Abstract

In this paper, a method to optimize the milling process parameters based on the real-coded self-adaptive genetic algorithm (RAGA) and Grey relational analysis (GRA) is proposed. Experiments have been designed with four input milling process parameters at four different levels. The RAGA coupled with GRA has been applied for solving the proposed optimization problem to achieve the desired machined surface quality characteristics. Simulation experiments give the optimal parametric combination. Furthermore, experiments for the machined surface topography with the initial and optimal combination of milling process parameters are implemented and the results verify the feasibility of the proposed method.

Access provided by CONRICYT-eBooks. Download conference paper PDF

Similar content being viewed by others

Keywords

- Process parameter optimization

- Real coded self-adaptive genetic algorithm

- Grey relational analysis

- Surface topography

1 Introduction

Milling is the primary operation in most of the production processes in the industry. One of the essential criterions for selecting a proper milling process is the functional performance of machined surface [1]. Taking CNC milling for example, the surface roughness is the critical quality index for machined surface [2]. The corresponding performance is closely related to several machining parameters, such as the spindle speed, the feed per tooth, the axial depth of cut, and the cutter radius [3]. Surface topography of machined surface is significant for their functional performance. Among many parameters to characterize the surface topography, surface roughness is one of the most important parameters for evaluating the technological quality of a product. Accordingly, how to enhance the quality of the machined surface has been become an essential issue in the field of optimizing milling process parameters.

The RAGA and GRA are general methods that can be used to solve the complex problems for engineering design. Results demonstrate that RAGA can find optimal solutions [4]. Gong et al. [5] combined the RAGA and cumulative prospect theory to solve the portfolio choice problem. The computational results showed that the improved algorithm was more effective in realizing the global optimization and promoting evolution efficiency. Lee et al. [6] used RAGA to solve several benchmark optimization problems. This outcome of the study clearly demonstrated the effectiveness and robustness of the RAGA. Subbaraj et al. [7] introduced RAGA to solve the combined heat and power economic dispatch (CHPED) problem. The results showed that RAGA solved the CHPED problem efficiently. Subbaraj et al. [8] used the Taguchi-RAGA to solve the economic dispatch problem with valve-point loading. The result showed that the Taguchi-RAGA was very competitive in the field of solution quality, handling constraints and computation time. Abbas et al. [9] presented the adaptive real-coded genetic algorithm to identify the Volterra-system. The error between the identified nonlinear system and the Volterra model was reduced. Oyama et al. [10] obtained better performance in wing design by using the RAGA. The proposed method was to resolve the continuous search-space of an optimization problem. Deng [11, 12] proposed the Grey system theory, which was proven to be useful for dealing with the incomplete and uncertain information. Grey relational analysis (GRA) was adopted to combine multiple-quality parameters into one numerical score, and to determine the optimal setting for machine parameters by ranking these scores [13]. The optimization of many properties can be converted by Grey relational theory into a single grade value [14]. The RAGA-GRA method is proposed for the optimization of milling process parameters in this study.

2 Milling Process Parameters Optimization

2.1 Grey Relational Analysis (GRA)

In the Grey relational analysis, the first step is the generation of Grey relational, that is, normalize the S/N ratio ranging from zero to one and calculate the Grey relational coefficient to express the correlation between the desired and actual S/N ratios. In this study, the normalized values of surface roughness, corresponding to the lower-the-better characteristics criterion, can be expressed as

where \( x_{i} (k) \) is the value after the Grey relational generation, \( \hbox{min} \,y_{i} (k) \) and \( \hbox{max} \,y_{i} (k) \) are the smallest value and the largest value of \( y_{i} (k) \) for the kth response, respectively. The Grey relational coefficient \( \xi_{i} (k) \) can be formulated as

where \( \Delta_{0i} (k) = \left\| {x_{0} (k) - x_{i} (k)} \right\| \) is the absolute value of the difference between the ideal sequence \( x{}_{0}(k) \) and \( x{}_{i}(k) \), \( \psi \) is the distinguishing coefficient satisfying \( 0 \le \psi \le 1 \). \( \Delta_{\hbox{min} } \) and \( \Delta_{\hbox{max} } \) are the smallest value and the largest value of \( \Delta_{0i} \), respectively. By averaging the Grey relational coefficients, the Grey relational grade can be given as

where \( n \) is the number of process responses. The evaluation of overall performance characteristic is depended on the Grey relational grade. Using this method, the optimization of multiple performance characteristics can be converted to optimize a single Grey relational grade, since the optimal combination of process parameters is achieved corresponding to the highest Grey relational grade.

2.2 Real-Coded Self-adaptive Genetic Algorithm (RAGA)

Before executing the RAGA process, the population size, maximum generation number, crossover probability, mutation probability, fitness function, and range of each parameter must be assigned for the RAGA by expert knowledge and numerical experience [15]. In this paper, the population size is set at forty, and the maximum generation is twenty. The Grey relational grade is used as the fitness function. The reproduction procedure adopts the roulette wheel selection to pick chromosomes into the mating pool. Therefore, the probability of the jth chromosome entering into the mating pool is determined by the following equation.

where \( k \) is the population size.

The RAGA is able to adjust its crossover and mutation through contemporary adaptation of the maximum and minimum values, to accelerate evolutional speed and enlarge searching scope. The adaptation crossover and mutation can be used with the following equations [15].

where \( C_{c} \) is the crossover, \( C_{c0} \) is the initial crossover, \( \alpha = 0.3 \), \( C_{m} \) is the mutation, \( C_{m0} \) is the initial mutation, \( m_{c} = 2 \), \( F_{\hbox{max} } \) is the fitness maximum, \( F_{\hbox{min} } \) is the fitness minimum, \( F_{avg} \) is the fitness average, \( \beta = 0.2 \), \( C_{new} \) is the gene after mutation.

2.3 Combined RAGA and GRA Methods

In this paper, the RAGA and GRA are combined for the optimization of milling process parameters. The regulation value of surface roughness can be used as the target value. The GRA is used to integrate multiple quality control values into a single one, which is the Grey relational grade, and is the fitness function of the RAGA. The crossover and mutation rates of the RAGA change in the next generation according to the obtained fitness function. If the average fitness becomes big, the crossover probability also becomes big, and vice versa. The whole process will do loop until achieving the stop condition or the optimal solution. In this study, the steps are repeated to search for the optimal solution until the end of the maximum generation number. The optimization flow chart can be illustrated in Fig. 1.

3 Verification

3.1 Experimental Design and Results

Various milling process parameters affect the machined surface topography and the surface roughness, which are indexes of importance for evaluating the machining quality. In the experiment, four cutting process parameters at four different levels each have been taken into consideration, namely, the cutter radius, the spindle speed, the feed per tooth, and the cutter helix angle. Process parameters with their symbols and values at different levels are listed in Table 1.

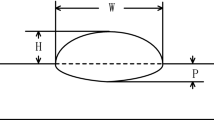

In order to compare the reliability, the Taguchi-Grey method is firstly performed with this case. The design matrix is selected according to the Taguchi’s orthogonal array design, which consists of 16 sets of coded conditions. The surface roughness is usually quantified by the vertical deviations of a real surface from its ideal form. The commonly used three surface roughness parameters are Ra, Ry and Rz. Ra represents the arithmetical mean deviation of the profile. Ry represents the maximum height of the profile. Rz represents the mean roughness depth. Here, only Ra is considered in both down milling process and up milling process. The analysis of variance (ANOVA) results for the roughness of down milling process are listed in Table 2. The ANOVA results for the roughness of up milling process are listed in Table 3.

By using the Taguchi-GRA optimization, a set of optimization parameters can be found in Table 2 for down milling and Table 3 for up milling. As the result of Taguchi method is not the best result, the result is used to setting feasible domain of the RAGA and GRA, as shown in Table 4. The comparisons of the two optimization methods for down milling process and up milling process are shown in Tables 5 and 6. The comparison results show that the RAGA-GRA method can find a better combination of milling process parameters than the Taguchi-GRA method.

3.2 Comparison of Surface Topography

With the derived optimal milling process parameters, this section mainly concentrates on the topography of the machined surface in the case of both optimal milling process parameter settings and initial milling process parameter settings for verifying the foregoing evaluated optimal parameters. In each case, both down milling process and up milling process are studied. The results are shown in Figs. 2 and 3. Figure 2(a) and (b) show the surface topography of down milling process for the initial and the RAGA-GRA parameter settings, respectively. Figure 3(a) and (b) show the surface topography of up milling process for the initial and the RAGA-GRA parameter settings, respectively.

Some conclusions can be drawn by comparing and analyzing Figs. 2 and 3. The results show that the values of the machined surface roughness in the case of down milling process are much smaller than that of in the case of up milling process. The quality characteristic of the machined surface with the RAGA-GRA parameter settings is better than that of the machined surface with the initial parameter settings by comparing Fig. 2(a) and (b) as well as Fig. 3(a) and (b). Furthermore, the values of the machined surface roughness with the RAGA-GRA parameter settings are obviously smaller than that of with the initial parameter settings. This further demonstrates the RAGA-GRA method is feasible in optimization of milling process parameters.

4 Conclusions

The present study concentrates on the application of real-coded self-adaptive genetic algorithm coupled with Grey relational analysis for solving the optimization of milling process parameters. The detailed methodology of the RAGA-GRA is applied for evaluating the optimal combination of milling process parameters so as to achieve the desired quality characteristics of the machined surface. Furthermore, the experiments of machined surface topography are implemented in the case of both down milling process and up milling process with the initial and optimal parameter settings. The experimental results indicate that the machined surface quality is improved after using the RAGA-GRA method, which further verify the feasibility of the proposed method.

References

Tönshoff, H.K., Arendt, C., Amor, R.B.: Cutting of hardened steel. CIRP Ann. Manufact. Technol. 49(2), 547–566 (2000)

Benardos, P.G., Vosniakos, G.C.: Prediction of surface roughness in CNC face milling using neural networks and taguchi’s design of experiments. Robot. Comput. Integr. Manufact. 18(5), 343–354 (2002)

Zhang, J.Z., Chen, J.C., Kirby, E.D.: Surface roughness optimization in an end-milling operation using the Taguchi design method. J. Mater. Process. Technol. 184(1), 233–239 (2007)

Sabanayagam, A., Kumar, V.A., Raju, S., Kumar, N.S.: Optimization of interconnects for signal integrity using self-adaptation in real-parameter genetic algorithms with simulated binary cross over (SBX). In: 10th International Conference on Electromagnetic Interference & Compatibility, pp. 123–129. IEEE, India (2008)

Gong, C., Xu, C., Wang, J.: An efficient adaptive real coded genetic algorithm to solve the portfolio choice problem under cumulative prospect theory. Comput. Econ. 1–26 (2017). doi:10.1007/s10614-017-9669-5,

Lee, L.H., Fan, Y.: An adaptive real-coded genetic algorithm. Appl. Artif. Intell. 16(6), 457–486 (2002)

Subbaraj, P., Rajnarayanan, P.N.: Optimal reactive power dispatch using self-adaptive real coded genetic algorithm. Electr. Power Syst. Res. 79(2), 374–381 (2009)

Subbaraj, P., Rengaraj, R., Salivahanan, S.: Enhancement of self-adaptive real-coded genetic algorithm using Taguchi method for economic dispatch problem. Appl. Soft Comput. 11(1), 83–92 (2011)

Abbas, H.M., Bayoumi, M.M.: Volterra-system identification using adaptive real-coded genetic algorithm. IEEE Trans. Syst. Man Cybern. Part A Syst. Hum. 36(4), 671–684 (2006)

Oyama, A., Obayashi, S., Nakahashi, K.: Wing design using real-coded adaptive range genetic algorithm. In: 1999 IEEE International Conference on Systems, Man, and Cybernetics, pp. 475–480. IEEE, Japan (1999)

Deng, J.L.: Introduction to Grey system theory. J. Grey Syst. 1(1), 1–24 (1989)

Deng, J.L.: A Course on Grey System Theory. Huazhong University of Science and Technology Press, Wuhan (1990)

Tzeng, C.J., Lin, Y.H., Yang, Y.K., Jeng, M.C.: Optimization of turning operations with multiple performance characteristics using the Taguchi method and Grey relational analysis. J. Mater. Process. Technol. 209(6), 2753–2759 (2009)

Yang, Y.S., Huang, W.: A Grey-fuzzy Taguchi approach for optimizing multi-objective properties of zirconium-containing diamond-like carbon coatings. Expert Syst. Appl. 39(1), 743–750 (2012)

Wang, L., Tang, D.: An improved adaptive genetic algorithm based on hormone modulation mechanism for job-shop scheduling problem. Expert Syst. Appl. 38(6), 7243–7250 (2011)

Acknowledgements

This work is supported by the National Natural Science Foundation of China (Grant No. 51505343) and the Postdoctoral Science Foundation of China (Grant No. 2015M572192).

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2017 Springer International Publishing AG

About this paper

Cite this paper

Zeng, S., Yuan, L. (2017). Optimization of Milling Process Parameters Based on Real Coded Self-adaptive Genetic Algorithm and Grey Relation Analysis. In: Huang, Y., Wu, H., Liu, H., Yin, Z. (eds) Intelligent Robotics and Applications. ICIRA 2017. Lecture Notes in Computer Science(), vol 10464. Springer, Cham. https://doi.org/10.1007/978-3-319-65298-6_77

Download citation

DOI: https://doi.org/10.1007/978-3-319-65298-6_77

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-65297-9

Online ISBN: 978-3-319-65298-6

eBook Packages: Computer ScienceComputer Science (R0)