Abstract

Diaphragm walls are normally used for the deep excavations and underground construction inside the cities. The trenching process of diaphragm walls causes deformation in the ground surface. The construction of the diaphragm walls near deep foundations may not be avoided specially in the crowded cities. This research focuses on the deflection and bending moment of piled foundations near slurry trench. Since the trench is considered as a three dimensional problem, a three-dimensional numerical analysis was used in this research. It was conducted using a commercial analysis software known as FLAC 3D which is based on the finite different analysis method. Verification was made for the numerical analysis method using two case histories, one in Hong-Kong and another one in Giza, Egypt. The results from the numerical analysis were in quite a good contrast with the field data results. This means the trenching process could be numerically modeled with the proposed method and provides good results. The verified numerical analysis method was used to conduct a numerical parametric study that discusses the effect of a single or double panel(s) on the nearby piled foundation. The parametric study showed that the pile deflection and bending moment are affected by the panel length, pile diameter, pile location from the trench, groundwater level and the existence of a weak soil layer that could cause reduction in slurry pressure. The panel thickness did not show any influence on the pile bending moment or deflection. The decrease of the panel length and controlling the slurry level will reduce the influence of trenching on nearby piles. Lowering the groundwater level before trenching could probably reduce the influence on the pile as well.

Access provided by CONRICYT-eBooks. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

The soil deformation caused by the diaphragm wall trenching process was monitored by many researchers. Generally, they used the settlement points to measure the surface soil settlement and inclinometers to measure the horizontal soil displacement. Deep soil settlements could also have been measured in some cases. Monitoring during trenching process was made for either tested panel or multiple panels. DiBiagio and Myrvoll (1972), Tsai et al. (2000) and Ng et al. (1999) had intensely monitored tested panel for research purposes, while Karlsrud (1983), Cowland and Thorley (1985), Hamza et al. (1999), Poh et al. (2001) and L’Amante et al. (2012) monitored the diaphragm wall installation of case histories in real projects. The monitoring results were varied according to many parameters such as panel dimensions, groundwater level and soil properties.

Trench panels were simulated using three-dimensional numerical analysis by Ng and Yan (1998), Gourvenec and Powrie (1999), Grandas-Tavera (2012) and Comodromos et al. (2013). These researchers compared the results from the numerical analysis with that from the field data. There intension was to find out the ability of the trenching numerical analysis in modeling the trenching process. They found out that three-dimensional numerical analysis could be used in modeling the trenching problem.

Generally, the trenching process causes settlement and horizontal displacement for the ground surface which could probably affect the nearby existing deep foundations. However, a very limited research has been made regarding such effect. Davies and Henkel (1982), Abdel-Rahman and El-Sayed (2009) and Korff (2013) monitored the trenching process near existing piled foundation but they were not able to monitor the existing piles. Choy et al. (2007) studied the effect of the trenching process on a single pile using the centrifuge model test through conducting a limited parametric study. His study did not take into consideration the effect on pile group and the possible existence of groundwater.

In this research, the three-dimensional numerical analysis was used to simulate the trenching process of diaphragm walls adjacent to piled foundation for two different case histories. The results from the numerical analysis were compared to the field data results. Such simulation method was used to conduct a parametric study which discusses the different parameters that affect the existing piled foundation near diaphragm wall panel(s).

2 Numerical Analysis of Case Histories and Verification

The numerical modeling for different geotechnical engineering problems is considered to be an acceptable tool. However, the modeling method of the different types of such problems should be verified. The trenching process of slurry trench walls required a three-dimensional simulation with a special attention to the stages and simulation assumptions. This section describes the numerical modeling of two case histories using FLAC 3D. The results from modeling were compared to those from the field.

2.1 Case History 1 (Underground Station Near the Court of Justice in Hong Kong)

A diaphragm wall system was used as a part of the Charter underground metro station. This station was very close to the court of justice which was constructed in a timber piled foundation. The piles cross section area was equal to 0.0254 m2 and it extended to a level of 14 m beneath the ground surface. The building load was distributed over the beams that connect the piles. The details of the project are described by Davies and Henkel (1982). The numerical modeling and verification related to the diaphragm wall panels construction adjacent to the building are described in the following subsections.

2.1.1 Modeling and Construction Stages

The construction stages of the diaphragm wall panels were modeled as was described in Fig. 1. According to Stround and Sweeney (1977) the soil was found to be consisted of five layers. The soil layers’ depths and their properties are presented in Table 1. The soil was modeled using strain hardening softening soil model which is defined in FLAC 3D by conducting a relation between mobilized friction angle and plastic shear strain which can be calculated according to Byrne (2003) as:

where

- Pref :

-

is the reference pressure,

- β:

-

is calibration factor,

- ϕ:

-

is the ultimate friction angle,

- ϕm :

-

is the mobilized friction angle,

- Rf :

-

is the failure ratio.

The elastic tangent shear modulus is calculated from the following equation:

where

- \( E_{ur}^{ref} \) :

-

is the required strain to mobilize the limit friction angle,

- νur :

-

is the undrained Poisson’s ratio.

The relation between the plastic shear strain and mobilized friction angle based on the previous equations for the soil layers are presented in Fig. 2.

The trenching process of each panel was made by replacing the soil elements at the panel location with a hydrostatic pressure equivalent to the slurry pressure. The concreting process of the panel is made then by reactivation of the zones and changing its properties to concrete properties. Figure 3 shows the trenching process of a panel in different situations. The pile and beams connecting the piles were modeled using the beam and pile elements, respectively. These elements are described and discussed by Itasca (2012). The mesh model contains 157800 zones and its shape and dimension are presented in Fig. 4. The relative normal and shear displacement between the pile and the soil are defined by the normal stiffness Kn and shear stiffness Ks, respectively. They are considered to be equal and can be calculated from the following empirical equation:

where

- k:

-

is the soil bulk modulus

- G:

-

is the soil shear modulus

- ∆zmin :

-

is the minimum distance in the vertical direction of the mesh

2.1.2 Results and Comparison

The settlement results of the numerical analysis compared to field data for points D and E at different stages are presented in Fig. 5. The results showed that the settlement values increase with stages and decrease with the distance from the trench.

The values of settlement from the numerical analysis nearest to the trench (point D) were in a very good agreement with those from the field data. This good agreement was not found in case of comparing the results at point E. Generally, the comparison showed that the numerical analysis provides reliable results that can present the reality.

2.2 Case History 2 (Basement Near High-Rise Buildings in Giza, Egypt)

The underground construction of a basement in a crowded area in Giza, Egypt was done using diaphragm wall technique. The construction area was surrounded by several buildings as described by Abdel-Rahman and El-Sayed (2009). The soil was mainly sand and it was simulated using the same soil model that was used in the first case history. The soil properties are shown in Table 2. The panels construction stages are presented in Fig. 6 and they were modelled as in the field. Each panel was modeled as previously described and as shown in Fig. 3.

The piles and the grade beams connecting the pile caps were modelled as described in the first case history. The pile caps were modeled using the shell elements and they carry the building load. The mesh used to simulate this case history is presented in Fig. 7.

The results from the numerical analysis compared to those from the field are presented in Fig. 8. The comparison was made for the three sections. The values of settlement were measured during trenching of the last panel (i.e. stage P-20-B) and it shows a decrease with distance from the trench. There was a slight difference regarding the settlement shape between the field and the numerical analysis. The settlement values from the numerical analysis adjacent to the trench and at a distance of 19 m from the trench are identical with those from the field, but the settlement values from the numerical analysis were slightly higher than those from the field at a distance of 5 m from the trench. Generally, the output from the numerical analysis is in a good contrast with the field results.

3 Numerical Parametric Study

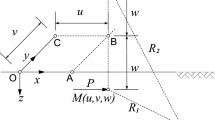

The numerical simulation and comparison for the presented case histories showed that the method of simulating the trench numerically is acceptable and provides reliable results. This method was used to conduct a numerical parametric study includes several parameters. Two main models were used for the parametric study. The first model simulated the effect of the single panel on the pile group as presented in Fig. 9, while the second model simulated the effect of the double panels on similar pile group as shown in Fig. 10.

3.1 Studied Parameters

The soil used in this study was sand with a friction angle ϕ = 32°, a bulk density γb = 18 kN/m3 and shear modulus G = 9.6 MPa. The pile depth was 12 m and its diameter (D) was 0.8 m in all cases, but in case of studying the effect of the pile diameter and its properties were chosen as variables according to Table 3. The panel depth was chosen to be 30 m because below this depth the pile with a 12 m depth will almost not be affected (Mohamed 2015). The trench length (L) was either 3 m or 6 m while its thickness (T) was 0.6 m and 1.2 m. The slurry and groundwater levels were chosen to be 0.5 m and 2 m below the ground surface, respectively. Five other different values of groundwater levels were studied separately. The effect of loss in the slurry pressure due to the existence of a weak soil layer at a certain depth of the trench was simulated by reducing the slurry pressure (SP) at some depths. The pile group was located at a distance (x) from the trench. This distance was considered to be 3.5 m in case of studying the other parameters.

3.2 Results from the Parametric Study

The effect of each parameter on piles deflection and bending moment is shown in Figs. 11, 12, 13, 14, 15 and 16, such an effect was generally presented for the first pile within the group. The effect of change of panel length on the pile behavior was very high but the effect of change in panel thickness shows was very low as shown in Fig. 11.

The location of the pile within the group and its distance from the trench controls the values and shape of the pile deflection and bending moment as shown in Figs. 12 and 13. The piles nearest to the trench within the group (i.e. piles 1 and 2) their tip deflect more than their top, because they move with the soil while the rear piles (i.e. piles 3 and 4) deflect from their top higher because they are affected by the drag force of the front pile. Generally, the deflection and bending moment values decrease with the distance from the trench.

The effect of different groundwater levels on the first pile within a pile group is presented in Fig. 14. The deeper the groundwater level the lower the deflection and bending moment. A noticeable difference was found when the groundwater table was 1.0 m below the ground surface. The effect of the slurry pressure reduction was higher than the effect of change in the groundwater level as shown in Fig. 15. The pile was greatly affected when the slurry pressure was reduced at depths between 11.5 m and 12.5 m (i.e. the location of the pile tip).

The large diameter pile is associated with low values of deflection but high values of bending moment as shown in Fig. 16. The large diameter pile provides a high stiffness and hence a high resistance to the soil movement. The ratio of change of bending moment values associated with the decrease in deflection is almost constant but the difference in deflection values was not constant. The deflection at pile diameters of 40, 60 and 80 cm was almost the same but it was slightly higher at a pile diameter of 20 cm and relatively low for a pile diameter of 100 cm.

The effect of panel construction stages on the first and third piles within the group is shown in Fig. 17. The values of the pile deflection and bending moment due to trenching the panel in two stages were lower than that due to trenching the panel in one stage.

4 Conclusions

The three-dimensional numerical simulation of the diaphragm wall trenching process was verified using two different case histories. The settlement results from the numerical analysis and field data were in a good agreement. However, some differences between both results were found due to the random nature of the field data results, while the numerical analysis depends on mathematical relations and provides systematic results.

The pile deflection and bending moment due to trenching were presented through a parametric study. The different values of panel thickness and pile diameter did not show a noticeable difference in the pile deflection, but the different values of pile diameter causes a noticeable change in pile bending moment. On the other hand, the change in panel length is associated with a great change in pile deflection and bending moment.

The change in values of groundwater level and pile group location causes a noticeable effect on the pile behavior, while the reduction of slurry pressure at some levels causes a great effect on the pile deflection and bending moment.

The piles within the group behave differently according to their position within the pile group. Generally, the piles nearest to the trench show higher deflection than those far from the trench and they are affected by the soil movement while the rear piles are affected by the drag force from the front piles.

The effect of trenching on piles could be reduced by conducting the panel in two stages, using shorter panel lengths and controlling the slurry pressure. It also could be reduced by lowering the groundwater table in the area before trenching.

References

Abdel-Rahman, A.H., El-Sayed, S.M.: Foundation subsidence due to trenching of diaphragm walls and deep braced excavations in alluvium soils. In: Proceedings of the 17th International Geotechnical Engineering Conference, vol. 3, pp. 1935–1938. Alexandria, Egypt (2009):

Byrne, P.M., Park, S.S., Beaty, M.: Seismic liquefaction: centrifuge and numerical modeling. In: FLAC and Numerical Modeling in Geomechanics: Proceedings of the 3rd International FLAC Symposium, Sudbury, Ontario, Canada, pp. 321–331 (2003)

Choy, C.K., Standing, J.R., Mair, R.J.: Stability of a loaded pile adjacent to a slurry-supported trench. Géotechnique 57(10), 807–819 (2007)

Comodromos, E.M., Papadpoulou, M.C., Konstantinidis, G.K.: Effects from diaphragm wall installation to surrounding soil and adjacent buildings. Comput. Geotech. 53, 106–121 (2013)

Cowland, J.W.; Thorley, C.B.B.: Ground and building settlement associated with adjacent slurry trench excavation. In: Proceedings of the Third International Conference on Ground Movements and Structures, pp. 723–738. Cardiff, England (1985)

Davies, R.V., Henkel, D.: Geotechnical problems associated with the construction of Charter station, Hong Kong. Arup J. 17(1), 4–10 (1982)

DiBiagio, E., and Myrvoll, F.: Full scale field tests of a slurry trench excavation in soft clay. In: Proceedings of the 5th European Conference on Soil Mechanics and Foundation Engineering, Madrid, vol. 1, pp. 473–483 (1972)

Gourvenec, S.M., Powrie, W.: Three-dimensional finite-element analysis of diaphragm wall installation. Géotechnique 49(6), 801–823 (1999)

Grandas-Tavera, C.E., Triantafyllidis, T.: Simulation of a corner slurry trench failure in clay. Comput. Geotech. 45, 107–117 (2012)

Hamza, M.M., Atta, A., Roussin, A.: Ground movements due to the construction of cut-and-cover structures and slurry shield tunnel of the cairo metro. Tunn. Undergr. Space Technol. 14(3), 281–289 (1999)

Itasca: Fast Lagrangian Analysis of Continua in 3 Dimensions (FLAC 3D) version 5 User’s Guide. 5th edn. Itasca Consulting Group Inc., Minneapolis (2012)

Karlsrud, K.: Performance and design of slurry walls in soft clay. Nor. Geotech. Inst. Oslo 149, 1–9 (1983)

Korff, M.: Response of piled buildings to the construction of deep excavations. Ph.D. Dissertation. University of Cambridge, UK (2013). http://www.dspace.cam.ac.uk/handle/1810/244715

L’Amante, D., Flora, A., Russo, G., Viggiani, C.: Displacements induced by the installation of diaphragm panels. Acta Geotech. 7, 203–218 (2012)

Mohamed, A.: Effect of groundwater table rising and slurry reduction during diaphragm wall trenching on stability of adjacent piles. In: IOP Conference Series: Earth and Environmental Science, Conference, vol. 1, p. 26 (2015). doi:10.1088/1755-1315/26/1/012012

Ng, C.W.W., Yan, R.W.M.: Stress transfer and deformation around a diaphragm wall. J. Geotech. Geoenviron. Eng. 124(7), 638–648 (1998)

Ng, C.W.W., Rigby, D., Lei, G.H., Ng, S.W.L.: Observed performance of a short diaphragm wall panel. Géotechnique 49(5), 681–694 (1999)

Poh, T.Y., Goh, A.T.C., Wong, I.H.: Ground movements associated with wall construction: case histories. J. Geotech. Geoenviron. Eng. 127(12), 1061–1069 (2001)

Stround, M.A., Sweeney, D.J.: A review of Diaphragm wall. Discussion Appendix. Institution of Civil Engineers (1977)

Tsai, J.-S., Jou, L.-D., Hsieh, H.-S.: A full-scale stability experiment on a diaphragm wall trench. Can. Geotech. J. 37(2), 379–392 (2000)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2018 Springer International Publishing AG

About this paper

Cite this paper

Mohamed, A., Shahin, M., Klapperich, H. (2018). The Deflection and Bending Moment of Existing Piles Influenced by Trenching Diaphragm Wall Panel(s). In: Abdoun, T., Elfass, S. (eds) Soil Dynamics and Soil-Structure Interaction for Resilient Infrastructure. GeoMEast 2017. Sustainable Civil Infrastructures. Springer, Cham. https://doi.org/10.1007/978-3-319-63543-9_1

Download citation

DOI: https://doi.org/10.1007/978-3-319-63543-9_1

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-63542-2

Online ISBN: 978-3-319-63543-9

eBook Packages: Earth and Environmental ScienceEarth and Environmental Science (R0)