Abstract

This paper presents the analyses of twelve prestressed concrete (PSC) instrumented test piles that were driven in different locations of Louisiana in order to develop analytical models to estimate the increase in pile capacity with time or pile set-up. The twelve test piles were driven mainly in cohesive soils. Detailed soil characterizations including laboratory and in-situ tests were conducted to determine the different soil properties. The test piles were instrumented with vibrating wire strain gauges, piezometers and pressure cells. Several static load tests (SLT) and dynamic load tests (DLT) were conducted on each test pile at different times after end of driving (EOD) to quantify the magnitude and rate of set-up. Measurements of load tests confirmed that pile capacity increases almost linearly with the logarithm of time elapsed after EOD. Case Pile Wave Analysis Program (CAPWAP) were performed on the restrikes data and were used along with the load distribution plots from the SLTs to evaluate the increase of skin friction capacity of individual soil layers along the length of the piles. The logarithmic set-up parameter “A” for unit skin friction was calculated of the 70 individual clayey soil layers, and were correlated with different soil properties. Nonlinear multivariable regression analyses were performed and three different empirical models are proposed to predict the pile set-up parameter “A” as a function of soil properties.

Access provided by CONRICYT-eBooks. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

It is well-known that the axial capacity of piles usually increases with time after driving in cohesive soils. Many researchers (e.g., Komurka et al. 2003; Rausche et al. 2004; Fellenius 2008; Abu-Farsakh et al. 2016) have studied this increase in capacity, known as “set-up”. Several empirical, analytical and numerical techniques have been proposed over the past few decades to predict the magnitude and rate of pile set-up with time. It has been well recognized that the magnitude of set-up is dependent upon the pile size, pile length, pile material, soil type and soil strength (Long et al. 1999; Chen et al. 2014).

Pile set-up phenomenon is mainly attributed to three main mechanisms: (1) Dissipation of excess pore water pressure (PWP) (or consolidation), (2) Thixotropic effect, and (3) Aging effect. During pile driving, the surrounding soil is displaced predominantly radially along the side and vertically and radially beneath the tip, thus generating a significant amount of excess PWP. In addition, the soil within the vicinity of pile face loses its strength due to an increase in excess PWP, disturbance of the soil structure and the soil remolding (McVay et al. 1999). As the excess PWP starts to dissipate, the effective stress of the disturbed soil starts to increase, and consequently set-up primarily occurs due to the increase in shear strength and the increase in lateral stresses against the pile (Rausche et al. 2004; Chen et al. 2014). Thixotropic effect (or regaining of soil strength of disturbed soil with time) also plays a significant role at the early stage of set-up (Ng et al. 2013; Haque et al. 2016a, b). Any set-up occurs after the completion of excess PWP dissipation is mainly due to “aging” effect (i.e., time dependent change in soil properties at a constant effective stress) (Schmertmann 1991; Wang and Gao 2013). Several empirical models (e.g., Skov and Denver 1988; Ng et al. 2013; Wang et al. 2015) have been proposed to estimate the pile set-up capacity with time. Of these models, the relationship developed by Skov and Denver (1988) is considered the most popular relationship due to its simplicity. They postulated that the pile capacity increases with the logarithm of time as follows:

where: Rt = Total pile capacity at time, t; Rto = Total pile capacity at reference time, to; t = Time elapsed since end of initial pile driving; to = Initial reference time, a reference time before which there is no predictable Rto increase as a function of elapsed time; A = Set-up rate parameter (log-linear). The “A” parameter can be assumed, back-calculated from field data, or gleaned from empirical relationships available in the literature. However, most of the available models in literature (e.g., Skov and Denver 1988) did not consider the soil properties in their formulations and that the total capacity (Rt) was mostly used instead of the skin friction (Rs). However, very few models (e.g., Ng et al. 2013; Karlsrud et al. 2014) incorporated the soil properties in their models to predict pile set-up. Table 1 presents the most recent pile set-up developed models.

The construction of pile foundation usually becomes expensive. Each year, millions of dollars are spent in order to drive prestressed concrete (PSC) piles. Therefore, the incorporation of even a small percentage of pile setup into pile design, can result in significant cost savings. The accurate prediction/estimation of the increase in pile capacity with time can be incorporated into a rational design through (a) reducing the number of piles, (b) shortening pile lengths, (c) reducing pile cross-sectional area (using smaller-diameter piles), and/or (d) by reducing the size of driving equipment (using smaller hammers and/or cranes).

2 Objective

The objective of this study is to develop analytical models to estimate the set-up parameter “A” of individual soil layers from soil properties. The set-up parameter “A” of individual soil layers were back-calculated using the unit skin friction (fs) rather than the total pile capacity (Rt) as proposed by Skov and Denver (1988) model. The soil properties of individual soil layers for each test pile location [i.e., undrained shear strength (S u ), Atterberg limits, sensitivity (S t ) and vertical coefficient of consolidation (c v )] were obtained from the laboratory testing and/or interpreted from the piezocone penetration test (PCPT) or dissipation test. The back-calculated set-up parameters “A” were correlated with the selected soil properties and nonlinear analytical models were developed to estimate the skin friction set-up for individual soil layers along the pile length.

3 Test Site and Subsurface Geotechnical Condition

3.1 Test Location and Test Piles (TP)

Five different sites were selected in Louisiana to perform the pile set-up study. These sites include: Bayou Zourie, Bayou Lacassine, Bayou Teche, Bayou Bouef and LA-1. Detailed description of the Bayou Zourie, Bayou Lacassine and LA-1 project sites can be found in Chen et al. (2014), Haque et al. (2014), and Haque et al. (2016a, b), respectively. Figure 1 shows the approximate locations of the pile set-up project sites. This set-up study was performed only on 12 square PSC instrumented test piles driven in cohesive dominated subsurface soil conditions. The objective of this study is to develop analytical models that can predict pile set-up for individual soil layers along the pile lengths. In order to meet this criterion, the test piles in all sites were instrumented with strain gauges in order to calculate the increase in skin friction of individual soil layers after EOD. With the aim to understand the consolidation behavior with pile set-up, a combination of piezometers and pressure cells were also installed in selected test piles to measure the total and excess pore water pressure and hence effective lateral stresses on pile face. The pile ID, their width and length and the hammer type used for installation are presented in Table 2.

3.2 Geotechnical Subsurface Characterization

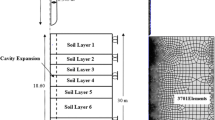

Both laboratory and in-situ tests were conducted at each test pile location to evaluate the different soil properties. 7.6 cm Shelby tube samples were retrieved from boreholes drilled at different depths at each test pile location for comprehensive laboratory testing. Water content, unit weight, Atterberg limits, one-dimensional consolidation tests and unconsolidated undrained (UU) triaxial tests were performed on selected soil samples to characterize the subsurface soil conditions. The in-situ testing program included both piezocone penetration tests (PCPT), piezocone dissipation tests and standard penetration test (SPT). One-dimensional consolidation tests were also performed to calculate the coefficient of consolidation (cv) of soil in the absence of PCPT dissipation tests. Table 3 presents the information of the soil properties that have been used in this study.

4 Load Testing Program

The load testing program was designed to measure the increase in pile capacity with time (or pile set-up). Table 3 summarizes the total number of tests, testing period, set-up ratio (i.e., capacity during a load test over initial driving capacity) and the back-calculated set-up factor “A” for the individual soil layers along the 12 instrumented test piles. The details of load test results for Bayou Zourie, Bayou Lacassine and LA-1 project can be found in Chen et al. (2014), Haque et al. (2014) and Haque et al. (2016a, b), respectively. The dynamic measurements were acquired with Pile Driving Analyzer (PDA) during initial driving and subsequent restrike events on each test pile. The DLTs were performed in accordance with the ASTM D 4945-89. In addition, the CAPWAP was also used to evaluate the skin friction of individual soil layers.

SLTs were performed after 6 to 14 days from EOD to evaluate the increase in pile capacity with time in each test pile as compared to DLT restrikes. The compression SLTs were performed in accordance with the ASTM D-1143 quick test loading option in all the test piles. The ultimate load capacity from the pile load test was determined based on the modified Davisson interpolation method (1972). Figure 2 presents the result of a SLT that was conducted at TP-2 location of LA-1 site. Embedded strain gauges were used to calculate the Rs, Rtip and Rt during each SLT, and to estimate the distribution of Rs along the pile length. In order to capture the strain gauge measurements for every incremental load during SLTs, the data acquisition system was set to collect the data at two minute intervals during each SLT. The axial load transfer can be determined from the strain measurements, the cross-sectional area and the Young’s modulus of the pile. Figure 2b depicts an example of the load distribution plot obtained during the SLT at TP-2 location of LA-1 site.

5 Results

5.1 Set-up in Terms of Total (Rt) and Skin Friction (Rs) Capacity

The total pile capacities estimated from the DLTs as well as the capacities measured by the SLTs are analyzed to study the set-up behavior for all test piles. However, performing repeated load tests numerous times can significantly affect the soil-pile interface and affect the true setup behavior. Performing frequent static and dynamic load tests on the same pile was a limitation of this study and can affect the result on some content. All the test piles exhibited significant amount of set-up as shown in Table 3. The results of skin friction set-up of all test piles are presented in Fig. 3. Figure 3 shows that the test piles of LA-1 site exhibited higher amount and rate of set-up compared to the test piles of other sites. The presence of very soft soil at the project location (i.e., near Gulf of Mexico) as compared to the other test pile location contribute to this behavior. The figure demonstrated that the skin friction capacities are best fitted to linear logarithmic of time with high coefficients of correlation (R2). As seen in Table 3 and Fig. 3, the pile set-up was mainly due to increase in Rs. The Rtip was almost constant over time for all the test piles.

5.2 Set-up of Individual Soil Layers

Most of the models available in literature to predict pile set-up consider either the total pile capacity set-up or the skin friction capacity set-up of entire pile. As a result, the soil properties of different soil layers along the pile length were not incorporated into those models, which results on difficult implementation of set-up models on different soil conditions. In this study, the unit skin friction (fs) (i.e., skin friction /contact area) was used to analyze the set-up behavior for individual soil layers along the pile length (Eq. 2). The set-up behavior for individual soil layers along the pile length were calculated in this study with the aid of vibrating wire strain gauges measurements during the SLTs and from the CAPWAP analyses during the DLTs.

Examples of analyses of set-up for individual soil layers are presented in Tables 4 for the TP-3 of Bayou Lacassine. The published literature (e.g., Paikowsky et al. 2005; Ng et al. 2013) documented that set-up is mainly dominant in clayey soil layers, and that small amount of set-up was observed in the sandy soil layers. In this study, the sandy soil layers exhibited smaller amount of set-up compared to the clayey soil layers due to quick dissipation of excess PWP after EOD. The tabulated data in Table 4 show that the clayey soil layers exhibited an average increase of 70% to 260% of set-up while sandy soil layers exhibited insignificant amount of set-up during the testing period compared to the EOD skin frictions.

5.3 Correlations Between Soil Properties and Set-up Parameter “A”

The set-up rate in this study as measured by “A” parameter is calculated using the unit skin friction for each soil layers along the pile length. 94 soil layers from 12 PSC test piles driven in five different project sites were included in the analyses. Clayey soil behavior was dominant in 70 clayey soil layers and the remaining 24 soil layers exhibited sandy soil behavior. The average value of “A” parameter for clayey and sandy soil layers are 0.31 and 0.15, respectively. The effects of soil properties on these back-calculated “A” parameters are investigated here in order to develop correlations between “A” parameter and the different soil properties. The soil properties that have significant influence on the set-up parameter “A” can be identified as the S u , PI, c h or c v and S t .

5.4 Effects of Undrained Shear Strength (S u )

The S u in this study is correlated with the rate of set-up parameter “A” for the individual clayey soil layers. S u was experimentally measured for 70 clayey soil layers and it ranges from 7 kPa to 157 kPa. The clayey soil layers of LA-1 project with the lowest S u values generally exhibited higher rate and magnitude of set-up compared to the clayey soil layers of the other sites. The correlation between S u and set-up parameter “A” is presented in Fig. 4a. The figure clearly demonstrates that there is an inverse-power relationship between the “A” parameter and S u value.

5.5 Effects of Plasticity Index (PI)

Atterberg limit tests were performed on all the 70 clayey soil layers and the value of PI ranges from 4% to 77%. The correlation between the PI of clayey soil layers and the set-up parameter “A” is presented in Fig. 4b. The figure shows that a linear proportional relationship do exists between the PI and the “A” parameter with a relatively high coefficient of correlation (R2 = 0.73) for this correlation.

5.6 Effects of Coefficient of Consolidation (C v )

The coefficient of consolidation (c v or c h ) is believed to be one of the most important factor to influence the set-up behavior of clayey soils. In-situ piezocone dissipation tests were performed and the c h values were calculated using Teh and Houlsby (1991) interpretation method. Laboratory consolidation tests were also performed on soil samples collected at LA-1 and Bayou Teche pile sites. The correlation between the c v and set-up parameter “A” for this study is depicted in Fig. 4c. In order to better represent the relationship, the normalized logarithmic value of c v is considered in this analyses. The figure shows that there exists an inverse linear proportional relationship between the set-up rate parameter “A” and the log c v values.

5.7 Effects of Sensitivity (S t )

Due to thixotropic property of the soil, the subsequent remolding and reconsolidation of the disturbed soil at the soil-pile interface zone will also be associated with long-term increase in soil strength, depending on S t values of the soil. The correlation between the S t and the set-up parameter “A” is presented in Fig. 4d. The figure shows that there exists a linear proportional relationship between the S t and set-up parameter “A”, similar to the PI-set-up parameter “A” relationship.

5.8 Development of Empirical Models for “A”

Non-linear multivariable regression analyses were conducted to develop empirical models to estimate the set-up parameter “A” from soil properties. Three different empirical models were developed for the set-up rate “A” using three different levels of soil properties for use by design engineers based on available soil properties. The procedure to develop the three different empirical models is similar; however, the difference is only in incorporation of different soil properties in three different empirical models. Two soil parameters (S u and PI) that are usually available in typical soil borelog are used to develop a simple correlation for the set-up parameter “A” in level-1 empirical model. Three soil parameters (S u , PI and c v ) are incorporated in level-2 empirical model. c h or c v parameters are usually not available in typical soil borelog; however, it is believed to be the most important parameter that can incorporate the effect of consolidation on set-up model. The developed model of level-3 is complex to implement, but it incorporated the effect of S t in this level. The correlation results between the set-up parameter “A” and the selected soil properties (Fig. 4) such as S u , PI, S t , c v were used to develop the analytical models. All possible regressions procedures were examined to select the best subset of predictor. R-Square, adjusted R-Square, sum of square error (SSE) and mean square error (MSE) were used as criteria to assess best predictors. Once preliminary models were selected, detail statistical analysis such as significance of the model as whole (F test) and significance of the partial multiple regression coefficient (t test) was carried out. The following three analytical models were finally selected amongst all models after examining all of the statistical analyses.

Figures 5a, b and c present the comparison of measured versus predicted set-up parameter “A” of the 70 individual clayey soil layers. The models that had been developed to predict the set-up parameter “A” from soil properties for three different levels need to be incorporated in Eq. 2 in order to predict the set-up for f s as:

Where, to = 1 day and fso = unit skin friction at 1 day restrike for individual soil layer.

Equations 6, 7 and 8 can be implemented to estimate the increase of f s with time of individual clayey soil layer after EOD. The f s value will be multiplied with the contact area of that layer to calculate the skin friction (Rsi ) of that layer. In the absence of sandy soil layers, the skin friction of all clayey soil layers along the pile length can be added to evaluate the total skin friction of the piles, Rs of the pile. A constant value of A = 0.15 (Average value of “A” parameter of all sandy soil layers in this study) is proposed here to estimate the f s value for the sandy soil layers and hence to calculate the skin friction of the sandy soil layers. Since no set-up was observed for the end-bearing capacity (Rtip) in this study as well as reported in the literature (e.g., Ng et al. 2013), no set-up is considered in calculating Rtip in the proposed model to estimate the Rt.

5.9 Model Verification

Other available pile set-up data from LADOTD were analyzed here to verify the developed analytical set-up models in Eqs. 6, 7 and 8. The three developed models in Eqs. 6, 7 and 8 were used to predict the “A” for the individual soil layers of these 18 test piles, followed by calculating the Rt using the methodology described earlier. Figure 6 presents the comparison between the measured and predicted set-up parameter “A” for verification of these 18 test piles.

6 Summary and Conclusions

Pile set-up study was conducted on 12 instrumented test piles of five different projects in mainly cohesive soils with the presence of interlayers of sand and silt in Louisiana. Laboratory and in-situ soil testing were conducted at the test pile location in order to characterize the subsurface soil profile. Based on field measurements of load tests on PSC driven piles and the statistical regression analyses, the following conclusions can be drawn:

-

1.

The total capacities measured by the static and dynamic load tests demonstrated that the set-up behavior follows a linear logarithmic rate of time after EOD. The end-bearing capacity was almost constant, and the majority of set-up was mainly attributed to increase in skin friction.

-

2.

The CAPWAP analyses from the DLTs and the load-distribution plots from the SLTs were used to calculate the skin friction capacity for individual soil layers along the piles. Almost all the clayey soil layers exhibited significant amount of set-up compared to sandy soil layers.

-

3.

The logarithmic rate of set-up parameter “A” was back-calculated for individual soil layers. A total 94 pile segments were considered in this study with the clayey soil behavior was dominant in 70 soil layers. The corresponding average values of the set-up rate “A” for clayey and sandy soil layers were 0.31 and 0.15, respectively, for this study.

-

4.

The magnitude and rate of set-up “A” exhibited a good correlation with the different soil properties. The undrained shear strength (S u ), plasticity index (PI), coefficient of consolidation (c v or c h ) and sensitivity (S t ) have shown significant influence on the set-up parameter “A”. The set-up parameter “A” decreases with increasing S u and c v , and increases with increasing PI and S t .

-

5.

Three different multivariable non-linear regression models were developed to estimate the “A” parameter and the increase of unit skin friction capacity (fs) with time for the clayey soil layers. The models incorporate different soil properties in three different levels with similar implementation procedure. The comparison between measured and predicted “A” parameter and “fs” value are in good agreement.

References

Abu-Farsakh, M.Y., Haque, M.N., Tsai, C.: A full scale field study for performance evaluation of axially loaded large diameter cylinder with pipe piles and PSC piles. Acta Geotech. (2016). doi:10.1007/s11440-016-0498-9

Bogard, J.D., Matlock, H.: In-situ pile segment model experiments at Empire, Louisiana. In: Proceedings of the Conference of Offshore Technology, Houston, TX, May 7–10, pp. 459–467 (1990)

Bullock, P.J., Schmertmann, J.H., McVay, M.C., Townsend, F.C.: Side shear setup. I: Test piles driven in Florida. J. Geotech. Geoenviron. Engng. 131(3), 292–300 (2005)

Chen, Q., Haque, MdN, Abu-Farsakh, M., Fernandez, B.A.: Field investigation of pile setup in mixed soil. Geotech. Test. J. 37(2), 268–281 (2014)

Davisson, M.T.: High capacity piles. In: Proceedings of the Soil Mechanics Lecture Series on Innovations in Foundation Construction, ASCE, Reston, VA, pp. 81–112 (1972)

Fellenius, B.H.: Effective stress analysis and set-up for shaft capacity of piles in clay. From Research to Practice in Geotechnical Engineering, Canada, pp. 384–406 (2008)

Haque, MdN, Abu-Farsakh, M., Chen, Q., Zhang, Z.: A case study on instrumenting and testing full-scale test piles for evaluating set-up phenomenon. J. Transp. Res. Rec. 2462, 37–47 (2014)

Haque, MdN, Abu-Farsakh, M.Y., Zhang, Z., Okeil, A.: Developing a model to estimate pile set-up for individual soil layers on the basis of PCPT data. J. Transp. Res. Board 2579, 17–31 (2016a)

Haque, M.N., Abu-Farsakh, M.Y., Tsai, C., Zhang, Z.: Load testing program to evaluate pile set-up behavior for individual soil layers and correlation of set-up with soil properties. J. Geotech. Geoenviron. Eng. (ASCE) (2016b). doi:10.1061/(ASCE)GT.1943-5606.0001617

Karlsrud, K., Clausen, C.J.F., Aas, P.M.: Bearing capacity of driven piles in clay, the NGI approach. In: Proceedings of the 1st International Symposium on Frontiers in Offshore Geotechnics, Perth, Sep 19–21, pp. 775–782 (2005)

Karlsrud, K.: Ultimate shaft friction and load displacement response of axially loaded piles in clay based on instrumented pile tests. J. Geotech. Geoenviron. Engng. 140(2), 481–495 (2014)

Komurka, V.E., Wagner, A.B., Edil, T.B.: Estimating soil/pile set-up. Wisconsin Highway Research Program #0092-00-14, Wisconsin Department of Transportation (2003)

Long, J.H., Kerrigan, J.A., Wysockey, M.H.: Measured time effects for axial capacity of driven piling. J. Transp. Res. 1663, 57–63 (1999)

McVay, M.C., Schertmann, J., Townsend, F., Bullock, P.: Pile friction freeze: a field investigation study. Research Report No. WPI 0510632, Vol. 1, Report submitted to Florida Department of Transportation (1999)

Mesri, G., Smadi, M.M.: Discussion: time-related increases in the shaft capacities of driven piles in sand. Geotechnique 51(5), 475–476 (2001)

Ng, K.W., Suleiman, T.M., Sritharan, S.: Pile setup in cohesive soil. II: analytical quantifications and design recommendations. J. Geotech. Geoenviron. Eng. 139(2), 210–222 (2013)

Paikowsky, S.G., Hajduk, E.L., Hart, L.J.: Comparison between Model and Full Scale Time Dependent Pile Capacity Gain in the Boston Area. ASCE Geotechnical Special Publication 132 Advances in Deep Foundations, pp. 1–16 (2005)

Rausche, M.F., Robinson, B., Likins, G.: On the prediction of long term pile capacity from End-Of-Driving information. In: Proceedings of the Current Practices and Future Trends in Deep Foundation, Los Angeles, CA, July 27–31, pp. 77–95 (2004)

Schmertmann, J.H.: The mechanical aging of soils. J. Geotech. Eng. 117(9), 1288–1330 (1991)

Svinkin, M.R., Skov, R.: Set-up effect of cohesive soils in pile capacity. In: Proceedings of the 6th International Conference on Application of Stress Waves to Piles, S. Niyama and J. Beim, (Ed.), Sao Paulo, Brazil, Sep 11–13, pp. 107–111 (2000)

Skov, R., Denver, H.: Time-dependence of bearing capacity of piles. In: Fellenius, B.G. (ed.) Proceedings of the 3rd international conference on the application of stress-wave theory to piles, pp. 879–888. BiTech Publishers, Canada (1988)

Wang, Y.H., Gao, Y.: Mechanisms of Aging-Induced modulus changes in sand with inherent fabric anisotropy. J. Geotech. Geoenviron. Eng. 139(9), 1590–1603 (2013)

Wang, J.X., Verma, N., Steward, E.J.: Estimating Pile Setup using 24-h restrike resistance and computed static capacity for PPC piles driven in soft Louisiana Coastal deposits. Geotech. Geol. Eng. 1, 1–17 (2015)

Acknowledgements

This research is funded by the Louisiana Transportation Research Center (LTRC Project No. 11-2GT) and LADOTD (State Project No. 736-99-1732).

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2018 Springer International Publishing AG

About this paper

Cite this paper

Abu-Farsakh, M.Y., Haque, M.N. (2018). Analytical Models to Estimate the Time Dependent Increase in Pile Capacity (Pile Set-Up). In: Abu-Farsakh, M., Alshibli, K., Puppala, A. (eds) Advances in Analysis and Design of Deep Foundations. GeoMEast 2017. Sustainable Civil Infrastructures. Springer, Cham. https://doi.org/10.1007/978-3-319-61642-1_12

Download citation

DOI: https://doi.org/10.1007/978-3-319-61642-1_12

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-61641-4

Online ISBN: 978-3-319-61642-1

eBook Packages: Earth and Environmental ScienceEarth and Environmental Science (R0)