Abstract

Gear and bearing are widely used in a variety of rotating machinery. They are considered as the most critical components of gearbox system. Vibration-based feature extraction is an effective approach to fault diagnosis of gear and bearing units. Fault diagnosis plays an important role in assuring equipment availability and reducing operational costs. This paper proposes a new fault diagnosis method that synthesizes time synchronous technique, fast empirical mode decomposition and correlated kurtosis. Our study shows that an improved fault feature extraction method can be obtained from sampled vibration signals. Energy of gear wheel rotational frequency and its harmonics are designated as the degradation indicators. The effectiveness of proposed method is verified and validated using the vibration data from gearbox test rigs and commercial wind turbines.

Access provided by CONRICYT-eBooks. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Gearbox is an important part of transmission systems used in helicopters, wind turbines and ground vehicles. Unexpected or unplanned failures usually result in large production losses and maintenance costs. Many vibration techniques have been developed for gearbox fault diagnosis and condition monitoring with different levels of efficiency. However, gearbox faults by their nature are time dependent and non-stationary phenomena, belonging to localized transient events. To deal with the non-stationary signals generated by gearbox, empirical mode decomposition (EMD) has been widely used for mechanical fault diagnosis domain [1]. EMD is more suitable to handle non-stationary and non-linear mechanical fault signals than wavelet analysis, S-transform, and Fourier transform methods. To effectively identify gearbox faults, the use of EMD and its variants or the combination with other signal processing methods became an important research topic.

Extensions have been made on EMD to overcome the mode mixing phenomenon, including ensemble empirical mode decomposition (EEMD) and the noise assisted multivariate empirical mode decomposition (MEMD) [2, 3]. These techniques are increasingly adopted for fault diagnosis and prognosis of mechanical systems. Wu et al. [4] use EEMD and autoregressive model to detect mechanical looseness faults. Ibrahim and Albarbar [5]compare the gear fault diagnosis effect of Wigner-Ville distribution and EMD. Experimental results show that EMD is able to detect the early faults more effectively than other methods. Guo et al. [6] propose an impulsive signal recovery method based on spectral kurtosis (SK) and EEMD. Later, Lei et al. [7] review the application of EMD in fault diagnosis of rotating machinery. Its applications in fault diagnosis of bearings, gears and rotors have been discussed extensively and the main challenges are highlighted as well. In this paper, we propose an approach to selecting the optimal frequency band containing fault impulse signal using spectral kurtosis. Then, correlated coefficients are used to determine the best intrinsic mode function (IMF) decomposed by EEMD for post processing.

Recently, many researchers attempt to diagnose mechanical faults using EMD or its variants combined with other signal processing methods, such as machine learning. Signal processing methods consist of wavelet transform, wavelet packet decomposition, minimum entropy deconvolution, morphological filter, spectral coherence, Bi-spectrum, and high order spectrum. For statistical-based machine learning methods, there are self-zero space projection analysis, high order cumulant, artificial neural network, fault leading algorithm, least square support vector machine, support vector machine, ensemble optimal extreme learning machine, Hidden Markov model and singular value decomposition. Besides these methods, Feng et al. [8] investigate the problem of planetary gearbox fault diagnosis using EEMD. Zheng et al. [9] propose a generalized empirical mode decomposition (GEMD) method for bearing fault diagnosis. Li et al. [10] develop a differential based empirical mode decomposition to analyze a multi-fault issue. Dybała and Zimroz [11] construct a new method by integrating all IMFs into three combined mode functions. Hence the fault signal can be divided into three components: noise-only part, signal-only part and trend-only part. To resolve the capacity problem in data transmission through wireless communication, Guo and Tse [12] propose a new bearing fault signal compression method based on optimal EEMD. Georgoulas et al. [13] develop an anomaly detection method based on EMD and three machine learning methods, namely Gaussian mixed model, nearest neighbor model, and principal component analysis.

However, the major drawback of EMD and EEMD is the low processing speed when the sample size of signals becomes large. If the number of samples used for decomposition is too small, it results in poor resolution for spectral analysis. Another trade-off of EMD is the calculation of IMFs using cubic spline function. It is effective to extract the harmonic feature, but fail to extract the transient feature. These issues are very inconvenient for fault diagnosis. In order to overcome this problem, Wang et al. [14] redesign the algorithm and the code such that EMD and EEMD have fast processing speed even if the signal under decomposition is very long.

Previous researchers usually select IMFs for post process using kurtosis and correlation coefficient [6] method. The proposed new criterion in this paper is named correlated kurtosis (CK) and will be used to select the best IMF. CK was proposed by McDonald et al. [15]. They develop a maximum CK deconvolution to replace the minimum entropy deconvolution because of its good effect. To mitigate specified problems, we propose hybrid fault diagnosis method based on time synchronous technique, fast EMD and CK. In particular, time synchronous technique is used to eliminate the rotating speed variation. Hence it guarantees the feasibility of spectral analysis of IMFs without spectral dispersion phenomenon. CK is used to select the best IMF through the comparison with other two indicators (i.e. kurtosis and correlation coefficient). Two data sets are used to verify the proposed method. One is the gear fault data with different tooth wear levels generated by test rigs in the laboratory setting. The other is the bearing fault data of a commercial wind turbine. The results show that the proposed method can effectively diagnose gear wear fault and gear wheel rotational frequency energy with first and second harmonic outperform root mean square (RMS) for degradation tracking. For bearing fault, IMF determined by CK contains obvious fault information.

This remainder of the paper is organized as follows. Section 2 introduces the algorithm of Fast EMD. Section 3 proposes the fault diagnosis framework of gear and bearing. Section 4 discusses the results of gear fault diagnosis and degradation track as well as the outcome of bearing fault diagnosis, and Sect. 5 concludes the work.

2 Fast Empirical Mode Decomposition

EMD algorithm is able to decompose a signal into finite IMFs which are extracted through an iterative sifting process. Generally, IMFs satisfy two conditions: First, in the whole time domain, the number of extrema and the number of zero-crossings are either equal or differ by only one. Second, the mean value of the envelopes defined by local maxima and local minima is zero. Given a signal y 0(t), t∈[1, n], the upper and the lower envelops can be acquired by cubic splines. The average of two envelops is obtained by subtracting from the original signal. First IMF is obtained through repeating the sifting process several times. Usually, the first IMF contains relatively higher frequencies compared to the residual signal. Next, this residual signal can be continually decomposed into second IMF and new residual signal. If this process is repeated, a series of IMFs and residual signal r(t) are obtained. The whole decomposition process can be represented using the following equation:

Where M is the number of IMFs. Detailed algorithm can be referred to [1].

Traditionally, EMD algorithm is known as computationally intensive. It can only handle the decomposition of short signals, resulting in a low resolution of spectrum. Recently Wang et al. [14] proved that the time complexity of EMD or EEMD is T = 41•NE•NS•n(log2 n) = O(nlogn) where n is the signal length and NS and NE are the sifting and ensemble numbers, respectively. This is equal to the complexity of FFT. The space complexity of EMD is M = (13 + log2 n)•n = O(n•logn). In addition, they optimized the program and a fast EMD algorithm was developed with the speed increased by 1000 times. Therefore this fast EMD algorithm is capable of processing the long vibration signals with high resolution quality.

3 The Fault Diagnosis Framework

Compared with laboratory experiments, load profile and rotating speed of rotating machinery in industrial applications generally are non-stationary. Take the wind turbine for example. A three percent of speed variation can cause 10 Hz difference of the bearing fault frequency [16]. If the raw vibration signal is used for EMD processing, the spectral analysis of selected IMF cannot accurately reveal the true fault information. This may lead to a miss-detection of faults. Therefore, time synchronous technique should be used for preprocessing the vibration signal collected from rotating machinery.

Presence of sideband frequencies around gear mesh frequency is the indication of amplitude modulation. For fault diagnosis, sideband frequencies represent the abnormality in the gearbox elements due to some faults or irregularity. The space between the sideband frequencies generally represents the rotating frequency of gear wheel. Therefore, one object of gear fault diagnosis is to find whether there exists an intense, equally spaced sideband frequency in frequency spectrum. Another objective could be the energy of gear mesh frequency and their associated harmonics. For bearing fault diagnosis, fault frequencies and their harmonics indicate the bearing fault presence. The object is to find the presence of these fault frequencies across the entire frequency spectrum. The detail diagnosis framework can be divided into four steps:

Step 1: Original vibration signal is processed using time synchronous technique. This technique guarantees the same sampling points for every revolution and overcomes the spectral spreading phenomenon. It should be noted that there is no need to perform the averaging operation, because the CK needs long signal to ensure the accuracy.

Step 2: Fast EMD is used to decompose the vibration signal into several IMFs containing different frequency fault information. The length of vibration signal should be long enough so that high spectral resolution of selected IMF is guaranteed. The processing can be done nearly in real time.

Step 3: CK is used to select the best IMF which contains the main fault information of gear or bearing. It can be expressed by following equation:

where y(t) is the input signal, τ is the interesting period of the fault, and N is the number of samples of y(t). If τ = 0 and M = 1, it gives the traditional kurtosis and can be used to detect the specific periodic impulse signals. For example, if the desired fault frequency is 50 Hz and the sampling frequency is 10,000 Hz, the value of τ could be 200 samples.

CK can detect the presence of some specific fault types. This characteristic can be used to find the best IMF that contains specific fault information and is very beneficial for degradation tracking when multi-fault exist.

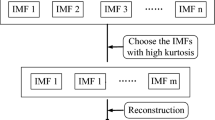

Step 4: The selected IMF can be used for post processing. For gear fault diagnosis, gear wheel rotational frequency and the associated harmonics in envelope spectrum are important indicators to determine which gear wheel has fault. In addition, gear wheel rotational frequency energy and their associated harmonics can be used to track the fault degradation trend. For bearing fault diagnosis, specific fault frequencies of envelope spectrum are the indicators to identify faulty component. The fault diagnosis framework based on Fast EMD and CK is illustrated in Fig. 1.

4 Experimental Validation

4.1 Experimental Setup

In this section, the proposed method is used to analyze the experimental vibration signal of a gearbox in a laboratory setting. The setup of the gearbox test rig is illustrated in Figs. 2 and 3. The test rig contains a 4 kW three phase asynchronous speed-adjustable motor for driving the gearbox, two-stage gearbox and a magnetic powder brake. The adjusted load is provided by the powder brake connected to the gearbox output shaft.

Vibration signals are measured by accelerometer secured by magnetic bases. The accelerometer is mounted on the top of low shaft speed bearing pedestal of the tested gearbox and the data are sampled at the frequency of 20 kHz. The tachometer resolution is 60 impulses per revolution. The teeth number and rotational speed of high speed shaft are 25 and 13.33 Hz, respectively. Gear wheel on the high speed shaft meshes with gear wheel on intermediate speed shaft with 50 teeth. Gear wheel on the low speed shaft has 81 teeth and meshes with gear wheel on intermediate speed shaft with 19 teeth, which gives 1:8.53 gearbox transmission ratio and 1.56 Hz speed of low speed shaft. Gear wheel on low speed shaft is used for testing. The presented results refer to nominal low speed shaft torque of 5.54 Nm and the tests were carried out under constant load.

4.2 Processing Results

Distributed faults, as uniform wear around whole gear wheel generally produce high level side bands and its associated harmonics in the envelope spectrum. The goal of CK is to detect the periodic impulse with a period of about 25,479 samples (new sampling frequency after time synchronous processing) divided by gear wheel rotational frequency. However, the length of time synchronous averaging (TSA) generally is very short. It can only guarantee that there is one period in TSA data. Therefore, there is no need to perform the averaging operation. It only needs to resample the signal according to tachometer signal for assuring equal angle-interval sampling. That ensures the signal length is long enough to calculate the CK value. After time synchronous processing, the signal can be decomposed into ten IMFs using Fast EMD. For illustration purpose, the vibration data of gear wear state 2 is being analyzed. Figure 4 is the results of ten IMFs, and Fig. 5 is the corresponding frequency spectrum of FFT.

In this paper, all the computations including the plot of figures are performed in Matlab environment. Matlab is a very useful tool for scientific calculations in research. Certainly, other software applications can also be used to implement these functions also.

5 Discussions

From Fig. 5, we can see that IMF 2 contains more harmonics of low gear wheel rotational frequency and higher energy. The values of three indicators of these IMFs are depicted in Figs. 6, 7, and 8. They correspond to correlation coefficient (CC), kurtosis and correlated kurtosis (CK), respectively. The approximately best IMF can be determined from these indicators. Root mean square values (RMS) of original vibration signals prior to EMD processing, and optimal IMF selected by CK value can be acquired for five wear states of gear. In addition, energy of low gear wheel rotational frequency and its second and third harmonics in the envelope spectrum can also be obtained. Figure 9 represents the normalized RMS and energy values. It shows that gear wheel rotational frequency energy is the best indicator to track the gear degradation, because they have systematic increasing trend compared with RMS values of other two types.

6 Conclusions

This paper proposes a hybrid gear and bearing fault diagnosis method based on three indicators, namely, time synchronous technique, fast EMD and correlated kurtosis. To demonstrate the effectiveness in real applications, the method is tested on the gear wear fault identification of fixed-axis gearbox; and on the bearing faults in drive train gearbox of wind turbines. Fast EMD algorithm can decompose a long signal into several IMFs in real time manner, enabling us to obtain high resolution frequency spectrum. Correlated kurtosis can determine the best IMF used for post processing. The length of time synchronous averaging is very short, which guarantees a single period of TSA data. Therefore, the averaging operation is not required; instead it only resamples the signal by the tachometer through equal angle-interval waveform. This ensures that the signal is long enough for calculating the CK value. After time synchronous processing, the signal can be decomposed into ten IMFs using Fast EMD. Finally, gear and bearing fault data of test rigs and field wind turbines are used to verify the effectiveness of proposed method. The results show the rotational frequency energy with first and second harmonic frequency outperforms the root mean square for degradation tracking. In the future the proposed method will be extended to industrial applications where machines or systems are subject to random shocks or vibration signals of certain components are available.

References

Huang NE, Shen Z, Long SR, Wu MC, Shih HH, Zheng Q, Yen NC, Tung CC, Liu HH (1998) The empirical mode decomposition and the Hilbert spectrum for non-linear and non-stationary time series analysis. Proc R Soc London Ser A 454:903–995

Mandic D (2011) Filter bank property of multivariate empirical mode decomposition. IEEE Trans Signal Process 59:2421–2426

Wu Z, Huang NE (2009) Ensemble empirical mode decomposition: a noise assisted data analysis method. Adv Adapt Data Anal 1:1–41

Wu TY, Hong HC, Chung YL (2011) A looseness identification approach for rotating machinery based on post-processing of ensemble empirical mode decomposition and autoregressive modeling. J Vib Control 18:796–807

Ibrahim GR, Albarbar A (2011) Comparison between Wigner-Ville distribution and empirical mode decomposition vibration-based techniques for helical gearbox monitoring. Proc IME C J Mech Eng Sci 225:1833–1846

Guo W, Tse PW, Djordjevich A (2012) Faulty bearing signal recovery from large noise using a hybrid method based on spectral kurtosis and ensemble empirical mode decomposition. Measurement 45:1308–1322

Lei YG, Lin J, He ZJ, Zuo MJ (2013) A review on empirical mode decomposition in fault diagnosis of rotating machinery. Mech Syst Signal Process 35:108–126

Feng ZP, Liang M, Zhang Y, Hou SM (2012) Fault diagnosis for wind turbine planetary gearboxes via demodulation analysis based on ensemble empirical mode decomposition and energy separation. Renew Energy 47:112–126

Zheng JD, Cheng JS, Yang Y (2013) Generalized empirical mode decomposition and its applications to rolling element bearing fault diagnosis. Mech Syst Signal Process 40:136–153

Li M, Li FC, Jing BB, Bai HY, Li HG, Meng G (2013) Multi-fault diagnosis of rotor system based on differential based empirical mode decomposition. J Vib Control 21(9):1821–1837

Dybała J, Zimroz R (2014) Rolling bearing diagnosing method based on empirical mode decomposition of machine vibration signal. Appl Acoust 77:195–203

Guo W, Tse PW (2013) A novel signal compression method based on optimal ensemble empirical mode decomposition for bearing vibration signals. J Sound Vib 332:423–441

Georgoulas G, Loutas T, Stylios CD, Kostopoulos V (2013) Bearing fault detection based on hybrid ensemble detector and empirical mode decomposition. Mech Syst Signal Process 41:510–525

Wang YH, Yeh CH, Young HWV, Hu K, Lo MT (2014) On the computational complexity of the empirical mode decomposition algorithm. Phys A 400:159–167

McDonald GL, Zhao Q, Zuo MJ (2012) Maximum correlated Kurtosis deconvolution and application on gear tooth chip fault detection. Mech Syst Signal Process 33:237–255

Bechhoefer E, Hecke BV, He D (2013) Processing for improved spectral analysis. In: Annual conference of prognostics and health management society

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2018 Springer International Publishing AG

About this paper

Cite this paper

Zhang, X., Kang, J., Bajrić, R., Jin, T. (2018). Gearbox Fault Diagnosis Based on Fast Empirical Mode Decomposition and Correlated Kurtosis. In: Zuo, M., Ma, L., Mathew, J., Huang, HZ. (eds) Engineering Asset Management 2016. Lecture Notes in Mechanical Engineering. Springer, Cham. https://doi.org/10.1007/978-3-319-62274-3_32

Download citation

DOI: https://doi.org/10.1007/978-3-319-62274-3_32

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-62273-6

Online ISBN: 978-3-319-62274-3

eBook Packages: EngineeringEngineering (R0)