Abstract

An appropriate characterization of the thermo-mechanical behavior of elastic-plastic Finite Element (FE) models is essential to ensure realistic results when welded joints are studied. The welded joints are subject to severe angular distortion produced by an intense heat concentration on a very small area when they are manufactured. For this reason, the angular distortion and the temperature field, which the joints are subjected, is very difficult to model with the Finite Element Method (FEM) when nonlinear effects such as plasticity of the material, radiation and thermal contacts are considered. This paper sets out a methodology to determine the most appropriate parameters needed for modelling the thermo-mechanical behavior in welded joints FE models. The work is based on experimental data (temperature field and angular distortion) and the combined use of Support Vector Machines (SVM) and Genetic Algorithms (GA) with multi-objective functions. The proposed methodology is applied for modelling Butt joint with single V-groove weld manufactured by Gas Metal Arc Welding (GMAW) process when the parameters of speed, current and voltage are, respectively, 6 mm/sec 140 amps and 26 V.

Access provided by CONRICYT-eBooks. Download conference paper PDF

Similar content being viewed by others

Keywords

- Finite element method

- Genetic algorithms

- Support vector machines

- Welding temperature distribution

- Angular distortion

- Multi-objective optimization

1 Introduction

Welded joint components are widely used in many industrial applications, therefore knowing the manufacturing process can help significantly to the industry. The regions near to the weld line, when manufacturing such joints, are subjected to severe thermal cycles due to the intense concentration of heat in a small area. These thermal cycles generate changes in the microstructure and in the mechanical properties, and cause residual stresses that produce important angular distortions on welded joints [1]. Furthermore, these thermal cycles are substantially affected by the way the welds have been manufactured and the welding process parameters [2]. During decades, the Finite Element Method (FEM) has been used as an alternative in an attempt to reduce the costs during the design phase of the welded joints. Generally, the Finite Element (FE) models welded joints require a large number of parameters, which are difficult to adjust when the chosen methodology is based solely on test error. Many authors have studied the temperature field and the angular distortion separately in FE models to study welded joints. For example, [3] studied the welding temperature distribution in Gas Tungsten Arc Welding (GTAW) process. In this case, the FEM was applied to predict temperature distributions throughout the plates welded using ABAQUS software, and was validated experimentally with thermocouples. Other researchers have based their studies of welded joints with FEM on the angular distortion instead of the temperature fields. For example in [4], the combination of FE models and experiments was applied to study the effects of arc distance and welding parameters to control the residual angular distortion in Tungsten Inert Gas (TIG). The conduction and convection phenomenon and the elastic-plastic material behavior were the parameters considered on the welded joints FE models.

The current paper presents a methodology to determinate the most appropriate parameters for modelling the thermo-mechanical behavior in welded joints FE models on the basis of experimental data (temperature field and angular distortion). The work is focused in Butt joint single V-groove weld manufactured by Gas Metal Arc Welding (GMAW) when the parameters of speed, current and voltage are, respectively, 6 mm/sec 140 amps and 26 V. The process is based on the combined use of Support Vector Machines (SVM) to predict critical features of the process and Genetic Algorithms (GA) with multi-objective functions to adjust the variables that define the FE models.

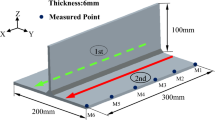

2 Experimental Data and FE Model Proposed

During the manufacturing process with GMAW, the plates that composed the welded joint studied had the dimension 60 × 80 × 6 mm, and were composed by low carbon steel ST37. The gas mixture used was 80% Argon (Ar) and 20% Carbon Dioxide (CO2), and the parameters of speed, current and voltage considered were, respectively, 6 mm/sec, 140 amps and 26 V. Also, the plates to be welded were mounted on a refractory surface, and one of the plates was fixed by a clamp. In these conditions, the forces that produced the angular distortion of the welded joint were the gravity and the force of thermal shrinkage. The temperature field was recorded during the manufacture of the welded joint using a thermographic camera (Thermovision 570 AGEMA infrared system AB) every two seconds during a period of 100 s, while the angular distortion was measured on the most distorted edge using a coordinate-measuring machine (model Zeiss PMC 850). To avoid possible errors in the temperature field measurement produced by the transient event on starting and completion of the welding process, only the central points of the weld cord were taken into consideration. In this case, the locations P1, P5, P6, P10, P11 and P15 were not taken into consideration, and only the locations P2, P3, P4, P7, P8, P9, P12, P13 and P14 were considered. Figure 1(a) shows the temperature field obtained experimentally during the experiment after 6 s, and Fig. 1(b) shows the temperature field obtained after 20 s. In addition, the FE models proposed in the current work were formulated parametrically to determine the temperature field and the angular distortion of the butt welded joints with MSC Marc software. These FE models were composed by a weld bead, a pair of plates and a refractory surface. They considered coupled thermal-mechanical fields and temperature dependent material of the ST37 steel [4]. The FE simulations proposed used the technique of birth and death of elements to model the addition of weld metal on the parts to weld [5].

A total of thirteen different parameters of the welded joint FE models were taken into consideration. They were: The thermal conduction phenomena considering six parameters based on the different pairs of contacts that made up the welded joints (melt_point; contac_p_init; contac_p_center; contac_p_end; contact_p1_p2; contact_p2_ap). Also, the weld flux for all FE models was assumed to be a double ellipsoidal shaped [6] and it was defined by four parameters that defined the shape of the ellipsoid (forward_lenght; rear_lenght; width; deep). In addition, the phenomenon of thermal convection was modelled using three different film coefficient parameters (face_film; face_film2; face_film3) [7]. Finally, the radiation was taken into consideration in the FE model and applied in the weld bead and the surrounding areas. Figure 1(c) shows the temperature field obtained from the FE models proposed after 6 s and Fig. 1(d) shows the temperature field obtained after 9 s in order to compare with those temperatures obtained experimentally.

Since the number of temperature samples from each of the 9 points studied during the welding process is very high (one sample every two seconds during a period of 100 s), the problem was simplified taking just the most significant points in each curve of temperature. These selected points are shown in Table 1.

Also, Fig. 1(e), (f) show the temperature curves vs time obtained experimentally for points P2, P3, P4, P7, P8 and P9 and the temperature values of the selected points according to Table 1. Table 2 shows the corresponding experimental values of temperatures obtained at each of the nine points studied in their respective times as well as the distortion angle obtained by thermal retraction when welded joint is cooled.

In addition and due that the simulation time for each of the welded joint FE models proposed were not excessive (around 2 h), the Design of Experiments (DoE) was performed using a Fractional Factorial Design to generate the design matrix (dataset) which was formed by 2048 FE simulations. This dataset was composed by the thirteen inputs and the corresponding twenty outputs (angular distortion and temperature points) obtained from the FE simulations.

2.1 Analysis of Features Significance

The dataset obtained from the DoE and the FE simulations was analysed to determine which variables were the most significant to define the outputs of the problem. This point was performed with three different analyses, which were:

-

Using an analysis of linear variance (ANOVA test) [8]

-

Using an analysis of nonlinear variance (Kruskal-Wallis test) [9, 10]

-

Using a backpropagation filter (random forest selection function) [11]

The following stages of the methodology were applied to the selected features according to these three methods, as well as for the entire set of variables analysed in the problem.

2.2 Support Vector Machines

There are numerous regression techniques inherently based on a nonlinear nature. One of the most intensively studied and applied are SVM thanks to its performance as a universal approximation [12]. This technique is based on a kernel-based algorithm that have sparse solutions, where the predictions for new inputs depend on the kernel function evaluated at a subset of instances during a training stage where a repeated cross validation is performed.

The goal of this technique is to find a function that minimizes the final error in Eq. 1.

Where \( y\left( x \right) \) is the predicted value, \( w \) is the vector with the parameters that define the model, \( b \) indicates the value of the bias and \( \phi \left( x \right) \) is the function that fixes the feature-space transformation.

The process is optimized and finally the initial function (Eq. 1) became the more complex function (Eq. 2).

Where \( \alpha \) is a solution of the optimization problem obtained through Lagrangian theory.

Also, the function makes a transformation of the data to a higher dimensional feature space to improve the accuracy of the nonlinear problem. In this way the final function became like Eq. 3.

Where in this case three kernels functions were used: linear (Eq. 4), polynomial (Eq. 5) and Gaussian Radial Basis Function (RBF) (Eq. 6).

R statistical software environment v2.15.3 was used to program the proposed methodologies, to develop the regression models and to perform the optimization based on GA [13].

2.3 Model Selection Criteria

The SVM models were trained using 50 times repeated 10 fold cross-validation using the entire training dataset obtained from the DoE, with 2048 entries, to create the models. This method involves dividing the initial database into 10 subsets, building the model with 9 subsets and calculating the error with the other partial sample of the dataset. This procedure is repeated 50 times obtaining other errors. And finally, the error is calculated as the arithmetic mean of all the errors of the process [14,15,16].

Once the different algorithms were trained during some of their most significant parameters were tuned, a selection was made of those with the best predictive performance. The coefficients indicative of the error used to evaluate the accuracy of the predictions were the RMSE and its standard deviation.

2.4 Optimization Based on Genetic Algorithms

Once the regression model with the best generalization capacity was selected, the optimal parameters for defining the welded joint FE models were performed applying evolutionary optimization techniques based on GA [7, 17], and was conducted as follows: firstly, a number of 1000 individuals or combinations of the 13 inputs were randomly generated and named as the initial generation. Subsequently, and based on these individuals, the 20 outputs were obtained applying the most accurate model according to previous results. Two objective functions were analyzed in this case: the objective function \( Jtemp_{j} \) implemented to adjust the nine curves of temperature (Eq. 7), and the objective function \( Jangle \), implemented to adjust the angular deformation (Eq. 8). Both functions are combined affected by the same weight.

Where \( T_{FEM\left( i \right)} \) are FE models temperature measurements, \( T_{EXP\left( i \right)} \) are experimental temperature measurements, n is the number of points where temperature is measured, \( \propto_{FEM} \) is the FE models angular deformation, and \( \propto_{EXP} \) is the experimental angular deformation.

The next generations were generated using selection, crossover and mutation. The new generation was comprised as follows:

-

25% comprised the best individuals from the previous generation.

-

60% comprised individuals obtained by crossover.

-

The remaining 15% is obtained by random mutation.

Finally the best combination of values of each feature was selected and tested to determinate the final error of the methodology.

3 Results

3.1 Analysis of Features Significance

First an analysis of variance ANOVA was performed to assess the uncertainty in the experimental measurements based on the proposed DoE. All the final outputs were analyzed against the input variables. The p-values that obtained low values were selected since indicate that the observed relationships were statistically significant. Subsequently a nonparametric Kruskal-Wallis test was performed by ranks in the same way than the previous technique in order to select some features. Table 3 shows the results of both techniques for the output feature “Distort_Angle”.

Finally, a feature selection using search backwards selection algorithms were performed. In this case, the selected attributes according to the RMSE obtained for the output feature “Distort_Angle” are those corresponded to the number 12 (see Table 4) with a value of RMSE = 0.01956.

3.2 SVM

The creation of regression models that predict the temperature on several points of the welded joint and also the angular distortion was based on machine learning techniques based on SVM. Also, and in order to compare linear and nonlinear techniques, a linear regression (LR) was also performed. In this case, the method was conducted in the following way: Firstly, the 2048 experiments were performed according to the proposed DoE. The dataset obtained from the experiments was normalized between 0 and 1. Thereafter, these 2048 instances were used to train the models using 50 times repeated cross-validation. During the training process, the RMSE and its standard deviation were also obtained while a tuning of the most important parameters of each algorithm was performed to improve its prediction capability.

The process was repeated four times, one per each of the feature selection method previously mentioned. For example, the results obtained when all the features were used in the process are shown in Table 5. For each feature selection method, one model was selected subsequently, and from the four models selected, the most accurate one was chosen. In that way, only the most accurate model per each output variable was selected and used in the following processes.

From each of the selected models, the tuned parameters that allow the model its most accurate behavior was obtained. For example, for the feature “angle” the best performance happened when ANOVA group of features was used, and the selected values from the tuning of parameters were a cost of 0.04 and a degree of the polynomial applied in the kernel was 2. In this case the RMSE was equal to 2.46% and its standard deviation was 0.06%.

3.3 Adjustment Based on Genetic Algorithms

The adjustment process to find the best combination of inputs to optimize both objective functions was performed minimizing their error based on the experimental data obtained experimentally (see Table 2).

The minimization of the objective functions generates the values that are shown in Table 6. These values indicate the closest values to the real behavior of the Butt joint single V-groove weld manufactured by GMAW. With these values, a new FE model was simulated to observe the real effectiveness of the methodology. In this case, RMSE equal to 12.35% was obtained comparing the new FE model simulated with the optimal values obtained from the adjustment process against the experimental data. This indicates that the methodology proposed to find the best combination of parameters is effective.

4 Conclusions

This work presents a methodology for determining the most appropriate parameters for modelling the thermo-mechanical behavior in welded joints FE models on the basis of experimental data (temperature field and angular distortion). The work is focused in Butt joint single V-groove weld manufactured by Gas Metal Arc Welding (GMAW). The process is based on the combined use of Support Vector Machines (SVM) to predict critical features of the process and Genetic Algorithms (GA) with multi-objective functions to adjust the variables that define the FE models. In this case, a value of 12.35% for the RMSE was obtained comparing the FE model with the optimal parameters obtained from the adjustment against the experimental data applying this methodology. This indicates that the methodology proposed to find the best parameters in Butt joint single V-groove weld manufactured by GMAW is effective when the parameters of speed, current and voltage are, respectively, 6 mm/sec 140 amps and 26 V.

References

Olabi, A.G., Lostado L.R., Benyounis, K.Y.: Review of microstructures, mechanical properties, and residual stresses of ferritic and martensitic stainless - steel welded. In: Comprehensive Materials Processing, vol. 6. Welding and Bonding Technologies (2014)

Macherauch, E., Kloos, K.H.: Origin, measurements and evaluation of residual stresses. Residual Stress Sci. Technol. 1, 3–26 (1987)

Attarha, M.J., Sattari-Far, I.: Study on welding temperature distribution in thin welded plates through experimental measurements and finite element simulation. J. Mater. Process. Technol. 211(4), 688–694 (2011)

Zhang, H., Zhang, G., Cai, C., Gao, H., Wu, L.: Fundamental studies on in-process controlling angular distortion in asymmetrical double-sided double arc welding. J. Mater. Process. Technol. 205(1), 214–223 (2008)

Gannon, L., Liu, Y., Pegg, N., Smith, M.: Effect of welding sequence on residual stress and distortion in flat-bar stiffened plates. Mar. Struct. 23(3), 385–404 (2010)

Goldak, J., Chakravarti, A., Bibby, M.: A new finite element model for welding heat sources. Metall. Trans. B 15(2), 299–305 (1984)

Lostado, R., Fernandez Martinez, R., Mac Donald, B.J., Villanueva, P.M.: Combining soft computing techniques and the finite element method to design and optimize complex welded products. Integr. Comput. Aided Eng. 22(2), 153–170 (2015)

Bailey, R.A.: Design of Comparative Experiments. Cambridge University Press, US (2008)

Kruskal, W.: Use of ranks in one-criterion variance analysis. J. Am. Stat. Assoc. 47(260), 583–621 (1952)

Corder, G.W., Foreman, D.I.: Nonparametric Statistics for Non-Statisticians, pp. 99–105. Wiley, Hoboken (2009)

Kuhn, M.: Caret: Classification and Regression Training. R package version 6.0-41 (2015)

Vapnik, V., Golowich, S.E., Smola, A.: Support vector method for function approximation, regression estimation, and signal processing. Adv. Neural. Inf. Process. Syst. 9, 281–287 (1997)

R Core Team. R: A language and environment for statistical computing. R Foundation for Statistical Computing, Vienna, Austria (2013).http://www.R-project.org/

Fernandez Martinez, R., Okariz, A., Ibarretxe, J., Iturrondobeitia, M., Guraya, T.: Use of decision tree models based on evolutionary algorithms for the morphological classification of reinforcing nano-particle aggregates. Comput. Mater. Sci. 92, 102–113 (2014)

Fernandez Martinez, R., Martinez de Pison, F.J., Pernia, A.V., Lostado, R.: Predictive modelling in grape berry weight during maturation process: comparison of data mining, statistical and artificial intelligence techniques. Span. J. Agric. Res. 9(4), 1156–1167 (2011)

Illera, M., Lostado, R., Fernandez Martinez, R., Mac Donald, B.J.: Characterization of electrolytic tinplate materials via combined finite element and regression models. J. Strain Anal. Eng. Des. 49(6), 467–480 (2014)

Martinez de Pison, F.J., Lostado, R., Pernia, A., Fernandez Martinez, R.: Optimising tension levelling process by means of genetic algorithms and finite element method. Ironmaking Steelmaking 38, 45–52 (2011)

Acknowledgements

The authors wish to thanks to the University of the Basque Country for its support through the project US15/18 OMETESA and to the University of La Rioja for its support through Project ADER 2014-I-IDD-00162.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2017 Springer International Publishing AG

About this paper

Cite this paper

Fernández Martinez, R., Lostado Lorza, R., Corral Bobadilla, M., Escribano Garcia, R., Somovilla Gomez, F., Vergara González, E.P. (2017). Adjust the Thermo-Mechanical Properties of Finite Element Models Welded Joints Based on Soft Computing Techniques. In: Martínez de Pisón, F., Urraca, R., Quintián, H., Corchado, E. (eds) Hybrid Artificial Intelligent Systems. HAIS 2017. Lecture Notes in Computer Science(), vol 10334. Springer, Cham. https://doi.org/10.1007/978-3-319-59650-1_59

Download citation

DOI: https://doi.org/10.1007/978-3-319-59650-1_59

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-59649-5

Online ISBN: 978-3-319-59650-1

eBook Packages: Computer ScienceComputer Science (R0)