Abstract

When auxiliary equipment like MBR or MBBR or granular sludge is used to reduce the reactor volume of activated sludge systems, the sludge concentration increases and this will affect the oxygen transfer capacity of the aeration system, so that for a given oxygen demand the required energy and hence the operational costs will increase. An experimental method is presented to determine the influence of sludge concentration on the oxygenation capacity. An investigation was carried out, in which the influence of the oxygenation capacity was measured as a function of sludge concentration, by applying respirometry. The results show that the sludge concentration affects severely the oxygen transfer coefficient. Flocculent sludge is much more affected than granular sludge: at 25° C.

Access provided by CONRICYT-eBooks. Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

The oxygenation capacity or of an aerator is determined by the critical concentration that is required to maintain enough dissolved oxygen in the system for proper performance and is expressed as the product of the transfer coefficient (Kla) and the difference between the saturation concentration (DOs) and the critical concentration (DOc) of dissolved oxygen (DO) (Van Haandel and Van de Lubbe 2012):

From Eq. (1) it can be seen that the oxygenation depends on three factors: the transfer coefficient, the saturation concentration for DO and the critical concentration. In principle each of these three factors can be affected by the sludge concentration. In this paper the influence of the sludge concentration on each factor is determined by respirometry. The result of our experimental investigation is that a high e sludge concentration reduces considerably the value of the transfer coefficient but has relatively little influence on the saturation concentration and the critical concentration of DO.

Some variants of the activated sludge process, have been applied as alternatives to operate the activated sludge systems at much higher than conventional sludge concentrations and thus reduce the required reactor volume. (Odegaard et al. 2000) These can be operated at a sludge concentration of 10-15 g.L−1, as against 3-6 g.L−1 in conventional systems. However the consequential higher sludge concentration is detrimental for oxygen transfer from the atmosphere to the mixed liquor.

The experimental results in this paper show that purely from the economic point of view, these high concentrations are counterproductive: The reduction of the investment costs due to the smaller volume does not compensate the increase of operational costs due to the large energy consumption for aeration. The results also show that the reduction of the transfer coefficient is much smaller for granular sludge than for flocculent sludge. Thus the optimal sludge concentration for granular sludge is higher than for flocculent sludge.

2 Materials and Methods

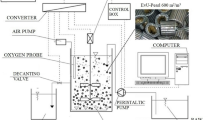

In this paper a method is presented to determine the influence of the sludge concentration on the oxygen transfer rate by using respirometry for the determination of K la , DO s and DO c at different sludge concentrations. This method makes use of an automated respirometer, which is an apparatus that determines the oxygen uptake rate (OUR) in an activated sludge reactor. Figure 1 shows the respirometer with the auxiliary equipment: a DO electrode for acquisition of the DO concentration in the reactor vessel equipped with a stirrer and a computer to store data of DO and OUR as functions of time, also allowing to view the values of these parameters on line. The reactor may either be a lab scale or a full scale unit.

A convenient method to determine the OUR is to fix an upper and a lower limit for the DO concentration and alternate periods of aeration until the upper set point and then switch off the aeration system till the lower set point is reached while to reactor continues to be stirred to ensure a uniform sludge concentration and substrate availability. Without aeration the decrease of the DO concentration in good approximation is linear with time until a critical concentration is reached, where DO becomes limiting and OUR decreases. Aeration is resumed when the lower set point is reached and a new cycle is initiated. The OUR is determined as the ratio between the decrease of the DO concentration from the upper to the lower set point and the time for the microbial sludge mass to consume the oxygen:

Where:

DO max – DO min = setpoint for the maximum and minimum DO concentration

t 1 , t 2 = beginning and end of a period without aeration

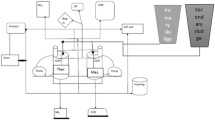

The software of the respirometer automatically calculates and plots both the variation of the measured DO concentration and the calculated OUR values as functions of time, so that the OUR variation with time can be seen on the monitor. Figure 2 is an example of such a respirogram: The top section of the figure shows the variation of the DO concentration with time and the bottom section shows the corresponding OUR values.

Figure 2 was obtained by measurements of DO and OUR of a sludge batch while periods of aeration were alternated with periods of non-aeration. As indicated the tests were carried out for different concentration of the sludge, thus obtaining OUR values for sludge concentrations from 13,2 to 2,2 gTSS.L−1.

The experimental OUR data thus obtained were used to calculate the values for Kla, and DOs by considering that during the period of aeration the rate of change of the DO concentration is expressed as the difference between the aeration rate (ra) and OUR or: dDO l /dt = r a – OUR = K la (DO s -DO l ) – OUR, whereas during the period of non-aeration the rate of change is equal to OUR. By solving the differential equation one gets:

Where:

DO o = the DO concentration at the beginning of the aeration period.

Equation (2) can be used to simulate the value of DO l as a function of time for any value of K la and DO s and for any sludge concentration. The simulated DO l curve can be compared to experimental DO l values (Fig. 2) and those K la and DOs values that generate a simulated DO l profile with the closest correlation to the experimental values will be chosen as the true values for the different sludge concentrations. Then by estimating DOc value from observed DO profiles the elements to calculate the oxygenation capacity in Eq. (2) are available. Table 1 is an example. The OCmax value for TSS = 0 is an extrapolation.

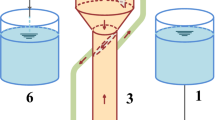

The results in Table 1 clearly show that the Kla value is very heavily influenced by the sludge concentration; the effect of DOs and DOc is only minor. Figure 3 shows the relationship between the sludge concentration and the oxygenation capacity for flocculent and for granular sludge. In both cases the experimental points indicate that there is a tendency of a linear relationship, but the OC value for granular sludge is much less affected by the sludge concentration. From the results the following empirical expressions was derived:

The relative energy consumption can be correlated to the oxygenation capacity:

Where:

E min = minimum energy required when OC = OC max

E x = Energy required when the sludge concentration has a value X t

In Fig. 4 the points based on experimental observations and the curves of Eqs. 4a and 4b are plotted. The plot of the empirical relationships in Fig. 4 shows the strong effect of sludge concentration on energy consumption, especially in the case of flocculent sludge. For example for a sludge concentration of Xt = 10 g.L−1 the energy consumption is 79% larger than the minimum value when the sludge is flocculent, whereas in the case of granular sludge the increase is only 22%. The large difference in energy consumption at high sludge concentration can be a decisive factor of the operational costs.

3 Conclusions

-

(1)

The oxygenation capacity of aerators (OC) in activated sludge systems is very heavily dependent on the sludge concentration: Experiments showed that OC decreases by 4.4% in the case of flocculent sludge and 1.8% for granular sludge per gram of total suspended solids.

-

(2)

The decrease of the oxygenation capacity at increasing sludge concentrations is mainly due to a decrease of the oxygen transfer coefficient of the aerator equipment.

-

(3)

The smaller reduction of the transfer coefficient for granular sludge is a very important factor for reduction of energy costs for aeration.

-

(4)

At very high sludge concentrations the oxygen uptake rate may become so high the aeration equipment itself may require an upgrade. This represents additional investment and/or operational costs.

References

Odegaard H, Gisvold B, Strickland J (2000) The influence of carrier size and shape in the moving bed biofilm process. Water Sci Technol 41(5):383–392

Van Haandel AC, Van Der Lubbe J (2012) Handbook Biological Waste Water Treatment - Second edition: Design and Optimisation of Activated Sludge System. IWA Publishing of Alliance House, London, p 816

Acknowledgements

This research received financial support from the Brazilian Government through its agencies CNPq (National research Council) and ANA (National Water Agency).

Author information

Authors and Affiliations

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2017 Springer International Publishing AG

About this paper

Cite this paper

dos Santos, S.L., Catunda, Y.C., van Haandel, A.C. (2017). Influence of the Sludge Concentration on Oxygen Transfer and Energy Consumption in Activated Sludge Systems. In: Mannina, G. (eds) Frontiers in Wastewater Treatment and Modelling. FICWTM 2017. Lecture Notes in Civil Engineering , vol 4. Springer, Cham. https://doi.org/10.1007/978-3-319-58421-8_99

Download citation

DOI: https://doi.org/10.1007/978-3-319-58421-8_99

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-58420-1

Online ISBN: 978-3-319-58421-8

eBook Packages: EngineeringEngineering (R0)