Abstract

A Corporation does not survive in isolation. It has its existence in time and space. And, it is this time and space, when managed responsibly, can take it towards sustainability. Sustainability, in its part, comprises of undertaking three broad panacea, namely, social, environmental and economic responsibility, also known as the three pillars (people, planet and profit) of sustainability. More often than not, academicians and specialists are concerned with the study and practice of these panacea with respect to the Corporation (or the focal company) alone. But, this may not be enough. The risks are deeper. The Corporation is just the facade. If the foundation is not strong, the structure has a potential to collapse.

This study, thus aims to delve deeper than only-the Corporation, to point out the dynamics of sustainability in its upward integration, i.e., the supply chain—indicate its relevance, and ways and means of management; with references and examples drawn from the Indian context.

Access provided by CONRICYT-eBooks. Download chapter PDF

Similar content being viewed by others

Keywords

1 Introduction

A company (also called, Corporation, Organization, business, firm in this paper) needs to go beyond mere existence, survival and growth to perpetuate. It is this concept of perpetuation or going concern, that has often made me think. How is this possible?

A Corporation is a social entity. It has its existence in time and space; it has its upwards and downwards dynamics that binds it together to form a whole that should be able to survive and perpetuate in a very competitive environment. Therefore, if we talk about the focal Company alone, the discussion will be incomplete. If a Company complies to sustainability norms , it is wonderful; but if the company’s supply chain flouts the sustainability norms and the company uses its products and services, is it still okay? Will there not be a lacuna then in their ‘responsibility’ to the society or in its issue of perpetuity?

2 Objectives

This paper, therefore seeks to delve deeper into:

-

1.

The dynamics of sustainability in its upward integration , that is, the supply chain,

-

2.

Point out its relevance, and

-

3.

Ways and means of management;

with references and examples drawn from the Indian context.

Now, the question is: what comprises of the supply chain? Christopher (2012) defines supply chain as “the network of organisations that are involved through upstream and downstream linkages, in the different processes and activities that produce value in the form of products and services in the hands of the ultimate consumer.”

Thus, supply chain comprises of a whole ecosystem from the minutest supplier to the final customer and, any non-compliance or irresponsibility in this milieu will ultimately affect the focal company’s sustainability, at the end. This supply chain, therefore, needs to be managed to ensure responsible governance , traceability and hence, accountability.

Supply chain Management, as defined by the Association for Operations Management (APICS) is “the design, planning, execution, control and monitoring of supply chain activities with the objectives of creating net value, building a competitive infrastructure, leveraging worldwide logistics, synchronizing supply with demand, and measuring performance globally” (Wisner et al. 2011).

3 Conceptual Framework

The conceptual framework of this paper is as follows (refer Exhibit 1):

4 Literature Review

Modern supply chains, in this age of globalisation and dynamic trade practices, are, in many cases, multi-tiered networks that involves various types of suppliers across various demographical, socio-political and geographic spread (Giblin 2013).

Therefore, in order to have an equilibrium between the focal company and its business ecosystem, there needs to be a uniformity in some of their key corporate policies and interactions that bind them together in linearity.

Here comes the debate, where, academicians and particularly practitioners have often questioned the scopes, limitations and extent of the focal companies’ role in ordering its suppliers and even their suppliers, to comply (Gilmore 2015).

Let us critically analyse and discuss the various sustainability concerns faced by the modern corporations.

4.1 Social Concerns

Vogel (2005) have noted that while prominently featuring information about their codes of conduct , some companies often ignore reporting the extent of compliance with them; while some others describe their own practices, but ignore those of their supply chain. Let us follow some of the Indian examples given below (Refer Table 1).

Given the above examples, in Table 1, who suffers? If the supply chain does not adhere to sustainable practices, is it not the focal company, whose brand is at stake? Is it not, always the company’s long-term sustainability that comes under question?

Infact, Anand Mahindra (2010) , the Vice Chairman and Managing Director, Mahindra and Mahindra Limited, an Indian industrial group feels, “The purchasing power of a corporation can become a unique driver for bringing about positive change in society. Companies must use this power to achieve a purpose and make their supply chain a vehicle for inclusive growth” (UNGC, 2010). The Company initiated a programme to enable knowledge and best practice sharing with suppliers in order to address environmental, health and safety impacts throughout the company’s supply chain (UNGC 2010).

4.2 Environmental Concerns

Among environmental concerns, the second panacea of sustainability, climate change is one of the major global concerns. Most climate scientists agree the main cause of the current global warming trend is human expansion of the “greenhouse effect ,” (GHG) caused by a build-up of greenhouse gases, primarily carbon dioxide, methane, and nitrous oxide that traps heat in the atmosphere, radiating from Earth toward space (Global Climate Change 2015).

The 2014 report from the Carbon Disclosure Project (CDP) , an independent global system for companies to measure, disclose, manage and share climate change and water information, which tracks the GHG emissions and the carbon footprint of not only their own manufacturing activities, but also their transportation, distribution and procurement activities, and monitors the related activities of their extended supply chains (Blanchard 2012), has, for the first time, put five Indian companies , namely Wipro, Essar Oil, Tech Mahindra, Larsen and Toubro and Tata Consultancy Services on its Global A-list (Clough 2015).

This is indeed a great news. The consciousness has begun.

Our collective greenhouse gas emissions will dictate whether or not we risk tipping the world towards dangerous climate change , that will change our dynamics of business, among a lot many other things (Supply Chain Report 2015). Thus, the foundation of the business, in terms of its supply chain, needs to be strong with respect to their own sustainability issues to make the focal company stronger and sustainable.

4.3 Economic Concerns

The third panacea of sustainability, profit, found eminence in the supply chain, post 2010, by the increased attention of the management from competition between firms to competition between supply chains (Anderson and Skjoett-Larse 2009). Thus, the challenge is to ‘effectively integrate the principles of sustainable supply chain practices into the existing supply chain programmes and operations’ of the focal company and also to ‘ensure that sustainability considerations are embedded within all their sourcing processes’ (UNGC 2014).

The truth here is: value (and cost) is not just the culmination of the focal firm in a network, but also of all the different cross-connecting entities present in its ecosystem; and this ‘extended enterprise’, as some have termed it, then, becomes a key factor of (gaining or losing) competitive advantage (Christopher 2012).

ITC Limited, an Indian multi-business conglomerate, recognizes the importance of extending its Triple Bottom Line (people, planet, profit) approach along its supply chain to ensure long-term competitiveness by adopting a balanced approach towards creation of social and environmental value and the economic viability of the businesses (ITC Limited 2012).

5 Managing the Foundation for Sustainability

Thus comes the concept of sustainable supply chain , as defined by Carter and Rogers (2008) as “the strategic achievement and integration of an organisations’ social, environmental and economic goals through the systematic coordination of key inter-organizational business processes to improve the long-term economic performance of the individual company and its value network.” In this definition, one talks about two critical aspects: (a) strategic achievement; and (b) improvement of the long-term economic performance of the individual company and its value network. Or, in other words, to employ strategic thinking for long-term profit of the focal company and its value network, comprising of a larger number of firms with a more complex set of relationships between them, and agreements on a greater number of interface standards (Funk 2009).

Thus, ensuring sustainability in the supply chain, in this time of globalisation , where, it may be spread across multiple countries, different segments of buying agents, suppliers and subcontractors may be challenging. A company of Wal Mart’s stature easily has 50,000–1,00,000 suppliers, spread all over the world, including India. According to the Supply Chain Digest, this retail giant stocks products made in more than 70 countries and at any given time, operates more than 11,000 stores in 27 countries around the world, and manages an average of 32 billion dollars in inventory (Lu 2014).

Moreover, as Vogel (2005) observed, the gap between the company and the industry codes and actual working conditions often remain large. This can be accounted to ineffective monitoring, independently unverifiable results and uneven compliance and violations (Vogel 2005); especially in a multi-tier supply chain. Therefore, monitoring and accountability needs to be done in an hierarchical process, one tier at a time till all the tiers are reached. Most often than not, majority of environmental, social and governance (ESG) risks lie deeper down the supply chain (Giblin 2013), resting with the grass root level suppliers, comprising mainly of the Micro, Small and Medium Enterprises (MSMEs) .

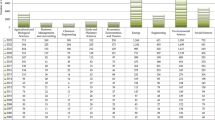

In India, these MSMEs play a vital role for the growth of Indian economy. The annual report of MSME 2012–2013, has confirmed that the 44.7 million MSME enterprise with a total employment of over 100 million and more than 6000 quality products account for a large share of industrial units; as well as 43% of India’s total exports in 2011–2012 (Ministry of Finance 2013). They act as the major link in the supply chain to corporate and the Public Sector Undertaking (PSUs) and significant contributors to (Ramesh 2013) large multinational enterprises (MNEs). By committing to engage in recognized traceability schemes, MSMEs can therefore demonstrate to customers their commitment to sustainability, and contribute to the achievement of MNEs, that increasingly demand more stringent sustainability requirements, and are looking for suppliers who can help them achieve these goals (UNGC 2014).

Therefore, sustainability is no longer the individual company’s domain; and, as Anderson and Skjoett-Larse (2009) has noted, multinational companies are not only expected to behave socially responsible within their own juridical walls; they are also held responsible for environmental and labour practices of their global trading partners such as suppliers, third party logistics provider, and intermediaries over which they have no ownership, thereby impacting the world at large.

Thus, all companies, at different points, fall within the various tiers of the supply chain requirement. The large companies usually have the onus of managing large supply chains on one hand as well as comply as a supply chain to other companies; whereas Micro, Small and Medium Enterprises (MSMEs) also have the onus of complying as the supply chain of larger organisations (Indian and Multi National Enterprises), as well as act responsibly and manage its own suppliers (refer Exhibit 2). It is thereby, a multi-pronged/multi-tiered process.

To develop various efforts to make MSMEs more socially responsible by awareness raising and technological capability building, several attempts have been made by the government, the Federation of Small and Medium Enterprises (FISME) , World Assembly of Small and Medium Enterprises (WASME) and associations of importers in developed countries, like the SUSBIZ India Project, initiated in 2007 by the Danish Federation of Small and Medium Sized Enterprises (DFSME) together with the Danish Commerce and Companies Agency (DCCA), that involved collaboration between eight Indian suppliers and their eight Danish buyers (Sundar 2013). However, unless these compliances are percolated and adopted among the entire MSME sector, there will always be lacuna in the supply chain management and even the largest of the corporation will not be sustainable.

The Indian government, in its National Voluntary Guidelines on Social, Environmental and Economic Responsibilities of Business issued by the Ministry of Corporate Affairs, first in 2009 and updated in July 2011, realized that promotion of responsible business among the SMEs will need a multi-pronged approach, that includes “facilitating SMEs to recognize the business case for adopting responsible business practices” and “preference by public agencies and large players in value chains to SME suppliers that follow CSR practices.” (Sundar 2013).

In order to do this, the foremost requirement of the focal company is to be able to trace its supply chain till its last piece. It is extremely challenging, but not impossible. Let us take the example of Marico industries.

Saugata Gupta , the Chief Executive Officer (CEO) of the fast moving consumer goods (FMCG) major, Marico Industries, feels “Supply chain is also a critical driver of efficiency in today’s complex business environment, given the existing cost structures and challenges” (Naren, 2013). Marico, the largest buyer of copra in India with a demand of about 100,000 tonnes a year, with the help of technology platforms could dis-intermediate its copra supply chain, in 2013, from the exploitative structures and agents, after a struggle for over two decades and trace it to the smallest possible vendor—a marginal farmer with a few coconut palms in his backyard from amongst 61 clusters involving 7982 farmers covering 1737 hectares for its popular range of Parachute coconut oils. This, indeed, is a very big successful transparency model (Naren 2013).

In view of the necessity of such deep rooted intervention in supply chain management and compliance, an entire cottage industry of auditors and consultants have emerged to advise manufacturers on the numerous regulatory efforts in place or on the horizon (Blanchard 2012).

The United Nations Global Compact (UNGC) also encourages participants to engage with suppliers around the ten principles (refer Table 2) and to advance sustainable development objectives as part of their commitment to the Global Compact, and thereby to spread good corporate citizenship practices throughout the global business community (UNGC 2010).

6 Conclusion

Awareness on supply chain sustainability in the context of the developing/emerging countries like India, is still in the nascent state. It is a ‘pull’ and ‘push’ process, between the corporations and the Government, where each one thinks, it is the duty and responsibility of the other to make the rules and monitor the compliance. The debate is inconclusive. In reality, unless the sustainability norms are complied, in all its tiers of upward integration , that is the supply chain, the focal Company remains weak at its foundation and will have a tendency to collapse anytime like a ‘house of cards.’ This issue of supply chain sustainability needs to be looked into, as an investment rather than an expenditure by the corporation.

Kris Gopalakrishnan , CEO and Co-Founder of Infosys, an Indian multinational corporation, thus pointed out that “We live in an increasingly resource aware and resource constrained world. We need to live within our means and not borrow from the future. To build a sustainable tomorrow we need to make our supply chain sustainable today. In fact, I firmly believe that increased sustainability in the supply chain reduces risks and increases profits for all organizations and stakeholders” (UNGC 2010).

However, discussion on who makes the rules—the Government or the Corporations, or, maybe a multilateral agency like the United Nations to take care of the complex issues of supply chain sustainability, spread over different countries, cultures, local laws, could be the content of a separate study.

References

Anderson, M., & Skjoett-Larse, T. (2009). Corporate social responsibility in global supply chains. Supply Chain Management: An International Journal, 14(2), 75–86.

Blanchard, D. (2012, May 14). Corporate social responsibility in the supply chain: Manufacturers are expected to fully disclose where they source their products, or suffer the PR backlash. Industry Week. Accessed June 3, 2015, from http://www.industryweek.com/environment/corporate-social-responsibility-supply-chain

Carter, C. R., & Rogers, D. S. (2008). A framework of sustainable supply chain management: Moving toward new theory. International Journal of Physical Distribution & Logistics Management, 38(5), 360–387.

Christopher, M. (2012). Logistics and supply chain management (4th ed.). Harlow: Pearson.

Clough, J. (2015, January 9). Made in India: Five companies demonstrate global leadership for the climate. Greenfutures Magazine. Accessed June 3, 2015, from http://www.forumforthefuture.org/greenfutures/articles/made-india-five-companies-demonstrate-global-leadership-climate-0

Daily Mail Reporter. (2008, June 23). Exposed: Primark’s fashion sweatshops that pay children just 60p a day. Mail Online. Accessed June 2, 2015, from http://www.dailymail.co.uk/news/article-1028449/Exposed-Primarks-sweatshops-pay-children-just-60p-day.html

Funk, J. L. (2009). The emerging value network in the mobile phone industry: The case of Japan and its implications for the rest of the world. Telecommunications Policy, 33(1–2), 4–18. Accessed June 3, 2015, from http://www.sciencedirect.com/science/article/pii/S0308596108000931

Giblin, C. (2013, November 7). Time for a multi-tiered approach to supply chain risk. Sedex. Accessed 5 June 2015, from http://www.sedexglobal.com/time-for-a-multi-tiered-approach-to-supply-chain-risk/

Gilmore, D. (2015, March 12). Any limits to large companies’ supply chain control? Supply Chain Digest. Accessed June 2, 2015, from http://www.scdigest.com/assets/firstthoughts/15-03-12.php?cid=9092

Global Climate Change: Vital Signs of the Planet. (2015). A blanket around the earth. Accessed 2 June 2015, from http://climate.nasa.gov/causes/

ITC Limited. (2012). Sustainability report 2012: Key impacts, risks and opportunities: Sustainability challenges. Accessed June 1, 2015, from http://www.itcportal.com/sustainability/sustainability-report-2012/key-impacts-05.aspx

Lu, C. (2014, May 8). Case studies, insights & analysis: Incredibly successful supply chain management: How does walmart do it? Singapore: Tradegecko. Accessed June 5, 2015, from http://www.tradegecko.com/blog/incredibly-successful-supply-chain-management-walmart

McDougall, D. (2007, October 28). Indian ‘slave’ children found making low-cost clothes destined for gap. The Observer, The Gurdian. Accessed June 1, 2015, from http://www.theguardian.com/world/2007/oct/28/ethicalbusiness.retail

Ministry of Finance. (2013). Government of India. Report of the Inter-Ministerial committee for boosting exports from MSME sector. Accessed June 1, 2015, from http://dgft.gov.in/exim/2000/imc-EXPORT-sme.pdf

Naren, K. (2013, November 26). Sustainability & India Inc: Why marico’s supply chain management is a case study at IIM-A. The Economic Times. Accessed June 3, 2015, from http://articles.economictimes.indiatimes.com/2013-11-26/news/44486941_1_saugata-gupta-fmcg-major-marico-supply-chain

Ramesh, M. (2013). Importance of worker engagement and empowerment for SME sustainability. In S. Mittal (Ed.), CSR and competitiveness: Essential of the corporate India and its sustainability (pp. 105–112). New Delhi: Allied Publishers Private Limited.

Sundar, P. (2013). Business & community: The story of corporate social responsibility in India. New Delhi: Sage.

Supply Chain Report 2014–15. (2015). Supply chain sustainability revealed: A country comparison: Report written for CDP by accenturestrategy. Accessed June 2, 2015, from http://www.accenture.com/SiteCollectionDocuments/PDF/Accenture-CDP-Supply-Chain-Report-2015.pdf

UNGC. (2010). Supply chain sustainability: A practical guide for continuous improvement. Accessed June 2, 2015, from http://www.bsr.org/reports/BSR_UNGC_SupplyChainReport.pdf

UNGC. (2014). A guide to traceability: A practical approach to advance sustainability in global supply chains. Accessed June 1, 2015, from https://www.unglobalcompact.org/docs/issues_doc/supply_chain/Traceability/Guide_to_Traceability.pdf

Vogel, D. (2005). The market for virtue: The potential and limits of corporate social responsibility (1st ed.). Washington, DC: The Brookings Institution.

Wisner, J. D., Tan, K. H., & Leong, G. K. (2011). Principles of supply chain management: A balanced approach (3rd ed.). Mason, OH: South Western.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2018 Springer International Publishing AG

About this chapter

Cite this chapter

Mitra, N. (2018). In the Pursuit of Building the Foundation for Sustainability. In: Lu, H., Schmidpeter, R., Capaldi, N., Zu, L. (eds) Building New Bridges Between Business and Society. CSR, Sustainability, Ethics & Governance. Springer, Cham. https://doi.org/10.1007/978-3-319-63561-3_2

Download citation

DOI: https://doi.org/10.1007/978-3-319-63561-3_2

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-63560-6

Online ISBN: 978-3-319-63561-3

eBook Packages: Business and ManagementBusiness and Management (R0)