Abstract

The article is devoted to the studies of the shock tube roughness effect on the measurements of ignition delay times and the structure of the gas flow behind reflected shock wave. All measurements were performed on cylindrical shock tube at the density of the gas behind the reflected shock wave of 2.8 kg/m3 for the smooth and rough surface of the shock tube. Experimental studies of the reflected shock wave bifurcation structure for a nitrogen-hydrogen mixture, which is a non-reacting referent mixture to the stoichiometric hydrogen-air one, are presented. Values of the oblique shock wave projection at the distance to the endwall of 50, 150 and 250 mm, as well as the local pressure distribution behind reflected shock wave, were determine. Ignition delay time measurements in stoichiometric H2-O2 mixture diluted with 80% Ar were conducted. Induction times were determined using OH emission profiles obtained along the tube axis and in the boundary layer. The influence of the wall roughness on the ignition delay time and the bifurcation structure were analyzed for smooth and rough surface of shock tube. It is found that the small surface roughness strongly affects the reflected shock wave bifurcation in hydrogen-nitrogen mixture but it does not affect the ignition delay time measurements significantly in stoichiometric H2-O2 mixture diluted with Ar.

Access provided by CONRICYT-eBooks. Download conference paper PDF

Similar content being viewed by others

Introduction

There are no theoretical models for the whole measurement diapason of thermodynamic conditions of hydrogen-oxygen mixtures to be able to predict induction time. As a result, till now there are a lot of questions concerning both experiment technique [1–5] and theoretical models of hydrogen oxidation mechanisms [2, 6, 7]. The chemical kinetic study in shock tube led to deep investigations of the processes characteristic of shock tubes themselves.

The inhomogeneity effects behind reflected shock wave have been mentioned responsible for the differences between theory and experiment, namely, local hot spot in the vicinity of extraneous solid particles, chemical impurities in the gas mixture, the roughness of the wall of the measuring section, the occurrence of secondary disturbances because of membrane rupture, low allowed observation time, boundary layer heterogeneity, ununiformity caused by boundary layer formation, and localized ignition [1, 2].

A good agreement of the calculation results and experiment was achieved in paper [2] by taking in account the impact of rising pressure behind the reflected shock wave. However the conclusions of paper [1] for blast wave in hydrogen-oxygen mixture for medium temperatures allow one to notice that results for induction time behind the reflected blast wave are much closer to those obtained with the shock waves than the calculated one behind reflected shock wave. Therefore the model proposed in [2] is strongly debatable. There are even attempts to explain deviations from the theoretical models due to the influence of acoustic effects on certain mixtures of hydrogen, oxygen, and argon and by means of the gas mixture sensitivity to perturbations [6, 7], vortices arising from the formation of the bifurcation structure [3, 4], and increased temperature near the triple-point trajectory of the bifurcation structure [5, 8].

We decide to evaluate the influence of the reflected shock wave bifurcation on the shock tube measurements for the hydrogen-oxygen and hydrogen-air mixtures using a shock tube measuring sections with different surface roughness. The small surface roughness influences the size of the bifurcation structure, and it may affect the induction time measurement as compared with a smooth tube. Anyway, such a comparison enables one to evaluate the error of determining the induction time of the reaction when shock tube cannot be called polished.

Experimental Setup

The first part of the study concerns with the dynamics and measured sizes of the bifurcation structure for a nitrogen-hydrogen mixture, which is a nonreacting referent mixture to the stoichiometric hydrogen-air one. After that, the experimental facility was transformed, and ignition delay time measurements in stoichiometric H2-O2 mixture diluted with Ar have been done. All measurements were conducted in a 76 mm inner dia., helium-driven cylindrical shock tube at the density of the gas behind the reflected shock wave of 2.8 kg/m3 for the smooth and rough surface of the shock tube. Experiments were conducted for a smooth surface of a measurement section with Ra = 0.18 ± 0.04 μm and for a rough surface of a profile height of 60 ± 5 μm (Ra = 20 ± 3 μm) (Fig. 1b). In both cases, Ra was measured along the shock tube. The surface roughness value used in experiments was chosen so as to create small-scale turbulence in the boundary layer and to exert a significant influence on the flow core. The gas parameters were calculated with the use of a shock adiabat by the measured velocity of the incident shock wave. The shock wave velocity was measured by PCB Piezotronics pressure sensors mounted flush with the surface of the shock tube at a distance of 50, 150, and 250 mm from its endwall and at the endwall.

Optical scheme, the light beam propagating scheme, and the pressure sensor arrangement: (1) mirror, (2) menisci, (3) vertical slot, (4) knife edge, (5) optical windows, (6) vertical slot and a lighting system of IAB-451, (7) pressure sensors, (8) narrow-band light filter (306 nm), (9) photomultiplier tube, (a) a part of experimental setup which applied for induction time measurements, (b) rough surface profile, (c) schematic illustration of bifurcation structure

Bifurcation Parameters Measurements

For observing the dynamics and sizes of the bifurcation structure, measurements were performed at the deflection of a plane-parallel beam propagating at a small angle to the reflected shock wave plane at 50, 150, and 250 mm from the endwall. The experimental setup, arrangement of pressure sensors, their notation, and the light beam path are seen in Fig. 1, where the part of the figure marked with “a” contains experimental setup elements which was applied only for the ignition delay time measurements without other parts of the optical scheme.

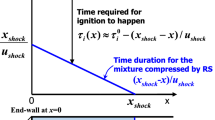

The light beams which passed through the test volume were recorded using photomultipliers PMT-119 and PMT-114. Typical records of pressure and PMT signals are presented in Fig. 2. We measured the time difference between the flow separation points t A and the normal reflected shock wave propagation t B through the measurement cross section, that is, Δt BA. The corresponding notations are shown in Figs. 1c and 2. The projection length, l, of the oblique shock wave onto the inner surface of the shock tube was calculated as the product Δt BA V R where V R is the reflected shock wave velocity. The similar techniques for measurement of the oblique shock wave projection were used in [9]. The oblique shock wave slope angle to the shock tube surface remains almost constant with distance and slightly varies with Mach number for our conditions. So, the projection length, l, could be used as the size parameter of the bifurcation structure. Studies for the hydrogen-nitrogen mixture were performed in the following conditions: 0.704 N2 + 0.296 H2 at M = 1.6–3.5, T 5 = 609–1496 K, P 5 = 0.72–1.59 MPa, ρ 5 = 2.81 ± 0.12 kg/m3.

Left—pressures at the surface and PMT signals when recording the light passing through the measurement cross section located at 50 mm to the endwall; right—oscilloscope records of the change in the glow of the OH radical and in the pressure at the face of the shock tube as a result of the ignition of hydrogen downstream of the reflected shock wave

Induction Time Measurement

The ignition delay was measured by the OH* chemiluminescence (λ = 306 nm, Δλ = 2.4 nm). To evaluate the influence of the reflected shock wave bifurcation on the hydrogen ignition, we directed the radiation from boundary layer through the optical window and 7 mm diameter diaphragm, located in the near-wall region at 1.5 mm to the tube wall, onto photomultiplier. The second photomultiplier registered radiant from the gas at the tube axis through the optical window of the same size installed at the axis of shock tube at the endwall (Fig. 1a). The ignition delay was determined as the time interval between the instant the shock wave begins to reflect and the instant the glow at the level of 5 % of the first intensity maximum appears in the volume of the reacting mixture. Figure 2 contains oscilloscope records obtained for ignition delay time measurement.

The mole concentration ratio of the H2/O2/Ar gas mixture was 2:1:12. Measurement conditions for the hydrogen-oxygen-argon mixture was following T 5 = 1045–1230 K, P 5 = 6.9–8.3 atm, ρ 5 = 2.80 ± 0.02 kg/m3.

Results

The studies showed that the bifurcation structure size for a hydrogen-nitrogen mixture grows with Mach number almost linearly for all distances to the endwall (Fig. 3). The bifurcation structure is characterized by the linear l growth with increasing distance up to the endwall to attain some value. After this, the steady value of bifurcation structure sizes is attained, the structure size depending on the boundary layer thickness [10]. The l growth with increasing distance for a smooth surface does not contradict the nitrogen results [10] for higher Mach numbers. However in [10], the steady-state regime is not found at a certain distance for a rough surface when the roughness profile height is 1.2 mm. In our experiments for a rough surface at a distance between 50 and 150 mm, the steady-state bifurcation regime is achieved.

The overshoot pressure caused by the bifurcation region vortices [3, 4] and stagnation pressure are enhanced for a rough surface. The pressure excess over the pressure P 5 at the point E (see Figs. 1 and 2) for M = 3.25 attains the value, that is, by a factor of 2 more than that for a smooth surface. For the small distance to the endwall, the bifurcation size also significantly increases with roughness. The availability of rough surface for Ra = 20 μm at the incident shock wave Mach number equal to 3.25 increased the oblique shock wave length projection by a factor of 1.5 at a distance of 50 mm to the endwall. A small surface roughness strongly affects the reflected shock wave bifurcation in the hydrogen-nitrogen mixture; however the bifurcation size became constant with increasing distance to the endwall.

The induction time for H2/O2/Ar gas mixture is seen on Fig. 4. The results of the measurements for different shock tube surface roughness show that there is no obvious roughness effect on the induction time through the investigated measurement diapason. And there is no need to do the shock tube surface substantially polished for those experiments. However, there are some features interesting to be discussed.

We did not obtain experiments with difference in the induction time less than the time that is needed for the flame to reach the region at the axis of the tube while moving from the boundary layer. But for the rough surface tube at the gas temperature 1063 K, it is found that weak luminescence arises at the axis three times earlier than the time needed for the sound wave to pass the distance from the boundary layer to the axis of the tube. The boundary layer thickness for smooth surface at similar conditions is about 1 mm, and the viscous dissipation increases the temperature inside the boundary layer, which is approximately 150 K higher than in the core region of the shock tube [11]. One can hypothesize that the boundary layer in our case is strongly cooled by the interaction with rough tube surface.

For both smooth and rough surface cases at temperatures 1100–1140 K, ignition sometimes arises on 10 % earlier of the ignition time in the boundary layer or in the near-axis region. For this time neither pressure nor diffusion of radical from the boundary layer cannot influence on induction time in the axis region.

Conclusions

It is found that for the hydrogen-nitrogen mixture, availability of rough surface for Ra = 20 μm at the incident shock wave Mach number equal to 3.25 increased the overshoot pressure behind the reflected shock wave by a factor of 2 and the oblique shock wave length projection by a factor of 1.5 at a distance of 50 mm to the endwall. The small surface roughness strongly affects the reflected shock wave bifurcation in hydrogen-nitrogen mixture. The values of the oblique shock wave projection length for the rough surface could be utilized for the estimation of the bifurcation structure size in the shock tube when the shock tube is polished, but the surface roughness value is unknown.

The ignition of the stoichiometric hydrogen-oxygen mixture diluted with argon (80 %) at pressures of 6.9–8.3 atm and temperatures of T 5 = 1045–1230 K was experimentally investigated. It was established that there is no obvious roughness effect on the induction time through the investigated measurement diapason. However, for rough surface tube at the gas temperature 1063 K, it is found that weak luminescence arises in the axis region significantly earlier than in the near-wall region. When reaction started in the near-wall region, the time difference between induction time in this region and in the axis region is so small that one can suppose the reactions of both regions occurs independently of each other. The obtained results could be useful for estimation of the roughness effects on hydrogen-oxygen reaction to be investigated by shock tube method.

References

Gel’fand, B., Medvedev, S., Khomik, S., Agafonov, G.: Self-ignition of hydrogen-air mixture behind the reflected blast wave [in Russian]. High Temp. Phys. 48(3), 458–462 (2010)

Pang, G.A., Davidson, D.F., Hanson, R.K.: Experimental study and modeling of shock tube ignition delay times for hydrogen–oxygen–argon mixtures at low temperatures. Proc. Combust. Inst. 32, 181–188 (2009)

Daru, V., Tenaud, C.: Numerical simulation of the viscous shock tube problem by using a high resolution monotonicity-preserving scheme. Comput. Fluids 38, 664–667 (2009)

Daru, V., Tenaud, C.: Evaluation of TVD high resolution scheme for unsteady viscous shocked flows. Comput. Fluids 30, 89–113 (2001)

Yamashita, H., Kasahara, J., Sugiyama, Y., Matsuo, A.: Visualization study of ignition modes behind bifurcated reflected shock waves. Combust. Flame 159(9), 2954–2966 (2012)

Oran, E., Boris, J.: Weak and strong ignition. II. Sensitivity of the hydrogen-oxygen system. Combust. Flame 48, 149–161 (1982)

Oran, E., Young, T., Boris, J.: Weak and strong ignition. I. Numerical simulations of shock tube experiments. Combust. Flame 48, 135–148 (1982)

Georgievskiy, P., Levin, V., Sutyrin, O.: Shock propagation through gas with density inhomogeneities. Proceedings of the 15th International Symposium on Flow Visualization [On CD]. Minsk, Belarus. Paper №120, ISBN 978-985-6456-75-9, (2012)

Petersen, E.L., Hanson, R.K.: Measurement of reflected-shock bifurcation over a wide gas composition and pressure range. Shock Waves 15, 333–340 (2006)

Taylor, J., Hornung, H.: Real gas and wall roughness effects on the bifurcation of the shock reflected from the endwall of a tube. Proceedings of the 13th International Symposium Niagara Falls, pp. 262–270, State University of New York, Buffalo, NY, (1982)

Ihme, M., Sun, Y., Deiterding, R.: Detailed simulations of Shock-Bifurcation and ignition of an argon-diluted hydrogen/oxygen mixture in a shock tube. AIAA Paper 2013-0538, (2013)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2017 Springer International Publishing AG

About this paper

Cite this paper

Penyazkov, O., Skilandz, A. (2017). Induction Time Measurements in Shock Tube of Different Roughness. In: Ben-Dor, G., Sadot, O., Igra, O. (eds) 30th International Symposium on Shock Waves 2. Springer, Cham. https://doi.org/10.1007/978-3-319-44866-4_67

Download citation

DOI: https://doi.org/10.1007/978-3-319-44866-4_67

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-44864-0

Online ISBN: 978-3-319-44866-4

eBook Packages: EngineeringEngineering (R0)