Abstract

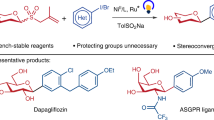

2-Chloro-1,3-dimethylimidazolinium chloride (DMC) and its derivatives are useful for numerous synthetic transformations, which involve selective activation of the anomeric centre of unprotected reducing sugars in water. This chapter summarises research reported to date using DMC and derivatives, such as 2-azido-1,3-dimethylimidazolinium hexafluorophosphate (ADMP). DMC has been successfully employed for the synthesis of glycosyl oxazolines, 1,6-anhydro-, 1-azido-, and a variety of thioglycosides. The use of ADMP allows the one-pot synthesis of glycosyl triazoles in water via the Cu-catalysed azide-alkyne Huisgen cycloaddition reaction. This latter methodology can be applied to a wide variety of carbohydrates and is also amenable to convergent glycopeptide synthesis in which oligosaccharides are directly conjugated to peptides that contain propargyl glycine residues. Such protecting group free methodologies, particularly when applied to complex oligosaccharides isolated from natural sources, may allow ready access to a wide variety of biologically interesting glycoconjugates.

Access provided by CONRICYT-eBooks. Download chapter PDF

Similar content being viewed by others

1 Introduction

Protecting groups are typically unavoidable in synthetic carbohydrate chemistry. However, their use inevitably involves additional synthetic steps, resulting in loss of materials, and the generation of a significant amount of waste; not only chemical waste, but also in terms of cost and time. Thus, there is an increasing need for the development of methods for the synthetic manipulation of carbohydrates that do not involve protecting groups, but yet still furnish the desired products in high yield and with the requisite selectivity.

2 Synthesis of Glycosyl Oxazolines in Water Using DMC

Glycosyl oxazolines have found wide application in carbohydrate chemistry, first in their protected forms as donors for oligosaccharide synthesis [1, 2], and subsequently, and perhaps more importantly as activated donor substrates for the enzymatic synthesis of glycopeptides and glycoproteins [3, 4].

In 2004, Kadokawa et al. [5] came close to developing a useful method for the direct synthesis of glycosyl oxazolines in water when they used a series of carbodiimides to activate the anomeric centre. However, these reactions only afforded the desired products in very low yield (<30%). Even so, the fact that this type of highly selective transformation was possible at all drew the attention of the Glycoscience community.

The dehydrative properties of the reagent, 2-chloro-1,3-dimethylimidazolium chloride 1 (DMC), were originally reported by Isobe and Ishikawa [6, 7]; however these reported transformations were all performed in organic solvents. In 2009, Shoda and co-workers [8] made a significant breakthrough in the field when they reported the use of DMC for the direct synthesis of glycosyl oxazolines from reducing sugars in D2O in high yield (Scheme 1).

Synthesis of glycosyl oxazolines directly from reducing sugars in water by Shoda et al. [8]

Prior to this report, the synthesis of glycosyl oxazolines typically required peracetylated 2-acetamido-2-deoxy sugars to be prepared. These could then be converted to the corresponding oxazolines using Lewis acids, such as ferric(III) chloride, tin(IV) chloride, boron trifluoride, or trimethylsilyl triflate, [9,10,11,12] before the final removal of acetate protecting groups under basic conditions. However, the use of strong Lewis acids can damage glycosidic linkages and, typically in the cases of larger oligosaccharides, may result in the formation complex reaction mixtures and low yields. This report, therefore, represented a significant advance in the production of N-glycan oxazolines, particularly as donor substrates for enzymatic synthesis.

The proposed mechanism [8] of oxazoline formation involves preferential attack of the hemiacetal hydroxyl on DMC; in the case of the β-anomer this yields reactive intermediate 2 (Scheme 2). Intramolecular attack of the 2-acetamido group at the anomeric centre, followed by abstraction of a proton by a suitable base, then affords the oxazoline. The α-imidazolinium intermediate 3 can also be formed by attack of the α-hemiacetal hydroxyl on DMC. However, since 3 cannot directly form an oxazoline it is then probably hydrolysed to regenerate the β-anomer of the free sugar; this β-anomer then follows the reaction pathway via intermediate 2 to the oxazoline product. Although this mechanistic pathway is plausible, Shoda has stated [8] that the intermediacy of a β-glycosyl chloride during the conversion of 3 into the oxazoline product cannot be ruled out.

Proposed mechanism for sugar oxazoline formation using DMC [8]

The use of DMC for the selective activation of reducing sugars in water has subsequently proved pivotal in facilitating the use of glycosyl oxazolines as donors for enzymatic glycosylation reactions catalysed by endo-β-N-acetylglucosaminidases (ENGases), such as those reported by the groups of Fairbanks [13,14,15,16], Wang [17,18,19], and Yamamoto [20,21,22].

Subsequently, Shoda and co-workers [23] reported another method for the direct synthesis of glycosyl oxazolines using the DMC analogue, 2-chloro-1,3-dimethyl-1H-benzimidazol-3-ium chloride 4, (CDMBI) as the dehydrative agent (Fig. 1).

DMC-analogue CDMBI 4, and the urea DMBI 5 formed by its hydrolysis [23]

CDMBI was alleged to be superior to DMC, as it is less hygroscopic and easier to handle, although most applications still use the commercially available DMC for oxazoline formation. Shoda also stated that replacing the imidazolidine ring of DMC with the more electron-rich benzimidazole would reduce the reactivity of the chloroformamidinium group toward nucleophilic attack by water, and that additionally it made the reactive glycosyl-imidazolidinium intermediate more stable. It was also postulated that the introduction of the aromatic ring would also reduce the aqueous solubility of the hydrolysed product, namely the urea 5 (1,3-dimethylbenzimidazol-2-one, DMBI) (Fig. 1). Indeed, when the complex bi-antennary N-glycan decasaccharide 6 (derived from a sialyl glycopeptide isolated from egg yolks [24]) was converted to the corresponding oxazoline 7 using CDMBI 4, DMBI 5 precipitated from the mixture as the reaction proceeded, and was easily removed by filtration (Scheme 3). Moreover, the filtrate containing the oxazoline could then be directly used for a subsequent enzymatic glycosylation of the acceptor p-nitrophenyl 2-acetamido-2-deoxy-β-D-glucopyranoside 8 using the glycosynthase, Endo-M N175Q [21], without the need for further purification or isolation of the oxazoline intermediate.

Enzymatic glycosylation of GlcNAc-β-pNP with the sialoglycan-oxazoline without isolation of the intermediate oxazoline [23]. Reaction conditions: i CDMBI 4, Na3PO4, H2O; ii 8, Endo-M N175Q

3 Synthesis of 1,6-Anhydro Sugars in Water Using DMC

Subsequent to the first report on oxazoline formation, DMC and its derivatives have been employed for the synthesis of a variety of glycosides formed by intercepting the α-imidazolinium intermediate 3 (Scheme 2) with different nucleophiles. In the absence of any external nucleophile, the 6-hydroxyl group may attack the anomeric centre. Thus, Shoda et al. [25] reported the use of DMC for the formation of 1,6-anhydro sugars from unprotected glycopyranoses in water in almost quantitative yield. The DMC procedure mitigated the requirement for the harsh reaction conditions that had previously been used for the synthesis of 1,6-anhydro sugars, such as pyrolysis [26, 27] or thermal degradation [28, 29]. The proposed reaction mechanism is illustrated in Scheme 4, and is similar to that previously suggested [8] for the formation of glycosyl oxazolines. Herein the first step is a nucleophilic attack of the anomeric hydroxyl group of the predominant β-anomer of glucose 9 on DMC 1, giving rise to intermediate 10. Intramolecular attack of the 2-hydroxyl group of 10 at the anomeric carbon affords a 1,2-anhydro intermediate 11, which is subsequently converted to the 1,6-anhydro sugar 12 via intramolecular nucleophilic attack by the 6-hydroxyl group. The α-anomer of glucose 13 also reacts with DMC to give the corresponding α-intermediate 14. Although direct conversion of 14 into the 1,6-anhydro sugar 12 is possible by an attack of the 6-hydroxyl at the anomeric centre, Shoda suggests that in fact 14 is hydrolysed by an attack of water to regenerate β-glucose 9. β-Glucose 9 then follows the above pathway via 11 to give the 1,6-anhydro sugar 12. Evidence for this overall mechanistic pathway, and the requirement for a 1,2-anhydro intermediate such as 11 en route to the 1,6-anhydro sugar, was the fact that the corresponding 1,6-anhydro sugars were not formed when D-mannose, 2-deoxy-D-glucose, and 2-fluoro-2-deoxy-D-glucose were used as substrates.

Proposed mechanism for 1,6-anhydro sugar formation [25]

The published optimised method uses a large excess of triethylamine to drive 1,6-anhydro sugar formation. In cases where other nucleophiles are to be introduced at the anomeric centre, e.g., for glycosyl azide synthesis using DMC (see Sect. 5) [30], fewer equivalents of base are commonly used. However, in these instances, 1,6-anhydro sugar formation can still be an undesired competing side reaction, which reduces the yields of desired products and can be particularly problematic when oligosaccharides, synthesised using multi-step methods and obtained in small quantities, are used. In these cases, 1,6-anhydro sugar formation can typically be minimised by the use of a large excess of the external nucleophile. Alternatively, Shoda has also reported that acetonitrile may be used as a co-solvent to suppress 1,6-anhydro sugar formation [31].

4 Synthesis of Thioglycosides Using DMC

Thioglycosides have found widespread application throughout the carbohydrate field as glycosyl donors for chemical oligosaccharide synthesis [32,33,34,35]. There has also been interest in the synthesis of de-protected thioglycosides as stable analogues of O-glycosides and as potential enzyme inhibitors [36, 37]. The introduction of sulfur at the anomeric centre often involves the reaction of a peracetylated sugar with a thiol in the presence of a Lewis acid [38], or alternatively substitution of a glycosyl halide with a thiolate [39]. In general, these methods require multi-step reaction sequences, involving protection/de-protection strategies, and are usually performed in organic solvents. Although direct methods for the preparation of thioglycosides from hemiacetals have been reported using trifluoroacetic acid as an activator, these reactions gave poor anomeric selectivities and also resulted in the formation of dithioacetal by-products [40, 41].

4.1 Aryl Thioglycosides

In 2009, Tanaka et al. [31] reported a simple method for the direct synthesis of aryl thioglycosides from reducing sugars in an aqueous solvent system using DMC and excess triethylamine (Scheme 5).

Synthesis of aryl thioglycosides from unprotected sugars [31]. Reaction conditions: i DMC 1, R-SH, Et3N, H2O/MeCN

The use of benzenethiol, p-toluenethiol, and 4-methoxybenzenethiol as the thiol component afforded the corresponding aryl thioglycosides as mixtures of anomers, in high yield. However, when 4-nitrobenzenethiol was reacted with D-glucose and DMC, the corresponding thioglycoside product was formed exclusively as the β-anomer, in 90% yield. It was found that the procedure could also be applied to disaccharides, and the corresponding products were formed in quantitative yield, and as exclusively the β-anomer.

4.2 2-Pyridyl 1-Thio-Glycosides

Shoda et al. [31, 42] then demonstrated that it was also possible to glycosylate 2-mercaptopyridine 16 with oligosaccharides having an N-acetylglucosamine unit at the reducing end 15 using DMC to give the corresponding 2-pyridylthioglycosides 17 (Scheme 6).

Glycosylation of mercaptopyridine 16 with unprotected sugars using DMC reported Shoda et al. [42] Reaction conditions: i DMC 1, Et3N, H2O/MeCN (4:1), 0 °∁, 1 h

Interestingly, the glycosyl oxazoline 18 was obtained as a by-product from these reactions. However, it was found that treating oxazoline 18 with 1 M HCl led to the opening of the ring and an increased yield of the desired 2-pyridylthioglycoside 17. A plausible mechanism, which explains the formation of both anomers of the 2-pyridylthioglycoside products as well as the oxazoline, was suggested and is shown in Scheme 7. Nucleophilic attack of the β-hemiacetal of 19 on DMC affords 20, which may then cyclise to give the oxazolinium intermediate 21. Attack on intermediate 21 by mercaptopyridine (PySH) will yield the β-2-pyridylthioglycoside 22. However, if the proton on the nitrogen atom of 21 is abstracted by a base, the intermediate will be converted to the corresponding oxazoline 18, which is itself unreactive towards nucleophilic opening. The addition of acid to oxazoline 18 leads to the re-protonation of the nitrogen to regenerate 21, which can subsequently react with mercaptopyridine to give 22. Alternatively, imidazolidinium intermediate 20 can react directly with mercaptopyridine to give the α-2-pyridylthioglycoside 23.

Proposed mechanism for 2-pyridylthioglycoside formation using PySH and DMC [42]

The α-anomer of the starting material 24 can also react with DMC to give intermediate 25, which can be directly attacked by mercaptopyridine to give the β-2-pyridylthioglycoside 22.

4.3 4-Methyl-7-Thioumbelliferyl-Labelled Glycosides (MUS-Labelled Glycosides)

There is a growing need to develop quantitative ways to label sugars with chromophores. The most common current method of labelling is reductive animation, in which an oligosaccharide is reacted with an amine containing the chromophore, and the ensuing imine is then reduced by a source of hydride [43]. However, sugars labelled in this manner contain an open-chain 1-aminoalditol moiety, essentially rendering the reducing end inert for further useful transformations. This ring opening also reduces the structural relevance of that part of the oligosaccharide, for example with respect to binding or conformational studies. Furthermore, the conversion of 1-aminoalditols back into reducing sugars requires harsh conditions, such as the use of hydrogen peroxide [44, 45]. A method for introducing a detectable chromophore that could also be easily detached would, therefore, be highly advantageous.

In 2013, Shoda et al. [46] reported the direct introduction of 4-methyl-7-thioumbelliferone 26 (MUS) at the anomeric centre of monosaccharides and at the reducing terminus of oligosaccharides using DMC activation (Scheme 8). The fluorescence spectrum of the MUS-labelled glycosides produced indicated that the labelled derivatives showed a high sensitivity for fluorescence detection based on the maximum wavelengths for excitation and emission at 330 and 395 nm, respectively.

Synthesis of MUS-labelled sugars using DMC by Shoda et al. [46]. Reaction conditions: i DMC 1, Et3N, H2O/MeCN (1:1), 0 °∁, 1.5 h

The yields of the MUS-sugars made by this DMC labelling method were sufficiently high to suggest its application in quantitative studies. Indeed, analysis of a mixture of laminari-oligosaccharides of known composition, which were then modified by both MUS-labelling and pyridylamination, showed very similar quantitative values (Table 1). The MUS-glycosides were also easily de-protected by conventional halosuccinimide-mediated thioglycoside activation (e.g. N-bromo, N-chloro-, and N-iodosuccinimide) to re-form the corresponding reducing sugars, which could then be used for further functionalisation; a significant advantage compared to the pyridylamination labelling method.

4.4 Glycopolymerisation

Although the binding of carbohydrates to proteins is a fundamental process, with widespread importance throughout Biology, it is now appreciated that the majority of carbohydrate–protein interactions are of low affinity. Nature has compensated for this apparent paradox by the use of multivalent receptor-ligand presentation, which amplifies the affinity of single interactions. It is fair to say that all aspects of this so-called ‘glycocluster effect’ [47, 48] are not yet completely understood, although detailed discussions and theories have been presented [49, 50]. Despite shortcomings in our understanding, there have been many reports on the design and production of synthetic glycoclusters, such as glycopolymers [51], glycodendrimers [52], and glyconanoparticles [53]. Many of these synthetic constructs have demonstrated an amplification in carbohydrate-mediated binding, in a similar manner to that achieved by multivalent carbohydrate presentations of natural glycopeptides [54] and glycoproteins [55].

The preparation of glycopolymers often requires laborious, multi-step procedures involving protection and de-protection of a saccharide and which must also include the introduction of a polymerizable group, such as vinyl or norbornene, at the anomeric centre [56, 57]. Only after multiple synthetic steps can the resulting glycomonomers be used in a polymerization reaction. Clearly, more efficient synthetic methodologies for the preparation of glycomonomers would be advantageous.

In 2014, Tanaka et al. [58] reported a one-pot method for the production of glycomonomers directly from unprotected sugars, by the DMC-mediated synthesis of 4-aminophenyl 1-thio-glycosides in water in the presence of triethylamine, and their subsequent acrylamidation (Scheme 9).

One-pot synthesis of glycomonomers [58]. Reaction conditions: i DMC 1, HS–C6H4–NH2, Et3N, H2O/MeCN; ii acryloyl chloride, Et3N, H2O/THF

These acylamide containing glycomonomers were then subjected to reversible addition-fragmentation chain transfer (RAFT) living radical polymerisation to give glycopolymers, which were subsequently immobilised onto gold nanoparticles for investigations into glycocluster effects.

4.5 S-Linked Glycopeptides

S-Linked peptide and protein glycosylation, where the anomeric oxygen of O-linked glycosides has been replaced by sulfur, has attracted a significant amount of interest from the Glycoscience community [59,60,61]. S-Linked glycopeptides are well known for their functional surrogacy, in addition to their chemical and biological stability as compared to their O-linked counterparts, especially towards glycosidase-catalysed cleavage [62].

S-Linked glycopeptides can be accessed by several strategies. The most common involve either conjugate addition or nucleophilic substitution reactions, with a glycosyl thiol acting as the nucleophile [63,64,65,66]. However, more recent approaches, such as free radical thiol-ene ‘Click’ reactions [67], desulfurative rearrangements [68], and the opening of 1,6-anhydrosugars [69], are alternatives that may possess certain advantages. Nevertheless, all of these methods still require multi-step methodologies in order to prepare the required glycosyl thiol.

Winssinger et al. [70] recently reported the use of DMC for the solid phase synthesis of S-linked glycopeptides. By using a H2O/dioxane solvent mixture and cooling to −10 °C, they demonstrated that unprotected sugars could be ‘pre-activated’ by DMC, and found the glycosyl-imidazolinium intermediate that was formed was stable for up to 1 h. The addition of a polymer-bound peptide containing a thiol to the reaction mixture during that time period then led to the formation of the desired polymer-bound S-linked glycopeptide 27 (Scheme 10).

Glycosylation of a thiol-containing resin with D-glucose using the DMC methodology [70]. Reaction conditions: i DMC 1, Et3N, H2O/dioxane (1:1), −10 °∁; ii RSH

An attempt was also made to glycosylate a polymer-bound tripeptide containing cysteine (Fmoc-Cys-Phe-Phe-Rink) with various mono- and disaccharides. Interestingly, direct reaction with D-glucose with DMC in the presence of the tripeptide 28 (i.e. without the pre-activation process) led to the exclusive formation of the thioimidazolidinium by-product 29 (Scheme 11a). However, when the conditions previously identified for pre-activation were used, the desired glycopeptide 30 was obtained in >90% yield (Scheme 11b).

Solid phase S-glycosylation of a resin-bound tripeptide 28 by Winssinger et al. [70]. Reaction conditions: 28, DMC 1, Et3N, H2O/dioxane (1:1), −10 °∁; ii DMC 1, Et3N, H2O/dioxane, −10 °∁, 15 min; iii 28

The process was applied to other monosaccharides (D-galactose, D-mannose, L-fucose) and also to disaccharides (lactose, mellibiose, and Galα(1 → 4)Glc), though the yields were lower in the cases of the disaccharides. An elegant method, involving an iterative addition strategy, was found to increase efficiency of glycopeptide formation, and led to conversions to the desired product of >99%. The process was then exemplified by the solid phase synthesis of an analogue of the repeat unit of the cancer-associated MUC1 glycopeptide, in which the two natural O-linked carbohydrates sites were replaced with S-linked glycans.

5 Synthesis of Glycosyl Azides in Water Using DMC

Glycosyl azides are highly useful synthetic intermediates in sugar chemistry [71]. The traditional method for their formation involves at least three or four steps, invariably involving protecting group manipulations, to furnish the desired de-protected product. For example, a typical sequence involves the conversion of the sugar, e.g. N-acetyl-D-glucosamine 31, into a protected glycosyl halide 32, followed by nucleophilic displacement of the anomeric leaving group by azide to give the glycosyl azide 33 (Scheme 12). Finally, the ester protecting groups are removed, for example by Zemplén de-acetylation, to give the de-protected glycosyl azide 34.

In addition to the inherent inefficiency of these multi-step reaction sequences, this type of synthetic route can also occasionally become problematic when applied to higher oligosaccharides due to cleavage of inter-glycosidic bonds during the synthetic pathway.

Following on from earlier studies in the Shoda group, Tanaka et al. [30] reported that glycosyl azides of monosaccharides could be formed directly when unprotected sugars were treated with excess DMC in water in the presence of a large excess (typically 10 equivalents of each) of azide and triethylamine (Scheme 13).

Direct synthesis of glycosyl azides from unprotected sugars using DMC [30]. Reaction conditions: i DMC 1, NaN3, base, H2O

Interestingly, when the reaction was applied to disaccharides using triethylamine as the base, 1,6-anhydro sugars were formed as by-products. It was suggested that, for some reason, intramolecular nucleophilic attack of the 6-hydroxy group at the anomeric centre was increased in the presence of triethylamine [30]. A screen of various other bases was performed, and it was found that the use of either N,N-diisopropylethylamine (Hunig’s base, DIPEA) or 2,6-lutidine led to reduced formation of the 1,6-anhydro derivative, presumably an effect that was related to their greater steric bulk. The use of 2,6-lutidine as the base was also found to be essential in the case of 2-acetamido sugars to avoid significant oxazoline formation.

Tanaka et al. [30] then demonstrated that the reaction could be applied to larger oligosaccharides, including a sialic acid terminated complex biantennary decasaccharide, which was converted to the corresponding glycosyl azide in 87% yield, though this reaction did require the use of 20 equivalents of DMC and 40 equivalents of 2,6- lutidine. Glycosyl azides were generally produced stereoselectively as the 1,2-trans glycosides, except in the cases of 2-deoxy sugars, which were formed as anomeric mixtures. To date, a detailed mechanism has not been presented, though the results suggest that reaction of sugars containing a 2-hydroxy group probably proceeds via 1,2-anhydro sugar intermediates.

6 Synthesis of Glycosyl Triazoles in a One-Pot Reaction

The original Shoda method [30] for glycosyl azide synthesis, like all DMC activation procedures, potentially generates up to two equivalents of HCl per equivalent of DMC used; one equivalent is produced from de-protonation of the anomeric hydroxyl group, and a second one may additionally be produced from water in the case of a hydrolysis reaction. This production of acid during the course of the reaction necessitates the use of excessive amounts of triethylamine. Furthermore, the use of a large excess of azide is also required.

As an alternative approach which would avoid the requirement for this large excess of reagents, we envisaged replacement of the chlorine on the dimethylimidazolinium ring of DMC with azide; such a reagent should still be able to activate a reducing sugar, would only result in the formation of one equivalent of acid, and would additionally itself act as the source of azide. 2-Azido-1,3-dimethylimidazolinium hexafluorophosphate (ADMP), has been previously used as an efficient agent for diazo-transfers [72,73,74,75], migratory aminations [76, 77], and azide transfer [78] reactions. Although ADMP contains a significant amount of nitrogen, impact sensitivity and friction sensitivity tests have demonstrated that it is not explosive [73], making it in fact safer to handle than sodium azide. Additionally unlike DMC, which is hygroscopic [23, 73], ADMP is isolated as a stable crystalline solid and is easily handled. Although, unlike DMC, it is not currently commercially available, ADMP can be very easily synthesised, for example following procedures originally reported by Kitamura et al. [72, 79] (Scheme 14), simply by conversion of DMC 1 to the hexafluorophosphate salt 35, and then treatment with sodium azide to give ADMP 36.

In 2014, we [80] reported an alternative method for the synthesis of glycosyl azides in water. N-Acetylglucosamine was reacted with ADMP 36 and triethylamine in a D2O/MeCN (4:1) solvent mixture to give the glycosyl azide 33, as well as oxazoline 37 (Scheme 15). The use of D2O as solvent, as first reported by Shoda in the original oxazoline formation study [8], resulted in higher yields of products, presumably due to reduced rates of competitive solvent-mediated hydrolysis.

Reaction of GlcNAc with ADMP to yield glycosyl azide 33 and oxazoline 37 [80]. Reaction conditions: i ADMP 36, Et3N, D2O/MeCN (4:1), 0 °C

However, applying the idea reported by Shoda et al. [42] that the subsequent addition of acid would result in oxazoline ring opening, we found that the desired azide 33 was obtained as the sole reaction product when the crude reaction mixture was simply acidified with 1 M aqueous HCl.

Glycosyl azides are obvious substrates for further elaboration by the modified Huisgen cycloaddition [81, 82], the most well known ‘Click’ reaction. This high yielding transformation may be performed in water, leading to numerous applications, as reaction conditions are compatible with biological systems. In the carbohydrate field, ‘Click chemistry’ has already been applied to the synthesis of a wide range of sugar derivatives [83] having interesting biological properties [84], including inhibitory activity against glycosidases [85,86,87,88,89,90] and glycosyltransferases [91]. The development of a one-pot process for glycosyl azide and then triazole formation by Click reaction with an alkyne was, therefore, an obvious avenue for investigation.

We found that after the formation of the glycosyl azide was complete, the addition of propargyl alcohol, CuSO4·5H2O, and L-ascorbic acid, and then heating at 50 °C for 14 h, led to the formation of the glycosyl triazole 38 in excellent yield and with complete stereoselectivity; the 1,2-trans glycosyl triazole being formed in all cases (Scheme 16). This procedure was then applied to a variety of sugars ranging from in size from mono- to trisaccharides [80]. In all cases, the use of D2O as co-solvent led to a variable, but minor, the amount of deuterium incorporation into the triazole ring during the course of the reaction.

Direct synthesis of glycosyl triazoles from reducing sugars in water by Fairbanks et al. [80]. Reaction conditions: i (1) ADMP 36, Et3N, D2O/MeCN (4:1), 0 °C, 3 h, then add propargyl alcohol, CuSO4·5H2O, L-ascorbic acid, 50 °C for 14 h

The generality of the one-pot process with respect to the alkyne was explored. The reaction was found to be widely applicable, including with interesting and potentially biologically relevant substrates such as propargyl glycine. All alkynes investigated were successfully Clicked with monosaccharides, and products formed in high yield and with complete stereoselectivity. The only limitation appeared to be in terms of the solubility of the alkyne-coupling partner in the aqueous reaction medium. The one-pot Click reaction also allowed the direct conjugation of reducing sugars to a variety of other carbohydrates which themselves contained an alkyne functionality, giving rise to a variety of di-, tri- and pentasaccharide mimics. All reactions were high yielding and completely stereoselective [80].

Click chemistry has previously been applied to access different glycopeptides, [92, 93] and also protein scaffolds decorated with oligosaccharides [94]. However, reported procedures require multiple protecting group manipulations. In terms of a biologically interesting application, glycosylated versions of the tandem repeat domain of the cancer-associated mucin MUC1 [95, 96] have shown potential as components of synthetic anti-cancer vaccines [97, 98]. A further exemplification of the one-pot azide/Click reaction, we, therefore, conjugated a variety of sugars to two synthetic MUC1 peptides that incorporated propargyl glycine (Pra) residues. Conversion of GalNAc to its azide using ADMP and then direct reaction with peptides 39 and 40, comprising one and two propargyl glycines, respectively, in the presence of CuSO4·5H2O, gave the corresponding glycopeptides 41 and 42 in good yield (Scheme 17).

Similarly tetrasaccharide 43 [99], which corresponds to a core region of N-glycans, was also directly reacted with peptide 39 and gave glycopeptide 44 in 42% yield (Scheme 18).

Reaction of tetrasaccharide 43 with 10-mer 39 by Fairbanks et al. [80]. Reaction conditions: i ADMP, Et3N, D2O, MeCN, 0 °C, 3 h, then add 10-mer 39, CuSO4·5H2O, L-ascorbic acid, and heat to 50 °C for 14 h

As a final example of the utility of the method, the complex biantennary N-glycan 6 decasaccharide [21, 100] was converted to the glycosyl azide using ADMP, and then directly reacted with peptide 39 in the presence of CuSO4·5H2O to furnish glycopeptide 45 in 42% yield (Scheme 19).

Conjugation of decasaccharide 6 to 10-mer 45 by Fairbanks et al. [80]. Reaction conditions: i 6, ADMP, Et3N, D2O, MeCN, 0 °C, 3 h, then add 10-mer 39, CuSO4·5H2O, L-ascorbic acid, and heat to 50 °C for 14 h

7 Conclusion

Traditional methods of accessing glycoconjugates typically involve multi-step syntheses and require complex and protracted protecting group strategies. These methods are generally technically demanding, inefficient, expensive, and the production of significant amounts of the target material is usually logistically difficult to achieve.

Since the initial report by Shoda and co-workers on the use of 1,3-dimethylimidazolinium chloride (DMC) for the selective conversion of unprotected 2-acetamido sugars to glycosyl oxazolines in water, various synthetic targets have been accessed using this, or related, highly selective activating agent. In particular, selective activation of the anomeric centre under aqueous conditions and direct reaction with a diverse range of nucleophiles allows ready access to a range of glycoconjugates without recourse to any protecting group manipulations. Additionally, the products of nucleophilic substitution at the anomeric centre may be further derivatised in the same reaction vessel, for example by Click chemistry.

As a wide variety of structurally complex reducing oligosaccharides are available from natural sources, protecting group free methods based on DMC and similar activating agents show significant promise for rapid access to a broad range of biologically interesting glycoconjugates.

References

Donohoe TJ, Logan JG, Laffan DDP (2003) Trichloro-oxazolines as activated donors for aminosugar coupling. Org Lett 5:4995–4998

Blatter G, Beau J-M, Jacquinet J-C (1994) The use of 2-deoxy-2-trichloroacetamido-D-glucopyranose derivatives in syntheses of oligosaccharides. Carbohydr Res 260:189–202

Fairbanks AJ (2011) Endohexosaminidase catalysed glycosylation with oxazoline donors: the development of robust biocatalytic methods for synthesis of defined homogeneous glycoconjugates. C R Chim 14:44–58

Fairbanks AJ (2013) Endohexosaminidase-catalyzed synthesis of glycopeptides and proteins. Pure Appl Chem 85:1847–1863

Kadokawa J, Mito M, Takahashi S et al (2004) Direct conversion of 2-Acetamido-2-deoxysugars to 1,2-Oxazoline derivatives by dehydrative cyclization in water. Heterocycles 63:1531–1535

Isobe T, Ishikawa T (1999) 2-Chloro-1,3-dimethylimidazolinium chloride. 2. Its application to the construction of heterocycles through dehydration reactions. J Org Chem 64:6989–6992

Isobe T, Ishikawa T (1999) 2-Chloro-1,3-dimethylimidazolinium chloride. 1. A powerful dehydrating equivalent to DCC. J Org Chem 64:6984–6988

Noguchi M, Tanaka T, Gyakushi H et al (2009) Efficient synthesis of sugar oxazolines from unprotected N-acetyl-2-amino sugars by using chloroformamidinium reagent in water. J Org Chem 74:2210–2212

Matta KL, Johnson EA, Barlow JJ (1973) A simple method for the synthesis of 2-acetamido-2-deoxy-β-D-galactopyranosides. Carbohydr Res 26:215–218

Srivastava VK (1982) A facile synthesis of 2-methyl-(3,4,6-tri-O-acetyl-1,2-dideoxy-α-D-glucopyrano)-[2,1-e]-2-oxazoline. Carbohydr Res 103:286–292

Nakabayashi S, Warren CD, Jeanloz RW (1986) A new procedure for the preparation of oligosaccharide oxazolines. Carbohydr Res 150:c7–c10

Colon M, Staveski MM, Davis JT (1991) Mild conditions for the preparation of high-mannose oligosaccharide oxazolines: entry point for β-glycoside and neoglycoprotein syntheses. Tetrahedron Lett 32:4447–4450

Kowalczyk R, Brimble MA, Tomabechi Y et al (2014) Convergent chemoenzymatic synthesis of a library of glycosylated analogues of pramlintide: structure–activity relationships for amylin receptor agonism. Org Biomol Chem 12:8142–8151

McIntosh JD, Brimble MA, Brooks AES et al (2015) Convergent chemo-enzymatic synthesis of mannosylated glycopeptides; targeting of putative vaccine candidates to antigen presenting cells. Chem Sci 6:4636–4642

Tomabechi Y, Krippner G, Rendle PM et al (2013) Glycosylation of pramlintide: synthetic glycopeptides that display in vitro and in vivo activities as amylin receptor agonists. Chem Eur J 19:15084–15088

Tomabechi Y, Squire MA, Fairbanks AJ (2014) Endo-β-N-acetylglucosaminidase catalysed glycosylation: tolerance of enzymes to structural variation of the glycosyl amino acid acceptor. Org Biomol Chem 12:942–955

Lomino JV, Naegeli A, Orwenyo J et al (2013) A two-step enzymatic glycosylation of polypeptides with complex N-glycans. Bioorg Med Chem 21:2262–2270

Orwenyo J, Huang W, Wang L-X (2013) Chemoenzymatic synthesis and lectin recognition of a selectively fluorinated glycoprotein. Bioorg Med Chem 21:4768–4777

Smith EL, Giddens JP, Iavarone AT et al (2014) Chemoenzymatic Fc glycosylation via engineered aldehyde tags. Bioconjug Chem 25:788–795

Umekawa M, Huang W, Li B et al (2008) Mutants of mucor hiemalis endo-β-N-acetylglucosaminidase show enhanced transglycosylation and glycosynthase-like activities. J Biol Chem 283:4469–4479

Umekawa M, Higashiyama T, Koga Y et al (2010) Efficient transfer of sialo-oligosaccharide onto proteins by combined use of a glycosynthase-like mutant of Mucor hiemalis endoglycosidase and synthetic sialo-complex-type sugar oxazoline. Biochim Biophys Acta Gen Subj 1800:1203–1209

Umekawa M, Li C, Higashiyama T et al (2010) Efficient glycosynthase mutant derived from mucor hiemalis endo-β-N-acetylglucosaminidase capable of transferring oligosaccharide from both sugar oxazoline and natural N-glycan. J Biol Chem 285:511–521

Noguchi M, Fujieda T, Huang WC et al (2012) A practical one-step synthesis of 1,2-oxazoline derivatives from unprotected sugars and its application to chemoenzymatic β-N-acetylglucosaminidation of disialo-oligosaccharide. Helv Chim Acta 95:1928–1936

Sun B, Bao W, Tian X et al (2014) A simplified procedure for gram-scale production of sialylglycopeptide (SGP) from egg yolks and subsequent semi-synthesis of Man3GlcNAc oxazoline. Carbohydr Res 396:62–69

Tanaka T, Huang WC, Noguchi M et al (2009) Direct synthesis of 1,6-anhydro sugars from unprotected glycopyranoses by using 2-chloro-1,3-dimethylimidazolinium chloride. Tetrahedron Lett 50:2154–2157

Köll P, Metzger J (1978) Thermal degradation of cellulose and chitin in supercritical acetone. Angew Chem Int Ed 17:754–755

Miura M, Kaga H, Yoshida T, Ando K (2001) Microwave pyrolysis of cellulosic materials for the production of anhydrosugars. J Wood Sci 47:502–506

Sasaki M, Takahashi K, Haneda Y et al (2008) Thermochemical transformation of glucose to 1,6-anhydroglucose in high-temperature steam. Carbohydr Res 343:848–854

Köll P, Borchers G, Metzger JO (1991) Thermal degradation of chitin and cellulose. J Anal Appl Pyrolysis 19:119–129

Tanaka T, Nagai H, Noguchi M, et al. (2009) One-step conversion of unprotected sugars to β-glycosyl azides using 2-chloroimidazolinium salt in aqueous solution. Chem Commun 3378–3379

Tanaka T, Matsumoto T, Noguchi M et al (2009) Direct Transformation of unprotected sugars to Aryl 1-Thio-β-glycosides in aqueous media using 2-Chloro-1,3-dimethylimidazolinium chloride. Chem Lett 38:458–459

Sarkar S, Sucheck SJ (2011) Comparing the use of 2-methylenenapthyl, 4-methoxybenzyl, 3,4-dimethoxybenzyl and 2,4,6-trimethoxybenzyl as N-H protecting groups for p-tolyl 2-acetamido-3,4,6-tri-O-acetyl-2-deoxy-1-thio-β-D-glucosides. Carbohydr Res 346:393–400

Milhomme O, Dhénin SGY, Djedaïni-Pilard F et al (2012) Synthetic studies toward the anthrax tetrasaccharide: alternative synthesis of this antigen. Carbohydr Res 356:115–131

Ennis SC, Fairbanks AJ, Slinn CA et al (2001) N-Iodosuccinimide-mediated intramolecular aglycon delivery. Tetrahedron 57:4221–4230

Yasomanee JP, Demchenko AV (2014) Hydrogen bond mediated aglycone delivery: synthesis of linear and branched α-glucans. Angew Chem Int Ed 53:10453–10456

Rye CS, Withers SG (2004) The synthesis of a novel thio-linked disaccharide of chondroitin as a potential inhibitor of polysaccharide lyases. Carbohydr Res 339:699–703

Rempel BP, Withers SG (2008) Covalent inhibitors of glycosidases and their applications in biochemistry and biology. Glycobiology 18:570–586

Drouin L, Cowley AR, Fairbanks AJ, Thompson AL (2008) 4-Methoxyphenyl 2,3,4,6-tetra-O-acetyl-1-thio-α-D-mannopyranoside. Acta Crystallogr E 64:o1401–o1401

Pei Z, Dong H, Caraballo R, Ramström O (2007) Synthesis of positional thiol analogs of β-D-galactopyranose. Eur J Org Chem 4927–4934

Funabashi M, Arai S, Shinohara M (1999) Novel syntheses of diphenyl and/or trimethylene dithioacetals of mono- and oligosaccharides in 90% trifluoroacetic acid. J Carbohydr Chem 18:333–341

Yanase M, Funabashi M (2000) Stereoselective 1,2-cis-1-thioglycosidation of aldohexoses with tert-butyl mercaptan in 90% trifluoroacetic acid. J Carbohydr Chem 19:53–66

Yoshida N, Noguchi M, Tanaka T et al (2011) Direct dehydrative pyridylthio-glycosidation of unprotected sugars in aqueous media using 2-chloro-1,3-dimethylimidazolinium chloride as a condensing agent. Chem Asian J 6:1876–1885

Hase S (2010) Pyridylamination as a means of analyzing complex sugar chains. Proc Jpn Acad Ser B 86:378–390

Kallin E, Lonn H, Norberg T (1988) Derivatization procedures for reducing oligosaccharides, part 2: chemical transformation of 1-Deoxy-1-(4-trifluoroacetamidophenyl)aminoalditols. Glycoconj J 5:145–150

Suzuki S, Fujimori T, Yodoshi M (2006) Recovery of free oligosaccharides from derivatives labeled by reductive amination. Anal Biochem 354:94–103

Yoshida N, Fujieda T, Kobayashi A et al (2013) Direct introduction of detachable fluorescent tag into oligosaccharides. Chem Lett 42:1038–1039

Lee YC, Lee RT (1995) Carbohydrate-protein interactions: basis of glycobiology. Acc Chem Res 28:321–327

Lundquist JJ, Toone EJ (2002) The cluster glycoside effect. Chem Rev 102:555–578

Lee RT, Lee YC (2000) Affinity enhancement by multivalent lectin-carbohydrate interaction. Glycoconj J 17:543–551

Dam TK, Brewer CF (2010) Multivalent lectin—carbohydrate interactions, pp 139–164

Le Droumaguet B, Nicolas J (2010) Recent advances in the design of bioconjugates from controlled/living radical polymerization. Polym Chem 1:563

Tanaka K, Siwu ERO, Minami K et al (2010) Noninvasive imaging of dendrimer-type N-glycan clusters. In Vivo dynamics dependence on oligosaccharide structure. Angew Chem Int Ed 49:8195–8200

Poonthiyil V, Nagesh PT, Husain M et al (2015) Gold nanoparticles decorated with sialic acid terminated Bi-antennary N-glycans for the detection of influenza virus at nanomolar concentrations. ChemistryOpen 4:708–716

Glunz PW, Hintermann S, Williams LJ et al (2000) Design and synthesis of Le y -bearing glycopeptides that mimic cell surface le y mucin glycoprotein architecture. J Am Chem Soc 122:7273–7279

Yamamoto N, Tanabe Y, Okamoto R et al (2008) Chemical synthesis of a glycoprotein having an intact human complex-type sialyloligosaccharide under the boc and fmoc synthetic strategies. J Am Chem Soc 130:501–510

Roy R, Tropper FD, Romanowska A (1992) New strategy in glycopolymer synthesis. Preparation of antigenic water-soluble poly(acrylamide-co-p-acrylamidophenyl beta-lactoside). Bioconjug Chem 3:256–261

Fraser C, Grubbs RH (1995) Synthesis of glycopolymers of controlled molecular weight by ring-opening metathesis polymerization using well-defined functional group tolerant ruthenium carbene catalysts. Macromolecules 28:7248–7255

Tanaka T, Inoue G, Shoda S-I, Kimura Y (2014) Protecting-group-free synthesis of glycopolymers bearing thioglycosides via one-pot monomer synthesis from free saccharides. J Polym Sci A 1(52):3513–3520

Gamblin DP, Garnier P, van Kasteren S et al (2004) Glyco-SeS: selenenylsulfide-mediated protein glycoconjugation—a new strategy in post-translational modification. Angew Chem Int Ed 116:846–851

Bernardes GJL, Marston JP, Batsanov AS et al. (2007) A trisulfide-linked glycoprotein. Chem Commun 3145–3147

Brimble MA, Edwards PJ, Harris PWR et al (2015) Synthesis of the antimicrobial s-linked glycopeptide, glycocin F. Chem Eur J 21:3556–3561

Driguez H (2001) Thiooligosaccharides as tools for structural biology. ChemBioChem 2:311–318

Levengood MR, van der Donk WA (2007) Dehydroalanine-containing peptides: preparation from phenylselenocysteine and utility in convergent ligation strategies. Nat Protoc 1:3001–3010

Galonić DP, van der Donk WA, Gin DY (2003) Oligosaccharide-peptide ligation of glycosyl thiolates with dehydropeptides: synthesis of S-linked mucin-related glycopeptide conjugates. Chem Eur J 9:5997–6006

Thayer DA, Yu HN, Galan MC, Wong C-H (2005) A general strategy toward S-linked glycopeptides. Angew Chem Int Ed 44:4596–4599

Bernardes GJL, Grayson EJ, Thompson S et al (2008) From disulfide- to thioether-linked glycoproteins. Angew Chem Int Ed 47:2244–2247

Dondoni A, Massi A, Nanni P, Roda A (2009) A new ligation strategy for peptide and protein glycosylation: photoinduced thiol-ene coupling. Chem Eur J 15:11444–11449

Crich D, Yang F (2008) Synthesis of neoglycoconjugates by the desulfurative rearrangement of allylic disulfides. J Org Chem 73:7017–7027

Zhu X, Dere RT, Jiang J et al (2011) Synthesis of α-glycosyl thiols by stereospecific ring-opening of 1,6-anhydrosugars. J Org Chem 76:10187–10197

Novoa A, Barluenga S, Serba C, Winssinger N (2013) Solid phase synthesis of glycopeptides using Shoda’s activation of unprotected carbohydrates. Chem Commun 49:7608–7610

Györgydeák Z, Thiem J (2006) Synthesis and transformation of glycosyl azides. Adv Carbohydr Chem Biochem 60:103–182

Kitamura M, Tashiro N, Miyagawa S, Okauchi T (2011) 2-Azido-1,3-dimethylimidazolinium salts: Efficient diazo-transfer reagents for 1,3-dicarbonyl compounds. Synthesis 1037–1044

Kitamura M, Kato S, Yano M et al (2014) A reagent for safe and efficient diazo-transfer to primary amines: 2-azido-1,3-dimethylimidazolinium hexafluorophosphate. Org Biomol Chem 12:4397–4406

Kitamura M, Yano M, Tashiro N et al (2011) Direct synthesis of organic azides from primary amines with 2-Azido-1,3-dimethylimidazolinium hexafluorophosphate. Eur J Org Chem 2011:458–462

Kitamura K, Shigeta M, Maezawa Y et al (2013) Preparation of L-vancosamine-related glycosyl donors. J Antibiot 66:131–139

Kitamura M, Murakami K, Shiratake Y, Okauchi T (2013) Synthesis of α-arylcarboxylic acid amides from silyl enol ether via migratory amidation with 2-Azido-1,3-dimethylimidazolinium hexafluorophosphate. Chem Lett 42:691–693

Kitamura M, Miyagawa S, Okauchi T (2011) Synthesis of α, α-diarylacetamides from benzyl aryl ketones using 2-azido-1,3-dimethylimidazolinium hexafluorophosphate. Tetrahedron Lett 52:3158–3161

Kitamura M, Koga T, Yano M, Okauchi T (2012) Direct synthesis of organic azides from alcohols using 2-Azido-1,3-dimethyl-imidazolinium hexafluorophosphate. Synlett 23:1335–1338

Kitamura M (2015) Synthesis Of 2-Azido-1,3-dimethylimidazolinium hexafluorophosphate (ADMP). Org Synth 92:171–181

Lim D, Brimble MA, Kowalczyk R et al (2014) Protecting-group-free one-pot synthesis of glycoconjugates directly from reducing sugars. Angew Chem Int Ed 53:11907–11911

Tornøe CW, Christensen C, Meldal M (2002) Peptidotriazoles on solid phase: [1,2,3]-triazoles by regiospecific copper(I)-catalyzed 1,3-dipolar cycloadditions of terminal alkynes to azides. J Org Chem 67:3057–3064

Rostovtsev VV, Green LG, Fokin VV, Sharpless KB (2002) A stepwise huisgen cycloaddition process: copper(i)-catalyzed regioselective “ligation” of azides and terminal alkynes. Angew Chem Int Ed 41:2596–2599

Dondoni A (2007) Triazole: the keystone in glycosylated molecular architectures constructed by a click reaction. Chem-Asian J 2:700–708

Wilkinson BL, Long H, Sim E, Fairbanks AJ (2008) Synthesis of arabino glycosyl triazoles as potential inhibitors of mycobacterial cell wall biosynthesis. Bioorg Med Chem Lett 18:6265–6267

El Akri K, Bougrin K, Balzarini J et al (2007) Efficient synthesis and in vitro cytostatic activity of 4-substituted triazolyl-nucleosides. Bioorg Med Chem Lett 17:6656–6659

Rossi LL, Basu A (2005) Glycosidase inhibition by 1-glycosyl-4-phenyl triazoles. Bioorg Med Chem Lett 15:3596–3599

Wilkinson BL, Innocenti A, Vullo D et al (2008) Inhibition of carbonic anhydrases with glycosyltriazole benzene sulfonamides. J Med Chem 51:1945–1953

Wilkinson BL, Bornaghi LF, Houston TA et al (2006) A novel class of carbonic anhydrase inhibitors: glycoconjugate benzene sulfonamides prepared by “click-tailing”. J Med Chem 49:6539–6548

De las Heras FG, Alonso R, Alonso G (1979) Alkylating nucleosides. 1. Synthesis and cytostatic activity of N-glycosyl(halomethyl)-1,2,3-triazoles. A new type of alkylating agent. J Med Chem 22:496–501

De las Heras FG, Camarasa M-J (1982) Synthesis of Alkylating 1-Glycosyl-5-substituted 1,2,4-Triazoles 1. Nucleos Nucleot 1:45–56

Yeoh KK, Butters TD, Wilkinson BL, Fairbanks AJ (2009) Probing replacement of pyrophosphate via click chemistry; synthesis of UDP-sugar analogues as potential glycosyl transferase inhibitors. Carbohydr Res 344:586–591

Li H, Aneja R, Chaiken I (2013) Click chemistry in peptide-based drug design. Molecules 18:9797–9817

Tomabechi Y (2015) Synthesis of glycopeptides by click chemistry. Trends Glycosci Glycotechnol 27:63–65

Wang H, Huang W, Orwenyo J et al (2013) Design and synthesis of glycoprotein-based multivalent glyco-ligands for influenza hemagglutinin and human galectin-3. Bioorg Med Chem 21:2037–2044

Hanisch F-G, Muller S (2000) MUC1: the polymorphic appearance of a human mucin. Glycobiology 10:439–449

Sherblom AP, Moody CE (1986) Cell surface sialomucin and resistance to natural cell-mediated cytotoxicity of rat mammary tumor ascites cells. Cancer Res 46:4543–4546

Kaiser A, Gaidzik N, Westerlind U et al (2009) A synthetic vaccine consisting of a tumor-associated sialyl-T N-MUC1 tandem-repeat glycopeptide and tetanus toxoid: induction of a strong and highly selective immune response. Angew Chem Int Ed 48:7551–7555

Lakshminarayanan V, Thompson P, Wolfert MA et al (2012) Immune recognition of tumor-associated mucin MUC1 is achieved by a fully synthetic aberrantly glycosylated MUC1 tripartite vaccine. Proc Natl Acad Sci 109:261–266

Rising TWDF, Heidecke CD, Moir JWB et al (2008) Endohexosaminidase-catalysed glycosylation with oxazoline donors: fine tuning of catalytic efficiency and reversibility. Chem Eur J 14:6444–6464

Seko A, Koketsu M, Nishizono M et al (1997) Occurrence of a sialylglycopeptide and free sialylglycans in hen’s egg yolk. Biochim Biophys Acta - Gen Subj 1335:23–32

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2018 Springer International Publishing AG

About this chapter

Cite this chapter

Lim, D., Fairbanks, A.J. (2018). Selective Transformations of the Anomeric Centre in Water Using DMC and Derivatives. In: Witczak, Z., Bielski, R. (eds) Coupling and Decoupling of Diverse Molecular Units in Glycosciences. Springer, Cham. https://doi.org/10.1007/978-3-319-65587-1_5

Download citation

DOI: https://doi.org/10.1007/978-3-319-65587-1_5

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-65586-4

Online ISBN: 978-3-319-65587-1

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)