Abstract

In Portugal, as in Europe, there are several different technologies to sort and treat the different components of municipal solid waste (MSW). For treatment of the organic fraction of MSW (OFMSW) there are also several technological options. The Anaerobic Digestion (AD) technology is a well-known solution in Portugal, with several AD plants working at their full capacity. However, the technology between plants differs, and with it, its operation, maintenance and biogas production results.

To control and operate an anaerobic digestion process a lot of factors have to be taken into account. As with all biological processes, the optimum conditions are essential. The AD process has a rapid response to any changes, such as changes in the feeding, temperature and O2 addition (sometimes needed in small quantities (less than 1%) to decrease the H2S amount in the digesters). If the feeding stops, for any maintenance of the pumping system or an unforeseen problem, the pH decreases, the volatile fatty acids increase and the biogas production abruptly decreases, also decreasing, if the normal feeding is not restored in a short period, the methane content and increasing the H2S content. This kind of instability, as common as it can be in a plant operation, is highly unfavorable for the process and increases the operating costs by reducing plant revenue.

Other factors, mainly in the pretreatment, have to be considered, such as a good system of glass and grit removal especially in a wet treatment, which will prevent damaged pumps, clogging, and extremely high maintenance costs.

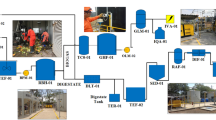

If the AD technology is based on a low solids content feeding, the plant will have a lot of piping and pumps, so the right project calculations for size and capacity are mandatory to decrease the costs. Arranging the different equipment in the plant to decrease the pumping distance will prevent capital costs in pumps and piping and will also prevent difficult clogging situations. To plan and design a simple piping system, with as little curves and short piping as possible, will prevent high maintenance costs and a lot of plant stops due to clogging.

Access provided by CONRICYT-eBooks. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

The construction of Anaerobic Digestion (AD) plants in Portugal comes within the scope of the Decree-Law 178/2006 establishing the PERSU II and Decree-Law n. ° 152/2002 of 23 May, which in Art.7. sets targets for the reduction of biodegradable municipal waste disposed in landfill. PERSU 2020 set a higher target to landfill biodegradable waste deviation with the Decree-Law n° 183/2009, increasing the need for treatment solutions that reduce, reuse and recycle the waste. Fig. 1 explains in a more detailed way the Portuguese situation in 2015.

In Portugal, as in Europe, there are several different technologies to sort and treat the different components of the municipal solid waste (MSW). For the treatment of the organic fraction of MSW (OFMSW) there are also several technological options. The AD technology is a well known solution in Portugal, with several AD Plants working at their full capacity. However, the technology between plants differs, and with it, it’s operation, maintenance, and biogas production results as well.

2 Control Ans Operation of an AD Process

To control and operate an anaerobic digestion process a lot of factors have to be taken into account. As with all biological processes, the optimum conditions are essential. The AD process has a fast response to any changes, such as changes in the feeding, temperature, O2 addition (sometimes needed in small quantities (less than 1%) to decrease the H2S amount in the digesters). If the feeding stops, for any maintenance of the pumping system or an unpredicted problem, the pH decreases, the volatile fatty acids increase and the biogas production abruptly decreases, consequently decreasing the methane content and increasing the H2S content, if the normal feeding is not restored in a short period. This kind of instability, very common in a plant operation, is highly unfavorable for the process and increases the costs of operation by reducing plant revenue.

Other factors, mainly in the pre-treatment have to be considered, namely a good system for the glass and grit removal, especially in the context of wet treatment, which will prevent damaged pumps, clogging, and extremely high maintenance costs.

Additionally, if the AD technology is based on a low solids content feeding, the plant will have a lot of piping and pumps, and being so, the right project calculations for size and capacity are mandatory to decrease the costs. Arranging the several different equipments in the plant to decrease the pumping distance will prevent capital costs in pumps and piping and will also prevent difficult clogging situations. To plan and design a simple piping system, with as little curves and short piping as possible, will prevent high maintenance costs and a lot of plant stopping due to clogging.

Figure 2 shows the Biogas Yeld as function of the Organic Loading Rate (OLR), temperature and different pre-treatments. As observed, plants that treat food waste and source separated MSW show high values of Biogas Yeld in the Anaerobic Digestion Treatment. The thermophilic reactors have also tendency to produce more biogas than the mesophilic digesters, for a similar OLR.

Biogas Yeld as function of OLR, Temperature and Pre-treatments (H. Hartmann, B. K. Ahring, (2006))

If the AD technology is based in a high solids content feeding, the digesters can be smaller but the efficiency of the process may then decrease. Reports about this systems point to a biogas yeld of 0.103–0.147 m3/kg of Volatile Solid (VS) fed. For the cases where AD technology is used as wet systems reports of a biogas yeld of 0.4–0.5 m3/kg VS were observed (see Fig. 2). However, the technologies are completely different and both have several advantages and disadvantages.

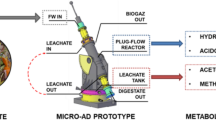

3 The Multi-Staged Anaerobic Digestion

The multi-staged anaerobic digestion must be taken in understanding because of the goal of using more than one reactor. Sometimes these digesters operate in parallel (and are not multi-staged reactors) but single-stage digesters that can exist because of tank size limitations or just to simplify the management. A lot of economical studies have to be made to understand the viability of these systems in each real case study.

The first high-solids content digesters (dry systems) were a type of small landfills, so that resulted in batch systems. This type of system has some advantages, namely a higher possibility of controlling the digesters conditions, with higher biogas production rates. The main disadvantage is the uneven biogas production and the lack of stability of the biomass.

Another very important factor to take into account is the digesters temperature. Two main range of temperatures, thermophilic and mesophilic can be observed in almost every AD Systems. The mesophilic microbes are adapted to roughly 30–40 °C and the thermophilic microbes to 50–60°. The thermophilic system has higher costs of operation, especially a higher energy consumption, but the records found were of a higher biogas yeld content (see Fig. 2), so, the possible revenue of the energy production would be higher, albeit with higher costs of operation and energy consumption.

4 The AD Plant Profits

The AD Plant profits are based on the selling of electrical energy and recycles and on the gate fee. The profits may also include the reduction of landfill deposition, because there is no need to spend due to the waste deviation. In the future, the carbon offset credits should also be taken into consideration. However, an AD Plant has several costs to be taken into account, namely, the electrical energy of the equipment in the plant, the landfill deposition of part of the waste input, the labor costs, the water, the wastewater disposal, the maintenance costs and the financial costs if applicable (Faria T et al. 2013). The thermal energy used in the heating can also be considered a cost because it is energy not sold. The capital cost should also be considered and all the chemical products used in the operation.

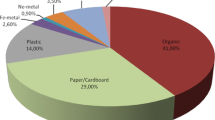

The Digesters performance and cost depends on its configuration and OFMSW source. The biogas yeld of the different technologies vary and there are some factors to take into account, such as the percentage of methane in the biogas (the 50–70% of methane range present in the biogas can mean a totally different energy potential of a biogas volume unit) and the digestibility of the OFMSW. To compare biogas yeld of different technological solutions there is a need for standardized methods of characterization and accounting of organic matter input to the plants and digesters, to understand the efficiency of the pre-treatment and the quality of the process. Fig. 3 explains how the definition of organic matter is important on the overall process.

5 Conclusion

Regarding the state of the art and the potential difficulties coming from the practical applications side, one may conclude that Anaerobic Digestion can be a solution to reduce the biodegradable municipal waste disposed in landfill. However, the costs of its implementation and operation have to be taken into account. The economic viability of these solutions is highly sustained in gate fees, the decrease of landfill deposition cost per ton and energy and recyclables selling market price. So, it’s very important to study its viability before investments are decided, because effects from the behavior of the dynamic market, potentially fluctuating across time and geography. An example: for a developing country, an MT solution can be a solution because it does not need environmental awareness since it treats MSW and there is no investment cost in the waste collection. On the other hand, in a developed country, an organic valorization plant with an upstream automatic sorting can be a valuable solution due to the conditions of the energy selling market since the landfill deposition is expensive.

References

Faria T et al. (2013) Anaerobic digestion of MSW – opportunities and challenges. VIII Jornadas Técnicas Internacionais de Resíduos. Lisboa.

PERSU 2020, Plano Estratégico para os Resíduos Sólidos Urbanos, 2014, MAORT

PERSU II, Plano Estratégico para os Resíduos Sólidos Urbanos, 2007–2016, MAORT, 2007, ISBN: 978-989-8097-01-9

Hartmann, H, Ahring, BK (2006) Strategies for the anaerobic digestion of the organic fraction of municipal solid waste: an overview. Water Science and Technology 53(8):7–22

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2018 Springer International Publishing AG

About this paper

Cite this paper

Moura, I., Pereira, D. (2018). Anaerobic Digestion of MSW: Challenges of a High Cost Technology. In: Dias, A., Salmelin, B., Pereira, D., Dias, M. (eds) Modeling Innovation Sustainability and Technologies. Springer Proceedings in Business and Economics. Springer, Cham. https://doi.org/10.1007/978-3-319-67101-7_22

Download citation

DOI: https://doi.org/10.1007/978-3-319-67101-7_22

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-67100-0

Online ISBN: 978-3-319-67101-7

eBook Packages: Economics and FinanceEconomics and Finance (R0)