Abstract

There is a constant effort from aluminium producers to reduce energy consumption of the Hall-Héroult cells in order to decrease cost and environmental fingerprint. Among others, slotted anodes were introduced in order to promote faster evacuation of the electrically isolating anode gas bubbles and thus diminish their contribution to the total cell voltage . A bubble layer simulator was developed to reproduce cell voltage fluctuations, caused by the dynamics of anode bubbles. Results of simulations show that the slots cut in the right position and direction can reduce both the amplitude of fluctuations and the average cell voltage. This impact is even higher for new, almost horizontal flat anode bottoms. It is also revealed that the slots are acting mainly as a simple bubble sink, but they also contribute to the acceleration of the bubble layer as well and thus their role in the momentum exchange between liquid and gas must be taken into account.

Access provided by CONRICYT-eBooks. Download conference paper PDF

Similar content being viewed by others

Keywords

Introduction

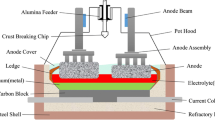

The reduction of energy consumption and green house gas emission is a priority for aluminum producers. As aluminium smelters are using very high forced current to increase the production rate, even a small decrease in electrical resistance (and thus cell voltage) can be advantageous. For this reason, among others, they introduced slotted anodes , reduced anode-cathode distance (ACD) and in some cases increased the bath conductivity.

Originally, slots were cut into the anode bottom in order to prevent the cracking of cold anodes by thermal shock when they are inserted into the hot molten cryolite based bath. Later, it was observed that the slots have an additional advantage. Namely, they promote the faster evacuation of the electrically isolating anode gas bubbles and thus diminish their contribution to the total cell voltage [1, 2]. However, this positive effect disappears gradually with time as the carbon anodes are consumed by anodic reaction. Big efforts have been made to optimise the design of the slots, including their number, position and direction. The tests in industrial cells are expensive, time consuming and can affect the earlier well-established operations. Direct observation of the phenomenon is not possible due to the high temperature, corrosive environment and low transparency of the bath. Effectiveness of the slots can be evaluated by the analysis of the cell voltage recordings. However, the variation of some other independent parameters (such as temperature, bath height and composition, anode consumption etc.) can also affect the readings. Mathematical modeling of the influence of the slots can help to choose the most promising designs before testing in real cell. Several CFD models were published [3,4,5,6] which consider the two-phase fluid as a homogenous medium with average property values without describing the details at the scale of individual bubbles .

The mathematical model development was supported in many cases by different experimental setups, including big, room temperature water tanks [3, 7,8,9] or reduced scale see-through cells with molten cryolite bath [10,11,12,13]. In the first approach, the gas is produced either by injection at high pressure through a porous plate or by electrolysis. Due to the difference in physical properties, water models can be used mainly to validate mathematical models. The kinematic viscosity of room temperature water is relatively close to that of molten cryolite, but the difference in densities and especially in the wetting of the anode can make it difficult to transfer experimental results directly to industrial cells.

On the other hand, the see-through cells went through a great progress from the first graphite crucible of Haupin with small sapphire window [10] to the latest multi-chamber quartz containers [12]. Observations, using X-ray technique, were published as well [11]. However, the small size with different bubble dynamics remains a limitation to draw valid conclusions for the real cells [12]. However, the experiments confirmed the effectiveness of appropriate slots in the reduction of average cell voltage as well as its fluctuations [12].

A bubble layer simulator has been developed and presented in an earlier paper [7] that can reproduce the evolution of the structure of the bubble laden layer around the anodes and predict the additional cell voltage and stirring effect caused by the presence of those bubbles. This tool can effectively support anode design, including the optimisation of the slot’s geometry. There are a few published attempts to create similar models [5, 14], but according to the knowledge of the authors, they do not describe the whole bubble layer and its impact on the cell voltage with the same details and precision. In this paper, some revelations obtained by our bubble layer simulator are presented, concerning the mechanism of the bubble evacuating effect of the slots.

Simulations

Bubble Layer Simulator

The bubble layer simulator deals with one single anode. It is using a Lagrangian approach where each and every bubble are followed from the nucleation, through the growth, detachment, gliding under the anode bottom and rising until it disappears either by coalescence with other bigger bubbles or by escaping into the air [7, 15]. The evolution of the bubble shapes along their travel is better described by this simulator than those mentioned by other publications, where only spherical and hemi-spherical shapes were used. The simulator does not try to solve the Navier-Stokes equation for the typical number of several thousand bubbles dispersed in the bath around an anode as some other tried without success, despite the powerful computation tools they used. Instead it uses a simplified momentum balance between the bubbles and the surrounding liquid as well as the viscous momentum transfer between the dominant liquid layers as well as between the liquid and the solid surfaces in contact. The development of the simulator was supported by observations made in a large scale, low temperature liquid-liquid-gas experimental setup. The graphical output of the simulator helped greatly the understanding of the behaviour of the bubble laden layer and the comparison between the model and the experimental. The excess cell voltage caused by bubbles is determined by an original mathematical model as function of the structure of the bubble layer [16]. More details about the simulator were published earlier [7].

Anode Geometry and Simplifications Used for the Simulation

A hypothetical anode with bottom size of 1 m × 0.5 m immersed 15 cm into the bath was considered in this study. These dimensions are similar to the ones used by most of aluminium producers but does not fit exactly any existing technology for confidentiality reasons. Both planar and rounded bottoms with 5 cm radii of curvature at the corner (Fig. 1) were examined. The first represents a new anode while the last corresponds to an anode after a short period of electrolysis because of erosion and higher reaction rate due to higher current density at the corners. The shape of the rounded bottom is approximated by two circular arcs of different radii, connected smoothly at 5° slope.

As anodes are symmetrical, only half anodes were used for the simulations in order to decrease computation time. Anodes with and without slots were compared. The slotted half-anodes contained one slot at the middle, parallel either to the longer or the shorter sides (longitudinal and transversal cases respectively). The top of the slots was horizontal and they were 1 cm wide with 10 cm in height. Both the size and position of the slots were hypothetical and did not correspond to any existing technology.

As only one anode is modelled, redistribution of individual anode currents due to any local increase of resistivity, observed in the real cells [17], cannot be considered here. The impact of MHD on the bath velocity was not taken into account neither. Generally, most of the bubbles escape at the side that is closest to their nucleation sites, which is the most often the longer side. The vertically escaping bubbles in the inter-anode gaps accelerate the liquid by drag force and this creates a certain suction effect in the same direction for the other bubbles situated under the anode bottom. For this reason, the simulation was carried out with unidirectional two-phase fluid flow in the direction perpendicular to the longer side.

The ACD and anode-anode gap were 4 and 20 cm respectively. The temperature of bath is 960 ℃ and its composition corresponds to that used in modern RTA plants.

Results and Discussion

Table 1 presents the average values and the amplitude of fluctuations of anode covering by bubbles (henceforth called covering), the excess voltage drop due to the bubble layer (henceforth called bubble voltage drop) and the average bath velocity, computed by the simulator with different anode geometries for a period of 30 s. The covering and voltage data shown in the brackets indicate the minimum and maximum values. In a simplified approach, the slots can be treated as simple sinks that swallow the bubbles. In reality, the gas entering the slots contributes also the acceleration of the bubble layer.

The average voltage drop varies between 72 and 453 mV, depending on geometry. The biggest computed gain was obtained with perfectly horizontal anode. This range is in good accordance to the literature [2], except that the maximal bubble voltage drop is smaller in a real cell due to the possibility of current redistribution toward other anodes. The results confirm the observations reported in the literature, obtained both at industry and laboratory scale; namely the appropriate slots reduce significantly both the average value and the amplitude of fluctuations of the voltage drop. The simulator suggests that the slots decrease strongly the amplitude of fluctuations but only slightly the average value of the covering. In fact, the slots reduce both the average path length of evacuation for the bubbles and their maximal possible size. The strong fluctuations of covering and of bubble voltage drop are caused by the huge bubbles formed by coalescence, which can occupy and then sweep off a big portion of the anode bottom when released. Huge bubbles deviate more the current lines than a large number of small coexisting bubbles [16]. Consequently, even if the covering is reduced only slightly, the prevention of the formation of huge bubbles itself can decrease significantly the bubble voltage drop (Fig. 2).

Maximum values of bubble voltage drop—obtained when a large bubble formed by a series of consecutive coalescences can be seen overestimated by the model. However, the reader must keep in mind that this is a single anode model and in a real cell, increased local resistance will redistribute the current toward the other anodes and thus prevents the creation of such a high bubble voltage drop even for a short period.

Impact of the Shape of Anode Bottom

Rounded anode bottom promotes the evacuation of the bubbles as the accelerating buoyancy force increases with anode slope. Consequently it increases the velocity of bubbles and the bath, while decreases the covering and bubble voltage drop by decreasing average residence time and maximal possible size of the bubbles. All those tendencies can be seen when analysing the results shown in Table 1. As the rounded shape itself accelerates evacuation and decreases the maximal bubble size, the presence of slots (which have similar effects) gives a smaller additional gain for rounded anode bottom, compared to the horizontal one (Table 1 and Fig. 3).

It must be mentioned that anode consumption decreases gradually the height and thus the impact of the slots. This phenomenon is not investigated in this paper.

Impact of the Direction of the Slot

The direction of the slot has much bigger impact on the bubble voltage drop than on the covering or the bath velocity. Especially for the rounded anode bottom, its influence is very limited on the covering. This observation suggests that the role of the slot to limit the biggest possible size of the bubbles is the key design factor when the optimal slot geometry must be chosen (Table 1 and Figs. 4 and 5). In the simulated case, the slot parallel to the longer side seems to be more efficient as it greater reduces the maximal possible size of the bubbles.

Contribution of the Slot to the Momentum Balance Between the Liquid and the Gas

Slots can be seen as simple sinks, which decrease the average evacuation path length and the biggest possible size for the bubbles. However as water modeling showed, bubbles rising inside the slot and then exiting under the effect of buoyancy force exert a “suction” effect on the other bubbles still residing under the anode bottom [8]. In fact, they contribute also to the acceleration of the liquid under the anode through the coupling by the drag force. This phenomenon is considered by a separate subroutine in the simulator. By omitting this subroutine, the relative importance of the simple sink effect versus contribution to the acceleration of the bath can be investigated. Results show that the sink effect is dominant but the acceleration term cannot be neglected in certain cases (Table 1 and Fig. 6). In fact, if the contribution of the bubbles entering into the slots, to the acceleration of the two-phase layer under the anode bottom is neglected, the average velocity of the bath will be lower, which in turn slows down the evacuation of the bubbles as well. However, this affects the covering more than the bubble voltage drop.

Role of the Size of the Anode

As see-through cells are often used to investigate the dynamics of bubble layer under slotted and non-slotted anodes, a 5 × 5 cm anode, inserted 15 cm deep into the cryolite based bath was analysed with the simulator as well. Such systems do not work long enough to create rounded corners; therefore only planar, horizontal anode bottom was examined. Results obtained with this geometry were compared to the horizontal anode of 1 × 0.5 m with the same immersion and without slot (Fig. 7). Table 2 resumes the two cases.

Strongly reduced anode size results in some decrease of covering but in a very strong diminution of bubble voltage drop. For the latest, both the average value and the amplitude of fluctuations fall drastically. This is related to the reduction of the biggest possible bubble that can exist under the anode. The same tendency must be valid for curved or inclined anodes but with smaller difference.

Conclusions

The simulator presented earlier was used to investigate the effect of slots with different geometries on square and rounded bottom anodes, representing new and used anodes respectively. Analysis of the results permitted to draw the following conclusions:

-

Anode slots definitely decrease the voltage drop created by the presence of bubbles . The gain varies between 71 and 453 mV with the simulated geometries for a single anode system. The biggest computed gain was obtained with perfectly horizontal anode but this gain should be smaller in a real cell due to the possibility of current redistribution toward other anodes.

-

The slots reduce the bubble voltage drop by three mechanisms:

-

Reducing average path length for bubble evacuation

-

Limiting the maximal possible size of individual bubbles

-

Similarly to the anode-anode gaps, they accelerate the bath by the drag force of the rising bubbles

The second mechanism seems to be the most important as the amplitude of fluctuation of the covering decreases generally stronger than the average value in the presence of a slot. By preventing the formation of very big bubbles, which deviate more the current, the bubble voltage drop will decrease significantly even when the average covering does not.

-

-

The role of the slot to limit the biggest possible size of the bubbles is the key design factor when the optimal slot geometry (orientation, number) must be chosen. In the examined cases, the slot parallel to the longer side was more efficient.

-

Both the slot and the slope of the anode bottom reduce the average residence time for the bubbles and the biggest possible size. For this reason, a bigger gain of voltage can be obtained by the slots for a perfectly horizontal anode bottom than for a curved or inclined one.

-

The use of small, laboratory scale anodes results in a drastic reduction of bubble voltage drop, due to the limitation of the biggest possible bubble that can strongly increase ohmic resistance. For this reason, the effect of anode size is more important on the voltage than on the gas covering.

References

B.J. Moxnes, B.E. Aga, H. Skaar, How to obtain open feeder holes by installing anodes with tracks. Light Met. 247–255 (1998)

X.W. Wang, Development and deployment of slotted anode technology at Alcoa. Light Met. 539–544 (2007)

M.A. Cooksey, W. Yang, PIV measurement on physical models of aluminium reduction cells. Light Met. 359–365 (2006)

Y.Q. Feng, M Cooksey, M.P. Schwarz, CFD modelling of electrolyte flow in aluminium reduction cells. Light Met. 339–344 (2007)

D.S. Severo, V. Gusberti, E.C.V. Pinto, R.R. Moura, Modelling the bubble driven flow in the electrolyte as a tool for slotted anode design improvement. Light Met. 287–292 (2007)

K.Y. Zhang, Y Feng, M.P. Schwarz, M. Cooksey, Z. Wang, Numerical investigation of bubble dynamics in aluminium electrolysis cells. Light Met. 881–886 (2012)

L.I. Kiss, S. Poncsák, J Antille, Simulation of the bubble layer in aluminium electrolysis cells. Light Met. 559–564 (2005)

D. Toulouse, L.I. Kiss, Gas-liquid two-phase flow in a downward facing open channel. Multiph. Flow 219–226 (2006)

Y. Liu, Research on the penetration depth in aluminum reduction cell with new type of anode and cathode structures. J. Met. 66(7), 1202–1209 (2014)

W.E. Haupin, W.C. McGrew, See-through Hall-Héroult Cell. Aluminium 51, 273–275 (1975)

L. Cassayre, T.A. Utigard, S. Bouvet, Visualizing gas evolution on graphite and oxygen-evolving anodes. J. Met. 54(5), 41–45 (2002)

Z. Zhao, Z. Wang, B. Gao, Y. Feng, Z. Shi, X. Hu, Observations of anodic bubble behaviours using laboratory scale transparent aluminium electrolysis cell. Light Met. 801–806 (2015)

Z. Zhao, Z. Wang, B. Gao, Y. Feng, Z. Shi, X. Hu, Anodic bubble behaviour and voltage drop in a laboratory transparent aluminum electrolytic cell. Metall. Mater. Trans. B 47(3), 1962–1975 (2016)

K. Zhang, Y. Feng, P Schwarz, M. Cooksey, Z. Wang, Numerical investigation of bubble dynamics in aluminium electrolytic cells. Light Met. 881–886 (2012)

N. Richards, H. Gudbrandsen, S. Rolseth, J. Thonstad, Characterization of the fluctuation in anode current density and bubble events in industrial reduction cells. Light Met. 315–322 (2003)

A. Perron, L.I. Kiss, S. Poncsák, Mathematical model to evaluate the ohmic resistance caused by the presence of a large number of bubbles in Hall-Héroult Cells. J. Appl. Electrochem. 37, 303–310 (2007)

B.J. Welch, Quantifying PFC emissions from smelter cells. Proceedings of 10th Australasian Aluminium Smelting Technology Conference, Launceston, Australia, 9–14 October 2011, 12 pp

Acknowledgements

The authors would like to thank the valuable financial support of Rio Tinto Aluminium and its predecessors.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2017 The Minerals, Metals & Materials Society

About this paper

Cite this paper

Poncsák, S., Kiss, L.I., Guérard, S., Bilodeau, JF. (2017). Study of the Impact of Anode Slots on the Voltage Fluctuations in Aluminium Electrolysis Cells, Using Bubble Layer Simulator. In: Ratvik, A. (eds) Light Metals 2017. The Minerals, Metals & Materials Series. Springer, Cham. https://doi.org/10.1007/978-3-319-51541-0_75

Download citation

DOI: https://doi.org/10.1007/978-3-319-51541-0_75

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-51540-3

Online ISBN: 978-3-319-51541-0

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)