, one on the TX and RX beamforming and the other on digitisation. Both require higher internal clock rates than conventional US for any on-chip processing as well as input and output pins, with resulting stricter design criteria for trace lengths, jitter and rise/fall times. In particular, the higher sampling rate required by the Nyquist criterion can result in an inability to use pre-existing ADC blocks and other intellectual properties (IP), adding complexity and design time. Additionally, it is usually impractical to implement high enough clock rates to achieve full μUS beamforming delays, so additional circuitry and layout work is required to implement either fixed delay paths or to calculate delays via interpolation [7, 9].

4.1.3 Gain to Overcome Attenuation

To generate images suitable for clinical diagnosis, μUS systems require multiple gain stages to overcome the frequency-dependent attenuation discussed previously. As signals become more attenuated over the course of a complete signal acquisition cycle due to the additional travel time through tissue, one stage of the amplifier chain is a voltage-controlled amplifier used for time gain compensation (TGC). The gain of this amplifier is increased through the course of a single acquisition and then reset to a low gain for each new acquisition. The entire gain chain will normally achieve 60–90 dB of gain, depending on application [49].

4.1.4 Power Consumption

The importance of total power consumption is heavily dependent on the particular application and probe design. For probes with a fixed connection to an external base station such as catheters or endoscopes, power consumption is not critical, so long as any waste heat produced within the internal components can be dissipated via cooling systems. For battery-powered autonomous systems such as implants and capsules, however, power consumption must be strictly controlled, both to minimise heat production and to extend battery life.

4.1.5 Noise Performance

The high frequencies, mixed signal design and high gain issues previously discussed can lead to concerns about noise performance both within the system and coupled from external sources. The noise induced by the ultrasound transducer itself is dominated by thermal noise [39] which can be calculated from the equivalent circuits (Fig. 8.1) using Nyquist’s relation. The RX chain, in particular, must be shielded from parasitic interference from the high-voltage transmitter, the ADC and the digital logic blocks as the input signals to the amplifier chain usually have low signal-to-noise ratio (SNR) due to acoustic attenuation. The beamforming process increases SNR as most of the noise is decorrelated between channels, but standard design procedure is to use a low-noise amplifier (LNA) at the head of each amplifier chain to control the overall noise figure and maximise SNR.

4.1.6 Summary of IP Blocks

Reviewing the specifications discussed in this section as well as the overall system design discussed in Sect. 2, a generalised set of IP blocks necessary for a fully integrated μUS IC can be defined, as shown in Fig. 8.4.

5 Implementation and Demonstration

Previous sections have focused on a general discussion of the application of μUS to biosensing and the required circuit and systems to implement a functional system suitable for clinical purposes. While these principles can be applied in any application, specific applications and particularly the types of μUS transducers that are used may require modifications to the general system design and will affect which of the specifications dominates the design process. This section will discuss the various types of μUS transducer currently in use in clinical and research environments and their interactions with IC architectures.

Examples of the three main configurations of piezoelectric transducers are given in Fig. 8.5. The first configuration, Fig. 8.5a, is based on bulk piezoceramic or piezocomposite material operating in the thickness mode and can also be used for thick films such as polyvinylidene fluoride (PVDF). The second configuration, Fig. 8.5b, is an example of a CMUT which operates in a flexural mode, with acoustic signals transduced into changes in capacitance rather than changes in electric field. The final configuration, Fig. 8.5c, is an example of a PMUT. PMUTs represent a compromise between the integration possible with CMUTs and the traditional piezoelectric materials as they operate in the same flexural mode as CMUTs but with a thin piezoelectric film providing electromechanical transduction, allowing the use of more conventional electronics.

Mechanical configurations of ultrasonic transducers and their electrical input/output ports. (a) Standard bulk ceramic or thick film configuration for thickness-mode operation. (b) Capacitive micromachined ultrasonic transducer (CMUT) configuration with flexural mode and capacitive readout. (c) Piezoelectric micromachined ultrasonic transducer (PMUT) configuration with voltage readout

5.1 Alternative Implementations

5.1.1 Bulk Piezoelectric Components

The most common type of US transducer is manufactured using bulk lead zirconate titanate (PZT), a piezoelectric material with properties that make it suitable for operation in both the TX and RX modes of US and μUS imaging. Other materials such as crystalline lead magnesium niobate doped with lead titanate (PMN-PT) and lithium niobate (LiNbO3) have also been used with very similar manufacturing principles, so for the purposes of the electronics, they can be treated as a single category.

Despite being the most common implementation, there is minimal reporting in the literature on the design of ASICs for bulk piezoelectrics, with most applications using commercial chip solutions [9]. Integrated flip-chip solutions are particularly difficult to implement with bulk PZT due to the temperature sensitivity of PZT and other similar materials and acoustic interaction of the physical IC structure with the transducer. Flip-chip bonding as implemented conventionally uses relatively high temperatures which can degrade the piezoelectric properties of bulk ceramics. Some groups have had some success working with alternative epoxies [40, 43], but the acoustic loading effects make optimisation and testing difficult, and work in this area is still at an early stage. This has led to approaches which achieve a compromise between integration and acoustic optimisation by direct bonding to an intermediate connector which is then interfaced with the supporting electronics [50].

5.1.2 PVDF Piezoelectric Film

PVDF is a piezoelectric polymer which comes in the form of a thick film and can be used in place of bulk ceramic in the same transducer configuration. Its material properties make it inefficient in TX mode compared to PZT, but its RX properties are excellent. Its acoustic impedance is also a much better match to tissue, making it a contender in applications where a good acoustic impedance match is critical.

PVDF transducers typically have higher capacitance than PZT because of their reduced thickness, requiring additional work on the electronics. However, the much lower permittivity allows the film to be coupled to substrate electrodes without the use of conductive epoxies or adhesives, leading to the development of direct-bonded solutions impossible with bulk materials [11]. Capacitive coupling through non-conductive epoxies also allows the electrodes to be patterned on the interconnecting flexible circuit rather than the PVDF [23]. Array element patterns can thus be designed and manufactured through flexible circuit processes, simplifying prototyping and allowing an easier pathway to mass manufacturing.

5.1.3 CMUTs

CMUTs are an alternative approach to US transducers, able to be manufactured on the same semiconductor fabrication line as ASICs and other ICs. This brings the potential to integrate a complete US imaging system in a single IC. As mentioned previously, conventional transducers operate in the thickness mode when generating and detecting US. CMUTs operate in a flexural mode and generate charge rather than voltage output. Additionally, they need a high-voltage DC bias, so circuits designed to support them do not port well to other transducer types.

The integration-led aspects of CMUT design have led to the development of a relatively large number of IC designs, with varying approaches to system partitioning between the base station and ASICs integrated with or close to the transducer. Because of the physical properties of membranes, individual CMUTs are often small relative to the ultrasonic array elements required for imaging. It is thus standard to use them in sub-arrays, with switching networks integrated in the system design to allow the correct connectivity [15]. The combined complexity of these networks and the necessary drive circuitry has led most implementations to integrate only the networks and preliminary gain stages with the probe, with the remainder of the receive system in the base station [30, 51].

5.1.4 PMUTs

As the manufacturing approach to PMUTs is, in some ways, a compromise between bulk ceramic approaches and CMUTs, it is logical that the supporting electronic systems are also a compromise. As with CMUTs, individual PMUTs are often quite small relative to the area of each array element, so they are usually used in sets connected electrically in parallel. However, a major advantage is that their piezoelectric film layer allows the same TX and RX electronics to be used as in conventional bulk ceramic arrays, though operating at lower voltages. The very limited thickness of the piezoelectric films in the PMUT membranes reduces the drive voltage to <10 V, simplifying the analogue TX circuitry and reducing electrical coupling levels [42].

The need for access to piezoelectric thin film deposition and IC fabrication facilities has led to the development of PMUTs and their associated electronics in only a few key centres, but μUS systems have nevertheless been developed with both TX and RX capabilities [24]. Systems have also been implemented successfully to integrate PMUT arrays with a TX and RX IC for fingerprint sensing [19]. In this implementation, the flexural mode operation of the PMUTs allowed the ASIC to be integrated directly under the PMUT array without affecting the ultrasonic performance of the transducers, allowing very high electronic density.

6 Conclusions and Future Work

MicroUS is already being applied in key areas of biosensing and has great potential for broader applications as the field matures. The inherently small dimensions of μUS devices and their suitability for use in minimally invasive medical devices lead directly to the need for supporting circuitry which can be fully integrated with millimetre-scale devices. Research in this field is already exploring various applications of high-density circuit design as well as IC-oriented interconnections. Related research and development in the mobile phone, medical device and LOAC sectors are also providing new solutions which may lead to further development in the μUS domain.

The current state of the art in electronic systems for μUS has begun a migration to IC technologies. However, the unusual combination of specifications for high voltage, mid frequency, low noise and high SNR has led to a piecemeal approach aimed at particular applications, and true generalisation has not yet been achieved, either in the research domain or in commercial offerings. Partly because of this, μUS is still a niche application, limiting resources available to fund ASIC development.

6.1 Future Work

There has been a significant progress in the past few years in terms of μUS imaging in general and in the development of ICs. μUS scanners are now available commercially from VisualSonics (Fujifilm VisualSonics Inc., Toronto, Canada) with f c up to 70 MHz, with established capabilities in small animal imaging and early work in humans. Vermon (Vermon S.A., Tours, France) currently offers transducers up to 18 MHz, and they have published research with f c = 30 MHz [36], suggesting the intention to enter the μUS market at an appropriate time. With the wider availability of μUS imaging, new applications within the imaging and biosensing domains are likely to appear with increasing frequency over the next decade.

Current research is investigating the integration of US sensors and circuitry into minimally invasive medical devices such as the surgical needles previously mentioned as well as endoscopy capsules [29], an application currently dominated by optical techniques. These and other similar approaches require particularly compact form factors which emphasise the need for miniaturised electronics compatible with direct connection to the active sensors. Work in this area will need to address questions of power management, electronic space efficiency and system partitioning. This will provide the potential for creation of stand-alone μUS devices which are small enough and versatile enough to find many applications within the biosensing domain, as well as for non-destructive testing in confined spaces and other potential industrial applications.

Outside traditional biomedical imaging, continuous wave and contact measurement modes such as Doppler, SAW and fingerprint detection often feature reduced electronic complexity which allows further miniaturisation, creating the potential for sensing devices which can be implanted at the point of interest [38, 41].

μUS has consistently enjoyed attention from research and commercial interests as it has an appealing balance between imaging resolution and tissue penetration without the need for ionising radiation. However, the necessary integrated electronics to fully realise the biosensing potential of this modality have lagged somewhat behind the ultrasonic and mechanical developments, presenting a worthy engineering challenge. Through the existing approaches and the adoption of new interconnect and integration technologies driven by the microelectronics sector, practical, miniaturised μUS systems are clearly feasible in the near future.

References

AFE5807 | Ultrasound | Medical Analog Front End | Description & parametrics [WWW Document], (2017), URL http://www.ti.com/product/afe5807/description?keyMatch=AFE5807&tisearch=Search-EN. Accessed 10 Jan 2017

M. Analoui, J.D. Bronzino, D.R. Peterson, Medical Imaging: Principles and Practices (CRC Press, Boca Raton, 2012)

H. Azhari, Basics of Biomedical Ultrasound for Engineers (Wiley-IEEE, Hoboken, 2009)

A.L. Bernassau, D. Flynn, F. Amalou, M.P.Y. Desmulliez, S. Cochran, Techniques for wirebond free interconnection of piezoelectric ultrasound arrays operating above 50 MHz, in Ultrasonics Symposium (IUS), 2009 IEEE International. Presented at the Ultrasonics Symposium (IUS), 2009 IEEE International, (2009), pp. 1–4. https://doi.org/10.1109/ULTSYM.2009.5441700

E. Berry, S. Kelly, J. Hutton, H. Lindsey, J. Blaxill, J. Evans, J. Connelly, J. Tisch, G. Walker, U. Sivananthan, M. Smith, Intravascular ultrasound-guided interventions in coronary artery disease: a systematic literature review, with decision-analytic modelling, of outcomes and cost-effectiveness. Health Technol. Assess. 4, 1–117 (2000)

J.A. Brown, F.S. Foster, A. Needles, E. Cherin, G.R. Lockwood, Fabrication and performance of a 40-MHz linear Array based on a 1-3 composite with geometric elevation focusing. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 54, 1888–1894 (2007). https://doi.org/10.1109/TUFFC.2007.473

J.A. Brown, G.R. Lockwood, A digital beamformer for high-frequency annular arrays. Ultrason. Ferroelectr. Freq. Control IEEE Trans. On 52, 1262–1269 (2005). https://doi.org/10.1109/TUFFC.2005.1509785

Chang-Hong Hu, Fan Zheng, Yi Huang, J.M. Cannata, K.K. Shung, Ping Sun, Design of a 64-channel digital high frequency linear array ultrasound imaging beamformer on a massively parallel processor array, in Ultrasonics Symposium, 2008. IUS 2008. IEEE. Presented at the Ultrasonics Symposium, 2008. IUS 2008. IEEE, (2008), pp. 1266–1269. https://doi.org/10.1109/ULTSYM.2008.0306

Chang-Hong Hu, K.A. Snook, P.-J. Cao, K. Kirk Shung, High-frequency ultrasound annular array imaging. Part II: Digital beamformer design and imaging. Ultrason. Ferroelectr. Freq. Control IEEE Trans. On 53, 309–316 (2006). https://doi.org/10.1109/TUFFC.2006.1593369

R.S.C. Cobbold, Foundations of Biomedical Ultrasound (Oxford University Press, Oxford, United Kingdom, 2006)

V. Daeichin, C. Chen, Q. Ding, M. Wu, R. Beurskens, G. Springeling, E. Noothout, M.D. Verweij, K.W.A. van Dongen, J.G. Bosch, A.F.W. van der Steen, N. de Jong, M. Pertijs, G. van Soest, A broadband Polyvinylidene difluoride-based hydrophone with integrated readout circuit for intravascular photoacoustic imaging. Ultrasound Med. Biol. 42, 1239–1243 (2016). https://doi.org/10.1016/j.ultrasmedbio.2015.12.016

EUS Imaging [WWW Document], (2017), URL http://www.eusimaging.com/reference/papers/artifacts/artifacts_print.html. Accessed 18 Jan 2017

A. Fatehullah, S. Sharma, I.P. Newton, A.J. Langlands, H. Lay, S.A. Nelson, R.K. McMahon, N. McIlvenny, P.L. Appleton, S. Cochran, I.S. Näthke, Increased variability in ApcMin/+ intestinal tissue can be measured with microultrasound. Sci Rep 6, 29570 (2016). https://doi.org/10.1038/srep29570

J.O. Fiering, P. Hultman, W. Lee, E.D. Light, S.W. Smith, High-density flexible interconnect for two-dimensional ultrasound arrays. Ultrason. Ferroelectr. Freq. Control IEEE Trans. On 47, 764–770 (2000). https://doi.org/10.1109/58.842067

R. Fisher, K. Thomenius, R. Wodnicki, R. Thomas, S. Cogan, C. Hazard, W. Lee, D. Mills, B. Khuri-Yakub, A. Ergun, et al, Reconfigurable arrays for portable ultrasound, in Proceedings of IEEE Ultrasonics Symposium, (2005), pp. 495–499

H.M. García-García, V. Klauss, N. Gonzalo, S. Garg, Y. Onuma, C.W. Hamm, W. Wijns, J. Shannon, P.W. Serruys, Relationship between cardiovascular risk factors and biomarkers with necrotic core and atheroma size: a serial intravascular ultrasound radiofrequency data analysis. Int. J. Card. Imaging 28, 695–703 (2012). https://doi.org/10.1007/s10554-011-9882-6

U. Guler, A. Bozkurt, 5G-3 A low-noise front-end circuit for 2D cMUT arrays, in 2006 IEEE Ultrasonics Symposium. Presented at the 2006 IEEE Ultrasonics Symposium, (2006), pp. 689–692. https://doi.org/10.1109/ULTSYM.2006.186

S.R. Heron, R. Wilson, S.A. Shaffer, D.R. Goodlett, J.M. Cooper, Surface acoustic wave nebulization of peptides as a microfluidic Interface for mass spectrometry. Anal. Chem. 82, 3985–3989 (2010). https://doi.org/10.1021/ac100372c

D.A. Horsley, Y. Lu, H.Y. Tang, X. Jiang, B.E. Boser, J.M. Tsai, E.J. Ng, M.J. Daneman, Ultrasonic fingerprint sensor based on a PMUT array bonded to CMOS circuitry, in 2016 IEEE International Ultrasonics Symposium (IUS). Presented at the 2016 IEEE International Ultrasonics Symposium (IUS), (2016), pp. 1–4. https://doi.org/10.1109/ULTSYM.2016.7728817

J.W. Hunt, M. Arditi, F.S. Foster, Ultrasound transducers for pulse-Echo medical imaging. IEEE Trans. Biomed. Eng. BME 30, 453–481 (1983)

Y. Jiang, C. Meggs, T. Button, G. Schiavone, M.P.Y. Desmulliez, Z. Qiu, S. Mahboob, R. McPhillips, C.E.M. Démoré, G. Casey, S. Eljamel, S. Cochran, D.R. Sanmartin, 15 MHz single element ultrasound needle transducers for neurosurgical applications, in 2014 IEEE International Ultrasonics Symposium. Presented at the 2014 IEEE International Ultrasonics Symposium, (2014), pp. 687–690. https://doi.org/10.1109/ULTSYM.2014.0169

S. Kelly, K.M. Harris, E. Berry, J. Hutton, P. Roderick, J. Cullingworth, L. Gathercole, M.A. Smith, A systematic review of the staging performance of endoscopic ultrasound in gastro-oesophageal carcinoma. Gut 49, 534–539 (2001). https://doi.org/10.1136/gut.49.4.534

J.A. Ketterling, O. Aristizabal, D.H. Turnbull, F.L. Lizzi, Design and fabrication of a 40-MHz annular array transducer. Ultrason. Ferroelectr. Freq. Control IEEE Trans. On 52, 672–681 (2005). https://doi.org/10.1109/TUFFC.2005.1428050

I. Kim, H. Kim, F. Griggio, R.L. Tutwiler, T.N. Jackson, S. Trolier-McKinstry, K. Choi, CMOS ultrasound transceiver Chip for high-resolution ultrasonic imaging systems. IEEE Trans. Biomed. Circuits Syst. 3, 293–303 (2009). https://doi.org/10.1109/TBCAS.2009.2023912

R. Krimholtz, D.A. Leedom, G.L. Matthaei, New equivalent circuits for elementary piezoelectric transducers. Electron. Lett. 6, 398–399 (1970)

W.K. Law, L.A. Frizzell, F. Dunn, Determination of the nonlinearity parameter B/a of biological media. Ultrasound Med. Biol. 11, 307–318 (1985)

H.S. Lay, B.F. Cox, M. Sunoqrot, C.E.M. Démoré, I. Näthke, T. Gomez, S. Cochran, Microultrasound characterisation of ex vivo porcine tissue for ultrasound capsule endoscopy. J. Phys. Conf. Ser. 797, 012003 (2017). https://doi.org/10.1088/1742-6596/797/1/012003

H.S. Lay, G.R. Lockwood, A low cost receive beamformer for a high frequency annular array, in Ultrasonics Symposium (IUS), 2011 IEEE International. Presented at the Ultrasonics Symposium (IUS), 2011 IEEE International, (2011), pp. 462–465. https://doi.org/10.1109/ULTSYM.2011.0111

H.S. Lay, Y. Qiu, M. Al-Rawhani, J. Beeley, R. Poltarjonoks, V. Seetohul, D. Cumming, S. Cochran, G. Cummins, M.P.Y. Desmulliez, M. Wallace, S. Trolier-McKinstry, R. McPhillips, B.F. Cox, C.E.M. Demore, Progress towards a multi-modal capsule endoscopy device featuring microultrasound imaging, in 2016 IEEE International Ultrasonics Symposium (IUS). Presented at the 2016 IEEE International Ultrasonics Symposium (IUS), (2016), pp. 1–4. https://doi.org/10.1109/ULTSYM.2016.7728692

J. Lim, C. Tekes, F.L. Degertekin, M. Ghovanloo, Towards a reduced-wire Interface for CMUT-based intravascular ultrasound imaging systems. IEEE Trans. Biomed. Circuits Syst., 1–11 (2016). https://doi.org/10.1109/TBCAS.2016.2592525

S.-C.S. Lin, X. Mao, T. Jun Huang, Surface acoustic wave (SAW) acoustophoresis: Now and beyond. Lab Chip 12, 2766–2770 (2012). https://doi.org/10.1039/C2LC90076A

G.R. Lockwood, J.W. Hunt, F.S. Foster, The design of protection circuitry for high-frequency ultrasound imaging systems. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 38, 48–55 (1991). https://doi.org/10.1109/58.67834

G.R. Lockwood, D.H. Turnball, D.A. Christopher, F.S. Foster, Beyond 30 MHz [applications of high-frequency ultrasound imaging]. IEEE Eng. Med. Biol. Mag. 15, 60–71 (1996). https://doi.org/10.1109/51.544513

Y. Lu, H.Y. Tang, S. Fung, B.E. Boser, D.A. Horsley, Short-range and high-resolution ultrasound imaging using an 8 MHz aluminum nitride PMUT array, in 2015 28th IEEE International Conference on Micro Electro Mechanical Systems (MEMS). Presented at the 2015 28th IEEE International Conference on Micro Electro Mechanical Systems (MEMS), (2015), pp. 140–143. https://doi.org/10.1109/MEMSYS.2015.7050905

R.G. Maev, E.Y. Bakulin, E.Y. Maeva, F.M. Severin, High resolution ultrasonic method for 3D fingerprint representation in biometrics, in Acoustical Imaging, (Springer, Dordrecht, 2008), pp. 279–285

S. Michau, P. Mauchamp, R. Dufait, Piezocomposite 30MHz linear array for medical imaging: design challenges and performances evaluation of a 128 elements array, in Ultrasonics Symposium, 2004 IEEE. Presented at the Ultrasonics Symposium, 2004 IEEE, vol. 2 (2004), pp. 898–901. https://doi.org/10.1109/ULTSYM.2004.1417880

I.G. Mina, H. Kim, I. Kim, S.K. Park, K. Choi, T.N. Jackson, R.L. Tutwiler, S. Trolier-McKinstry, High frequency piezoelectric MEMS ultrasound transducers. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 54, 2422–2430 (2007). https://doi.org/10.1109/TUFFC.2007.555

T.A. Nappholz, H.L. Valenta Jr., S.M. Maas, K. Koestner, Method and apparatus for chronically monitoring the hemodynamic state of a patient using doppler ultrasound. US5188106 A. (1993)

C.G. Oakley, Calculation of ultrasonic transducer signal-to-noise ratios using the KLM model. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 44, 1018–1026 (1997). https://doi.org/10.1109/58.655627

M. Pertijs, C. Chen, S. Raghunathan, Z. Yu, M. ShabaniMotlagh, Z. Chen, Z. y. Chang, E. Noothout, S. Blaak, J. Ponte, C. Prins, H. Bosch, M. Verweij, N. de Jong, Low-power receive electronics for a miniature real-time 3D ultrasound probe, in 2015 6th International Workshop on Advances in Sensors and Interfaces (IWASI). Presented at the 2015 6th International Workshop on Advances in Sensors and Interfaces (IWASI), (2015), pp. 235–238. https://doi.org/10.1109/IWASI.2015.7184963

V.C. Protopappas, D.A. Baga, D.I. Fotiadis, A.C. Likas, A.A. Papachristos, K.N. Malizos, An ultrasound wearable system for the monitoring and acceleration of fracture healing in long bones. IEEE Trans. Biomed. Eng. 52, 1597–1608 (2005). https://doi.org/10.1109/TBME.2005.851507

Y. Qiu, J.V. Gigliotti, M. Wallace, F. Griggio, C.E.M. Demore, S. Cochran, S. Trolier-McKinstry, Piezoelectric micromachined ultrasound transducer (PMUT) arrays for integrated sensing, actuation and imaging. Sensors 15, 8020–8041 (2015). https://doi.org/10.3390/s150408020

S.B. Raghunathan, D. Bera, C. Chen, S. Blaak, C. Prins, M.A.P. Pertijs, J.G. Bosch, N. de Jong, M.D. Verweij, Design of a miniature ultrasound probe for 3D transesophageal echocardiography, in 2014 IEEE International Ultrasonics Symposium. Presented at the 2014 IEEE International Ultrasonics Symposium, (2014), pp. 2091–2094. https://doi.org/10.1109/ULTSYM.2014.0521

K. Ranganathan, M.K. Santy, T.N. Blalock, J.A. Hossack, W.F. Walker, Direct sampled I/Q beamforming for compact and very low-cost ultrasound imaging. Ultrason. Ferroelectr. Freq. Control IEEE Trans. On 51, 1082–1094 (2004). https://doi.org/10.1109/TUFFC.2004.1334841

N.K. Ratha, V. Govindaraju, Advances in Biometrics: Sensors, Algorithms and Systems (Springer Science & Business Media, London, 2008)

M. Sautto, D. Leone, A. Savoia, D. Ghisu, F. Quaglia, G. Caliano, A. Mazzanti, A CMUT transceiver front-end with 100-V TX driver and 1-mW low-noise capacitive feedback RX amplifier in BCD-SOI technology, in ESSCIRC 2014 – 40th European Solid State Circuits Conference (ESSCIRC). Presented at the ESSCIRC 2014 – 40th European Solid State Circuits Conference (ESSCIRC), (2014), pp. 407–410. https://doi.org/10.1109/ESSCIRC.2014.6942108

R.M. Schmitt, W.G. Scott, R.D. Irving, J. Arnold, C. Bardons, D. Halpert, L. Parker, Ultrasonic imaging of fingerprints using acoustical impediography, in IEEE Ultrasonics Symposium, 2004. Presented at the IEEE Ultrasonics Symposium, 2004, vol. 1 (2004), pp. 680–688. https://doi.org/10.1109/ULTSYM.2004.1417814

S. Sharma, T. Ytterdal, Low noise front-end amplifier design for medical ultrasound imaging applications, in 2012 IEEE/IFIP 20th International Conference on VLSI and System-on-Chip (VLSI-SoC). Presented at the 2012 IEEE/IFIP 20th International Conference on VLSI and System-on-Chip (VLSI-SoC), (2012), pp. 12–17. https://doi.org/10.1109/VLSI-SoC.2012.7332069

K.K. Shung, Diagnostic Ultrasound: Imaging and Blood Flow Measurements (Taylor and Francis, Boca Raton, 2006)

E.A. Simpson, H.S. Lay, G.R. Lockwood, Novel interconnection and fabrication method for high-frequency ultrasound arrays, (2010), pp. 76290P–76290P–13. https://doi.org/10.1117/12.845383

J. Song, S. Jung, Y. Kim, K. Cho, B. Kim, S. Lee, J. Na, I. Yang, O. Kwon, D. Kim, Reconfigurable 2D cMUT-ASIC arrays for 3D ultrasound image, (2012), pp. 83201A–83201A–6. https://doi.org/10.1117/12.911263

T.L. Szabo, Diagnostic Ultrasound Imaging: Inside Out (Academic Press, Burlington, 2004)

H. Tang, Y. Lu, S. Fung, J.M. Tsai, M. Daneman, D.A. Horsley, B.E. Boser, Pulse-echo ultrasonic fingerprint sensor on a chip, in 2015 Transducers – 2015 18th International Conference on Solid-State Sensors, Actuators and Microsystems (TRANSDUCERS). Presented at the 2015 Transducers – 2015 18th International Conference on Solid-State Sensors, Actuators and Microsystems (TRANSDUCERS), (2015a), pp. 674–677. https://doi.org/10.1109/TRANSDUCERS.2015.7181013

H.Y. Tang, D. Seo, U. Singhal, X. Li, M.M. Maharbiz, E. Alon, B.E. Boser, Miniaturizing ultrasonic system for portable health care and fitness. IEEE Trans. Biomed. Circuits Syst. 9, 767–776 (2015b). https://doi.org/10.1109/TBCAS.2015.2508439

K.E. Thomenius, Evolution of ultrasound beamformers, in Ultrasonics Symposium, 1996. Proceedings., 1996 IEEE. Presented at the Ultrasonics Symposium, 1996. Proceedings, 1996 IEEE, vol. 2 (1996), pp. 1615–1622. https://doi.org/10.1109/ULTSYM.1996.584398

J. Tillak, J. Yoo, A 23 uW digitally controlled pMUT interface circuit for Doppler ultrasound Imaging, in 2015 IEEE International Symposium on Circuits and Systems (ISCAS). Presented at the 2015 IEEE International Symposium on Circuits and Systems (ISCAS), (2015), pp. 1618–1621. https://doi.org/10.1109/ISCAS.2015.7168959

Transesophageal Echocardiography (TEE) [WWW Document], (2017), URL http://www.heart.org/HEARTORG/Conditions/HeartAttack/SymptomsDiagnosisofHeartAttack/Transesophageal-Echocardiography-TEE_UCM_441655_Article.jsp#.WH9SCRuLSUk. Accessed 18 Jan 2017

Ultrasound | Analog Devices [WWW Document], (2016), URL http://www.analog.com/en/products/application-specific/medical/ultrasound.html. Accessed 19 Dec 2016

Ultrasound Imaging – Maxim [WWW Document], (2017), URL https://www.maximintegrated.com/en/markets/healthcare/imaging.html. Accessed 10 Jan 2017

D. Vilkomerson, T. Chilipka, Implantable Doppler system for self-monitoring vascular grafts, in IEEE Ultrasonics Symposium, 2004. Presented at the IEEE Ultrasonics Symposium, 2004, vol. 1 (2004), pp. 461–465. https://doi.org/10.1109/ULTSYM.2004.1417762

R.M. Vlad, S. Brand, A. Giles, M.C. Kolios, G.J. Czarnota, Quantitative ultrasound characterization of responses to radiotherapy in cancer mouse models. Clin. Cancer Res. 15, 2067–2075 (2009). https://doi.org/10.1158/1078-0432.CCR-08-1970

P.N. Wells, Advances in ultrasound: from microscanning to telerobotics. Br. J. Radiol. 73, 1138–1147 (2000)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2018 Springer International Publishing AG

About this chapter

Cite this chapter

Lay, H.S., Cochran, S. (2018). Circuits and Systems for Biosensing with Microultrasound. In: Mitra, S., Cumming, D. (eds) CMOS Circuits for Biological Sensing and Processing. Springer, Cham. https://doi.org/10.1007/978-3-319-67723-1_8

Download citation

DOI: https://doi.org/10.1007/978-3-319-67723-1_8

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-67722-4

Online ISBN: 978-3-319-67723-1

eBook Packages: EngineeringEngineering (R0)