Abstract

Polypropylene (PP) and polyethylene (PE) are the leading plastics used for food packaging with surface metallization to protect the foodstuff. Unlike the polyethylene terephthalate (PET) bottles, metalized plastic wastes (MPW) produced by discarded food packaging articles are not suitable for recycling and reuse owing to the metalized layer. MPW litter in waste streams or sent to the landfill as a part of municipal solid waste (MSW) resulting in hazardous environmental impacts. Efforts are made in this work to utilize MPW in concrete as a sustainable usage of the specific waste. In present work, MPW is shredded into fibers of varying sizes and added to concrete ranging 0% to 2% by volume of concrete. The response of addition of MPW in concrete was evaluated by assessing workability and strength properties namely slump, compaction factor, compressive strength, splitting tensile strength and flexure strength. The results show significantly improved crack resistance and ductility in concrete reinforced with MPW. The increase in tensile resistance of concrete containing MPW up to 1% of volume fraction was observed. Flexure test results exhibited improved ductility of concrete containing MPW. However, reduction in the fresh properties and compressive and flexure strength of concrete was noticed with the increased fraction of MPW beyond 1% dosage. The experimental study establishes the potential of the sustainable use of MPW in concrete to reduce adverse environmental impacts and to improve the tensile resistance of the conventional concrete.

Access provided by CONRICYT-eBooks. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

The annual generation of plastic waste has reached beyond 300 million tons by the year 2015 (Plastics-the facts 2015). Plastic being the most durable material it has gained popularity in past few decades with changing modern lifestyles. Most of the plastics are recyclable and being reused in many forms except a few namely metalized plastics. Polyethylene (PE) and Polypropylene (PP) are the plastics used in food packaging with additional metalized layer called metalized plastic (A report: American Plastic Council 1997) making them unfit for recycling. Metalized plastic waste, therefore, has become one of the challenges raised by the ever-increasing post-consumer activities for a safe disposal. Major concerns of metalized plastic wastes are the littering issues and prolonged existence in the environments.

The construction industry has initiated the usage of post-consumer plastic waste in past few years. The area of research has attracted the attention of researchers and plastic wastes generated by post consumer activities namely polyethylene terephthalate (PET) bottle wastes and plastic carry bags have been used in concrete as aggregates and fibers. Partial replacement of natural aggregates by recycled aggregates has shown a balanced influence on concrete properties. Properties namely density, workability are influenced due to the addition of plastic aggregates (Rahmani et al. 2013). Hardened properties of concrete are tested for obtaining the response of addition of aggregates. It is observed that modulus of elasticity; density and strengths properties namely compressive strength, splitting tensile strength are reduced for a higher dosage of replacement of natural aggregates by PET aggregates (Saiki and de Brito 2012). However, the addition of PET aggregates improved the flexural response of concrete (Ferreira et al. 2012).

Recycled plastics are incorporated as fibers in concrete by other researchers. Most of the researchers have used PET bottles to retrieve fibers. The addition of plastic fibers influenced workability of concrete and showed a reduction in higher dosage (Pacheco-Torgal et al. 2012). Recycled plastic fibers affected the properties namely shrinkage, drying shrinkage, slump up to an extent and showed improvement for a given dosage (Yin et al. 2015; Borg et al. 2016). Hardened properties namely compressive strength, splitting tensile strength, flexural strength was improved due to the addition of recycled PET waste fibers (Foti 2011, 2013; Yin et al. 2016).

The deformation characteristics of concrete were improved and the addition of PET fibers improved the ductility of concrete (Kim et al. 2010; Fantilli et al. 2016). PET fibers are utilized in self-compacting concrete (SCC) also. It is studied that the fresh properties of SCC at a given dosage of PET fibers exhibits the acceptable response of concrete. Hardened properties of SCC were improved by the use of recycled PET fibers (Mazaheripour et al. 2011).

The literature review provided extended information on the usage of recycled plastic waste in concrete. However, metalized plastic wastes have not been utilized in the desired quantum of research. The paper, therefore, focuses on a feasibility study of metalized waste plastic (MPW) in concrete as a constituent. Fresh and strength properties of concrete are investigated to obtain the influence of MPW.

2 Experimental Program

Materials for Concrete Mixes

Ordinary Portland Cement (OPC grade 53) manufactured by the Ultratech cement company from Gujarat having a specific gravity of 3.15 g/cm3 was used. Locally available aggregates around the Rajkot city area of the average sizes of 20 mm and 10 mm were used. River sand from the banks of Aaji River near Rajkot was used as fine aggregates. The specific gravity of coarse and fine aggregates was 2.71 and 2.63 with 0.5% and 0.78% water absorption respectively. The fineness modulus of coarse aggregates was 4.76 and fine aggregates were 2.99.

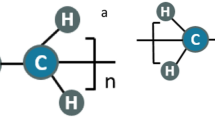

Metalized Plastic Waste

Metalized plastic used by food packaging industries was obtained from Shri Umiya Plastics – a plastic packaging industrial unit at Shapar-Veraval industrial area near Rajkot city. Metalized plastic film was shredded into fibers and flake from as shown in Fig. 1. Two types of plastics namely type A and Type B were designated as per the size of 1 mm and 5 mm of average dimensions respectively. The fibers were mixed in varying fractions from 0% to 2% by volume of concrete mix. Concrete containing 0% of MPWF was considered as reference concrete. General properties of metalized plastics are shown in Table 1.

Mixture Proportions and Specimens

Total 10 mixes were prepared including reference concrete mix at 0.45 water cement ratio. Detailed mixture proportions and quantities of MPW are shown in Tables 2 and 3 respectively. Concrete mixes were prepared from references suggesting the inclusion of macro recycled plastic fibers. All ingredients were first mixed in a mixer in dry conditions first. At last, the MPW were mixed in the dry mix. Water was added after few initial revolutions of the mixer to allow MPW settlement in the mix. The MPW was utilized as one of the constituents in the conventional mix. It was observed that they readily get settled in the mixture.

Specimens namely cubes (150 mm*150 mm*150 mm), and cylinders (150 mm*300 mm) were prepared to obtain compressive strength and splitting tensile strength respectively.

3 Tests on Concrete

Workability Tests

Slump and compaction factor tests were employed on the fresh mix to obtain the workability of concrete. The tests are commonly used to determine the consistency of fresh concrete. As shown in Fig. 2, standard apparatus for slump and compaction factor were used. The results obtained were compared with the standard values suggested in the literature for comparative study.

Strength Tests

Cubes and cylinder specimens were tested to determine compression and splitting tensile strength respectively. All specimens were cured for 28 days. The experimental arrangements are shown in Fig. 3. Average of three specimens test results were regarded as the strength of the concrete.

The tests were carried out with CTM machine of 2000kN loading capacity and the rate of loading was maintained at 0.5 MPa/s cubes were subjected to axial compression until a final failure of the specimen. cylinders were conditioned for the splitting tensile strength by mounting in CTM machine with necessary attachments like timber planks and metal bars to achieve effective splitting action in the specimens. The tests results were compared with the results of reference concrete for analysis purpose.

4 Results and Discussion

Workability of Concrete

Slump and compaction factor test results are shown in Figs. 4 and 5 respectively. It was observed that addition of MPW in concrete reduced workability. Different works carried out on the use of waste plastic fibers have shown a similar response (Yin et al. 2015). The inclusion of plastic fibers tends to reduce the segregation required to maintain the flow of concrete. The presence of MPW improved the viscosity of mix and obstructed the relative movements of sand and aggregate particles as observed during the mixing and testing of concrete.

Type A fibers reduced the slump in the range of 3%, 7%, 12% and 18% for the range of dosage of 0.5% to 2% respectively. Type B fibers with larger dimensions showed a more significant reduction in workability. The fresh properties namely slump were reduced in the range of 5% to 25% and compaction factor reduced from 3% to 15% for the dosage range of 0.5% to 2% for Type B fibers of MPW. It was noticed that the response of freshly mixed concrete was influenced by fraction and type of MPW simultaneously.

Compressive Strength

Figure 6 shows test results of compressive strength of concrete reinforced with varying size and fractions of MPW fibers. It is reported by different researchers that compressive strength is less influenced by the addition of macro plastic fibers (Kim et al. 2010). However, the test results in this study exhibited a reduction in strength at a higher dosage of MPW.

Type A and Type B showed a nearly similar response in compressive strength and showed a negligible reduction for a small dosage of MPW till 1% by volume of a mix. However, the reduction was dominant beyond the 1% dosage and the strength reduced up to 15% and 25% at 1.5% and 2% dosage of MPW. Irrespective of the type of MPW, compressive strength reduced with increased dosage of MPW. However, the failure patterns showed a uniform and controlled crack patterns at the surface at initial loading stages. Brittle failure of concrete was observed in the case of cubes prepared by the reference concrete, while the presence of fibers of MPW provided ductility to the material and showed a less brittle failure when mixed in concrete.

Splitting Tensile Strength

The indirect tensile strength of concrete was obtained by performing splitting tensile strength tests on cylinders of concrete containing varying types and fractions of MPW fibers. The addition of MPW improved the splitting tensile strength of concrete for all test conditions. Type A showed a moderate rate of increase of strength compared to Type B fibers for a given fraction.

Tensile strength was improved from 5%, 9%, 14% and 18% for fractions values from 0.5% to 2% in case of Type A fibers. Similarly, improvement of strength from 8%, 15%, 22% and 27% was observed in the case of Type B fibers for the full range of fractions of MPW. The test results are shown in Fig. 7.

During the tests on cylinders, it was observed that the cracks developed at initial loading were similar for both types of fibers. However, progressively at higher loading Type B fibers showed better resistance against the splitting action in concrete. Type B fibers tend to hold the cracked concrete with better grip and interrupted the development of macrocracks with higher fractions. The randomly distributed fibers were capable of providing the ductility to the cement paste by getting anchored effectively in the hardened cement paste. Researchers have confirmed similar response by macro-sized plastic fibers (Yin et al. 2015). The availability of macro sized fibers locally entrapped the development of micro-cracks those may result in large sized cracks eventually. A similar response was observed at the surface of the specimens subjected to splitting action.

5 Conclusion

Experimental investigations on concrete containing MPW fibers provided following conclusions,

-

The addition of MPW fibers in concrete improves splitting tensile strength of concrete significantly.

-

Workability of fresh concrete was adversely affected by MPW fibers and slump and compaction factors reduced with increased fractions of MPW.

-

Compressive strength was less influenced by MPW at a lower dosage up to 1% by volume.

-

The experimental work ensured the potential of usage of metalized plastic waste generated by different post consumer activities with 1% volume fraction as optimum dosage.

-

The present work encouraged the possible usage of metalized plastic waste as an alternate way of disposal and dual advantage of improvement of effective crack resistance of concrete subjected to tensile forces.

References

PLASTICS-THE FACTS 2015: An Analysis of European Plastics Production, Demand and Waste Data. A report by plastics Europe, Association of plastic manufacturers. www.plasticseurope.org

Understanding Plastic Films: It’s Uses, Benefits and Waste Management Options. A report prepared by Headly Pratt Consulting for American Plastic Council (1997)

Rahmani, E., Dehestani, M., Beygi, M.H.A., Allahyari, H., Nikbin, I.M.: On the mechanical properties of concrete containing waste PET particles. Constr. Buil. Mater. 47, 1302–1308 (2013). doi:10.1016/j.conbuildmat.2013.06.041

Saikia, N., de Brito, J.: Use of plastic waste as aggregate in cement mortar and concrete preparation: a review. Constr. Build. Mater. 34, 385–401 (2012). doi:10.1016/j.conbuildmat.2012.02.066

Ferreira, L., de Brito, J., Saikia, N.: Influence of curing conditions on the mechanical performance of concrete containing recycled plastic aggregate. Constr. Build. Mater. 36, 196–204 (2012). doi:10.1016/j.conbuildmat.2012.02.098

Pacheco-Torgal, F., Ding, Y., Jalali, S.: Properties and durability of concrete containing polymeric wastes (tire rubber and polyethylene terephthalate bottles): an overview. Constr. Build. Mater. 30, 714–724 (2012). doi:10.1016/j.conbuildmat.2011.11.047

Yin, S., Tuladhar, R., Shi, F., Combe, M., Collister, T., Sivakugan, N.: Use of macro plastic fibers in concrete: a review. Constr. Build. Mater. 93, 180–188 (2015). doi:10.1016/j.conbuildmat.2015.05.105

Borg, R.P., Baldacchino, O., Ferrara, L.: Early age performance and mechanical characteristics of recycled PET fiber reinforced concrete. Constr. Build. Mater. 108, 29–47 (2016). doi:10.1016/j.conbuildmat.2016.01.029

Foti, D.: Preliminary analysis of concrete reinforced with waste bottles PET fibers. Constr. Build. Mater. 25(4), 1906–1915 (2011). doi:10.1016/j.conbuildmat.2010.11.066

Foti, D.: Use of recycled waste pet bottles fibers for the reinforcement of concrete. Compos. Struct. 96, 396–404 (2013). doi:10.1016/j.compstruct.2012.09.019

Yin, S., Tuladhar, R., Riella, J., Chung, D., Collister, T., Combe, M., Sivakugan, N.: Comparative evaluation of virgin and recycled polypropylene fiber reinforced concrete. Constr. Build. Mater. 114, 134–141 (2016). doi:10.1016/j.conbuildmat.2016.03.162

Kim, S.B., Yi, N.H., Kim, H.Y., Kim, J.H.J., Song, Y.C.: Material and structural performance evaluation of recycled PET fiber reinforced concrete. Cement Concr. Compos. 32(3), 232–240 (2010). doi:10.1016/j.cemconcomp.2009.11.002

Fantilli, A.P., Chiaia, B., Gorino, A.: Fiber volume fraction and ductility index of concrete beams. Cement Concr. Compos. 65, 139–149 (2016). doi:10.1016/j.cemconcomp.2015.10.019

Mazaheripour, H., Ghanbarpour, S., Mirmoradi, S.H., Hosseinpour, I.: The effect of polypropylene fibers on the properties of fresh and hardened lightweight self-compacting concrete. Constr. Build. Mater. 25(1), 351–358 (2011). doi:10.1016/j.conbuildmat.2010.06.018

Acknowledgements

The authors are thankful to Umiya plastics, Rajkot for providing a friendly supply of metalized plastic and to Marwadi Education foundation for extending the facilities of laboratory and funding for all the raw materials required for the experimental work.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2018 Springer International Publishing AG

About this paper

Cite this paper

Bhogayata, A., Arora, N.K. (2018). Feasibility Study on Usage of Metalized Plastic Waste in Concrete. In: Singh, D., Galaa, A. (eds) Contemporary Issues in Geoenvironmental Engineering. GeoMEast 2017. Sustainable Civil Infrastructures. Springer, Cham. https://doi.org/10.1007/978-3-319-61612-4_27

Download citation

DOI: https://doi.org/10.1007/978-3-319-61612-4_27

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-61611-7

Online ISBN: 978-3-319-61612-4

eBook Packages: Earth and Environmental ScienceEarth and Environmental Science (R0)