Abstract

In Algeria, the siltation phenomenon affects all dams. Million cubic meters of sediments are deposited annually. A research program is developed for a rational use of dredged sediments.

This study aims to develop sediment management methodology and valorization of dredged materials in western region of Algeria. Experimental results are presented for the exploitation of dredged sediments and its potential uses as a new material resource for road engineering. The goal is to provide formulations economically competitive and easy to implement in situ.

The paper is composed of two parts. The first one presents the geotechnical characteristics of the dredged sediment. The second provides an analysis of the experimental results and discusses the influence of physico-chemical treatment composed of a size particle correction and treatment with binders on the compaction properties and bearing capacity of the material as well as its durability.

The results analysis show that the addition of lime influences the plasticity of material which is clearly decreases (55%). An improvement of the dry density is also observed (25%), which indicating an acceptable level of compactness.

The bearing capacity indices are significantly improved after treatment and continue to increase with lower water contents. The values of bearing capacity are ranging from 34–42%, acceptable values according to the technical guide (IIBCR > 25%), and sufficient to use in the pavement layers.

The compressive strength increases with the curing time or a significant increase appears for the lime treated sediment from a cure period of 28 days and the minimal strength criterion (1 MPa) set by the technical guide to allow trafficability on the treated layers is reached before seven days of curing time. This increasing of the curing time also improves the elastic modulus which indicated that the curing time affected the compressive strength and elastic modulus.

Access provided by CONRICYT-eBooks. Download conference paper PDF

Similar content being viewed by others

1 Introduction

Mediterranean countries are commonly reported to be severely affected by soil erosion. In north Africa, the high degree of climatic variability, the torrential nature of storm runoff, the low vegetation cover, and the excessive soil exploitation, have a great impact on erosion, sediment yield, and fluvial transport, on dam sedimentation and, consequently, on socio-economic conditions (Lahlou 1996).

The increased development of water resources in North African countries and Algeria in particular, increasingly demands an improved knowledge and understanding of the sediment generation, transport and deposition which seriously threatens the life of many reservoirs.

According to the ICOLD World Register of dams, there are 114 large dams in Algeria where 35% of dams are represented by the average sediment yield rate (Basson 2010).

The sediment deposits in Algerian reservoirs generate a siltation rate of about 50 million m3/year (Bensafia and Remini 2014).

Faced with this difficult situation, Algeria has taken a number of measures in order to limit the negative impact of erosion and suspended solids inflow, and to preserve the water resources stored in the dams. Dredging is therefore of crucial importance for the sustainable development of these natural resources. A significant number of dams were recovered whose lifetime is extended by several years.

However, the quantities of sediment removed by dredging and deposited downstream of the dam may lead to long-term pollution in rural areas. The management of such sediments is a worldwide problem at present.

For that, the recovery and re-use of this sediment should allow in the medium-term, the valorization of these materials in the field of Civil Engineering and Public Works (road engineering, bricks manufacturing and production of cementitious materials). This study focuses on the road sector because the road construction companies consume large quantities of natural aggregates; consequently, their natural resources are being depleted as it has become increasingly difficult to open new quarries. The dredged sediments can be viewed as a new source of materials and can be proposed, what will reduce the consumption of natural aggregates coming from quarries.

Previous research on the use of dredged sediments in road construction has shown that different processes of treatment have been developed to improve the geotechnical parameters of these sediments. The solidification-stabilization (S/S) treatment is frequently used to improve the mechanical properties of such dredged sediments. In this treatment process, the improvement of mechanical behavior of sediment by adding physico-chemicals such as, granular material, cement, fly ash, geofiber, lime, or a combination of these often alters the physical and chemical properties of the treated material. Two primary mechanisms are considered (Boutouil and Levacher 2001; Asgari et al. 2015):

-

1.

Increase in particle size due to cementation, increase in strength parameters, change in the plasticity properties, and reduced deformation potential.

-

2.

Absorption and chemical binding of moisture that will facilitate compaction.

According to Levacher et al. (2012), the addition of lime to sediments is suggested in a stabilization process for the following effects: immediate decreasing of water content of sediments, improvement of workability for the lime-sediment composite, obtaining a possible long-term mechanical performance, and attenuation of the effects of organic matter. Indeed, Song et al. (2003) investigated solid waste soils for use as sub-base materials in road construction. It was shown that the geotechnical properties are clearly affected by the magnitude of organic matter content. As it increases, the maximum dry unit weight, shear strength and bearing capacity of ground decrease, while the void ratio and compressibility increase. Song et al. (2003) noted that if the organic matter content is more than about 8% in solid waste soils, it is not suitable for use as a sub-base material in road construction. This is due to the significant decrease of shear strength and bearing capacity.

Le Guern et al. (2014) studied the mechanical performances of three marine dredged sediments treated with hydraulic binders from three different French harbors, showing that the organic matter content and optimal dry density have a major influence on unconfined compressive strength, and a moderate one on the indirect tensile strength.

According to Wang et al. (2013), the addition of lime results in a significant improvement in the unconfined compressive strength (UCS) and the shear strength. The failure mode of sediments treated with lime develops gradually from plastic to brittle failure. In the meantime, failure strength increases, whereas failure strain decreases with lime content. The shear strength parameters of the solidified sediments are increased owing to the pozzolanic reaction between lime and clay minerals, compared to those of untreated sediments. In addition, the preconsolidation pressure, coefficient of consolidation and the compression index are increased, while the swelling index decreased after lime treatment.

Dermatas et al. (2003) studied the geotechnical properties of cement treated dredged sediment. They found that the compressibility decreased with decreasing water content and increasing cement content. The higher the coefficient of consolidation value and the lower the volumetric strain, the higher the unconfined compressive strength will be. Moreover, the hydraulic conductivity increased with the cement content.

Nor Zurairahetty et al. (2015) investigated the effectiveness of lime stabilization of marine clay based on their strength and compressibility characteristics. An increase in strength was found with increasing lime content. In addition, strength also increases significantly as early as seven curing days and continues for 28 curing days. The coefficient of consolidation with the addition of lime decreases as the lime content increases compared to the untreated marine clay. The compression index value decreases as the lime content increases.

In conclusion, the research in the literature agrees generally on the increase in strength parameters (UCS, shear strength and preconsolidation pressure) of treated sediments with binders; however, for the compressibility characteristics, results in the literature differ somewhat. These variations depend on several parameters: mineralogy, binder content, binder type, curing time, organic matter content, etc.

This study is part of a research program on the dredged sediments management of dams in the western Algeria for reuse in road engineering. Several dam study sites have been selected, depending on the accessibility of the site, their siltation rates and the dredged sediments extraction area. The Cheurfas dam site is part of this selection list.

In this paper, an experimental study based on a treatment protocol, and aiming at the valorization of Cheurfas dredged sediments as a new material resource for road embankments. The treatment proposed is based on the formulations of mixtures with different percentages of dredged sediment, granular materials and binders according to the technical guide (GTS 2000). Several physico-chemical and mechanical tests are performed such as compactness, bearing capacity, elastic modulus and the unconfined compressive strength. The aim is to propose a treated material that is economically competitive and easy to implement in situ.

2 Presentation of Site

The studied sediment comes from the Cheurfas dam, which is located in the north-west of Algeria. Its exploitation began in 1992 and was intended to irrigate surrounding agricultural lands and supply drinking water for the town of Sig (west of Algeria).

This dam, which crosses the Wadi El Mebtouh, regulates 45 106 m3 of water, and is built on the ruins of an old dam swept away by a flood in 1927 (Labiod et al. 2001). Its major river basin has a total estimated area of 4190 km2 with a maximum altitude of 1754 m and an average altitude of 855 m.

According to the USCS/LCPC classification and the road technical guide (GTR 2000), which are based on the values of geotechnical parameters presented in Table 1, the Cheurfas sediment is classified as an organic and highly plastic soil OH (Ot) and a F1-A2 class material, respectively.

This sediment cannot be used in its natural state in road engineering, and therefore needs to be treated to improve its mechanical performance.

3 Use of Cheurfas Sediment in Road Engineering

The sediments have a complex structural composition and can be considered as an evolutionary material. The presence of organic matter constitutes a plastic and moderately compressible behavior. Recent studies revealed that the organic matter has a significant effect on the geotechnical properties of soils (Thiyyakkandi and Annex 2011; Adejumo 2012).

Indeed, the physico-chemical and geotechnical testing performed on natural and calcined Cheurfas sediments have demonstrate that the organic activity is highly influential on the sedimentary matrix. The plasticity decreases with the organic matter content. The relative difference observed is higher than 50%, with a significant difference found in the size fraction and swelling-shrinkage potential (Bourabah 2012).

This difference is probably attributed to the elimination of organic matter, leading to deterioration in the internal mineralogical complex of the sediment (clay humic complex). Consequently, a new internal structure material is created, having a non evolutive internal structure in time.

Thus, as long as no particular treatment, simple or complex, will be made on these sediments to destroy organic matter, they can always act in the material structure.

4 Physico-Chemical Behavior of Sediment After Treatment

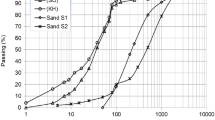

To be used as pavement layer structure, a well-graded granular distribution of material is recommended (Dubois 2006; Predis 2007).

For this purpose, the particle size and organic matter content are the most important factors in choosing the valorization of dredged sediment in road engineering. It is necessary to manage their impact on the achievement of durable material on the mechanical and environmental plan, based on the general valorization methodology approach taken in this study, which is mainly not to use treatments heavy and expensive.

The studied sediment is mixed with other granular components in interesting proportions from the economic point of view, which allow an easy application on the industrial scale and an interesting reduction of the water content and the proportion of organic matter. The addition of hydraulic binders, for obtaining the final road material, will allow, reducing the water content, by the phenomena of hydration and dry matter contribution (Sfar Felfoul et al. 2003).

The added granular fraction is a quarry sand (0/4) mm with 3% of elements smaller than 80 µm, and 47% coarse sand. It is a well-graded clean sand SW (Sb) according to the USCS/LCPC classification. The lime used is quicklime (0/2) mm.

The treatment consists of adding a granular fraction of sand (0/4) mm and secondly 3% of quicklime (0/2) mm. This binder content corresponds to what is usually used in road construction of pavement layers for soil treatment.

Table 2 shows the types, physico-chemical and geotechnical characteristics of the two studied formulations. The proportion of granular addition with fine sediment has given a mainly clayey sand mixture with a well-graded granular distribution.

The addition of lime in treatment process influences the plasticity of material which is clearly decreases (55%). In general, adding lime causes the rapid flocculation of clays. This action results in an improvement of the consistency, which causes a displacement of the plasticity domain to larger water contents. The shift of the plasticity index is related to the lime content, the nature of the clay minerals and the water content (Ola 1977; Bell 1996; Lasledj and Al-Mukhtar 2008).

5 Mechanical Behavior of Sediment After Treatment

A series of mechanical tests were conducted on the studied formulations, which allow knowing the changes in the parameters of the compactness (γdMPO), bearing capacity (IIBCR, CBR), unconfined compressive strength (UCS) and the elastic modulus (E).

5.1 Compaction and Bearing Capacity

The compaction-bearing capacity test was performed according to the modified Proctor method (MPO). Samples of about 6 kg were spray-moisturized in order to reach different water contents. Following the method, amounts of soil from these homogenized wet samples were compacted into five equal layers in a cylindrical compaction mold of 152 mm in diameter and height. Each layer received 56 blows of a 4.53 kg falling hammer of 5.1 cm diameter and 45.7 cm height. The energy density was 2.41 kJ dm−3. The weight of the wet compacted soil in the mold was determined, and the samples were dried and weighed again to estimate the moisture content and dry density.

This process is repeated for various moisture contents, and the dry densities are determined for each. Two graphical relationships of the dry density and bearing capacity to moisture content are then plotted to establish the compaction and bearing capacity curves. The maximum dry density (γdMPO) is finally obtained from the peak point of the compaction curve, and its corresponding moisture content, also known as the optimum moisture content (wMPO). Two indices are determined for the bearing capacity curve:

-

The Immediate Bearing Capacity Ratio index (IIBCR): This index is carried out to evaluate the ability of the soil to support the movement of construction machinery. The principle is to measure the force corresponding to the driving of a cylindrical punch (with a diameter equal to 49.6 mm) into the sample at a constant rate of 1.27 mm/min (NF P 94-078). The forces for two conventional displacements (2.5 and 5 mm) are compared to the corresponding values for a reference material.

The Immediate Bearing Capacity Ratio index (IIBCR): is determined by the following equation:

$$ {\text{I}}_{IBCR} = max\left( {{\text{I}}_{IBCR25} \text{;}\,\,{\text{I}}_{IBCR50} } \right) $$(1)$$ {\text{IIBCR}}25 = \frac{{{\text{F}}25}}{13.35} \times 100\quad {\text{IIBCR}}50\,{ = }\, \frac{{{\text{F}}50}}{20} \times 100 $$(2)-

\( F_{25} \) = load corresponding to 2.5 mm of penetration (kN)

-

\( F_{50} \) = load corresponding to 5 mm of penetration (kN)

-

-

The California Bearing Ratio index (CBR): This index is performed to estimate the bearing capacity of a finished pavement. The principle of the test for this index is the same as that of the IIBCR test, the difference being that the specimen is overloaded at the top by annular discs of 150 mm diameter and 2.3 kg mass representing the equivalent of imposed stress by the pavement on the platform (NF P 94-078).

Table 3 indicates the values of the Modified Proctor Optimum (MPO) corresponding for each formulation.

For these mixtures, a decrease in water content at the MPO is clearly observed compared to that of the Cheurfas sediment (CS).

It is also observed that, more a mixture contains sediment, more the optimum water content is high, and therefore the dry density and bearing capacity corresponding are less important. The use of this sediment without treatment cannot be considered in the road construction.

The results presented in Table 3 show that the maximum dry density achieved for Cheurfas sediment is 15.54 kN/m3 and the optimum water content is 23.3% and 14% for immediate bearing capacity ratio index. The material will be considered as usable for a pavement layer if the water content allows a dry density greater than 95% of γdMPO and a IIBCR higher than 25%. The Cheurfas sediment studied in its natural state does not check for this condition for use in pavement layer.

The treatment of Cheurfas sediment (CS) by 70% of sand (0/4) mm (For 1), indicates the following:

-

The water content was clearly decreased by the addition of sand (0/4) mm compared to that of Cheurfas sediment (CS), showing that the addition of sand as a granulometric corrector significantly affects the optimal water content of the mixture.

-

An improvement of the maximum dry density is also observed, where an average increase of γdMPO is of around 25%. However, we note a little variation of the immediate bearing capacity ratio index (IIBCR) with this decrease in the optimum water content, compared to the Cheurfas sediment. This is probably due to occluded air bubbles generating a reversible compressibility of the interstitial fluid and thus occurrence of the phenomenon known as “quilting”. This phenomenon describes the behavior of a too humid soil during compaction. This operation results in the formation of pads due to the instability of the engine and finally an impossibility of compaction.

The sediments, such as mixtures are sensitive to the water and their use without binders may be detrimental to the durability of the pavement (Boutouil and Saussaye 2011). This sensitivity is related to the presence of organic matter, which by the water retention increases the phenomena.

The addition of lime as binder type in the composition of the final material can change the values of mechanical parameters (Wang et al. 2013). Indeed, the analysis of the results, in Table 3, indicates the following:

-

Adding lime to sediments increases their optimum moisture content and slightly reduces their maximum dry density;

-

The bearing capacity indices are significantly improved after treatment. According to Fig. 1, the IIBCR and CBR indices increase immediately after the addition of lime and continue to increase with lower water contents. The treated sediment gives values of IIBCR and CBR ranging from 34–42%.

According to the French standard GTR (2000), these parameters are sufficient to use this treated material in a pavement layers (IIBCR > 25%). However, the bearing capacity curves show a rapid decrease when the water content is higher.

5.2 Compressive Strength and Elasticity

The compressive strength determines the trafficability criterion of the soil according to NF P 98-232-1 standard that allows one, in the short term, to estimate the necessary waiting period in order to allow the harmless passage of construction equipment on the soil layer.

Based on the results of Proctor Modified test, the compression strength test is performed on cylindrical specimens of 35 mm diameter and 70 mm height according to the NF P 98 114-3 standard, compacted statically at wMPO and 98.5% γdMPO, with respect to the NF P 98-230-2 standard. Then, the specimens of treated materials are stored for 24 h at constant water content in an airtight container for homogenizing the water content, and then placed in the open air in a room at controlled humidity for even drying during the curing time, respectively of 7 to 180 days. When the targeted curing times are achieved, the elastic modulus (E) and the unconfined compressive strength (UCS) are measured.

The elastic modulus (E) is determined by the ultrasonic test according to the NF P 18-418 standard. This test consists of emitting a wave in a sample (treated sediment) and measuring the time and the propagation velocity of this wave by traveling a known distance. The elastic modulus (E) is determined by the following equation:

-

V = Propagation velocity (m/s)

-

ρ = Solid density (MN/m3)

-

g = Acceleration of gravity (m/s²)

-

ν = Poisson’s ratio

-

d = Distance between the transmitter and receiver transducers (m)

-

t = Propagation time of the wave (s)

The unconfined compression strength (UCS) is determined by applying increasing pressures up to the rupture of the sample. The results of the UCS test in Fig. 2 show that:

-

The UCS increases with the curing time or a significant increase of this strength appears for the formulations from a cure period of 28 days.

-

The minimal mechanical strength criterion (1 MPa) set by the technical guide (GTS 2000) is reached before seven days of curing time, which allows them to be used as a road layer.

-

After a curing time of 28 days, there is a significant change in the mechanical strength for the formulation treated with quicklime which stabilizes at a curing time of 90 days. This sharp increase of the mechanical strength after 28 days is justified by the lime hydration reaction.

According to Bell (1996), when lime is added to a clay soil, it has an immediate effect on the properties of the soil, as cation exchange begins to take place between the metallic ions associated with the surfaces of the clay particles and the calcium ions of the lime. The clay particles are surrounded by a diffuse hydrous double layer that is modified by the ion exchange of calcium. This alters the density of the electrical charge around the clay particles, which leads them to be attracted closer to each other to form flocs, the process being termed flocculation, which is responsible for the modification of the engineering properties of soils.

Figure 3 shows the effect of lime and curing time on the elastic modulus of stabilized sediments. It can be seen that the addition of lime, leads to an increase in the stabilized samples’ stiffness. Consequently, the strength and elastic modulus of the treated sediment increased after lime treatment.

As can be seen from Fig. 3, increasing the curing time leads to an increase in the elastic modulus of the treated specimens. It can be concluded that the curing time affected the compressive strength and elastic modulus.

This may be due to the fact that the hydration process still occurs between the binder and fine sediment and, in continuation; the pozzolanic reactions are responsible for increasing the strength and stiffness.

6 Conclusions

The valorization approach proposed in this study is based on choice of preparation and simple formulation, facilitating the use of Cheurfas sediment in road engineering. The main objectives were to identify the influence of granular material and lime, on the strength behavior and durability of sediments under extreme conditions. The improvement in mechanical properties such as dry density, bearing capacity, unconfined compressive strength and elastic modulus, were investigated.

The studied fine sediment presents a high value of the organic matter content, which can influence the physical and mechanical properties of this material.

The analysis of physico-chemical and mechanical results on studied formulations is encouraging for the management of this dredging sediment where a particle size correction has been well observed, followed by an improvement of the maximum dry density obtained by substitution of this sediment by a granular material. The optimum water content is relatively small and the organic matter content does not affect the compactness of the material, it acts adversely against the bearing capacity.

The addition of lime as a type of hydraulic binders in these sediment mixtures allowed us to notice that their influence is on the plasticity of the material which clearly decreases and largely on these mechanical parameters which are clearly improved, which indicates a good hydraulic jack.

This research has shown that, the addition of granular material and binder may be considered as an interesting alternative for stabilization of Cheurfas sediments and its beneficial use as a new material for the construction of foundation and base layers for roads.

References

Adejumo, T.E.: Effect of organic content on compaction and consolidation characteristics of Lagos organic clay. Electron. J. Geotechn. Eng. (EJGE) 17, 2201–2211 (2012)

Asgari, M.R., et al.: Experimental study on stabilization of a low plasticity clayey soil with cement/lime. Arab. J. Geosci. (2015). doi:10.1007/s12517-013-1173-1. Springer

Basson, G.: Sedimentation and sustainable use of reservoirs and river systems. In: International Commission on Large Dams (ICOLD), Bulletin (2010)

Bell, F.G.: Lime stabilization of clay minerals and soils. Eng. Geol. (1996). doi:10.1016/0013-7952(96)00028-2. Elsevier

Bensafia, D., Remini, B.: Le rôle de la vase dans l’accélération de l’eutrophisation des eaux de barrages. Etude expérimentale. Larhyss J. 19, 161–181 (2014)

Bourabah, M.A.: Comportement mécanique des sols fins. Application à la valorisation des sédiments de barrages en technique routière. Thèse de Doctorat, Université de Tlemcen, Algérie (2012)

Boutouil, M., Levacher, D.: Etude expérimentale de la solidification d’une vase de dragage à base de ciments: Evaluation de la porosité et de la structure poreuse après solidification (Experimental study of cement-based solidification of dredged sludge: assessment of the porosity and pore structure after solidification). Mater. Struct./Matériaux et Const. (2001). doi:10.1007/BF02480510. Springer

Boutouil, M., Saussaye, L.: Influence of granulometric corrector on the properties of the sediments treated with hydraulic binders. Revue Paralia, Editions Paralia CFL (2011). doi:10.5150/revue-paralia.2011.008

Dermatas, D. et al.: Geotechnical properties of cement treated dredged sediment to be used as transportation fill. In: Garbaciak Jr., S. (ed.) Proceedings of Dredging 2002, Key Technologies for Global Prosperity. ASCE, New York (2003)

Dubois, V.: Etude du comportement physico-mécanique et caractérisation environnementale des sédiments marins-Valorisation en technique routière. Thèse de doctorat, Ecole Nationale Supérieure des Mines de Douai, France (2006)

GTR: Guide technique pour la réalisation des remblais et des couches de forme, fascicules 1, principes généraux (Technical Guide for the realization of embankments and subgrades, fascicles 1 General Principles), LCPC-SETRA (2000)

GTS: Traitement des sols à la chaux et/ou aux liants hydrauliques en remblai et en couche de forme, Guide technique (Treatment of soils with lime and/or hydraulic binders embankment and subgrade, Technical Guide), LCPC-SETRA (2000)

Labiod, Z., et al.: Auscultation des barrages en Algérie (Auscultation of dams in Algeria). In: Séminaire National de Génie Civil SNGC 2001 (2001)

Lahlou, A.: Environmental and socio-economic impacts of erosion and sedimentation in North Africa. In: Erosion and Sediment Yield: Global and Regional Perspectives, Proceedings of the Exeter Symposium. IAHS Publ. No. 236 (1996)

Lasledj, A., Al-Mukhtar, M.: Effect of hydrated lime on the engineering behaviour and the microstructure of highly expansive clay. In: The 12th International Conference of International Association for Computer Methods and Advances in Geomechanics (IACMAG), Goa, India (2008)

Le Guern, M., et al.: Geotechnical and mechanical characterisation of three marine dredged sediments treated with hydraulic binders. In: Proceedings of the South Baltic Conference on Dredged Materials in Dike Construction, Rostock, Germany (2014)

Levacher, D., et al.: A civil engineering application in sediment management: A confined embankment in Cherbourg harbour. XIIèmes Journées Nationales Génie Côtier-Génie Civil, Cherbourg, France, Editions Paralia CFL (2012). doi:10.5150/jngcgc.2012.114-L

NF P 18-418: Concrete - Sonic auscultation - Measurement of the sonic wave transmission time in concrete. Association Française de Normalisation, France (1989)

NF P 94-078: Soils: investigation and tests - CBR after immersion - Immediate CBR - Immediate bearing ratio - Measurement on sample compacted in CBR mould. Association Française de Normalisation, France (1997)

NF P 98 114-3: Roadway foundations - Methodology for laboratory study of materials treated with hydraulic binders - Part 3: Soils treated with hydraulic binders possibly combined with lime. Association Française de Normalisation, France (2001)

NF P 98-230-2: Test relating to pavements - Preparation of materials bound with cementitious binders or aggregates mixes - Part 2: Preparation by static compression of sands or fine grained soils specimens. Association Française de Normalisation, France (1993)

NF P 98-232-1: Tests relating to pavements - Determination of the mechanical characteristics material bound with hydraulic binders - Part 1: Unconfined compression test on aggregate. Association Française de Normalisation, France (1991)

Nor Zurairahetty, M.Y. et al.: Performance of lime-treated marine clay on strength and compressibility characteristics. Int. J. Geomate Jpn. Geotech. Const. Mat. Env., 2186–2990 (2015). ISSN: 2186-2982(P)

Ola, S.A.: The potentials of lime stabilization of lateritic soils. Eng. Geol. (1977). doi:10.1016/0013-7952(77)90036-9. Elsevier

Predis: Améliorer la valorisation des déchets industriels en BTP. Guide Technique Régional Relatif à la méthodologie de gestion des sédiments de dragage portuaire (Improve the recycling of industrial waste in construction. Regional Technical Guide Related to the methodology of port dredging sediments management). Démarche PREDIS Nord Pas de Calais, Groupe de travail no. 5, Ecole des Mines de Douai, Université Sherbrooke, Université D’artois (2007)

Sfar Felfoul, H., et al.: Traitement des sols à la chaux et au ciment en technique routière tunisienne: présentation d’un exemple. Séminaire International de Géomatériaux, M’sila, Algérie (2003)

Song, Y.S., et al.: Investigation of solid waste soil as road construction material. Environ. Geol. (2003). doi:10.1007/s00254-002-0746-1. Springer

Thiyyakkandi, S., Annex, S.: Effect of organic content on geotechnical properties of Kuttanad clay. Electron. J. Geotechn. Eng. (EJGE) 16, 1653–1663 (2011)

Wang, D., et al.: Effect of lime treatment on geotechnical properties of Dunkirk sediments in France. Road Mater. Pavement Des. (2013). doi:10.1080/14680629.2012.755935. Taylor & Francis Online

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2018 Springer International Publishing AG

About this paper

Cite this paper

Bourabah, M.A., Taibi, S. (2018). Effect of Physico-Chemical Treatment on the Mechanical Properties of Dredged Sediment. In: Singh, D., Galaa, A. (eds) Contemporary Issues in Geoenvironmental Engineering. GeoMEast 2017. Sustainable Civil Infrastructures. Springer, Cham. https://doi.org/10.1007/978-3-319-61612-4_29

Download citation

DOI: https://doi.org/10.1007/978-3-319-61612-4_29

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-61611-7

Online ISBN: 978-3-319-61612-4

eBook Packages: Earth and Environmental ScienceEarth and Environmental Science (R0)