Abstract

The consumption of brown rice has been increasing due to its higher nutrition value, nutty flavor, and rich texture compared to white rice. At the same time, there is a strong demand in storing rice as brown rice instead of rough rice for saving space and energy before milling. However, the short shelf life of brown rice has been a significant concern. The effective and economic way to extend the shelf life of brown rice is to inactivate the lipase enzyme to minimize the lipid oxidation, which cannot be achieved by currently used hot air drying. Infrared (IR) drying has been reported that it effectively inactivated the lipase enzymes during rough rice drying. This chapter summarizes the mechanism of IR heating, IR emitter types, advantages of IR drying and investigations performed on IR drying of rough rice and parboiled rice, and its influence on the milling yield, quality, and storage characteristics of rough rice, brown rice, and rice bran. The IR drying resulted in high drying rate, good milling quality, effective disinfestation and disinfection of rough rice, and improvement in shelf life of both rough and brown rice due to partial lipase inactivation in the bran layer. IR-dried rice can be stored in brown rice form at ambient temperature with even longer shelf life than that of rough rice dried with ambient and hot air. The rice bran from milling of IR-dried rice has sufficient shelf life for further value-added utilization without need for additional stabilizing treatment.

Access provided by CONRICYT-eBooks. Download chapter PDF

Similar content being viewed by others

Keywords

Introduction

Rice is the most widely consumed staple food for a large percentage of the human population in the world, particularly in Asia. Most of the rough rice produced is consumed as white (milled) rice. After harvest, rough rice is normally dried with hot air or ambient air and then stored in silo or warehouse for an extended duration to meet the supply needed for daily consumption of our society with ensured food safety and quality (Patindol et al. 2005). Recently, there has been an increasing trend in the consumption of brown (unmilled) rice due to its higher nutrition value than that of white rice. Meanwhile, avoiding polishing and whitening by consuming brown rice could reduce the energy use in milling process by as much as 65% (Javier 2004). There is also a desire to store brown rice before milling rather than rough rice, which saves significant amount of space and allows quick and easy access to rice by people during emergencies. Both brown rice stored as bulk before milling and in retail packages have a short shelf life problem because the lipid in rice bran on the whole grain can cause quality deterioration due to lipid oxidation . In addition, the lipid-rich bran layer on the whole grain is susceptible to microbial and insect damage.

Brown rice produced by dehulling of rice (without milling) is superior to white rice in terms of nutrients and biologically active phytochemicals, such as minerals, oils, vitamins, iron, dietary fiber, thiamine, tocopherols, tocotrienols, γ-oryzanol, and γ-aminobutyric acid, and it has been acknowledged as a healthy food (Juliano and Bechtel 1985; Chen et al. 2015). Thiamine and oil contents of brown rice are about five times that of white rice, while fiber, niacin, phosphorous, potassium, iron, sodium, and riboflavin are about two to three times greater than white rice (Champagne 1994). These nutrients are typically in the rice bran layer of the brown rice (Chen et al. 2015). Brown rice has a low carbohydrate than white rice. Moreover, brown rice has the bran layer and germ intact, giving it a nutty flavor and rich texture.

Storing rice in brown rice form before milling is more popular in Japan, South Korea, and Taiwan than the other regions in the world. However, to extend the shelf life of brown rice, the store facilities are equipped with climate control to keep the brown rice at a low temperature for reducing the oxidation, which is costly, particularly during summer time. It is ideal to store rice at ambient temperature if the rice bran layer can be stabilized by inactivating the lipase enzyme. Storage of brown rice at ambient temperature may save more than 30% of storage space and reduce 20% of weight during storage and transportation compared to rough rice storage (Malekian et al. 2000; Thakur and Gupta 2006). In addition, the hulling process used for brown rice production may break up the cells in the outer layer, releasing lipase enzyme, which accelerates the breakdown of oil in the bran layer, liberating free fatty acids (FFAs) causing rancidity and off flavor of brown rice during storage which reduces the sensory quality (Das et al. 2012).

It has been reported that brown rice can be stored for 3–6 months at ambient temperature (23–34 °C) if the grain is dried to 14% moisture content (Champagne 1994; Javier 2004; Das et al. 2012). Brown rice packed in modified atmospheres such as carbon dioxide flushing and under vacuum also showed a slow deterioration in quality and extended its shelf life (Sharp and Timme 1986; Genkawa et al. 2008; Ory et al. 1980). At the retail market, brown rice is also packaged in heat-sealed cans and bags (Sharp and Timme 1986) to effectively minimize the rancidity and maintain stability of brown rice.

The susceptibility of brown rice to become rancid due to lipid hydrolysis and oxidation has limited the storage and marketing of the brown rice. The lipids in brown rice are readily hydrolyzed by lipases, which releases free fatty acids. Several approaches have been utilized to stabilize brown rice or rice bran against lipolytic hydrolysis : (a) inactivating lipase by heating rough rice with moist gas (Van Atta et al. 1952) or by parboiling or precooking (McCabe 1976); (b) removing the kernel oil, which serves as the substrate for lipase, through organic solvent extraction (Kester 1951); and (c) denaturation and inactivation of lipase and lipase-producing bacteria and mold by liquid ethanol and ethanol vapors (Champange et al. 1991; Champagne and Hron 1992). The technologies employed in industry include (a) extrusion, (b) microwave treatment, (c) ohmic heating, (d) dry heat treatment, (e) γ-irradiation, (f) parboiling, (g) toasting, and (h) infrared (IR) drying (Pan et al. 2008; Yilmaz et al. 2014; Chen et al. 2015; Bergonio et al. 2016; Ding et al. 2016, 2017). The most popular technique for stabilizing rice bran is high temperature and pressure extrusion.

An ideal and economical way for extending the shelf life of brown rice and rice bran is achieving stabilization during drying since it is an essential step in rice postharvest. However, the hot air temperature used in current drying practice is too low to achieve inactivation of lipase. IR drying was studied to effectively inactivate the lipase enzymes in rough rice and brown rice and to reduce free fatty acid formation, thus improving long-term storage stability (Ding et al. 2015). In addition to inactivation of lipase, IR drying of rice has significant other advantages over conventional hot and ambient air drying of rice. Since IR radiation can penetrate into a rice kernel, the heat transfer to the grain is faster and more energy-efficient than with convective air-drying methods (Ginzberg 1969). IR drying provides faster and uniform heating of kernels during drying and thus reduces fissuring, resulting in increased total rice yield (TRY), head rice yield (HRY), and milling quality compared to hot air drying. Infrared drying also provides disinfestation action for common insects, including lesser grain borers, Angoumois grain moths, and dark-brown grain beetles (Ginzberg 1969; Pan et al. 2008). This chapter summarizes the mechanism of IR heating, advantages of IR drying of food materials, IR emitter types and investigations performed on IR drying of rough rice, and its influence on the milling yield, rice quality, and storage characteristics of rough rice, brown rice, and rice bran quality.

Infrared Heating of Food Materials

IR heating has been gaining popularity in several food processing unit operations, including drying, peeling, baking, roasting, blanching, pasteurization, sterilization, disinfection, and disinfestation, cooking, and popping (Pan et al. 2016). It offers many advantages over conventional hot air and steam heating methods, including:

-

1.

A consistent and uniform distribution of IR energy provides better product quality.

-

2.

High energy efficiency is achieved as IR energy is transferred from IR emitters by radiation to product surface without requiring any heating medium.

-

3.

High intensity of IR heat can reduce the needed processing time.

-

4.

High degree of automation allows precise control of process parameters.

-

5.

Compact design and different types of IR emitters permit a space-saving footprint.

-

6.

It provides water saving and reduces waste generation in blanching and peeling of foods and is environmentally friendly (Pan and Atungulu 2010a; Pan et al. 2016).

Infrared Radiation

IR radiation is a part of the electromagnetic spectrum as shown in Fig. 13.1 (Modest 1993; Pan and Atungulu 2010b) and has both a spectral and directional dependence. IR has wavelengths ranging from 0.7 to 1000 μm (Siegel and Howell 2002) and is classified into three different categories, near-IR (NIR), mid-IR (MIR), and far-IR (FIR), with corresponding spectral range of 0.75–1.4 μm, 1.4–3.0 μm, and 3.0–1000 μm, respectively (Krishnamurthy et al. 2008; Sakai and Hanzawa 1994; Pan et al. 2016). The IR radiation band relevant to heating of foods, including drying, was provided by Sandu (1986). Water has very strong absorption of IR radiation at around 2.7–3.3, 6.0, and greater than 12.5 μm. The O–H bonds in water absorb IR energy and start to rotate with the same frequency as the incident radiation. This transformation of IR radiation to rotational energy causes the evaporation of water (Nindo and Mwithiga 2010).

Electromagnetic wave spectrum (Source: Pan and Atungulu 2010b)

In IR heating, the temperature of IR emitter is directly related to the wavelength of the radiation. The relationship between the wavelength and temperature can be described by the basic laws for blackbody radiation, including Planck’s law, Wien’s displacement law, and Stefan–Boltzmann’s law (Sakai and Hanzawa 1994; Dangerskog and Osterstrom 1979). The high temperature of NIR can result in rapid increase of product temperature and potentially reduce processing time, but risk overheating the product, causing product quality deterioration. If the operating temperature of the emitter is too low, it may not produce adequate radiant energy to meet the energy requirement for a thermal process of foods (Pan et al. 2016). Therefore, it is critical to select IR emitters with appropriate wavelengths and emissive power for different food processes.

Infrared Absorption Characteristics of Food Materials

Food materials are considered as complex matrices consisting of different biochemical macromolecules , biological polymers, inorganic salts, and water. During IR heating, the food absorbs radiation at certain wavelength and also reflects and transmits radiation at other wavelengths. The absorbed radiation energy produces heat within the object. The interaction between IR radiation and the optical and physical properties of food materials is important in the design of an IR heating system or optimizing IR-based thermal processes. During IR heating, the IR absorption properties of foods depend on three factors: chemical composition, physical dimension, and properties of food products (Sandu 1986; Krust et al. 1962; Ginzberg 1969). For surface treatments, it is ideal that radiation energy is absorbed at the product surface with minimal penetration, while for other applications such as blanching and dehydration, selecting the electromagnetic wavelengths with strong penetration capability to the products is desirable.

Selection of wavelength range in IR heating is critical to ensure IR heating efficiency and final product quality. Otherwise, excessive heating of material surface and inadequate heating of product interior may be observed when the IR-emitting wavelength was not consistent with the optimal absorption wavelengths of food materials (Lentz et al. 1995). It was found that the maximum absorption of IR radiation by medium-grain rough rice occurred at a wavelength of 2.9 μm (Bekki 1991). The penetration depths of NIR on various food products were summarized by Ginzburg (1969). The penetration capacity and reflectance increases as the wavelength of the radiation decreases during IR heating. This indicates that NIR has a higher penetrating capability than FIR. FIR radiation has been more advantageous for food thermal processing by considering the total energy input and easy control, as well as most of the components in food absorb radiant energy in the region of FIR.

Infrared Emitters for Food Processing Applications

IR emitters are divided into three categories based on wavelength: short-wave, medium-wave, and long-wave emitters. The short-wave emitters operate at very high emissive power and temperatures. They are not suitable for most of food processing applications due to the possibility of overheating without appropriate temperature control. Medium-wave IR emitters emit a radiation spectrum of wavelengths ranging from 1.4 to 3.0 μm and are used for drying and curing of food products. Long-wave IR emitters are useful for low-temperature process applications in combination with convection heating (Pan et al. 2005). The thermal efficiency, heat transfer rate, and effect of radiation on heated materials are closely related to the range of wavelength emitted by the IR emitters (Siegel and Howell 2002).

IR radiation can be produced by systems utilizing either electricity or hydrocarbon gases. The corresponding emitters are classified into electrical and gaseous types based on energy sources. Electrical IR emitters have a filament that can be heated to a high temperature. They are manufactured with standardized energy values or powers, such as 60, 100, 150, 200, and 500 watts. A number of electrical emitters can be mounted on a panel at required spacing between each emitter to give the desired energy intensity. These emitters consist of a reflector, incandescent lamp, quartz tube, and resistance elements such as metallic tube, ceramic tube, and nonmetallic rod. Electrical IR emitters normally have conversion efficiency from 78% to 85%, whereas gas-fired IR emitters have a conversion efficiency of 40–46% (Ramaswamy and Marcohe 2005). Electric emitters can reach a power intensity of up to 400 kW/m2, while gas-fired emitters normally do not exceed a power intensity of 22 kW/m2 (Nindo and Mwithiga 2010). In general, electric heaters are expensive and can conveniently manipulate the power intensity of a given system according to the design requirement (Pan et al. 2016).

Gas-fired IR emitters use propane or natural gas as fuel and are available in different sizes for industrial application. The advantages of gas-fired emitters include uniform heating of the target with high thermal efficiency and low operating cost; they are also more reliable and durable than electrical emitters and are independent of electricity. There are different types of gas-fired IR emitters, such as direct flame IR radiator, ceramic burner, metal fiber burner, high-intensity porous burner, and catalytic gas-fired IR emitter. Among these, the catalytic gas-fired IR emitter is a relatively new diffusion-type heater that operates on a catalytic exothermic chemical oxidation–reduction principle. It converts methane or propane gas to moisture and carbon dioxide in the presence of platinum and oxygen and thus releases IR energy. The catalytic IR emitter emits radiation heat over a wide range of wavelengths without any visible flame. These emitters require preheating of the catalyst before the combustion process is initiated. Typically, these emitters have a power density varying from 6 to 28 kW/m2 and radiation efficiency ranging from 30% to 75% (Das and Das 2010). The heating efficiency of gas-fired emitters depends on the size of the heater and the separation distance between the heater and the object being heated (Lia et al. 2004, Nindo and Mwithiga 2010). Detailed descriptions of emitter types, designs, selections, and characteristics were reviewed by Das and Das (2010).

Infrared Drying and Dehydration of Food Materials

In IR drying , also called thermal radiation drying, heat is transferred to the drying materials by radiant energy. In natural radiation drying (solar drying), radiation from the sun is tapped either directly or indirectly for drying purposes. Artificial IR drying involves the use of IR radiation generators or emitters. IR drying has been investigated as a potential method for obtaining high-quality dried foodstuffs, including fruits, vegetables, and grains (Abe and Afzal 1997; Pan et al. 2008, 2011, 2016). IR radiation drying is fundamentally different from convective drying because the material is dried directly by absorption of IR energy rather than transfer of heat from the air (Bal et al. 1970). IR energy is transferred from the heating element to the product surface without heating the surrounding air. The radiation impinges on the exposed material, penetrates it, and is converted to sensible heat. The penetration capability depends on the properties of the treated material and the temperature of the radiation source. The penetration provides more uniform heating in individual rice kernels and reduces the moisture gradient during heating and drying. In addition, due to radiation heating, the temperature of a rice kernel is not limited by the wet bulb temperature of the surrounding air and would become high in a short timeframe.

The merits and demerits of IR drying are described in detail by Nindo and Mwithiga (2010). IR has several advantages over the conventional drying, including the high heat transfer rates, use of alternative energy source, increased energy efficiency, short drying time, easy control of material temperature, a reduced necessity for air flow across the product, high degree of process control parameters, space saving along with clean working environment, better product quality, and ability to achieve complete disinfestation and disinfection of foods (Afzal et al. 1999; Tan et al. 2001; Pan et al. 2008; Shih et al. 2008; Khir et al. 2014; Dostie et al. 1989; Navari et al. 1992; Sakai and Hanzawa 1994; Mongpreneet et al. 2002; Nowak and Lewicki 2004; Krishnamurthy et al. 2008; Gabel et al. 2006; Wang et al. 2014). In IR drying, there is a very little absorption of heat by the space separating the product and emitter unless the intervening medium is saturated with water vapor. No direct contact with material is required as in conduction drying. IR radiation, similar to visible radiation (light), can be focused to increase heating intensity, provide fast treatments, or target a particular area (Nindo and Mwithiga 2010). Energy efficiency of IR drying can be improved by placing IR source enclosed in a chamber with a highly reflective surface to take advantage of the multiple reflections within the enclosure. To achieve maximum uniformity of radiant flux density on the surface of foodstuffs being irradiated, there should be proper spacing between individual IR generators (if more than one unit is used) and the distance between the radiation sources and the foodstuff (Il’yasov and Krasnikov 1991).

IR drying is not always easily applicable. Since foods usually come in complex shapes and sizes, the application of IR in such situations may be limited because energy impinging on the material will be different from place to place (Nindo and Mwithiga 2010). Normally, IR modules are used to dry a thin layer of foods (Nindo and Mwithiga 2010). The products to be dried can be in motion facilitated by a conveyor belt or a vibrating plate. Because IR radiation does not depend on the surrounding medium, the product surface can be quickly heated up to desired temperatures. However, allowing the temperature to rise too high and/or heating for extended periods of time is detrimental to the product quality (Sharma et al. 2005; Gabel et al. 2006; Kumar et al. 2005). To prevent high product temperatures especially for heat-sensitive materials, intermittent heating and IR heating in combination with hot air drying or freeze drying have been practiced (Wang et al. 2016; Ding et al. 2015, 2016, 2017: Atungulu and Pan 2010). Since, IR can be used to quickly heat rough rice in a single or thin layer to a relatively high temperature, it should be possible to use the sensible heat from the heated rice to remove more moisture during cooling, which could make the overall IR rough rice drying process more energy efficient (Pan et al. 2008).

Combination of IR and hot air drying has been used as an efficient and rapid drying method compared to hot air drying alone. The energy and operating costs of the combined drying mode are lower than convective drying systems for several food and agricultural products, particularly for the drying of heat-sensitive products (Kocabiyik 2010). Use of tempering or holding treatment by maintaining the temperature of heated product after IR heating followed by natural cooling was found to reduce the moisture content of rice by up to 2.2% by using the sensible heat from heated rice without using additional energy and achieved high rice milling quality (Pan et al. 2011). In addition, IR heating followed by tempering and natural cooling inactivates lipase enzyme and significantly reduces the generation of free fatty acids in rough and brown rice (Ding et al. 2015). Controlling the IR radiation intensity or shortening the drying frequency by using intermittent IR drying has been used to minimize the changes in color and nutrients of dried product (Chua et al. 2004). Several studies proved that using IR for drying of food results in a better-quality product and saving of drying time and energy (Riadh et al. 2015).

Infrared Drying of Rice

Infrared Drying of Rough Rice

The earliest use of IR for drying rough rice was reported in the early 1960s (Schroeder and Roseberg 1960; Pan et al. 2011). A high drying rate of rice was achieved by spreading the rice in a single layer. It has been reported that only 7 min were required to reduce the moisture content (MC) from 20% to 14.8% (d.b.) using NIR radiation heating, compared to 30 min for hot air drying (Rao 1983). Using IR to preheat the rough rice to 60 °C followed by hot air drying at 49 °C for 2–3 min removed approximately 2% MC in single pass. Bekki (1991) found that the maximum absorption of IR radiation by medium-grain rough rice occurred at a wavelength of 2.9 μm. IR drying results in uniform heating of kernels in the drying process and thus reduces fissuring, thereby maintaining the yield and milling quality of rice (Khir et al. 2014; Pan et al. 2011). IR drying of rice has been resulted in a high drying rate, good milling quality, effective disinfestation and disinfection of rough rice, inactivation of lipase enzyme, improvement in shelf life of both rough and brown rice, and effective stabilization of rice bran (Pan et al. 2008, 2011, Khir et al. 2011, 2014, Wang et al. 2016).

Catalytic IR heating of rough rice having high and low harvest MCs in single layer was performed by Pan et al. (2008, 2011) to study the effect of IR heating time, IR intensity, bed thickness on heating and drying rates, and milling characteristics of rice followed by tempering and cooling treatments. The technical feasibility of simultaneous drying and disinfestation of rice using IR heating has been evaluated. A catalytic emitter with dimensions of 30 × 60 cm, surface temperature of 650 °C, and corresponding peak wavelength of 3.1 μm was used for the study. The average IR intensity at the rough rice bed surface was 5348 W/m2. A single layer of rice of 250 g at a loading rate of 2 kg/m2 was placed on the drying bed. The tempering was conducted by keeping the rice samples in closed containers placed in an incubator at the same temperature as the heated rice for 4 h immediately following the heating. The tempered and non-tempered samples were each cooled using natural cooling (slow cooling) or forced-air cooling at ambient temperature. The results of this study related to drying rates and milling characteristics of rice followed by tempering and cooling treatments are summarized in the following sections.

Rough Rice Temperature and Heating Rate

The average rice temperature during IR heating increased with the increase in heating time and IR intensity and decreased with increase in bed thickness (Pan et al. 2008, 2011). The rice sample temperatures for different heating durations at different initial MCs, radiation intensities, and drying bed thicknesses are shown in Fig. 13.2a, b. The rice temperature increased with increase in heating duration and radiation intensity for samples with the same initial MC and drying bed thickness. No significant differences in rice temperature were observed between the low and high MC rice after IR heating; however, the low MC rice samples had slightly higher temperatures than the high MC rice samples, especially at 60, 90, and 120 s heating time, which could be due to less energy being used for heating the water and a lower evaporative cooling effect in the low MC rice than in the high MC rice with the constant radiation heat supply (Pan et al. 2011). The heating rate of rice during IR heating decreased with increase of the drying bed thickness as increased bed thickness increases the mass of the rice per batch. In another study, Das et al. (2004a) used a vibration-aided IR dryer having a radiation intensity of 3100–4290 W/m2 to dry rough rice grain with bed depths of 12–16 mm and found that the grain depth had an insignificant effect on the drying rate at a given IR intensity.

Relationship between rice temperatures and heating time at drying bed thickness and initial moisture contents under radiation intensity of (a) 5348 W/m2 and (b) 4658 W/m2 (Source: Pan et al. 2011)

Moisture Removal and Drying Rate

The moisture removal for rice samples with an initial moisture content (IMC) of 20.5% and 23.8% during IR heating and after tempering and cooling treatment with different drying bed thicknesses and radiation intensities was studied by Pan et al. (2011). Rice moisture removal during IR heating increased with the increased heating time and radiation intensity under a specific drying bed thickness and IMC as shown in Fig. 13.3. The moisture removal increase was resulted from the increased rice temperature due to more energy being absorbed by the rice kernels with longer heating time and higher radiation intensity which caused more water evaporation compared to a shorter heating time and low radiation intensity. When rice samples with different depths were heated to a similar temperature, the moisture removal during heating was similar, indicating that depth was not a limiting factor for moisture removal. Therefore, moisture removal mainly depended on the rice temperature (Pan et al. 2011). In significant effect of grain depth on drying rate was also observed by Das et al. (2004a & b). Pan et al. (2011) experimentally proved that a high drying rate was achieved by using IR heating alone, even without counting the moisture removal during tempering and cooling, compared to conventional heated air drying of 0.1 to 0.2 percentage points per min due to the low air temperature used (Kunze and Calderwood 2004). The influence of initial moisture content, rice temperature, drying bed thickness, tempering, and cooling methods on moisture diffusivity of rough rice under IR heating was studied by Khir et al. (2011). Rough rice moisture diffusivities under IR heating and cooling were significantly affected by rice temperature and tempering treatment, respectively. High heating rate and moisture diffusivity were achieved with IR heating of rough rice than hot air drying.

Moisture removal of rice with initial moisture contents (MCs) of 20.5% and 23.8% caused by infrared heating and cooling after tempering treatment with (a) single-layer, (b) 5 mm, and (c) 10 mm drying bed thicknesses under radiation intensity of 5348 W/m2. MR moisture removal, IRH infrared heating, TMR total moisture removal (Source: Pan et al. 2011)

Milled Rice Quality

IR drying of rough rice resulted in high moisture removal and milling quality by heating the rice samples to about 60 °C followed by tempering and natural cooling (Amaratunga et al. 2005; Pan et al. 2008, 2011; Khir et al. 2011). Meeso et al. (2004) achieved a significant improvement in the head rice yield and whiteness of rough rice using infrared radiation heating as a result of partial gelatinization of rice kernels. Bekki (1991) used FIR heating immediately after hot air drying (at approximately 40 °C) for the drying of paddy to produce better-quality dried product compared to convective or FIR methods in separate conditions. IR drying results in improvement of milling yield and rice quality compared to hot air drying. High total rice yield (TRY) and head rice yield (HRY) were achieved by Pan et al. (2011) for single-layer, 5 mm, and 10 mm drying bed thicknesses by IR heating the rice samples to about 60 °C compared to the controls (ambient air drying) for the rice samples with IMCs of 20.5% and 23.8%. TRYs of IR-dried rough rice with IMC of 20.5% heated to 61 °C (single layer), 60.2 °C (5 mm bed thickness), and 61.2 °C (10 mm bed thickness) were found to be 0.65, 0.88, and 0.59 percentage points higher than the hot air-dried samples. Moreover, compared to control, the rice samples dried using IR with tempering and natural cooling had significantly higher HRY (by 1.52, 0.94, and 1.06 percentage points) when the rice samples were heated by IR to about 60 °C in single-layer, 5 mm, and 10 mm drying bed thicknesses, respectively. No significant difference in whitening index (WI) of IR-dried and the ambient air-dried samples was found by Pan et al. (2011), and WI increased with the increase of the rice drying temperature. IR heating also has no significant effect on the sensory quality of rice (Pan et al. 2008).

The high temperature of IR heating does not lower the rice quality as uniform heating of the rice kernel by IR radiation results in less moisture gradient compared to conventional heated-air drying. Tempering and natural cooling of rice after IR drying have been found to be very important to preserve rice quality (Pan et al. 2008, 2011). IR drying does not affect the proximate compositions, starch digestibility, and energy values of the rice. A brief, intense, but well-controlled infrared irradiation of rice increases the wholesomeness and its nutritive value (Keya and Sherman 1997). The effect of IR drying on microstructure of rice kernels was studied using electron microscopy (SEM) technique by Ding et al. (2015). The SEM photos of whole and segment transverse sections of dried samples by IR, hot air, and ambient air (Fig. 13.4) did not show any significant differences. Microstructures of starch granules in the rice samples were similar for the three rice samples, and IR heating had no adverse effect on rice microstructure.

Scanning electron micrograms of the rice dried with ambient air (a, b), infrared radiation (c, d), and hot air (e, f) (Source: Ding et al. 2015)

Disinfestation and Disinfection

Influence of IR heating of rough rice on disinfestation of lesser grain borer and Angoumois grain moths was investigated. IR heating of single-layer rough rice samples to 60 °C, followed by tempering at 60 °C for 4 h and forced natural cooling, achieved complete disinfestation of moths and grain borers in addition to high moisture removal and milling quality (Pan et al. 2008). The effect of infrared (IR) heating and tempering treatments on disinfection of Aspergillus flavus in freshly harvested rough rice and storage rice was investigated by Wang et al. (2014). The log reductions of A. flavus spores for the rice samples with different IMCs heated with IR to 60 °C followed by tempering for different time periods are presented in Fig. 13.5.

Disinfection and fitting curves for Aspergillus flavus spores for rough rice with different initial moisture contents (Source: Wang et al. 2014)

The A. flavus populations in IR-dried rough rice significantly decreased (α < 0.05) as tempering time increased. With the same tempering time, the A. flavus population significantly decreased (α < 0.05) as the IMC of rough rice increased. Therefore, heating rice samples to 60 °C followed by tempering for 120 min was more than adequate to inactivate A. flavus (based on a 5-log reduction requirement) in rice with an IMC above 21.1% (Wang et al. 2014). Measured quantity of moisture can be added to bring the rice with low IMC to 21.1% before IR drying to inactivate the A. flavus populations. From these studies, it can be concluded that IR heating can be used for simultaneous drying and disinfestation of freshly harvested rough rice. For dry rice, the disinfection can be achieved by rewetting the dry rice to sufficient moisture.

Infrared Drying of Parboiled Rice

Rice Temperature and Heating Rate

IR heating of parboiled rice has been found to provide faster heating of rice to increase the temperature of rice to the drying temperature quickly compared to the hot air drying. Results of drying of parboiled rice of two varieties by Tirawanichakul et al. (2012) using IR at two intensities (1000 and 1500 W) and hot air under the temperature range of 60–100 °C at an inlet air flow rate of 1.0 ± 0.2 m/s are shown in Fig. 13.6. The IR drying increased the rice temperature to the target temperature quickly compared to that of hot air drying and reduced the drying time.

Moisture content and grain temperature against drying time of parboiled rice drying with IR 1000 W (top), IR 1500 W (middle), and hot air (bottom) at inlet drying temperatures of 57.1–100 °C (Source: Tirawanichakul et al. 2012)

Moisture Removal and Drying Rate

The IR heating resulted in high drying rate or moisture removal compared to hot air drying and reduced the drying time for parboiled rice because energy in the form of electromagnetic wave (IR) can be transferred and absorbed directly to the rice grain kernel by heat radiation with a low heat loss to the surrounding. The drying rate increased with the increase in the intensity of IR radiation (Tirawanichakul et al. 2012). The increased drying rate decreased the drying time by almost half compared to hot air drying.

Milling Quality

IR drying of parboiled rice had higher HRY compared to hot air-dried and ambient-dried samples. This is because high infrared power can penetrate more deeply leading to higher rate of heat transfer to kernel resulting in greater starch gelatinization (Tirawanichakul et al. 2012). However, contradicting results on HRY were reported by Das et al. (2004a) for IR drying of parboiled rice using higher radiation intensities of 1509–5514 W/m2. About 6–8% reduction in HRY was observed when the intensity increased from 1509 to 5514 W/m2. The HRY reduction increased with increase in IR intensity. The reduction in HRY was attributed to a marked increase in drying rate as the intensity level increased. The rapid moisture removal contributed to a higher state of stress in the rice kernel at the time of drying, causing a high percent of breakage.

The whiteness value of the milled parboiled rice was lower than that of the milled rough rice. Parboiled rice became discolored as a result of Maillard reaction and the diffusion of hull and bran pigments into the endosperm during soaking (Bhattacharya 2004). The color or yellowness index (YI) of the milled rice was influenced by grain bed depth and the IR intensity used for drying of parboiled rice. The grain bed depth was found to have a negative effect and the radiation intensity had a positive effect on YI. At a particular bed depth, the YI increased with increased radiation intensity or increased heating. At higher radiation intensity, a darker color was observed. Radiation intensity and bed depth significantly changed the percent gelatinization of the kernels.

Modeling of Infrared Drying of Rice

Several models have been developed to describe drying of rough rice with IR drying, combined IR, and convective drying and intermittent IR heating conditions (Abe and Afzal 1997; Cihan and Kahvec 2007). The Page model , a diffusion model based on spherical grain shape, an exponential model, and an approximation of the diffusion model had been used to explain the thin-layer infrared drying characteristics of rough rice. The Page model was the most acceptable for describing the thin layer of rough rice under infrared drying (Abe and Afzal 1997; Das et al. 2004a). Prakash (2011) developed mathematical models to describe heat and moisture transport phenomena in the rice kernels during sorption, convective air drying, and IR drying processes. The models successfully predicted MC and temperatures in the rice kernels during air and IR drying and sorption processes. The temperature dependence of moisture diffusivity was successfully described by Arrhenius equation. Khir et al. (2011) investigated the effects of initial moisture content, rice drying bed thickness, temperature, and cooling methods on the moisture diffusion coefficient and the moisture diffusivity using an unsteady diffusion equation based on Fick’s law and slope methods. Rough rice moisture diffusivities under infrared heating and cooling were dramatically influenced by rice temperature and tempering treatment, respectively. The moisture diffusion coefficients during the heating and cooling of infrared dried rice with tempering were much higher than those of convective drying (Khir et al. 2011).

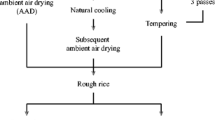

Shelf Life of Infrared Dried Rice

Storage stability of IR-dried rough rice stored in the form of rough rice and brown rice was studied and compared with that of hot air-dried (43 °C) and ambient air-dried rough rice (Ding et al. 2015, 2016, 2017). Storage characteristics including the changes in color, microstructure, free fatty acid, peroxide value, and iodine value gelatinization, pasting, cooking, and textural properties of rough rice were determined to detect any notable degradation of lipids in rough and brown rice during storage. IR drying was performed by heating rough rice to 60 °C under radiation intensity of 4685 W/m2 in the IR dryer (Fig. 13.7), followed by 4 h tempering and natural cooling to 16.1% (dry basis) moisture content. The rough rice samples dried by the three methods were stored in the form of rough rice and brown rice at 35 ± 1 °C with relative humidity of 65 ± 3% for 10 months using an experimental plan shown in Fig. 13.8 (Ding et al. 2015).

Rice drying in a custom-designed catalytic IR heating unit (Source: Pan et al. 2016)

Experimental procedure for rough rice drying and storage (Source: Ding et al. 2015)

Storage of Infrared Dried Rough Rice

Milled Rice Quality

IR drying produced slightly higher TRY than hot air and ambient air drying (Ding et al. 2015). The TRY of IR-dried rice was slightly higher than other drying methods for the entire 10-month storage. The HRY values of rice dried with IR in initial 4 months of storage were slightly higher than rice dried with hot and ambient air-drying methods. At the 10 months of storage, the HRY of IR-dried rice was similar to the HRY from other two methods. The whiteness index of milled rice from IR drying and hot air drying was slightly higher than ambient air-dried samples. The whiteness index did not change during the first 4 months of storage of rough rice, and beyond 4 months of storage, the whiteness values were found to decrease. The IR drying significantly increased the whiteness of the white rice compared to hot air and ambient air drying. This is because high temperature of IR drying results in partial gelatinization of starch and collapse of the starch granules producing a transparent and glossy kernels. Moreover, a high drying temperature decreased the activity of enzymes and reduces the enzymatic browning. Shorter time of IR drying compared to other methods weakened the nonenzymatic browning reaction. No significant differences (p > 0.5) were found in the YI of rice dried using three drying methods. However, YI values increased during storage. The increase in yellowness of rice could be caused by lipid oxidation, Maillard reaction, and leaching of the yellow color from pigments present in rice hull and bran into the endosperm after a long period of storage. IR drying may stabilize the microstructure of the rough rice and prevents any changes in microstructure during storage. The high temperature during IR heating followed by tempering process could anneal the starch and denature protein in rice and make their structure more stable than the samples dried with hot air and ambient air drying . IR-dried rice has been reported to have better gelatinization, pasting, cooking, and textural properties compared to hot air- and ambient air-dried rice (Ding et al. 2016).

Storage Stability

Storage stability of rice can be assessed from the free fatty acid (FFA) content, peroxide value (PV), and iodine value (IV) of rice samples. The FFA and POV levels of lower than 10% and 20 Meq/kg, respectively, are considered as indicators of stable rice with accepted sensory qualities. Ding et al. (2015) studied the FFA of rough rice samples dried with IR, hot air, and ambient air over the storage period of 10 months (Fig. 13.9). FFA value of IR-dried rice was lower than the hot air- and ambient air-dried rice samples during the 0–4 months of storage. After 4 months of storage, FFA concentrations of rough rice samples dried with IR drying were significantly (p < 0.05) lower than those dried with hot air and ambient air.

Changes in free fatty acid (FFA) concentrations of stored rough rice dried by three methods. IRD IR drying, HAD hot air drying, AAD Ambient air drying (Source: Ding et al. 2015)

The studies on peroxide value (PV) and iodine value (IV) showed no significant difference among rice dried using three drying methods. In general, all the stored rice samples had similar changing trend for PV and IV over the storage period. PV of all samples increased after the first month and then decreased to the least at month 4. After that, PV increased again at month 7 and became stable till month 10. All the rice dried by IR, hot air, and ambient air did not have significant difference in iodine value at month 0, and it had a similar steady descend over the storage period (Ding et al. 2015). IR drying of rice stabilizes the microstructure and causes effective inactivation of lipase and reduces the lipid hydrolysis to improve the long-term storage stability and significantly extends the period of safe storage.

Storage of Brown Rice

Milled Rice Quality

Brown rice stored after IR drying produced slightly higher TRY and HRY than those dried with hot air. No significant differences were found in TRY and HRY of IR-dried and ambient air-dried rice samples stored as brown rice (Ding et al. 2015). The storage duration of 10 months did not affect the HRY. The whiteness index of milled rice from IR drying and hot air drying was slightly higher than ambient air-dried samples. The whiteness index did not change during the first 4 months of storage of brown rice, and beyond 4 months, the whiteness values were found to decrease. Color characteristics of the white rice milled from stored brown rice dried with IR, hot air, and ambient air were studied for the storage period of 10 months using L*, a*, and b* and also the yellowness index (YI) values to describe the color change in stored brown rice (Fig. 13.10). The results showed that IR drying increased the whiteness of milled rice without significant changes in yellowness. Moreover, the IR drying also reduced the changes in color of the stored brown rice during the first 4 months of storage compared to ambient air drying. Ding et al. (2017) used light transverse micrographs to show the changes in structure of white rice milled from stored brown rice dried with IR, hot air, and ambient air during 10 months of storage period. The micrographs showed that IR-dried rice had a more stable structure compared to hot air- and ambient air-dried rice kernels.

Color characteristics of the white rice milled from stored brown rice dried with infrared (IRD), hot air (HAD), and ambient air (AAD) during storage. The figures (a), (b), (c), and (d) show the a*, b*, L*, and yellowness index values of the rice samples, respectively (Source: Ding et al. 2017)

Storage Stability

Ding et al. (2015) studied the concentrations of free fatty acids (FFA) of brown rice over the storage period of 10 months prepared from rough rice dried using IR, hot air, and ambient air (Fig. 13.11). FFA value of IR-dried rice was lower than the hot air- and ambient air-dried rice samples during the 0–4 months of storage. After 4 months of storage, FFA concentrations of rough rice samples dried with IR drying were significantly (p < 0.05) lower than those dried with hot air and ambient air. The PV and IV values of stored brown rice samples showed no significant difference among rice dried using three drying methods. IR heating had no negative effects on oxidation of unsaturated fatty acids to saturated fatty acids (Ding et al. 2015). PV of all samples increased after the first month and then decreased to the least at 4 months of storage. PV increased again at month 7 and became stable till month 10. The IV values steadily decreased from 0 to 10 months of storage.

Changes in free fatty acid (FFA) concentrations of stored brown rice prepared from rough rice dried by three methods. IRD IR drying, HAD hot air drying, AAD ambient air drying (Source: Ding et al. 2015)

Storage of brown rice prepared from IR -dried rough rice did not have adverse effects on the cooking quality of milled rice. The cooking characteristics water uptake ratio (WUR), volume expansion ratio (VER), and solid loss percentage (SLP) of the milled rice samples dried with IR showed no significant difference (p > 0.05) with those dried with hot air and ambient air drying. WUR and VER of rice samples from three drying methods slightly increased in the first 4 months, following a considerable increase until the seventh month; in the end there was a slight decrease between seventh and tenth months of storage period.

No significant difference in the hardness values of the cooked white rice samples dried with IR, hot air, and ambient air was noticed. The hardness of all cooked rice samples was in the same level during the first 4 months of storage, and then it significantly increased during the prolonged storage beyond 4 months. Adhesiveness of cooked rice samples dried using IR and hot air was slightly higher than those dried with ambient air, and the adhesiveness of all rice samples slightly decreased during the storage.

The thermal and pasting properties of stored brown rice dried using IR, hot air, and ambient air were investigated by studying the onset (To), peak (Top), conclusion (Tc), range of gelatinization temperature (Wp), and the gelatinization enthalpy (ΔH) of rice flour prepared from the milled white rice from stored brown rice (Ding et al. 2017). IR-dried rice had a slightly lower To, Tc, Wp, and ΔH values than hot air- and ambient air-dried rice, whereas rice from all three drying methods had similar gelatinization characteristics. IR drying reduced the changes in the cooking and textural characteristics by stabilizing the microstructure and properties of proteins and starch granules located in the surface layer of rice kernels. All the parameters (To, Tp, Tc, Wp, and ΔH) of the stored brown rice congruously increased in the first 4 or 7 months and then slightly decreased. The results showed that IR drying could be used as a feasible efficient drying technique that can maintain the physicochemical properties of brown rice during storage and improve its storage characteristics (Ding et al. 2017).

The accelerated storage study of rough rice and brown rice by storing at 35 ± 1 °C with relative humidity of 65 ± 3% showed that FFA concentration of hot air-dried rough rice was increased to 7.84% (Fig. 13.9) after 10 months of storage, whereas the FFA concentration of IR-dried rice stored in the form of brown rice was increased to only 6.91% (Fig. 13.11) after 10 months of storage. These results show that IR-dried rice can be stored in brown rice form at ambient temperature with even longer shelf life than that of rough rice dried with ambient and hot air.

Stabilization of Rice Bran by IR Drying of Rice

Rice bran is an important by-product of rice milling that constitutes 8–10% of the weight of brown rice. Rice bran is a nutritionally valuable by-product of paddy milling containing significant amounts of bioactive phytochemicals such as tocopherols, tocotrienols, γ-oryzanol, and other plant sterols (Yilmaz et al. 2014). Utilization of rice bran is severely restricted by the activity of endogenous enzymes, such as lipase, which can hydrolyze the triglyceride into glycerol and free fatty acids (FFAs). Immediately after milling, the FFA level begins to increase and the bran soon becomes unsuitable for further processing to produce oil for human consumption or as animal feed owing to its reduced pH, rancid flavor, and soapy taste. Lipases are the major cause of this deterioration in addition to oxidases (indirectly). In order to better utilize the rice bran from rice milling process, the oil must be extracted quickly after milling process to control FFAs at a low level. However, this practice may not be feasible due to restriction of facility and production schedule. Therefore, it is a normal practice that the bran undergoes an energy-intensive extrusion stabilization process to inactivate the potent lipase enzyme immediately after milling to extend storage time at ambient conditions for controlling the FFA concentration at a low level (less than 10%) before oil extraction (Wang et al. 2016).

IR irradiation can be used for the inactivation of lipases in order to extend the shelf life of rice bran. Rice bran was stabilized effectively by passing it in the rice bran stabilization system (Fig. 13.12) by varying the heating time from 1 to 10 min and IR power from 200 to 900 W (Yilmaz et al. 2014).

Schematic diagram of prototype IR rice bran stabilization system: 1, electric motor; 2, gear reducer; 3, fan; 4, conveyor; 5, IR emitter; 6, hopper; 7, frame; 8, reflector; 9, electronic variator (Source: Yilmaz et al. 2014)

The FFA content of raw and IR-stabilized rice bran samples was monitored every 15 days during 6 months of storage. FFA content of rice bran stabilized at 600 W IR power for 5 min remained below 5% for 165 days without a significant change in γ-oryzanol content or fatty acid composition. However, a significant decrease in tocopherol content was observed in stabilized rice bran compared with raw bran.

IR drying can be used for simultaneous rough rice drying and stabilization of bran. The effectiveness of IR drying for simultaneous rough rice drying and rice bran stabilization was evaluated by packing rice bran samples in plastic ziplock bags obtained from milling of IR-dried and hot air (control)-dried rice samples and storing the bran for 38 days at temperature of 20 ± 1 °C and RH of 46 ± 3% (Wang et al. 2016). FFA concentrations were determined for rice bran samples produced from milling rough rice samples with different initial MCs and stored for different durations. The FFA concentration of control samples increased sharply to more than 10% in less than 7 days of storage, whereas the FFA concentration of IR-dried samples gradually increased to 10% after 17, 19, and 30 days of storage for samples with initial MC of 20.06, 25.53, and 32.5 g moisture/100 g dry solid, respectively (Fig. 13.13). The lipase activity declined with increase in tempering time and initial moisture content of the rough rice. IR heating of freshly harvested rough rice to 60 °C followed by tempering treatment for 3 h or longer has effectively inactivated the lipase and extended the storage stability of rice bran for up to 38 days after milling. At the same time, high drying rate and good milling quality have been achieved by IR drying of rough rice.

Total FFA concentration in treated rice bran milled from IR-dried rice with initial moisture content 32.5 g moisture/100 g dry solid (Source: Wang et al. 2016)

■ control; □ IR; ● tempering, 1 h; ○ tempering, 2 h; ▲ tempering, 3 h; △ tempering, 4 h; ♦ tempering, 5 h

Conclusion

The consumption of brown rice has been increasing due to its higher nutrition value, nutty flavor, and rich texture. It is also desirable to store rice in brown rice form before milling which has been practiced in controlled climate with low temperature in some countries, which could save space and provide convenience. However, the short shelf life of brown rice in bulk storage before milling and in retail packing has been a significant concern. The effective and economic way to extend the shelf life of brown rice is to inactivate the lipase enzyme to minimize the lipid oxidation. The currently used low-temperature hot air drying cannot stabilize the rice against deterioration. Recently, IR drying has been reported that it effectively inactivated the lipase enzymes during rough rice drying. The IR drying resulted in high drying rate, good milling quality, effective disinfestation and disinfection of rough rice, and improvement in shelf life of both rough and brown rice due to partial lipase inactivation in the bran layer. More importantly, the IR-dried rice can be stored in brown rice form at ambient temperature with even longer shelf life than that of rough rice dried with ambient and hot air. The rice bran from milling of IR-dried rice has sufficient shelf life for further value-added utilization without need for additional stabilizing treatment, which make the product more competitive.

References

Abe T, Afzal TM (1997) Thin-layer infrared radiation drying of rough rice. J Agric Eng Res 67(4):289–297

Afzal TM, Abe T, Hikida Y (1999) Energy and quality aspects during combined FIR-convection drying of barley. J Food Eng 42:177–182

Amaratunga K, Pan Z, Zheng X, Thompson JF (2005) Comparison of drying characteristics and quality of rough rice dried with infrared and heated air. American Society of Agricultural Engineers Meetings Papers. ASAE paper no. 056005, St. Joseph, pp 1–10

Atungulu GG, Pan Z (2010) Infrared radiative properties of food materials. In: Pan Z, Atungulu GG (eds) Infrared heating for food and agricultural processing. CPC Press, Boca Raton, pp 19–40

Bal S, Wratten FT, Chesnen JL, Faulkner MD (1970) An analytical and experimental study of radiant heating of rice grain. Trans. ASAE 13(5):644–652

Bekki E (1991) Rough rice drying with a far-infrared panel heater. Journal of Japan Society Agriculture Machinery 53(1):55–63

Bergonio KB, Lucatin LGG, Corpuz GA, Ramos NC, Duldulao JBA (2016) Improved shelf life of brown rice by heat and microwave treatment. J Microbiol Biotechnol Food Sci 5(4):378–385

Bhattacharya KR (2004) Parboiling of rice. In: Champagne ET (ed) Rice chemistry and technology. AACC Int., Saint Paul, pp 329–404. ISBN-13: 978–1–891127-34-2

Champagne ET (1994) Brown Rice stabilization. In: Marshall WE, Wadsworth JI (eds) Rice science and technology. Marcel Dekker, Inc., New York, pp 17–35

Champagne ET, Hron RJ Sr (1992) Stabilizing brown rice to lipolytic hydrolysis by ethanol vapors. Cereal Chem 69(2):152–156

Champange ET, Hron RJ Sr, Abraham G (1991) Stabilizing brown rice products by aqueous ethanol ethanol extraction. Cereal Chem 67:267–271

Chen Y, Jiang W, Jiang Z, Chen X, Cao J, Dong W, Dai B (2015) Changes in physicochemical, structural, and sensory properties of irradiated brown japonica rice during storage. J Agric Food Chem 63:4361–4369

Chua KJ, Chou SK, Mujumdar AS, Ho JC, Hon CK (2004) Radiant-convective drying of osmotic treated agro-products: effects on drying kinetics and product quality. Food Control 15:145–158

Cihan A, Kahvec K (2007) Modeling of intermittent drying of thin layer rough rice. J Food Eng 79(1):293–298

Dangerskog M, Osterstrom L (1979) Infra-red radiation for food processing I. A study of fundamental properties of infrared radiation. Lebensm Wiss Technol 12(4):237–242

Das I, Das SK (2010) Emitters and infrared heating system design. In: Pan Z, Atungulu GG (eds) Infrared heating for food and agricultural processing. CRC Press, Boca Raton, pp 57–88

Das I, Das SK, Bal S (2004a) Drying performance of a batch type vibration aided infrared dryer. J Food Eng 64(1):129–133

Das I, Das SK, Bal S (2004b) Specific energy and quality aspects of infrared (IR) dried parboiled rice. J Food Eng 62:9–14

Das A, Das S, Subudhi H, Mishra P, Shrama S (2012) Extension of shelf life of brown rice with some traditionally available materials. Indian J Tradit Knowl 11(3):553–555

Ding C, Khir R, Pan Z, Zhao L, Tu K, El-Mashad H, McHugh TH (2015) Improvement in shelf life of rough and brown rice using infrared radiation heating. Food Bioprocess Technol 8(5):1149–1159

Ding C, Khir R, Pan Z, Wood DF, Tu K, El-Mashad H, Berrios J (2016) Improvement in storage stability of infrared dried rough rice. Food Bioproc Tech: Int J 9:1010–1020

Ding C, Khir R, Pan Z, Venkitasamy C, Tu K, El-Mashad H, Berrios J (2017) Influence of infrared radiation drying on storage characteristics of brown rice. Submitted to J Cereal Sci

Dostie M, Seguin JN, Maure D, Ton-That QA, Chatingy R (1989) Preliminary measurement on the drying of thick porous materials by combinations of intermittent infrared and continuous convection heating. In: Mujumdar SA, Roques MA (eds) Drying. Hemisphere Press, New York

Gabel M, Pan Z, Amaratunga KSP, Harris L, Thompson JF (2006) Catalytic infrared dehydration of onions. J Food Sci 71(9):E351-E357

Genkawa T, Uchino T, Inoue A, Tanaka F, Hamanaka D (2008) Development of a low-moisture-content storage system for brown rice: storability at decreased moisture contents. Biosyst Eng 99(4):515–522

Ginzberg AS (1969) Application of infrared radiation in food processing. Leonard Hill Books, London

Il’yasov SG, Krasnikov VV (1991) Physical principles of infrared radiation of foodstuffs. Hemisphere Publishing Corp, New York

Javier EQ (2004) Let’s promote brown rice to combat hidden hunger. Rice Today, January, 38

Juliano BO, Bechtel DB (1985) The rice grain and its gross composition. In: Juliano BO (ed) Rice Chemistry and technology, 2nd edn. American Association of Cereal Chemists, Eagan, pp 17–57

Kester EB (1951) Stabilization of brown rice. US Patent 2,538,007

Keya EL, Sherman U (1997) Effects of a brief, intense infrared radiation treatment on the nutritional quality of maize, rice, sorghum, and beans. Food Nutr Bull 18(4):382–387

Khir R, Pan Z, Salim A, Hartsough BR, Mohamed S (2011) Moisture diffusivity of rough rice under infrared radiation drying. LWT-Food Sci Tech 44(4):1126–1132

Khir R, Pan Z, Thompson JF, Salim A, Hartsough BR, Salah M (2014) Moisture removal characteristics of thin layer rough rice under sequenced infrared radiation heating and cooling. J Food Process Preserv 38(1):430–440

Kocabiyik B (2010) Combined infrared and hot air drying. In: Pan Z, Atungulu GG (eds) Infrared heating for food and agricultural processing. CRC Press, Boca Raton, pp 101–116

Krishnamurthy K, Khurana HK, Jun S, Irudayaraj J, Demirci A (2008) Infrared heating in food processing: an overview. Compr Rev Food Sci Food Saf 7:2–13

Krust PW, McGlauchlin LD, Mcquistan RB (1962) Elements of infrared technology. Wiley, New York

Kumar DGP, Hebbar HU, Sukumar D, Ramesh MN (2005) Infrared and hot-air drying of onions. J Food Process Preserv 29:132–150

Kunze OR, Calderwood DL (2004) Rough rice drying: Moisture adsorption and desorption. In Rice: Chemistry and Technology, 223–268. St. Paul, Minn. American Association of Cereal Chemists

Lentz RR, Pesheck PS, Anderson GR, DeMars J, Peck TR (1995) Method of processing food utilizing infrared radiation. US Patent 5,382,441

Lia BX, Lua YP, Liua LH, Kudo K, Tana HP (2004) Analysis of directional radiative behavior and heating efficiency for a gas-fired radiant burner. J Quant Spectrosc Radiat Transf 92:51–59

Malekian F, Rao RM, Prinyawiwatkul W, Marshall WE, Windhauser M, Ahmedna M (2000) Lipase and lipoxygenase activity, functionality and nutrient losses in rice bran during storage (Bull., no. 870, pp. 1–68). Baton Rouge: LSU Agricultural Centre.

McCabe D (1976) Process for preparing a quick-cooking brown rice and the resulting product. US Patent 3,959,515

Meeso NA, Madhiyanon T, Soponronnarit S (2004) Influence of FIR irradiation on paddy moisture reduction and milling quality after fluidized bed drying. J Food Eng 65(2):293–301

Modest MF (1993) Radiative heat transfer. McGraw-Hill International Editions, New York

Mongpreneet S, Abe T, Tsurusaki T (2002) Accelerated drying of welsh onion by far infrared radiation under vacuum conditions. J Food Eng 55:147–156

Navari P, Andrieu J, Gevaudan A (1992) Studies on infrared and convective drying of non-hygroscopic solids. In: Mujumdar SA, Roques MA (eds) Drying. Elsevier Science, Amsterdam, pp 685–694

Nindo CI, Mwithiga G (2010) Infrared drying. In: Pan Z, Atungulu GG (eds) Infrared heating for food and agricultural processing. CRC Press, Boca Raton, pp 89–100

Nowak D, Lewicki PP (2004) Infrared drying of apple slices. Innovative food Sci. Emerging Technol 5(3):353–360

Ory RL, Delucca AJ, St. Angelo AJ, Dupuy HP (1980) Storage quality of brown rice as affected by packaging with and without carbon dioxide. J Food Protection 43:929–932

Pan Z, Atungulu GG (2010a) Infrared dry blanching. In: Pan Z, Atungulu GG (eds) Infrared heating for food and agricultural processing. CRC Press, Boca Raton, pp 169–201

Pan Z, Atungulu GG (2010b) Infrared heating for food and agricultural processing. CRC Press, Boca Raton

Pan Z, Olson DA, Amaratunga KSP, Olsen CW, Zhu Y, McHugh TH (2005) Feasibility of using infrared heating for blanching and dehydration of fruits and vegetables. ASAE paper no. 056086. American Society of Agricultural Engineers, USA

Pan Z, Yang J, Brandl M, McHugh HT, Bingol G (2008) Infrared heating for improved safety and processing efficiency of dry roasted almonds. Report for Almond Board of California, pp 1–20

Pan Z, Khir R, Bett-Garber KL, Champagne ET, Thompson JF, Salim A, Hartsough BR, Mohamed S (2011) Drying characteristics and quality of rough rice under infrared radiation heating. Trans ASABE 54(1):203–210

Pan Z, Venkitasamy C, Li X (2016). Infrared processing of foods. Elsevier reference module in food sciences. doi:10.1016/B978-0-08-100596-5.03105-X

Patindol J, Wang YJ, Jane JI (2005) Structure-functionality changes in starch following rough rice storage. Starch/Stärke 57:197–207

Prakash B (2011) Mathematical modeling of moisture movement within a rice kernel during convective and infrared drying. PhD dissertations. University of California Davis, Department of Biological and Agricultural Engineering. Available online from ProQuest Dissertations & Theses Global

Ramaswamy HS, Marcohe M (2005) Food processing principles and applications. CRC Press, Boca Raton

Rao ON (1983) Effectiveness of infrared radiation as a source of energy for paddy drying. J. Agric. Eng. 20(2):71–76

Riadh MM, Ahmad SAB, Marhaban MH, Soh AC (2015) Infrared heating in food drying: an overview. Dry Technol 33(3):322–335

Sakai N, Hanzawa T (1994) Applications and advances in far-infrared heating in Japan. Trends Food Sci Technol 5:357–362

Sandu C (1986) Infrared radiative drying in food engineering: a process analysis. Biotechnol Prog 2:109–119

Schroeder HW, Roseberg DW (1960) Effect of infrared intensity on vixero visero rough rice. Rice J 61(1):28–43

Sharma GP, Verma RC, Parthare PB (2005) Thin layer infrared radiation drying of onion slices. J Food Eng 67(1):361–366

Sharp R, Timme L (1986) Effects of storage time, storage temperature, and packaging method on shelf life of brown rice. Cereal Chem 63(3):247–251

Shih C, Pan Z, McHugh TH, Wood D, Hirschberg E (2008) Sequential infrared radiation and freeze-drying method for producing crispy strawberries. Trans ASABE 51(1):205–216

Siegel R, Howell JR (2002) Thermal radiation heat transfer, 3rd edn. Hemisphere, Washington, 868 pp

Tan M, Chus KJ, Mujumdar AS, Chou SK (2001) Effect of osmotic pre-treatment and infrared radiation on drying rate and color changes during drying of potato and pineapple. Drying Tech 19(19):2193–2207

Thakur AK, Gupta AK (2006) Water absorption characteristics of paddy, brown rice and husk during soaking. J Food Eng 75(2):252–257

Tirawanichakul S, Bualuang O, Tirawanichakul Y (2012). Study of drying kinetics and qualities of two parboiled rice varieties: hot air convection and infrared irradiation. Songklanakarin Journal of Science and Technology, 34(5):557–568

Van Atta GR, Kester EB, Olcott HS (1952) Method of stabilizing rice products. US Patent 2,585,978

Wang B, Khir R, Pan Z, EI-Mashad H, Atungulu GG, Ma H, McHugh TH, Qu W, Wu B (2014) Effective disinfection of rough rice using infrared radiation heating. J Food Prot 77(9):1538–1545

Wang T, Khir R, Pan Z, Yuan Q (2016) Simultaneous rough rice drying and rice bran stabilization using infrared radiation heating. Accepted by LWT – Food Science and Technology

Yilmaz N, Tuncel BN, Kocabiyik H (2014) Infrared stabilization of rice bran and its effects on gamma-oryzanol content, tocopherols and fatty acid composition. J Sci Food Agric 94:1568–1576

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2017 Springer International Publishing AG

About this chapter

Cite this chapter

Venkitasamy, C., Pan, Z. (2017). Extending Shelf Life of Brown Rice Using Infrared Heating. In: Manickavasagan, A., Santhakumar, C., Venkatachalapathy, N. (eds) Brown Rice. Springer, Cham. https://doi.org/10.1007/978-3-319-59011-0_13

Download citation

DOI: https://doi.org/10.1007/978-3-319-59011-0_13

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-59010-3

Online ISBN: 978-3-319-59011-0

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)