Abstract

Thanks to the content of various high-value products (antioxidants, vitamins, fatty acids, oils, polysaccharides, etc.) and simple cultivation in large scale, microalgae have become an increasingly popular and utilized group of photosynthetic organisms with wide range of possible use in diverse areas of biosciences, biotechnology, food technology, and biorefinery processes. Their application potential can be increased after appropriate magnetic modification ; alternatively, magnetically responsive nano- and microparticles have been successfully used for microalgae harvesting . Magnetic materials can also be used for efficient separation of biologically active compounds or as carriers for (bio)catalysts immobilization. In all cases, the specific response to external magnetic field (magnetic separation ) can significantly simplify and accelerate the processes connected with microalgae biotechnology .

Access provided by CONRICYT-eBooks. Download chapter PDF

Similar content being viewed by others

Keywords

- Magnetic particles

- Magnetic techniques

- Magnetic modification

- Magnetic separation

- Microalgae harvesting

- Microalgae biotechnology

- Microalgae lipids

- Microalgae toxins

- Magnetic biocatalysts

- Immobilized lipase

- Biodiesel

1 Introduction

Microalgae form a diverse collection of microorganisms that conduct oxygen-evolving photosynthesis. Both prokaryotic and eukaryotic photosynthetic microorganisms are covered in this group; they can grow rapidly, live even in harsh conditions, and are present in almost all ecosystems around the globe. Examples of prokaryotic microorganisms are cyanobacteria (Cyanophyceae) and eukaryotic microalgae are, for instance, green algae (Chlorophyta) and diatoms (Bacillariophyta) (Mata et al. 2010). Large-scale cultivation of microalgae is a promising way to produce large amounts of biomass containing a wide variety of high-value products with considerable commercial value, with great potential use in the aquaculture, food, feed, pharmaceutical, cosmetic, fuel, and other industries. Species of Chlorella and Arthrospira (also known as Spirulina) are sold as dried biomass with a high content of proteins, carotenoids, phycobilin pigments, fatty acids, sterols, polyhydroxyalkanoates, polysaccharides, or vitamins (mainly B12, C, and D2). The green alga Haematococcus pluvialis is the producer of the carotenoid astaxanthin (a potent antioxidant) used as a food and feed supplements. Microalgal species, including Anabaena, Botryococcus, Dunaliella, Nostoc, Parietochloris, Porphyridium, Scenedesmus, and Synechococcus, are exploited for the production of antioxidants (carotenoids, especially beta-carotene) and important vitamins (e.g., retinol, biotin, thiamine, riboflavin, folic acid, l-ascorbic acid, and tocopherol). Furthermore, the increasing consumer awareness of the therapeutic properties of omega-3 polyunsaturated fatty acids (PUFAs), such as eicosapentaenoic and docosahexaenoic acids, and the expensive procedures for extracting them from fish oils boost the research toward marine microalgae (e.g., Chrysophyceae, Eustigmatophyceae, Chlorophyceae, and Cryptophyceae), where some species are capable to provide high levels of PUFAs (Sastre 2012; Encarnação et al. 2015; Borowitzka 2013; Lambreva et al. 2015; Bishop and Zubeck 2012; Guarnieri and Pienkos 2015). Microalgae are also intensively studied as a rich source of polysaccharides and oils important for biorefinery processes (Gouveia 2011).

Microalgae research and technology employ a wide variety of techniques, instrumentation, and materials. In this chapter, the attention is focused on the application of magnetically responsive nano- and microparticles which have already been used in many biotechnology applications (Borlido et al. 2013; Garcia et al. 2015; Safarik et al. 2012; Safarik and Safarikova 2009). In the microalgae technology, they can be especially used for magnetic flocculation of microalgae cells from cultivation media, magnetic modification of microalgae cells, magnetic isolation of target compounds produced by microalgae, magnetic detection of algae produced toxins , and preparation of magnetically responsive catalysts applicable in microalgae biotechnology . Despite the fact that there is a real boom of studies employing magnetic particles for microalgae separation from large volumes, other areas of microalgae research and technology have not fully employed the potential offered by magnetically responsive materials. This chapter should stimulate the microalgae research community in finding new progressive applications of magnetically responsive materials.

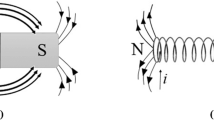

2 Preparation of Magnetic Materials

Magnetically responsive biocompatible materials have found many important applications in various areas of biosciences, medicine, biotechnology, and environmental technology. Both basic ferro- and ferrimagnetic materials (e.g., magnetite, maghemite, and different types of ferrites) and magnetically responsive composite materials formed by magnetically labeled diamagnetic materials are of great importance. One of the most significant properties of magnetic materials is their possibility to be selectively separated (removed) from the complex samples using an external magnetic field (e.g., by means of an appropriate magnetic separator, permanent magnet, or electromagnet). This process enabling efficient selective separation of magnetic materials is very important for bioapplications due to the fact that absolute majority of biological materials have originally diamagnetic properties (Safarik and Safarikova 2009).

Various procedures have been used to synthesize magnetic nano- and microparticles, such as classical coprecipitation, reactions in constrained environments (e.g., microemulsions), sol-gel syntheses, hydrolysis and thermolysis of precursors, sonochemical and microwave reactions, hydrothermal reactions, flow injection syntheses, electrospray syntheses, and mechanochemical processes (Laurent et al. 2008; Safarik et al. 2011; Wu et al. 2015).

Coprecipitation technique (aging stoichiometric mixture of ferrous and ferric salts in aqueous alkaline medium) is the simplest procedure to synthesize large amount of iron oxide nanoparticles, either in the form of magnetite (Fe3O4) or maghemite (γ-Fe2O3). The addition of chelating organic anions (e.g., citric, gluconic, or oleic acids) or polymer surface complexing agents (dextran, carboxydextran, starch, or polyvinyl alcohol) during the formation of magnetite can help to control the size of the nanoparticles (Laurent et al. 2008).

Synthesis of uniform iron oxide nanoparticles can be performed in synthetic and biological nanoreactors, such as water-swollen reversed micellar structures in nonpolar solvents, apoferritin protein cages, dendrimers, cyclodextrins, and liposomes.

Hydrothermal syntheses of magnetite nanoparticles are carried out in aqueous media in reactors or autoclaves at high pressure and temperature. The sol-gel process is based on the hydroxylation and condensation of molecular precursors in solution, originating a “sol” of nanometric particles; further condensation and inorganic polymerization followed by heat treatments are needed to acquire the final crystalline state. The polyol process employs, e.g., polyethylene glycol as a solvent exhibiting high dielectric constants, which can dissolve inorganic compounds. Polyols also serve as reducing agents as well as stabilizers to control particle growth and prevent interparticle aggregation (Laurent et al. 2008).

The flow injection synthesis employs continuous or segmented mixing of reagents under laminar flow regime in a capillary reactor which enables precise external control of the process. The obtained magnetite nanoparticles had a narrow size distribution in the range of 2–7 nm. Spray pyrolysis and laser pyrolysis enable high rate production of nanoparticles. In spray pyrolysis, a solution of ferric salts and a reducing agent in organic solvent is sprayed into a series of reactors, where the aerosol solute condenses and the solvent evaporates. Maghemite particles with size ranging from 5 to 60 nm with different shapes have been obtained using different iron precursor salts in alcoholic solution (Laurent et al. 2008; Safarik et al. 2011).

A wide variety of chemical reactions accelerated by microwave irradiation of reactants has been observed. Recently, a simple, quick, and cost-effective microwave method to prepare relatively uniform magnetite nanoparticles directly from Fe2+ salts has been developed; the formation of magnetic nanoparticles using microwave method requires only a few seconds or minutes (Zheng et al. 2010; Safarik and Safarikova 2014). Nanosized iron oxide powders can also be synthesized via a mechanochemical reaction. Ball milling of ferrous and ferric chlorides with sodium hydroxide led to the formation of magnetite (Lin et al. 2006) or maghemite (Safarik et al. 2014a). To avoid agglomeration, the excess of NaCl is usually added to the precursor before ball milling.

In order to obtain biocompatible magnetically responsive materials, stabilization of the prepared iron oxide nano- and microparticles by appropriate modification of their surface or by their incorporation into appropriate biocompatible matrix is usually necessary. Compounds with carboxylic and phosphate functional groups (e.g., citric and oleic acids) can bind to the surface of magnetic particles and stabilize them. Water-based ferrofluids can also be stabilized by ionic interactions, using, e.g., perchloric acid or tetramethylammonium hydroxide (Laurent et al. 2008).

Biocompatible (bio)polymers are also used for magnetic particles’ stabilization and modification. Dextran has often been utilized as a polymer coating mostly because of its excellent biocompatibility. The formation of magnetite in the presence of dextran 40,000 was reported for the first time in 1980s. Other common biopolymer coatings are formed, e.g., by carboxymethylated dextran, carboxydextran, starch, chitosan, alginate, arabinogalactan, or glycosaminoglycan, while polyethylene glycol (PEG) and polyvinyl alcohol (PVA) represent biocompatible synthetic polymers (Laurent et al. 2008).

Magnetic nanoparticles are often a magnetic component part of magnetically responsive composite microparticles formed from various synthetic polymers, biopolymers, inorganic materials, microbial cells, or plant materials (Safarik et al. 2012).

3 Magnetic Materials for Microalgae Harvesting

Algal cells can be harvested using various solid–liquid separation steps and methods such as centrifugation, sedimentation, flocculation, filtration, flotation, or by a combination of these methods. However, current harvesting methods have many disadvantages. Therefore, new harvesting procedures employing different types of magnetic nano- and microparticles have been developed and tested also for industrial-scale harvesting of algal biomass (Safarik et al. 2016; Wang et al. 2015).

Magnetic flocculation of microalgae enables simple magnetic separation . Naked magnetite is an efficient flocculation agent for the separation and removal of microalgal biomass. Magnetic iron oxide particles can be prepared using various methods (see above) and subsequently applied for microalgae harvesting . Magnetite particles synthesized by chemical coprecipitation with an average diameter of approximately 10 nm and an isoelectric point of approximately 7 were efficient in harvesting Botryococcus braunii, Chlorella ellipsoidea, and Nannochloropsis maritima (Xu et al. 2011; Hu et al. 2013).

An extremely simple procedure for the magnetic modification of algal cells which is based on the use of microwave-synthesized magnetic iron oxide nano- and microparticles has been developed recently. Two very inexpensive precursors are employed (ferrous sulfate heptahydrate and sodium or potassium hydroxide); after alkalization of ferrous salt and formation of mixed iron hydroxides precipitate, the suspension underwent microwave treatment (a regular kitchen microwave oven can be used successfully) and nano- and microparticles of magnetic iron oxides were formed (Zheng et al. 2010; Safarik and Safarikova 2014). Mixing of magnetic particles with algal cell (C. vulgaris) suspensions caused cell flocculation and magnetically responsive cell aggregates (usually ca. 100–300 μm in diameter) formation. Naked magnetite has ion-exchange characteristics, and the separation is primarily based on the electrostatic interactions between the magnetite and the algal cells. In addition, Fe2+/3+ ions released from the magnetic particles’ surface may act as flocculating agents and benefit the harvesting process (Prochazkova et al. 2013).

Due to the negative surface charge of microalgal cells, a positive charge on the surface of magnetic particles improves separation. Functionalization of the magnetic particles’ surface with cationic groups improves the cells’ magnetic flocculation. Two potential strategies can be used based on the place where a positively charged polyelectrolyte (polymer) is bound. One strategy consists in coating the cells with a suitable polymer in the first step and then attaching the naked magnetic particles ; in another approach, the naked magnetic particles are first surface-functionalized with a polyelectrolyte and then bound to the microalgal cells (Toh et al. 2014b; Lim et al. 2012).

Recently, several review papers summarizing the application of magnetic particles for microalgae harvesting have been published (Lee et al. 2015; Safarik et al. 2016; Wang et al. 2015).

4 Magnetic Modification of Microalgae Cells and Their Applications

Magnetic modification of prokaryotic and eukaryotic cells leads to the formation of extremely interesting biocomposites. The common characteristics of all magnetically modified cells are their specific interactions with an external magnetic field (Safarik et al. 2014b). The individual procedures used for magnetic modification of microalgae cells are given below (Safarik et al. 2016).

Dried Chlorella vulgaris cells were magnetically modified using perchloric acid-stabilized magnetic fluid in acidic buffer which led to the deposition of magnetic iron oxide nanoparticles onto the cell surface and formation of magnetically responsive algal cells. Modified cells were applied as a new inexpensive magnetic adsorbent for the removal of six water-soluble organic dyes. Data from dye adsorption process were fitted to Langmuir isotherm, and the maximum adsorption capacities were 24.2 and 257.9 mg of dye per g of dried magnetically modified cells for Saturn blue LBRR and aniline blue, respectively. Increasing pH value can positively affect the adsorption capacities of some dyes (e.g., crystal violet and safranin O) (Safarikova et al. 2008). The same acid magnetic fluid has been successfully used for magnetic modification of selected diatoms or chrysomonads (Diadesmis gallica, Mallomonas kalinae); in this case, magnetic modification can be performed in methanol (Kratosova et al. 2013). Diatom particles have also been magnetically labeled with human serum albumin (HSA)-coated iron oxide nanoparticles, prepared from oleic acid/oleylamine-coated nanoparticles after subsequent surface exchange with dopamine. Diatoms were contacted with the modified particles in PBS at room temperature for 2 h. Multiple amine groups on the surface of the MNPs ensured their partial positive charge, making them appropriate to interact with negatively charged cell surfaces (Todd et al. 2014).

Cationic polyelectrolyte promoted effective attachment of iron oxide nanoparticles onto microalgal cells through electrostatic attraction. Chitosan and poly(diallyldimethylammonium chloride) (PDDA)-modified magnetic iron oxide nanoparticles can easily modify Chlorella sp. cells during simple mixing. Subsequent magnetophoretic separation of magnetized Chlorella cells was carried out under low-gradient magnetic separation (LGMS) with a NdFeB permanent magnet in an inhomogeneous magnetic field with magnetic field gradient (∇B) < 80 T/m. It was also shown that magnetic nanoparticles can enter the cells. The internalization of nanoparticles may be through a passive uptake or adhesive interaction (Toh et al. 2014a, b). PDDA also promoted effective attachment of IONPs onto other microalgae cells (Lim et al. 2012; Toh et al. 2012).

Another procedure for coating algal cells by magnetite nanoparticles via electrostatic interactions has been described recently. (Poly)allylamine hydrochloride-stabilized positively charged MNPs (average diameter around 15 nm) were used for the magnetization of living Chlorella pyrenoidosa cells. The single-step magnetization procedure is very simple and consists of the dropwise introduction of the aqueous suspension of algal cells into the nanoparticles solution, followed by intensive shaking for 10 min. TEM images demonstrated the uniform layer of MNPs on the cell walls with the thickness around 90 ± 20 nm (Fakhrullin et al. 2010). The modified cells have been employed for the construction of a whole-cell amperometric herbicide biosensor using screen-printed electrodes. The electrode was connected with supporting tetrafluoroethylene plate with inserted NdFeB cylindrical magnet (2 mm in diameter) in the cavity below the working electrode area to produce strong magnetic field in the vicinity of the electrode. The magnetically modified cells were mixed with the electron mediator (K3Fe(CN)6) and electrolyte (Na2SO4), and the drop of this suspension was placed onto the working area of the electrode. The magnetized cells were immediately assembled above the magnet in the area of magnetic field. This biosensor was applied for the detection of triazine herbicides, inhibitors of photosynthetic activity. The biosensor was able to detect atrazine (from 0.9 to 74 mM) and propazine (from 0.6 to 120 mM) (the limits of detection 0.7 and 0.4 mM, respectively) (Zamaleeva et al. 2011). The same magnetic C. pyrenoidosa cells were used as “nanobait,” which was ingested by a nematode Caenorhabditis elegans as a sole food source. The magnetized cells were localized inside the digestive tract of the worms. Delivery of modified cells resulted in magnetic labeling of living nematodes, rendering them magnetically responsive (Daewlaetsina et al. 2013).

A magnetic material based on montmorillonite, a commonly used clay, was manufactured by the supporting of Cu(II)/Fe(III) oxides on pillared montmorillonite prepared from Na-montmorillonite using aluminum polycation. This magnetic material was used for modification and subsequent magnetic removal of the cyanobacteria Microcystis aeruginosa (Gao et al. 2009).

A specific modification procedure was employed for the magnetization of cyanobacterium Synechocystis sp. PCC 6803. This photosynthetic microorganism was immobilized on amine-functionalized MBs (Dynabead M-270 Amine) by 1-ethyl-3-(3-dimethylaminopropyl)carbodiimide (EDC) – N-hydroxysulfosuccinimide (NHS) coupling chemistry. The carboxylic groups present in the Synechocystis cell wall were activated with EDC and then subjected to NHS to produce amine-reactive NHS esters enabling interaction with amine-functionalized MBs to produce covalent amide bonds. Individual microorganisms immobilized on the magnetic beads (transporting objects) were directionally manipulated using a magnetic rail track, which was able to manipulate particles as a result of asymmetric forces from the curved and flat edges of the pattern on the disk. Transporting objects were then successfully trapped in a magnetic trapping station pathway (Venu et al. 2013).

Immunomagnetic detection and modification of cells is based on the use of magnetic nano- or microparticles with immobilized monoclonal- or polyclonal-specific antibody enabling their selective attachment to target cells. After incubation, target cells with attached magnetic particles are isolated with the help of an appropriate magnetic separator. In the direct method, the antibodies against target surface epitopes are attached to the magnetic particles, which are then added to the cells containing sample. In the indirect method, the cell suspension is incubated with free primary antibodies, which bind to the target cells; then, magnetic particles with immobilized secondary antibodies, protein A or protein G, are added, enabling the beads to bind rapidly and firmly to the primary antibodies on the target cells. Alternatively, primary antibodies can be biotinylated, and magnetic particles with immobilized streptavidin are used for capturing the target cells (Safarik and Safarikova 1999; Safarik et al. 2014b). Recently, the cells of toxic dinoflagellate Alexandrium fundyense have been isolated from natural seawater plankton samples using Dynabeads with immobilized monoclonal antibody against the surface antigens. Both direct and indirect procedures were tested as well as three types of modified magnetic beads (MBs) (streptavidin, and two secondary antibodies: sheep anti-mouse and goat anti-mouse). Optimal indirect bead attachment protocol enabled the separation of 90% of the labeled A. fundyense cells in unialgal cultures (with non-specific binding from 5 to 10%). Simpler “direct” technique (with recovery 80% and non-specific binding ca. 2%) enabled pre-coating of beads with the specific antibody in bulk before use, which shortened the procedure and eliminated target cell losses (Aguilera et al. 1996, 2002). Alternatively, purified polyclonal antibodies against Heterosigma akashiwo were immobilized to carboxylated MBs Seradyn; immunomagnetic separation enabled to detect an important species responsible for harmful algal blooms (Huang et al. 2012).

Immobilization of algal cells into different non-magnetic matrices has been described many times (Mallick 2002). However, only exceptional examples of algal cell entrapment into magnetic gels can be found in the literature such as the entrapment of microalgal cells (C. vulgaris) within a non-toxic polyvinylpyrrolidone (PVP) polymer matrix containing superparamagnetic magnetite nanoparticles using continuous flow vortex fluidic device. High entrapment efficiency (up to 95%) was obtained. Entrapped cells can be separated from the PVP matrix using mild sonication (Eroglu et al. 2013).

5 Magnetic Separation of Microalgae Biologically Active Compounds

Isolation, separation, and purification of various types of biologically active compounds, including proteins, peptides, (poly)saccharides, nucleic acids, oligonucleotides, lipids, as well as of other specific molecules, are used in almost all branches of biosciences and biotechnologies. Recently, separation techniques, capable of treating dilute solutions or solutions containing only minute amounts of target molecules, in the presence of vast amounts of accompanying compounds, even in the presence of particulate matter, have become available for both small- and large-scale processes. Specific group of separation processes is based on the use of magnetically responsive materials, which can be applied for magnetic affinity, ion exchange, hydrophobic or adsorption batch separation processes, applications of magnetically stabilized fluidized beds or magnetically modified two-phase systems (Safarik and Safarikova 2004; Franzreb et al. 2006).

The basic principle of batch magnetic separation is very simple. Magnetically responsive carriers bearing an immobilized affinity or hydrophobic ligand or ion-exchange groups, or magnetic biopolymer particles having affinity to the target compound, are mixed with appropriate source of biomolecules and incubated in order to capture the target compound(s). Then, the whole magnetic complex is easily and rapidly removed from the suspension using an appropriate magnetic separator. After washing out the contaminants, the isolated target compound(s) can be eluted and used for further work (Safarik and Safarikova 2004).

Large amounts of biologically active compounds have already been isolated using magnetic separation techniques (Franzreb et al. 2006; Safarik and Safarikova 2004). Surprisingly, this advanced technology has not found many applications in microalgae research and technology. The few existing examples should stimulate the interest of the broad microalgae research community.

Microalgae cells have to be disintegrated in order to enable efficient separation of intracellular components. Mild but efficient cell disruption is necessary. Various mechanical procedures (e.g., bead milling, high-pressure homogenization, high-speed homogenization, ultrasonication, microwave treatment, explosive decompression, and pulsed electric field treatment), chemical cell disruption, and enzymatic cell lysis can be successfully used. A review paper summarizing the microalgae disintegration procedures has appeared recently (Gunerken et al. 2015).

Magnetic particles have been successfully used for the isolation of algal cells that derived biologically active compounds and toxins. Genomic DNA from fixed cultures of Alexandrium minutum cultures was separated using silica-magnetite beads (Taylor et al. 2000); in this case, the silica-magnetite beads adsorb DNA under high salt conditions and release it when salt concentration decreases. Alternatively, DNA was separated using DEAE-agarose-magnetite microparticles (Bruce et al. 1996), and the ionically bound DNA was subsequently eluted via ion competition. Among the DNA extraction techniques compared, the magnetic particle -based methods provided the best results (Bertozzini et al. 2005).

A magnetic bead-based system for DNA isolation utilizing monodisperse beads (Dynabeads DNA DIRECT; originally designed for isolating PCR-ready DNA from human whole blood) was employed to produce a general approach for PCR-ready DNA. Different types of algae (Gyrodinium aureolum, Heterocapsa triquetra, Scrippsiella trochoidea, Chlorella vulgaris, Chlamydomonas reinhardtii, Caulacanthus ustulatus, Chrysochromulina polylepis, and Ceramium strictum) were used; all algae tested gave DNA yields in the range 100–200 ng/105 cells (50–100% relative to phenol-/chloroform-based isolations). Also, potential PCR-inhibitory polysaccharides as well as other inhibitory compounds, such as polyphenols, were removed (Rudi et al. 1997).

Silica-coated, superparamagnetic nanoparticles conjugated to a DNA capture sequence (probe) complementary to a specific region of 5.8S rDNA of the genus Alexandrium have been used for the specific purification of microalgal DNA from the cells of Alexandrium catenella in cultured or environmental samples. Then, a PCR assay was performed with primers specific for the genus Alexandrium to assess the specificity and sensitivity of the nucleic acid extraction method. In both cultured and field samples, the detection limit was one A. catenella cell (Galluzzi et al. 2006).

Bacterial magnetic particles (BMPs) were used for the identification of cyanobacterial DNA. Genus-specific oligonucleotide probes for the detection of Anabaena spp., Microcystis spp., Nostoc spp., Oscillatoria spp., and Synechococcus spp. were designed from the variable region of the cyanobacterial 16S rDNA of 148 strains. These oligonucleotide probes were immobilized on BMPs via streptavidin-biotin conjugation and employed for magnetic capture hybridization against digoxigenin-labeled cyanobacterial 16S rDNA. Bacterial magnetic particles were magnetically concentrated, spotted in 100-μm-size microwell on MAG-microarray, followed by the fluorescent detection. The entire process of hybridization and detection was automatically performed using a magnetic separation robot, and all five cyanobacterial genera were successfully discriminated (Matsunaga et al. 2001).

Paralytic shellfish poisoning (PSP) toxins from a toxic strain of the marine dinoflagellate Alexandrium tamarense CCMP-1493 have been isolated after cells’ disintegration using glutaraldehyde-activated amine-coated hollow glass magnetic microspheres (Ferrospheres-N) with immobilized monoclonal antibody. High toxin recovery (up to 96.2%) was obtained using optimized separation conditions (Devlin et al. 2011b). Alternatively, these coated microspheres were utilized for extracting PSP toxins from naturally contaminated mussel samples; it was shown that magnetic separation could be a convenient alternative to conventional extraction procedures used in toxin purification prior to sample analysis (Devlin et al. 2011a).

Recently, magnetic solid phase extraction (Safarikova and Safarik 1999) employing C18-functionalized magnetic silica nanoparticles (Fe3O4@SiO2@C18 MNPs) was successfully used for the determination of hepatic toxin microcystin-LR (MC-LR) in reservoir water samples, followed by high-performance liquid chromatography–diode array detection (HPLC–DAD). After the extraction, the adsorbent can be conveniently and rapidly separated from aqueous samples by an external magnet. High enrichment factor 500 was attained. The calibration curve of MC-LR was linear in the range of 0.1–10.0 mg/L; limit of detection was 0.056 mg/L. The developed method was successfully applied to the determination of MC-LR in reservoir water samples (Ma et al. 2015).

6 Magnetically Responsive Catalysts in Microalgae Oil Biotechnology

Biodiesel is a renewable, clean-burning diesel replacement; currently, mainly vegetables and seed oils are used as its precursor. In addition, the microalgae with high lipid content could also be employed as an oil source. The biodiesel synthesis is based on the triacylglycerol transesterification with a short-chain alcohol (e.g., methanol and ethanol); such a conversion is usually performed in the presence of the catalyst. Both enzymes (lipases) and solid acid/base catalysts have been successfully used (Mata et al. 2010; Takisawa et al. 2014). In the following part, only examples of magnetically responsive (bio)catalyst utilized for biodiesel synthesis and some other organic reactions using microalgae oil as a substrate will be presented. Magnetically responsive catalysts can be reused after their simple recovery by a magnetic field, thus avoiding the filtration or centrifugation separation processes.

6.1 Magnetic Lipases in Microalgae Biotechnology

An extracellular halo-thermo-tolerant, solvent stable lipase was purified from a bacterial strain isolated from brackish water. The purified enzyme showed optimum activity at pH 7 and temperature 30 °C. The enzyme was found to be stable at broad ranges of pH (5.0–9.0), temperature (10–60 °C), and salinity (up to 30%). Interestingly, the enzyme showed stability in different polar solvents of log P < 2 at a concentration of 75% (v/v) for 7 days. Lipase was immobilized on magnetite particles modified with [3-(2-aminoethylamino)propyl]trimethoxysilane after activation by glutaraldehyde. The recyclability of the enzyme was shown practically unchanged for seven consecutive cycles. The lipase-catalyzed hydrolysis of Chlorella oil showed selective enrichment of oleic acid content with a substantial threefold increase in concentration (Jain and Mishra 2015).

Lipase from Candida rugosa (CRL) was immobilized and stabilized on magnetically separable, large pore mesostructured magnetic hollow mesoporous silica microspheres (MHMSS) by means of multiple-mode adsorption based on both hydrophobic and strong cation-exchange interactions. Benefiting from the hollow large mesoporous structure, ultrafast enzyme immobilization could be realized in 5 min, with a high loading of CRL (95.2 mg g−1). Stabilized CRL@MHMSS was successfully used for the ultrafast transesterification of phytosterol with refined and bleached algae oil and other triglycerides in a solvent-free system, which reached high conversions (≧90.9%) within 15 min at 55 °C. Magnetic separation of MHMSS facilitated the repeated usage of CRL@MHMSS for more than 50 successive reactions without negative effect on its catalytic activity. Its high activity and stability make the MHMSS-immobilized enzyme an attractive catalyst for green synthesis in a solvent-free system (Zheng et al. 2015).

An indigenous microalga Chlorella vulgaris ESP-31 grown in an outdoor tubular photobioreactor with CO2 aeration obtained a high oil content of up to 63.2%. The microalgal oil was then converted to biodiesel by enzymatic transesterification using a lipase from Burkholderia sp. C20. Lipase was immobilized on commercial magnetic nanoparticles modified with tetraethyl orthosilicate and dimethyloctadecyl[3-(trimethoxysilyl)propyl] ammonium chloride (Tran et al. 2012a). The conversion of the microalgae oil to biodiesel was conducted by transesterification of the extracted microalgal oil (M-I) and by transesterification directly using disrupted microalgal biomass (M-II). The results showed that M-II achieved higher biodiesel conversion (97.3 wt% oil) than M-I (72.1 wt% oil). The immobilized lipase worked well when using wet microalgal biomass (up to 71% water content) as the oil substrate. The immobilized lipase also tolerated a high methanol to oil molar ratio (>67.93) when using the M-II approach and can be repeatedly used for six cycles (or 288 h) without significant loss of its original activity (Tran et al. 2012b).

In other experiments, Chlorella vulgaris ESP-31 containing 22.7% lipid was harvested by coagulation (using chitosan and polyaluminium chloride (PACl) as the coagulants) and centrifugation. The harvested cells were directly employed as the oil source for biodiesel production via transesterification catalyzed by Burkholderia lipase immobilized as described above. The enzymatic transesterification was significantly inhibited in the presence of PACl, while the immobilized lipase worked well with wet chitosan-coagulated cells, giving a high biodiesel conversion of 97.6% w/w oil, which is at a level comparable to that of biodiesel conversion from centrifugation-harvested microalgae (97.1% w/w oil). The immobilized lipase can be repeatedly used for three cycles without significant loss of its activity (Tran et al. 2013b).

Wet oil-bearing microalgal biomass of Chlorella vulgaris ESP-31 was directly converted into biodiesel using Burkholderia lipase immobilized on magnetic carrier as the catalyst. The microalgal biomass (water content of 86–91%; oil content 14–63%) was pre-treated by sonication to disrupt the cell walls and then directly mixed with methanol and solvent to carry out the enzymatic transesterification. Addition of a sufficient amount of solvent (hexane is most preferable) is required for the direct transesterification of wet microalgal biomass. The biodiesel synthesis process was more efficient and economic when the lipid content of the microalgal biomass was higher (Tran et al. 2013a).

Experiments employing a mixture of free fatty acids which simulates the composition of fatty acids coming from microalgae (Scenedesmus sp.) to synthesize biodiesel were carried out using commercial lipase B of Candida antarctica (EC 3.1.1.3; Lipozyme, Novozymes, Denmark). Lipase was immobilized on magnetite nanoparticles functionalized by 3-aminopropyltriethoxysilane and activated by glutaraldehyde. Alternatively, magnetic cross-linked enzyme aggregates were prepared using amino-modified magnetite nanoparticles and glutaraldehyde. Both robust magnetically separable biocatalysts formed by lipase showed higher stability and better performance for biodiesel formation than the soluble enzyme (López et al. 2014).

6.2 Magnetic Solid Acid/Base Catalysts

Green approach to biodiesel production has stimulated the application of sustainable solid acid catalysts as replacements for liquid acid catalysts so that the use of harmful substances and generation of toxic wastes are avoided; meanwhile, the easy way of catalyst separation after the reactions can be realized. Recent studies have proven the technical feasibility and the environmental and economical benefits of biodiesel production via heterogeneous acid-catalyzed esterification and transesterification. In this perspective, various solid acids including sulfated metal oxides, H-form zeolites, sulfonic ion-exchange resins, sulfonic-modified mesostructured silica materials, sulfonated carbon-based catalysts, heteropolyacids, and acidic ionic liquids can be used as catalysts for esterification and transesterification (Su and Guo 2014; Lee et al. 2014).

Recently, a new magnetic solid base catalyst has been employed in microalgae technology. Core–shell Fe3O4@silica magnetic nanoparticles functionalized with a strong base, triazabicyclodecene (TBD), were successfully synthesized for harvesting microalgae and for one-pot microalgae-to-fatty acid methyl ester (biodiesel) conversion. Three types of algae oil sources (i.e., dried algae, algae oil, and algae concentrate) were used, and the reaction conditions were optimized to achieve the maximum biodiesel yield. The results obtained in this study show that TBD-functionalized Fe3O4@silica nanoparticles could effectively convert algae oil to biodiesel with a maximum yield of 97.1%. Additionally, this material acts as an efficient algae harvester because of its adsorption and magnetic properties. This method demonstrates the wide scope for the use of covalently functionalized core–shell magnetic nanoparticles for the production of biodiesel from algal biomass (Chiang et al. 2015).

7 Future Trends

Magnetically responsive nano- and microparticles or their composites with diamagnetic materials have increasing potential for applications in many fields of biosciences, biotechnology, and environmental technology. A relatively novel approach to the application of magnetic materials and techniques in the field of microalgae flocculation can significantly simplify the harvesting processes even in industrial scale. Appropriate interaction of magnetic particles with microalgae biomass is an extremely simple step leading to the flocculation of algal cells with subsequent efficient magnetic separation . Future attention in this field should be focused on further development of simple and inexpensive methods for the preparation of magnetic materials or on the improvement of large-scale magnetic separation processes. Microalgae cells (or cell walls after disintegration and target compounds separation), magnetically modified by various types of magnetic particles , could be further applied for the adsorption of harmful xenobiotics from wastewaters. Equally interesting is the possibility of harmful algae detection in the environment after their interaction with immunomagnetic particles. Very promising is also the utilization of magnetically modified microalgae in bioanalytics, where the cells can act as a sensitive biorecognition element of biosensors for monitoring the inhibitors of algae photosynthetic activity, especially herbicides.

Despite the fact that microalgae magnetic harvesting is currently experiencing a real boom, other applications of magnetic materials in microalgae research are still in infancy. Magnetic separation of microalgae biologically active compounds using appropriate magnetic adsorbents has several advantages in comparison with “standard” separation techniques ; they can be separated in a single step even from complex mixtures, often bypassing other more complicated isolation and purification procedures. Few examples of recently published articles focused on the separation of genomic DNA or microalgae toxins should stimulate the microalgae research community to develop magnetic separation protocols using magnetic affinity or ion-exchange particles to isolate efficiently the target compounds. Such a development should lead to the construction of industrial-scale separation processes employing relatively inexpensive magnetic adsorbents and relatively simple magnetic separators.

Applications of immobilized enzymes have become a routine in many biotechnological processes. Immobilization of enzymes (specifically lipases) on magnetic carriers for biodiesel production from microalgae oils is only the first step which should be followed by the application of other relevant enzymes (e.g., polysaccharide hydrolases or proteinases) immobilization and application. Magnetically responsive solid/base and enzyme-like catalysts represent another promising direction leading to cost-effective transformation of microalgae raw materials and metabolites.

References

Aguilera A, Gonzalez-Gil S, Keafer BA, Anderson DM (1996) Immunomagnetic separation of cells of the toxic dinoflagellate Alexandrium fundyense from natural plankton samples. Mar Ecol Prog Ser 143(1–3):255–269

Aguilera A, Keafer BA, Rau GH, Anderson DM (2002) Immunomagnetic isolation of live and preserved Alexandrium fundyense cells: species-specific physiological, chemical, and isotopic analyses. Mar Ecol Prog Ser 237:65–78

Bertozzini E, Penna A, Pierboni E, Bruce I, Magnani M (2005) Development of new procedures for the isolation of phytoplankton DNA from fixed samples. J Appl Phycol 17(3):223–229

Bishop WM, Zubeck HM (2012) Evaluation of microalgae for use as nutraceuticals and nutritional supplements. J Nutr Food Sci 2: Article No. 147. doi:10.4172/2155-9600.1000147

Borlido L, Azevedo AM, Roque ACA, Aires-Barros MR (2013) Magnetic separations in biotechnology. Biotechnol Adv 31(8):1374–1385

Borowitzka MA (2013) High-value products from microalgae-their development and commercialisation. J Appl Phycol 25(3):743–756

Bruce IJ, Davies MJ, Howard K, Smethurst DE, Todd M (1996) Magnetizable solid-phase supports for purification of nucleic acids. J Pharm Pharmacol 48(2):147–149

Chiang YD, Dutta S, Chen CT, Huang YT, Lin KS, Wu JCS, Suzuki N, Yamauchi Y, Wu KCW (2015) Functionalized Fe3O4@silica core-shell nanoparticles as microalgae harvester and catalyst for biodiesel production. ChemSusChem 8(5):789–794

Daewlaetsina GI, Minullina RT, Fakhrullin RF (2013) Microworms swallow the nanobait: the use of nanocoated microbial cells for the direct delivery of nanoparticles into Caenorhabditis elegans. Nanoscale 5(23):11761–11769

Devlin R, Campbell K, Kawatsu K, Elliott C (2011a) Studies in the use of magnetic microspheres for immunoaffinity extraction of paralytic shellfish poisoning toxins from shellfish. Toxins 3(1):1–16

Devlin RA, Campbell K, Kawatsu K, Elliott CT (2011b) Physical and immunoaffinity extraction of paralytic shellfish poisoning toxins from cultures of the dinoflagellate Alexandrium tamarense. Harmful Algae 10(5):542–548

Encarnação T, Pais AA, Campos MG, Burrows HD (2015) Cyanobacteria and microalgae: a renewable source of bioactive compounds and other chemicals. Sci Prog 98(2):145–168

Eroglu E, D’Alonzo NJ, Smith SM, Raston CL (2013) Vortex fluidic entrapment of functional microalgal cells in a magnetic polymer matrix. Nanoscale 5(7):2627–2631

Fakhrullin RF, Shlykova LV, Zamaleeva AI, Nurgaliev DK, Osin YN, Garcia-Alonso J, Paunov VN (2010) Interfacing living unicellular algae cells with biocompatible polyelectrolyte-stabilised magnetic nanoparticles. Macromol Biosci 10(10):1257–1264

Franzreb M, Siemann-Herzberg M, Hobley TJ, Thomas ORT (2006) Protein purification using magnetic adsorbent particles. Appl Microbiol Biotechnol 70(5):505–516

Galluzzi L, Bertozzini E, del Campo A, Penna A, Bruce IJ, Magnani M (2006) Capture probe conjugated to paramagnetic nanoparticles for purification of Alexandrium species (Dinophyceae) DNA from environmental samples. J Appl Microbiol 101(1):36–43

Gao ZW, Peng XJ, Zhang HM, Luan ZK, Fan B (2009) Montmorillonite-Cu(II)/Fe(III) oxides magnetic material for removal of cyanobacterial Microcystis aeruginosa and its regeneration. Desalination 247(1–3):337–345

Garcia PF, Brammen M, Wolf M, Reinlein S, von Roman MF, Berensmeier S (2015) High-gradient magnetic separation for technical scale protein recovery using low cost magnetic nanoparticles. Sep Purif Technol 150:29–36

Gouveia L (2011) Microalgae as a feedstock for biofuels. Springer, Berlin

Guarnieri MT, Pienkos PT (2015) Algal omics: unlocking bioproduct diversity in algae cell factories. Photosynth Res 123(3):255–263

Gunerken E, D’Hondt E, Eppink MHM, Garcia-Gonzalez L, Elst K, Wijffels RH (2015) Cell disruption for microalgae biorefineries. Biotechnol Adv 33(2):243–260

Hu YR, Wang F, Wang SK, Liu CZ, Guo C (2013) Efficient harvesting of marine microalgae Nannochloropsis maritima using magnetic nanoparticles. Bioresour Technol 138:387–390

Huang J, Wen RB, Bao ZM, Sui ZH, Sun NB, Kang K (2012) Applications of immuno-magnetic bead and immunofluorescent flow cytometric techniques for the quantitative detection of HAB microalgae. Chin J Oceanol Limn 30(3):433–439

Jain D, Mishra S (2015) Multifunctional solvent stable Bacillus lipase mediated biotransformations in the context of food and fuel. J Mol Catal B Enzym 117:21–30

Kratosova G, Schrofel A, Safarik I, Horska K, Urban M, Rosenbergova K, Safarikova M, Slabotinsky J (2013) Bionanocomposite, process for its preparation and use. Czech Patent 304046

Lambreva MD, Lavecchia T, Tyystjärvi E, Antal TK, Orlanducci S, Margonelli A, Rea G (2015) Potential of carbon nanotubes in algal biotechnology. Photosynth Res 125(3):451–471

Laurent S, Forge D, Port M, Roch A, Robic C, Elst LV, Muller RN (2008) Magnetic iron oxide nanoparticles: synthesis, stabilization, vectorization, physicochemical characterizations, and biological applications. Chem Rev 108(6):2064–2110

Lee AF, Bennett JA, Manayil JC, Wilson K (2014) Heterogeneous catalysis for sustainable biodiesel production via esterification and transesterification. Chem Soc Rev 43(22):7887–7916

Lee YC, Lee K, Oh YK (2015) Recent nanoparticle engineering advances in microalgal cultivation and harvesting processes of biodiesel production: a review. Bioresour Technol 184:63–72

Lim JK, Chieh DCJ, Jalak SA, Toh PY, Yasin NHM, Ng BW, Ahmad AL (2012) Rapid magnetophoretic separation of microalgae. Small 8(11):1683–1692

Lin CR, Chu YM, Wang SC (2006) Magnetic properties of magnetite nanoparticles prepared by mechanochemical reaction. Mater Lett 60(4):447–450

López C, Cruz-Izquierdo Á, Picó EA, García-Bárcena T, Villarroel N, Llama MJ, Serra JL (2014) Magnetic biocatalysts and their uses to obtain biodiesel and biosurfactants. Front Chem 2:72. doi:10.3389/fchem.2014.00072

Ma JP, Yan FL, Chen FX, Jiang LH, Li JH, Chen LX (2015) C18-functionalized magnetic silica nanoparticles for solid phase extraction of microcystin-LR in reservoir water samples followed by HPLC-DAD determination. J Liq Chromatogr R T 38(6):655–661

Mallick N (2002) Biotechnological potential of immobilized algae for wastewater N, P and metal removal: a review. Biometals 15(4):377–390

Mata TM, Martins AA, Caetano NS (2010) Microalgae for biodiesel production and other applications: a review. Renew Sustain Energy Rev 14(1):217–232

Matsunaga T, Nakayama H, Okochi M, Takeyama H (2001) Fluorescent detection of cyanobacterial DNA using bacterial magnetic particles on a MAG-microarray. Biotechnol Bioeng 73(5):400–405

Prochazkova G, Safarik I, Branyik T (2013) Harvesting microalgae with microwave synthesized magnetic microparticles. Bioresour Technol 130:472–477

Rudi K, Kroken M, Dahlberg OJ, Deggerdal A, Jakobsen KS, Larsen F (1997) Rapid, universal method to isolate PCR-ready DNA using magnetic beads. Biotechniques 22(3):506–511

Safarik I, Safarikova M (1999) Use of magnetic techniques for the isolation of cells. J Chromatogr B 722(1–2):33–53

Safarik I, Safarikova M (2004) Magnetic techniques for the isolation and purification of proteins and peptides. Biomagn Res Technol 2(1): Article No. 7

Safarik I, Safarikova M (2009) Magnetic nano- and microparticles in biotechnology. Chem Pap 63:497–505

Safarik I, Safarikova M (2014) One-step magnetic modification of non-magnetic solid materials. Int J Mater Res 105(1):104–107

Safarik I, Horska K, Safarikova M (2011) Magnetic nanoparticles for biomedicine. In: Prokop A (ed) Intracellular delivery: fundamentals and applications. Springer, Netherlands, pp 363–372

Safarik I, Pospiskova K, Horska K, Safarikova M (2012) Potential of magnetically responsive (nano)biocomposites. Soft Matter 8:5407–5413

Safarik I, Horska K, Pospiskova K, Filip J, Safarikova M (2014a) Mechanochemical synthesis of magnetically responsive materials from non-magnetic precursors. Mater Lett 126:202–206

Safarik I, Maderova Z, Pospiskova K, Horska K, Safarikova M (2014b) Magnetic decoration and labeling of prokaryotic and eukaryotic cells. In: Fakhrullin RF, Choi I, Lvov YM (eds) Cell surface engineering: fabrication of functional nanoshells. RSC Smart Materials No. 9. RSC, London, pp 185–215

Safarik I, Prochazkova G, Pospiskova K, Branyik T (2016) Magnetically modified microalgae and their applications. Crit Rev Biotechnol 36:931–941

Safarikova M, Safarik I (1999) Magnetic solid-phase extraction. J Magn Magn Mater 194(1–3):108–112

Safarikova M, Pona BMR, Mosiniewicz-Szablewska E, Weyda F, Safarik I (2008) Dye adsorption on magnetically modified Chlorella vulgaris cells. Fresen Environ Bull 17(4):486–492

Sastre RR (2012) Products from microalgae: an overview. In: Posten C, Walter C (eds) Microalgal biotechnology: integration and economy. Walter de Gruyter GmbH, Berlin, pp 13–50

Su F, Guo Y (2014) Advancements in solid acid catalysts for biodiesel production. Green Chem 16(6):2934–2957

Takisawa K, Kanemoto K, Kartikawati M, Kitamura Y (2014) Overview of biodiesel production from microalgae. J Dev Sustain Agric 9(2):120–128

Taylor JI, Hurst CD, Davies MJ, Sachsinger N, Bruce IJ (2000) Application of magnetite and silica-magnetite composites to the isolation of genomic DNA. J Chromatogr A 890(1):159–166

Todd T, Zhen ZP, Tang W, Chen HM, Wang G, Chuang YJ, Deaton K, Pan ZW, Xie J (2014) Iron oxide nanoparticle encapsulated diatoms for magnetic delivery of small molecules to tumors. Nanoscale 6(4):2073–2076

Toh PY, Yeap SP, Kong LP, Ng BW, Chan DJC, Ahmad AL, Lim JK (2012) Magnetophoretic removal of microalgae from fishpond water: feasibility of high gradient and low gradient magnetic separation. Chem Eng J 211:22–30

Toh PY, Ng BW, Ahmad AL, Chieh DCJ, Lim J (2014a) Magnetophoretic separation of Chlorella sp.: role of cationic polymer binder. Process Saf Environ 92(6):515–521

Toh PY, Ng BW, Chong CH, Ahmad AL, Yang JW, Derek CJC, Lim J (2014b) Magnetophoretic separation of microalgae: the role of nanoparticles and polymer binder in harvesting biofuel. RSC Adv 4(8):4114–4121

Tran DT, Chen CL, Chang JS (2012a) Immobilization of Burkholderia sp. lipase on a ferric silica nanocomposite for biodiesel production. J Biotechnol 158(3):112–119

Tran DT, Yeh KL, Chen CL, Chang JS (2012b) Enzymatic transesterification of microalgal oil from Chlorella vulgaris ESP-31 for biodiesel synthesis using immobilized Burkholderia lipase. Bioresour Technol 108:119–127

Tran DT, Chen CL, Chang JS (2013a) Effect of solvents and oil content on direct transesterification of wet oil-bearing microalgal biomass of Chlorella vulgaris ESP-31 for biodiesel synthesis using immobilized lipase as the biocatalyst. Bioresour Technol 135:213–221

Tran DT, Le BH, Lee DJ, Chen CL, Wang HY, Chang JS (2013b) Microalgae harvesting and subsequent biodiesel conversion. Bioresour Technol 140:179–186

Venu R, Lim B, Hu XH, Jeong I, Ramulu TS, Kim CG (2013) On-chip manipulation and trapping of microorganisms using a patterned magnetic pathway. Microfluid Nanofluid 14(1–2):277–285

Wang SK, Stiles AR, Guo C, Liu CZ (2015) Harvesting microalgae by magnetic separation: a review. Algal Res 9:178–185

Wu W, Wu ZH, Yu T, Jiang CZ, Kim WS (2015) Recent progress on magnetic iron oxide nanoparticles: synthesis, surface functional strategies and biomedical applications. Sci Technol Adv Mat 16:023501. doi:10.1088/1468-6996/16/2/023501

Xu L, Guo C, Wang F, Zheng S, Liu CZ (2011) A simple and rapid harvesting method for microalgae by in situ magnetic separation. Bioresour Technol 102(21):10047–10051

Zamaleeva AI, Sharipova IR, Shamagsumova RV, Ivanov AN, Evtugyn GA, Ishmuchametova DG, Fakhrullin RF (2011) A whole-cell amperometric herbicide biosensor based on magnetically functionalised microalgae and screen-printed electrodes. Anal Methods-UK 3(3):509–513

Zheng BZ, Zhang MH, Xiao D, Jin Y, Choi MMF (2010) Fast microwave synthesis of Fe3O4 and Fe3O4/Ag magnetic nanoparticles using Fe2+ as precursor. Inorg Mater 46(10):1106–1111

Zheng MM, Mao LJ, Huang FH, Xiang X, Deng QC, Feng YQ (2015) A mixed-function-grafted magnetic mesoporous hollow silica microsphere immobilized lipase strategy for ultrafast transesterification in a solvent-free system. RSC Adv 5(54):43074–43080

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2017 Springer International Publishing AG

About this chapter

Cite this chapter

Safarik, I., Pospiskova, K., Baldikova, E., Safarikova, M. (2017). Magnetic Particles for Microalgae Separation and Biotechnology. In: Puri, M. (eds) Food Bioactives. Springer, Cham. https://doi.org/10.1007/978-3-319-51639-4_7

Download citation

DOI: https://doi.org/10.1007/978-3-319-51639-4_7

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-51637-0

Online ISBN: 978-3-319-51639-4

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)