Abstract

Graphene is a new member of the nanocarbon family that has revolutionized the field of materials science and has attracted much attention due to its exceptional properties. Recent progress has shown that graphene-based nanocomposites can be used in nanoelectronics, touch screens, optics, catalysis, supercapacitors, fuel cell transistors, flexible electronics, H2 storage, and polymer nanocomposites. The functionalization is a surface modification much used to reduce the cohesive force between the graphene sheets and also to manipulate the physical and chemical properties. The aim of this book was to provide a comprehensive scientific progress of graphene, containing topics such as synthesis, characterization, and application of functionalized graphene. The characterization of the functionalized graphene is extremely important for determining the physicochemical properties of the material obtained after the functionalization treatments. However, this characterization is rarely addressed in books or in review articles. Generally, the functionalization reviews are too wide-ranging, discussing the functionalization of various materials (e.g., nanomaterials) or too specific, analyzing only one functionalization agent (with some specific chemical group, for example). This book, however, proposes to discuss the functionalization of one of the most widely used nanomaterials in recent years: graphene. Thus, the reader will find information on graphene functionalization, using several functionalization agents, in the same book.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

1.1 Graphene

1.1.1 Introduction

Over the last few years, materials have played a key role in various industrial sectors of technology, such as aerospace, aeronautical, automotive, medical, and sensors. Therefore, understanding the relationship between structures and material properties has become increasingly important to develop novel materials with improved properties in order to meet these needs (Mittal et al. 2015). In this context, nanotechnology and nanoscience have shown great development, and as a result, many knowledge fields based on the macromaterials are currently exploited and manipulated at nanoscale (Ferreira et al. 2015). As a result, several nanomaterials with different sizes and shapes have appeared during the past few decades (Wang et al. 2015a).

A new member of the nanocarbon family has revolutionized the field of materials science: graphene. Graphene is the mother element of some carbon allotropes (Fig. 1.1), including graphite, carbon nanotubes, and fullerenes (Geim and Novoselov 2007; Chia et al. 2015; Li et al. 2015; Kim et al. 2010; Kuila et al. 2012). Graphene was theoretically established in 1940 (Wallace 1947), while Boehm and coworkers, in 1962, separated thin carbon layers from graphite oxide (Boehm et al. 1962; Rohini et al. 2015). In 2010, the Nobel Prize in Physics was awarded to Andre Geim and Konstantin Novoselov for the successful preparation and isolation of graphene samples of highly oriented pyrolytic graphite (Novoselov et al. 2004; Rohini et al. 2015; Sanchez et al. 2012; Mao et al. 2013). Graphene is an atomically thick 2D planar sheet of carbon atoms arranged in a sp2-hybridized configuration and densely packed in a honeycomb structure (Liu et al. 2015b; Suggs et al. 2011; Allen et al. 2010). These sp2-hybridized carbon bonds contain in-plane σ bonds and out-of-plane π bonds (Mao et al. 2013).

Graphene is the basis of all graphitic forms, and it is a 2D building material for carbon materials of all other dimensionalities. It can be wrapped up into 0D buckyballs, rolled into 1D nanotubes, or stacked into 3D graphite (Geim and Novoselov 2007)

Graphene is relatively new and the “thinnest” known material. The enormous amount of interest worldwide is due to its extraordinary properties: thermal conductivity (as high as 3000 Wm−1 K−1) (Compton et al. 2011), electrical conductivity of 2 × 103 S cm−1 (Rohini et al. 2015), excellent optical transparency (~97.7 %) (Liao et al. 2014), mechanical stiffness (>1000 GPa) (Rohini et al. 2015), Young’s modulus of 1 TPa (Wang et al. 2012b), high charge mobility (>200,000 cm2 V−1 s−1) (Liu et al. 2009), high surface area (2630 m2 g−1) (Liu et al. 2015b), and high thermal stability up to approximately 600 °C (Rohini et al. 2015), as well as (Liao et al. 2014). These properties make them viable candidates for a wide variety of potential applications, such as transparent conductive electrodes (Wang et al. 2015a), energy storage devices (Lv et al. 2015), drug delivery (Pinto et al. 2013), composite material (Rohini et al. 2015), and tissue engineering (Goenka et al. 2014), as well as (Liu et al. 2015b; Rohini et al. 2015; Kuila et al. 2012).

Graphene in general is expensive when compared to other carbon-based nanofillers, such as carbon nanotubes. However, some graphene derivatives, such as graphene oxide (GO), are inexpensive (Rohini et al. 2015). GO is a graphene analog with many functional groups that make the physical and chemical properties of GO largely different from those of graphene (Toda et al. 2015).

1.1.2 Synthesis

The large-scale production of graphene with high-quality sheets and defect free has become an urgent challenge as well as a labor-intensive task (Kuila et al. 2012; Mittal et al. 2015). In this context, to meet the demanding requirements, extensive research efforts have focused on developing large-scale methods of graphene synthesis (Green and Hersam 2009; Jayasena and Melkote 2015). Numerous graphene synthesis routes have been reported in the literature, but only six will be discussed here: mechanical exfoliation, chemical vapor deposition (CVD), reduction of graphite oxide, epitaxial growth on SiC, electrochemical exfoliation, and carbon nanotube unzipping. Figure 1.2 illustrates some types of graphene synthesis routes, outlining the general real-life applications (Mittal et al. 2015).

Scheme depicting various conventional synthesis methods of graphene along with their important features, and their current and potential applications (Mittal et al. 2015)

The advantages and disadvantages of each method are summarized in Table 1.1.

1.1.2.1 Mechanical Exfoliation

Mechanical exfoliation is the first method used for graphene preparation (Novoselov et al. 2004; Mittal et al. 2015; Rohini et al. 2015). This method is a simple peeling process where mechanical energy is primarily used to exfoliate graphite and to separate the stable graphene sheets (Fig. 1.3) (Yang et al. 2013; Singh et al. 2011). However, the yield obtained through mechanical exfoliation is not suitable for large-scale production of graphene (Jayasena and Melkote 2015). Therefore, an alternative to this is to produce large quantities of graphene via chemical vapor deposition.

Scotch tape method of graphene synthesis from highly oriented pyrolytic graphite (HOPG) block (Mittal et al. 2015)

1.1.2.2 Chemical Vapor Deposition (CVD)

The production of graphene by chemical vapor deposition was first reported in 2006 by Somani’s group (Somani et al. 2006) and is today one of the most promising techniques for large-scale production of graphene (Singh et al. 2011). Somani’s group synthesized few-layer graphene films using camphor as precursor and Ni foils as catalyst (Mittal et al. 2015; Singh et al. 2011). Later on, several new advances in this synthesis procedure were reported using different metal substrates, e.g., Cu (Liu et al. 2015e), Pt (Karamat et al. 2015), Mo (Grachova et al. 2014), Ir (Coraux et al. 2008), or Au (Oznuluer et al. 2011). Several metals can be used as catalyst in CVD graphene growth, but Cu and Ni are most widely used for scale-up graphene production (Frank and Kalbac 2014; Mittal et al. 2015).

In general, CVD of graphene is performed in a gas phase where a precursor (usually a small hydrocarbon) reacts with a catalyst in a reaction chamber at a high temperature (range from several hundred degrees Celsius up to the melting point of the catalyst metal). Thus, the graphene is formed on the catalyst surface (Frank and Kalbac 2014). When nickel is used as a catalyst, a Ni substrate is placed in a CVD chamber at a vacuum and temperature below 1000 °C in an atmosphere of diluted hydrocarbon gas. The deposition process starts when carbon deposits on a Ni surface after the cooling process (Mittal et al. 2015). The thickness and crystalline ordering of the precipitated carbon (graphene layers) are controlled by the cooling rate and the concentration of carbon dissolved in the nickel (Singh et al. 2011). Figure 1.4 shows the graphene formation by chemical vapor deposition using Ni as substrate.

a Schematic diagram of graphene formation on Ni. b Schematic diagram of graphene atoms (smaller atoms) on Ni (111) lattice (larger atoms). (Adapted from Zhang et al. 2013)

1.1.2.3 Reduction of Graphite Oxide

Another promising alternative to produce large quantities of graphene is the reduction of the graphene oxide (GO) produced by Hummers’ method, which is illustrated in Fig. 1.5 (Hummers and Offeman 1958). The reduction process can be performed thermally (Ho and Wang 2015; Compton et al. 2011) or chemically (Yuan et al. 2016; Mittal et al. 2015; Rohini et al. 2015). GO is synthesized by Hummers’ method through a graphite oxidation using strong oxidizing agents (Singh et al. 2011). The thermal reduction of graphene from GO can be achieved using a microwave. In this method, GO is dispersed in water and then sonicated with N,N-dimethylacetamide (DMAc). Next, GO suspensions are subjected to different microwave exposure time intervals (Rohini et al. 2015). Chemical reduction of GO sheets may be obtained using several reducing agents (Stankovich et al. 2007; Shin et al. 2009). However, hydrazine hydrate is one of the most commonly used reagents to produce very thin graphene sheets (Singh et al. 2011; Rohini et al. 2015).

Oxidation of graphite to graphene oxide (GO) and reduction to reduced graphene oxide (rGO). (Adapted from Toda et al. 2015)

1.1.2.4 Epitaxial Growth on SiC

The epitaxial growth of graphene is based on the sublimation of Si from a surface of a single-crystalline SiC, leaving a face rich in carbon that forms graphene (Zhang et al. 2015a). This method is very promising due to the production of large size graphene sheets, elevated purity, and uniform properties (Kumar et al. 2016). Furthermore, graphene produced by epitaxial growth is almost defect free (Liu et al. 2015e).

Several works in recent years have demonstrated the possibility of growing perfectly controlled layers of graphene on SiC using several procedures, such as under ultra-high vacuum (UHV) conditions, under Ar and N2 atmosphere (Kumar et al. 2016; Çelebi et al. 2012; Zarotti et al. 2016; Zhang et al. 2013). However, high temperatures (about 1500 °C) hamper the large-scale production of graphene (Mittal et al. 2015; Kim et al. 2010) due to the quick diffusion of silicon from the SiC surface at high temperatures, under non-equilibrium conditions (Zarotti et al. 2016).

1.1.2.5 Electrochemical Exfoliation

The electrochemical exfoliation is a green method of graphene production and was first reported in 1976 (Besenhard 1976; Parvez et al. 2015; Bose et al. 2014). In this method, graphite is oxidized in a mixture of sulfuric and nitric acid (Mittal et al. 2015) and then exfoliated in an electrochemical device (Mittal et al. 2015; Yu et al. 2015). Figure 1.6 shows the electrochemical experimental setup.

Schematic illustration of a typical setup for the electrochemical exfoliation of graphite. (Adapted from Yu et al. 2015)

The electrochemical method offers some advantages over the other methods, such as the simple one-step operation and control of the synthesis, functionalization, and exfoliation process (Parvez et al. 2015). However, the graphene produced by the electrochemical method presents a number of defects, which modify the electronic properties of graphene (Mittal et al. 2015; Kim et al. 2010).

1.1.2.6 Carbon Nanotube Unzipping

Carbon nanotubes are considered graphene sheets rolled up in seamless tubes (Jiao et al. 2009). Therefore, it would seem natural that CNTs can be unzipped to obtain graphene (Terrones et al. 2010). The first method to obtain graphitic nanoribbons from CNT unzipping was published by Márquez and coworkers (Márquez et al. 2009). In this method, carbon nanotubes were opened longitudinally by intercalation of lithium and ammonia followed by exfoliation. Two other new methods appeared two weeks later: solution-based oxidative (Kosynkin et al. 2009) and Ar plasma etching (Jiao et al. 2009). Since then, various other methods have been successfully applied to produce graphene from the CNT opening (Elías et al. 2010; Terrones et al. 2010). Figure 1.7 shows different methods to unzip carbon nanotubes (Terrones et al. 2010).

Schematics and representative images of several methods for unzipping CNTs into graphene nanoribbons (Terrones et al. 2010)

Carbon nanotube unzipping methods are very appealing, since they are simple and lead to well-defined shaped graphene (Kim et al. 2010; Hirsch 2009). However, these methods are not suitable for mass production of graphene (Chatterjee et al. 2015). Moreover, starting materials are expensive (Kim et al. 2010).

1.1.3 Graphene Functionalization

As summarized above, the properties and applications of graphene can be controlled by synthetic conditions. Each preparation method not only has advantages and drawbacks over the other methods, but also provides flexible graphene for various applications (Mittal et al. 2015; Liu et al. 2015e). Furthermore, the properties and applications of graphene can also be adjusted by other parameters, such as number of layers, dimensions, and in particular surface modification (Liu et al. 2015b).

Surface modification is one of the main methods used to reduce the cohesive force between the graphene sheets and also to manipulate the physical and chemical properties of graphene (Layek and Nandi 2013; Boukhvalov and Katsnelson 2009). It provides numerous additional functions to graphene sheets, hence playing a crucial role in their potential commercial applications in band gap engineering, gas sensing, spintronics, and so on (Chia et al. 2015; Sayin et al. 2015; Liu et al. 2015d; Chatterjee et al. 2015; Singh et al. 2011; Han et al. 2007).

Generally speaking, surface functionalization could be summarized as two main approaches: covalent functionalization, which is related to covalent bond formations, and non-covalent functionalization, which is associated with van der Waals forces (Boukhvalov and Katsnelson 2009). The works in the literature are often related to covalent functionalization because it forms a stronger modification of geometric and electronic properties of graphene (Boukhvalov and Katsnelson 2009).

1.1.3.1 Covalent Functionalization

Covalent modification offers great potential to develop new functional materials, structures, and devices for interesting and promising applications (Kim and Grossman 2015). The covalent linkage between unsaturated π bonds of carbon and other functional groups is the base of a covalent functionalization (Mittal et al. 2015). The functionalization occurs by the reaction of π orbitals transforming sp2 bonds into sp3 (Liu et al. 2015b; Haldar et al. 2012; Niyogi et al. 2010). Therefore, graphene is able to covalently bond with other species since it is chemically unsaturated (Mao et al. 2013). However, this functionalization may be accompanied by a deterioration of the electron transport due to the conversion of sp2 into sp3 carbon (Layek and Nandi 2013; Sayin et al. 2015). Figure 1.8 shows a schematic illustration of graphene covalent functionalization.

Schematic illustration of covalent functionalization of graphene. (Adapted from Mao et al. 2013)

Within the last few years, graphene covalent functionalization has been intensively investigated theoretically (Suggs et al. 2011). For instance, Li et al. (2011) studied the graphene functionalization by first-principle calculations. The authors considered functionalization only on one side with F (F-graphene), O (O-graphene), and OH (OH-graphene) and on both sides with F and H (F-graphene-H), O, and H (O-graphene-H). The results demonstrated that the functionalized graphenes allow much larger spin current density with lower fabrication requirements, when compared with ultra-narrow graphene nanoribbon spintronics devices. Using classical and quantum mechanical calculations, Kim and Grossman (2015) showed that chemical functionalization of graphene can improve the electronic properties (thermoelectric power factor, PF = S2σ) compared to pristine graphene.

Using molecular and lattice dynamics simulations in another work, Kim et al. (2012) investigated the effects of graphene functional groups on thermal transport. Graphene was functionalized with H atoms and hydrocarbon chains (pentane C5H12) on both sides in an alternating manner. The simulation results demonstrated that the chemical functionalization plays a significant role in the thermal transport of 2D materials. The 2D periodic patterns of a graphene sheet suppress the thermal conductivity as all atoms can be functionalized in the 2D system. In contrast to a 3D structure where only surface atoms can be functionalized, consequently, a minor influence on thermal transport is observed.

Covalent functionalization of graphene has also been investigated experimentally. In the experimental study, graphene oxide (GO) is synthesized by the Hummers’ method and subsequently functionalized. The Hummers’ method introduces some oxygenated species (carboxyl, epoxy, and hydroxyl groups) during the graphite oxidation processes (Mao et al. 2013). Therefore, the presence of these functional groups facilitates the covalent molecular functionalization of graphene (Hossain et al. 2012).

Maktedar et al. (2014) studied the antibacterial activity of modified graphene oxide. Sonochemical waves were employed to exfoliate GO. After that, GO was functionalized with 6-aminoindazole forming f-(6-AIND) GO. The results showed that f-(6-AIND) GO is an antibacterial and antifungal agent.

Lin et al. (2011) studied the capacitance of the functionalized graphene prepared by controlled reduction of graphene oxide. GO was synthesized using the Hummers’ method, and GO was functionalized using dimethylformamide (DMF) in a solvothermal method. The functionalized graphene showed the specific capacitance up to 276 F/g, which is much higher than the benchmark materials.

Mohanty and Berry (2008) reported the fabrication of chemically modified graphenes (CMGs) in a single-bacterium biodevice. CMGs were synthesized using GO and plasma-modified graphene-amine (PGA) on a silica substrate. GOs were synthesized from graphite flakes by the modified Hummers’ method. PGA was synthesized either by exposing the graphite flakes to ammonia (or nitrogen plasma) followed by exfoliation. Initially, the substrate was exposed to oxygen plasma and then functionalized with a monolayer of (3-aminopropyl) triethoxysilane to make the silica surface positively charged with tethered amine groups. Choi et al. (2010) created sulfonate (−SO3) groups in the graphene surface using microwave-assisted sulfonation.

Xue et al. (2015) investigated the catalytic performance of GO functionalized with ethylenediamine (N-GO) in the Knoevenagel condensation reactions. According to the results, pure GO showed almost no catalytic activity for the Knoevenagel condensation reactions of benzaldehyde. On the other hand, after functionalization, the conversion of benzaldehyde into N-GO samples significantly increased.

Although the electronic and chemical properties of graphene can be effectively tailored by covalent functionalizations, the properties related to the transport of electrons or phonons may be disrupted (Layek and Nandi 2013; Mao et al. 2013). An alternative to overcome this drawback is to use non-covalent functionalizations since they cause less perturbation to the graphene π-conjugated structure (Mao et al. 2013).

1.1.3.2 Non-covalent Functionalization

In summary, surface modification of graphene is a versatile method to manipulate its physical and chemical properties, essential condition to expand their potential commercial applications (Layek and Nandi 2013). The native electronic structure and physical properties of graphene can be effectively modified by covalent functionalization. However, this functionalization may be accompanied by some damage on the graphene electron conjugation (Sayin et al. 2015; Kuila et al. 2012). Non-covalent functionalizations of graphene are nondestructive methods, since the electronic, chemical, physical, and mechanical properties of the pristine graphene are preserved after the modification (Mao et al. 2013). However, the efficiency of load transfer and force between the wrapping molecules is weaker than the covalent functionalization (Layek and Nandi 2013). Therefore, the type of functionalization of graphene should be carefully selected based on the specific performances.

Non-covalent functionalizations with different organic compounds have become very attractive to make graphene soluble in different solvents, obtaining high dispersion. Non-covalent functionalizations are based on π interaction, attaching functional groups without disturbing the electronic network. Many π interactions can be developed as follows:

-

(1)

Nonpolar gas-π interaction: In this, the functionalizing molecule is a gas. The gas–graphene chemical bonding is based on both electrostatic and dispersion energies.

-

(2)

π–π interaction: Because graphene and the functionalizing agent have similar electron densities, the interaction is predominated by dispersion or induction.

-

(3)

Cation-π interaction: Because functionalizing agent is a metallic cation, the interaction is based on the induction energies.

-

(4)

Anion-π interaction: The contribution of the dispersion energies is substantial in the anion-π complexes.

The different types of non-covalent functionalization should be carefully selected based on the specific performances (Jo et al. 2015; Georgakilas et al. 2012).

1.1.3.3 Other Methods of Graphene Functionalization

Besides the covalent and non-covalent functionalizations, other methods of graphene functionalization have received considerable attention due to their wide range of applications (Liu et al. 2015b). For example, Chen et al. (2015) studied the electrochemical performance of functionalizing graphene oxide with Co2SnO4 (Co2SnO4/G). GO was synthesized from natural graphite by a modified Hummers’ method. Co2SnO4/G nanocomposites were synthesized using the hydrothermal method. The nanocomposites exhibited an improved electrochemical performance, such as high reversible capacities, good cycling stability, and excellent performance rate compared to pure Co2SnO4 nanoparticles. Cai et al. (2015) prepared the nanocomposite of SnO2 dodecahedral nanocrystals (DNCs) anchored on graphene sheets (GS) as an advanced anode for high-performance lithium-ion batteries. Graphene oxide was prepared from graphite powder via modified Hummers’ method. The composite of SnO2 DNCs anchored on GS was synthesized by a facile hydrothermal method. The SnO2 DNCs-GS nanocomposite exhibited a significant Li battery performance compared with pure SnO2 DNCs. Wang et al. (2015b) functionalized two-dimensional reduced graphene oxide (2D rGO) with MnO2 (MnO2/rGO) by the hydrothermal method and studied their activity in a catalytic ozonation. The results showed that the catalytic efficiency of MnO2/rGO was superior to either MnO2 or rGO in the catalytic ozonation of 4-nitrophenol. This method was employed by other authors for graphene functionalization with Co3O4 (Dong et al. 2012) and Co(OH)2 (Wang et al. 2012a).

Furthermore, other methods are used to prepare the functionalized graphene: Hassan et al. (2015) reported the microwave-assisted synthesis of metal nanoparticles (Pd, Cu, and PdCu) dispersed on the graphene sheets. The method allows the simultaneous reduction of GO and various metal salts. Using this method, many types of metallic and bimetallic nanoparticles can be dispersed on graphene sheets to create novel nanocatalysts supported on the large surface area of the thermally stable 2D graphene (Liu et al. 2015b). Song et al. (2012) prepared Fe3O4—GO nanocomposites by a chemical coprecipitation method. The results show that the nanocomposites exhibited a good activity for the electrooxidation of cysteine and N-acetyl cysteine in 0.1 M NaOH.

In addition, functionalization with Fe3O4 was also reported in other works (Wu et al. 2012). Renteria and coworkers used Fe3O4 nanoparticles for the functionalization of graphene (2015). Graphene nanocomposites were synthesized by a scalable technique based on liquid-phase exfoliation. The authors showed that Fe3O4 nanoparticles aligned the graphene fillers under an external magnetic field. The graphene filler alignment resulted in a strong increase in the thermal conductivity of the composites.

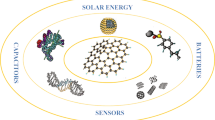

1.1.4 Graphene Applications

Graphene has attracted much attention due to its exceptional properties, especially in electronics, making this material an attractive candidate for future nanoelectronics (Xia et al. 2010; Georgakilas et al. 2012). Currently, graphene-based nanocomposites are studied to be used in nanoelectronics, touch screens, optics, catalysis, supercapacitors, fuel cell transistors, flexible electronics, H2 storage, and polymer nanocomposites (Sayin et al. 2015; Kuila et al. 2012).

In the following paragraphs, some graphene applications will be discussed in more detail.

1.1.4.1 Graphene/Polymer Matrix Composites

Graphene plays an important role in the development of nanocomposites due to its high specific surface area, unique graphitized plane structure, and excellent mechanical, electrical, magnetic, and thermal properties. Graphene and polymer composites have a wide range of exciting applications. However, as mentioned earlier, chemical functionalizations are essential to achieve a high performance of the nanocomposite, due to a uniform dispersion and enhanced compatibility with the matrix (Liu et al. 2015c).

1.1.4.2 Mechanical Applications

The main objective of a high-performance polymer composite for mechanic application is the balance between strength and toughness, and graphene improves these two mechanical properties when it is added into a polymer. These properties together with the large specific surface area make graphene excellent reinforcing nanofillers (Zhang et al. 2015b).

Yadav and Cho (2013) studied the properties of nanocomposites of graphene nanoplatelets and polyurethane (PU) by the incorporation of the functionalized graphene nanoplatelets into a polyurethane (PU) followed by an “in situ” polymerization. Graphene was functionalized by a coupling reaction with 4-aminophenethyl alcohol. Their results showed a formation of chemical bonding between the hydroxyl groups of graphene with polyurethane. These nanocomposites exhibited enhanced mechanical and thermal properties, in addition to good shape recovery in relation to the neat polymer. The addition of 2 wt% of the functionalized graphene nanoplatelets showed that the Young’s modulus and the thermal stability (at 30 °C) were ten times higher compared to a pure PU.

Graphene can be produced by unzipping multi-walled carbon nanotubes (MWCNT), which is called graphene nanoribbons (GNRs) (Lian et al. 2014). Lian et al. (2014) prepared GNRs by the CNT unzipping method, which were functionalized with non-covalent groups. These nanoparticles were used as reinforcement nanofillers for poly(vinyl chloride) (PVC) and poly(methyl methacrylate) (PMMA). GNRs were better dispersed in the PVC and PMMA matrices after the surface modification and exhibited strong interaction with matrices. The mechanical properties of both PVC and PMMA were enhanced. The effect of the addition of functionalized GNRs is most often superior to the addition of pure GNRs, or of functionalized carbon nanotubes or even of pure carbon nanotubes.

1.1.4.3 Electrical Applications

Some studies on graphene are related to mechanical reinforcement. However, the great majority of graphene composite applications are in the field of nanoelectronics. Despite all the exceptional properties mentioned in the previous chapters, graphene possesses zero band gap and chemical inertia. This characteristic limits the graphene applications as semiconductors and sensors. The surface modification by functionalization, both covalent and non-covalent, can modify the electronic properties of graphene by opening the energy gap, making possible nanoelectronic device applications (Georgakilas et al. 2012; Boukhvalov and Katsnelson 2009). The creation of this bang gap has driven many researches and has generated innovative applications in digital electronics, infrared nanophotonics, pseudospintronics, and terahertz technology (Xia et al. 2010).

Nowadays, new methods of energy conversion and storage have been developed, but the low efficient of these methods is an issue to be overcome. Therefore, much attention is given to the development of supercapacitors. Supercapacitors are energy storage devices capable of providing high power density by electrochemical systems. The energy conversion/storage capacity is dependent on the electrostatic forces between the electrode/electrolyte interface (Huang et al. 2013; Yu et al. 2014). Ren et al. (2015) functionalized rGO with methyl green (MG), obtaining a non-covalent functionalization and enhancing the supercapacitive performance. The mass ratio of 5:4 for the composite (rGO:MG) achieved a specific capacitance as high as 341 F g−1 at Ag-1 in the potential range of −0.25 to 0.75 V. The functionalization of rGO with MG provided an enhancement of 180 % in the specific capacitance when compared with pure RGO. These results showed that the functionalization of GO is an effective way to make new electrode materials, especially for supercapacitor systems.

When it comes to new technologies for energy generation and storage, many studies have also focused on the functionalized graphene applied in photovoltaic devices, such as solar cells. Graphene has been used in the development of organic solar cells, quantum dot solar cells (Chen et al. 2011), and dye-sensitized solar cells, among others (Wan et al. 2011), due to its favorable properties, such as high transparency in the visible spectrum and weak changes in electrical conductance (Lim et al. 2015; Wan et al. 2011; Liu et al. 2008).

Organic photovoltaic (OPV) cells produced with conjugated polymers have the advantages of low cost, solution-based processing, and fabrication on a flexible substrate. Due to these advantages, OPV cells have attracted much interest in solar cells technology. One of the goals in the field of solar cells is to increase significantly the power conversion efficiency (PCE). New processing techniques and new materials must be developed to achieve this objective. Graphene has demonstrated many advantages when compared with traditional transparent electrodes, thanks to its exceptional electrical properties, high mobility, and facility to change the surface by functionalization treatments (Wan et al. 2011; Liu et al. 2008; Yu et al. 2011). Lim et al. (2015) investigated the effects of surface-treated graphene thin films on the performance of organic solar cells for different surface treatments: (i) annealing in argon ambient, (ii) dipping in acetone, (iii) ultraviolet irradiation, and (iv) nitrogen plasma treatment. Organic solar cells were made with graphene and indium/tin oxide electrodes. The results showed that the device made with graphene and treated with acetone presented the best performance, including a better PCE value when compared with solar cell without graphene and cell with another surface-treated graphene. The authors concluded that the addition of acetone-modified graphene is very simple and can be used for other types of solar cells.

Graphene is an exceptional material for the detection of gases, ions, and biomolecules. Therefore, the functionalized graphene is the most promising nanomaterial for sensor fabrication. Besides the high surface area, graphene can also change its conductance due to molecule adsorption on its surface. This property makes graphene sensitive to many different molecules. For the most part, graphene is widely used in sensing applications in the biotechnology field, especially for the detection of diseases and biomolecules. Many researchers found that the functionalized graphene combined with single-stranded DNA and fluorescent molecules can diagnose several diseases. Fluorescent molecules are attached to the DNA, and then, they attached to graphene. This system is capable of detecting glucose, NADH, cholesterol, hydrogen peroxide, and others (Kuila et al. 2012). One example of this application is shown by Yang et al. (2015). They prepared a versatile nanocomposite with β-cyclodextrin functionalized graphene (CD-GR) with grafted fragments of DNA on the CD-GR surface to create a modified electrode which worked as a DNA biosensor. Due to the high surface area of graphene and the multi-site characteristic of CD, they concluded that the hybridization kinetics and biosensor efficiency were improved: The biosensor demonstrated a low background response and extremely high sensitivity for target DNA.

Du et al. (2015) also developed a biosensor based on the functionalized graphene. They deposited gold nanostructure on reduced graphene oxide that was functionalized for glucose sensing. The functionalization was made with β-lactoglobulin. The biosensor exhibits remarkable sensitivity and rapid response time, showing that the performance of the fabricated sensor is suitable for quantitative detection of glucose. Shen et al. (2015) synthesized a new aldehyde-functionalized graphene nanocomposite with poly-(epichlorohydrin) and 4-pyridinecarboxaldehydea for electrochemical immunosensor for identifying cancer. The aldehyde–functionalized graphene nanocomposite provided a promising method to immobilize and capture the antibodies on the electrode surface.

1.1.4.4 Anti-corrosion Applications

In addition to the electrical and mechanical applications, graphene is also being used to enhance the tribological and anti-corrosion properties of polymers, since it can inhibit corrosion and increase the polymer resistance.

Liu et al. (2015d) produced nanocomposites with two different fillers, functionalized fullerene C60 (FC60) and functionalized graphene (FG) using a polymer matrix of epoxy coating, and studied the tribological and anti-corrosion performances of these materials. They showed that the addition of FC60 and FG into epoxy matrix greatly improved the tribological and anti-corrosion properties when compared to the pure epoxy, which occurs due to the lubrication and barrier properties of nanofillers. The difference between the structure of fullerene and graphene results in their unique tribological properties. FC60 presented better tribological and scratch resistance, while FG showed better anti-corrosion performance. The authors concluded that the properties of epoxy nanocomposite depended on the nanofillers shape, and they also concluded that the functionalized graphene can be used for anti-corrosion applications.

Tribological and anti-corrosion properties have been studied not only with epoxy nanocomposites, but also with other polymer matrices as well. Mo et al. (2015) functionalized graphene (graphene named FG) and graphene oxide (graphene named FGO) with 3-aminopropyltriethoxysilane (APTES), and fabricated a series of polyurethane (PU)-based nanocomposites reinforced with different contents of FG and FGO. The tribological and anti-corrosion mechanisms of polyurethane nanocomposite were analyzed. They observed better dispersion and compatibility after the functionalization. Both FG and FGO addition enhanced the tribological and anti-corrosion properties, due to the lubrication and barrier properties provided by the addition. When the authors compared FG/PU with FGO/PU nanocomposites, FGO exhibited better tribological property but FG presented a better anti-corrosion property. As in the work cited in the previous paragraph, in this case, the addition of graphene in a polymer matrix was also able to improve the corrosion resistance of the material.

The functionalized graphenes have been extensively used in different areas of science. Many researches have conducted studies that incorporate the functionalized graphene in nanoelectronic devices, and biosensor systems, such as mechanical and anti-corrosion reinforcement, among other areas. Due to its exceptional properties, many other applications have been developed. It is necessary to innovate in order to achieve the best qualities of the material for the most promising applications.

1.1.5 Characterization of Functionalized Graphene

1.1.5.1 Raman Spectroscopy

Raman spectroscopy is a technique used to analyze geometric structure and chemical bonding of molecules. This aspect makes Raman spectroscopy extremely useful in studies of different allotropes of carbon, such as diamond, fullerenes, carbon nanotubes, graphene, and functionalized graphene. A typical Raman spectrum of carbon materials, including graphene, shows the presence of two prominent peaks, known as D and G bands. The G band is located at 1500–1590 cm−1 and is associated with disordered samples or edges (sp3 carbon domains). The D band is at 1290–1350 cm−1 and corresponds to graphitic domain (sp2 carbon domains). Graphene has an additional peak around 2700 cm−1, which is known as G′, sometimes referred as an overtone of the D band. This band is used to determine the graphene layer thickness (Zhang et al. 2012a; Xue et al. 2015; Lin et al. 2015) (Fig. 1.9).

The Raman scattering spectra of few-layer graphene, graphite nanoparticle, graphene oxide nanoparticle, carbon black nanoparticle, and charcoal nanoparticle. (Adapted from Lin et al. 2015)

The D band intensity is higher when the presence of defects and impurities increases, as observed in Fig. 1.9. Graphene oxides (GO) have some natural functional groups, showing a more intense D band when compared to graphite and graphene. The 2D band is highly sensitive to the number of graphene layers. When few layers of graphene are compared to graphene oxide, the 2D band intensity is attenuated and its bandwidth is broader. The functional groups in graphene oxide are able to stack large number of graphene layers (Maktedar et al. 2014; Feng et al. 2012; Kudin et al. 2007).

The intensity ratio of D band over G band (I D /I G ) is usually used to investigate the amount of structural defect and disorder. Some defects may occur due to the use of catalysts during its synthesis or due to the attachment of functional groups on the graphene surface. The I D /I G ratio is proportional to the number of defects or changes on graphene layer. Table 1.2 shows I D /I G of different functionalized graphene forms (Malard et al. 2009; Mhamane et al. 2011; Liu et al. 2014).

Table 1.2 shows that the I D /I G ratio increases with the graphene functionalization when compared to few layers of graphene or graphite. This can be assigned to the formation of covalent or non-covalent bonds between the functional groups and the graphene surfaces (Kaur et al. 2015).

1.1.5.2 X-ray Diffraction (XRD)

X-ray diffraction technique is used to determine the presence of functional groups on the graphene surface. A typical XRD pattern of graphite shows an intense and sharp peak at around 2θ = 26°, referring to the plane (002) of the graphene sheet. After a chemical modification of graphite by the Hummers’ method to obtain the graphene oxide, that peak is shifted to around 10° (2θ). GO can be reduced by thermal or chemical treatments to reduced graphene oxide (rGO). The XRD of rGO shows a narrow peak at around 24° (Fig. 1.10). These peak shifts suggest full oxidation and efficient formation of well-ordered two-dimensional structures of graphene sheets after the reduction of GO to rGO (Cui et al. 2011; Park and Lee 2015; Dreyer et al. 2009).

XRD pattern of graphite (black), graphene (red), and reduced graphene oxide (blue) (Cui et al. 2011)

Other expressive changes can be observed in the interlayer distances between the aromatic rings of graphene sheets. This distance can be determined by the following expression:

where n is order of reflection equal to 1, λ is the wavelength of cooper irradiation equal to 0.154 nm, d (002) is the interplanar distance between graphene sheets, and 2θ is the diffraction angle. The values of d (002) obtained in Fig. 1.10 were 0.334, 0.86, and 0.368 nm for graphite, graphene oxide, and reduced graphene, respectively. The increase in the d (002) value of graphene oxide is related to the insertion of functional groups (epoxy, hydroxyl, and carboxyl) between the graphene sheets. After the reduction of graphene oxide, the d (002) value is close to that of the graphite, suggesting an efficient bond removal of the graphene layer. Other shifts in the d (002) value can be observed when the graphene is subject to other types of functionalization agent. Table 1.3 lists the d (002) and 2θ values after graphene functionalization. The intercalation of different molecules in the graphene sheets significantly changes these parameters (Ji et al. 2015; Qian et al. 2014).

1.1.5.3 Fourier Transform Infrared Spectroscopy Analysis (FTIR)

Fourier transform infrared spectroscopy is used to study the chemical constituents of graphene after surface modification. Figure 1.11 shows a typical FTIR spectrum of graphene oxide obtained by the Hummers’ method.

The FT-IR spectrum of graphene oxide (Oh et al. 2010)

The peaks at 1740 and 1370 cm−1 are due to C=O and C–O stretching vibration, respectively. Figure 1.11 shows peaks at 1220, 880, and 850 cm−1 related to the presence of symmetric stretching, asymmetric stretching, and deformation vibrations of epoxy groups, respectively. Finally, Fig. 1.11 shows the peak at around 3390 cm−1, which is related to O-H stretching vibration of adsorbed water molecules (Oh et al. 2010; Lu et al. 2015; Naebe et al. 2014; Marcano et al. 2010). Table 1.4 shows the appearance of some bands associated with many treatments. The presence of these chemical groups is able to promote significant improvements in the graphene properties, such as solubility, thermal, electrical, and mechanical capacities (Naeimi et al. 2016).

1.1.5.4 Thermogravimetric Analysis (TGA)

TGA is a valuable and fairly simple method for investigating thermal stability, as well as for analyzing the presence of functional group in carbonaceous materials. Large differences related to mass loss can be observed when graphene is compared with the functionalized graphene. Figure 1.12 shows the TGA of graphene oxide (GO) and reduced graphene produced via γ-ray induced graphene oxide (rGO) (Zhang et al. 2012b).

TGA curves of graphene oxide (GO) and γ-ray induced graphene oxide (rGO) (Zhang et al. 2012b)

The mass loss of GO is 5 % at around 100 °C, which can be assigned to the removal of water molecules trapped inside the GO structure. At around 200 °C, with mass loss of 31 %, the pyrolysis of the labile oxygen-containing groups occurs until the formation of CO, CO2, and steam. The TGA of rGO shows a mass loss between 130 and 250 °C due to the decomposition of residual oxygen-containing groups. Therefore, γ-ray induced reduction (forming rGO), but also improves the thermal stability when compared with GO. Maktedar et al. (2014) functionalized reduced graphene oxide with 6-aminoindazole (6-AIND). The TGA results showed that graphene oxide presented a total of 82.9 % in mass loss due to the removal of thermally labile oxygen-containing groups. Meanwhile, reduced graphene oxide–6-AIND presented a total loss of 40.9 %, suggesting its thermal stability is higher than graphene oxide. The reduced mass loss of reduced graphene oxide–6-AIND and the enhanced residues formation depicts the high interaction between graphene and the new functional groups. Naeimi et al. (2016) prepared sulfonated graphene and predicted the amount of functional groups per carbon atoms through TGA analysis. For that purpose, weight loss values were employed together with the molecular weight of the various groups, according to Eq. (2):

where X stands for the number of carbon atoms in sulfonated graphene nanosheets per each covalent functional group, R (%) is the remaining mass in the TGA, L (%) is the weight loss range, and molecular weight (M w ) is the weight of the sulfonated groups. For that study, X was equal to 34 carbon atoms, which represents one functionalization group for approximately 34 carbon atoms.

1.1.5.5 X-ray Photoelectron Spectroscopy (XPS)

X-ray photoelectron spectroscopy (XPS) is one of the most sensitive and informative surface analysis techniques available. XPS analysis can be used on graphene materials to determine the functionalization degree. Marcano et al. (2010) developed three different graphene oxides using the Hummers’ method (HGO), improved Hummers’ method (IGO), and modified Hummers’ method (HGO+). The XPS spectrum was able to determine the relative levels of oxidation (Fig. 1.13).

C1s XPS spectra of improved Hummers’ method (IGO), Hummers’ method (HGO), and modified Hummers’ method (HGO+) (Marcano et al. 2010)

The spectra of the samples in Fig. 1.13 show that IGO is the most oxidized material and that IGO has a more organized structure than the other two materials. Using deconvolution, the peaks of all samples can be split into four peaks that correspond to the following groups: carbon sp2 (C=C, 284.8 eV), epoxy/hydroxyls (C–O, 286.2 eV), and carboxylates (O–C = O, 289.0 eV). The percentages of oxidized carbon and graphitic carbon in the IGO sample were 69 and 31 %, respectively. The HGO+ sample presented 63 and 37 %, while HGO contained 61 and 39 % of oxidized carbon and graphitic carbon, respectively. This suggests that XPS technique can accurately detect different levels of functionalization on graphene.

1.1.5.6 Dispersion of Functionalized Graphene in Different Solvents

The processability of aqueous graphene dispersions has attracted significant attention in various applications, including flexible electronics, batteries, conductive paper, and wire fabrications. Many studies were developed in order to achieve stable dispersions in various solvents such as water, dimethylformamide, alcohol, acetone, tetrahydrofuran, glycols, and alkanes (Zhang et al. 2012b; Ahmad et al. 2016). Graphene functionalization is one way of accomplishing successful dispersion in different solvents. Ahmad et al. (2016) introduced a new approach to enhance the graphene oxide dispersity in immiscible solvents. They prepared graphene oxide dispersions by mixing water/methanol and water/dioxane binary solvents. The results showed (Fig. 1.14) that the graphene oxide dispersion in 100 % methanol and 100 % dioxane exhibited poor stability. However, dispersions in the binary solvents (water/methanol and water/dioxane) exhibited excellent dispersivity. In these cases, the graphene oxide dispersity was even better than in pure water and no sedimentation was observed. Water molecules in these binary dispersions act like a surfactant. These molecules are located primarily around the graphene oxide particles, resulting in the separation of the graphene oxide sheets (Konios et al. 2014; Ahmad et al. 2016). Therefore, the dispersion of graphene in different solvents can also be used as a characterization method for their functionalization.

Stability of the graphene oxide dispersions in organic binary solvents: a water/methanol, b water/dioxane, and c–d water/dioxane without and with crossed polarizers. The numbers on the top denote the concentration of organic solvent (Ahmad et al. 2016)

References

Ahmad RTM, Hong SH, Shen TZ et al (2016) Water-assisted stable dispersal of graphene oxide in non-dispersible solvents and skin formation on the GO dispersion. Carbon 98:188–194

Allen MJ, Tung VC, Kaner RB (2010) Honeycomb carbon: a review of graphene. Chem Rev 110:132–145

Besenhard JO (1976) The electrochemical preparation and properties of ionic alkali metaland NR4-graphite intercalation compounds in organic eletrolytes. Carbon 14:111–115

Boehm HP, Clauss A, Fischer G et al (1962) Surface properties of extremely thin graphite lamellae. In: Proceedings of the fifth conference on carbon, p 73

Bose S, Kuila T, Kim NH et al (2014) Graphene produced by electrochemical exfoliation. Woodhead Publishing Limited, pp 81–98

Boukhvalov DW, Katsnelson MI (2009) Chemical functionalization of graphene. J Phys Condens Matter 21:344205

Cai D, Yang D, Wang D et al (2015) Tin dioxide dodecahedral nanocrystals anchored on graphene sheets with enhanced electrochemical performance for lithium-ion batteries. Electrochim Acta 159:46–51

Çelebi C, Yanık C, Demirkol AG et al (2012) The effect of a SiC cap on the growth of epitaxial graphene on SiC in ultra-high vacuum. Carbon 50:3026–3031

Chatterjee SG, Chatterjee S, Ray AK et al (2015) Graphene-metal oxide nanohybrids for toxic gas sensor: a review. Sens Actuators B 221:1170–1181

Chen J, Li C, Eda G et al (2011) Incorporation of graphene in quantum dot sensitized solar cells based on ZnO nanorods. Chem Commun (Cambrigde, England) 47:6084–6086

Chen C, Ru Q, Hu S et al (2015) Co2SnO4 nanocrystals anchored on graphene sheets as high-performance electrodes for lithium-ion batteries. Electrochim Acta 151:203–213

Chia JSY, Tan MTT, Khiew PS et al (2015) A bio-electrochemical sensing platform for glucose based on irreversible, non-covalent pi–pi functionalization of graphene produced via a novel, green synthesis metho. Sens Actuators B 210:558–565

Choi BG, Park H, Yang MH et al (2010) Microwave-assisted synthesis of highly water-soluble graphene towards electrical DNA sensor. Nanoscale 2:2692–2697

Compton OC, Jain B, Dikin DA et al (2011) Chemically active reduced graphene oxide with tunable C/O ratios. ACS Nano 5:4380–4391

Coraux J, N‘Diaye AT, Busse C et al (2008) Structural coherency of graphene on Ir(111). Nano Lett 8:565–570

Cui P, Lee J, Hwang E et al (2011) One-pot reduction of graphene oxide at subzero temperatures. Chem Commun 47:12370–12372

Dong XC, Xu H, Wang XW et al (2012) 3D graphene–cobalt oxide electrode for highperformance supercapacitor and enzymeless glucose detection. ACS Nano 6:3206–3213

Dreyer DR, Park S, Bielawski CW et al (2009) The chemistry of graphene oxide. Chem Soc Rev 39:228–240

Du X, Zhang Z, Miao Z et al (2015) One step electrodeposition of dendritic gold nanostructures on β-lactoglobulin-functionalized reduced graphene oxide for glucose sensing. Talanta 144:823–829

Elías AL, Méndez ARB, Rodríguez DM et al (2010) Longitudinal cutting of pure and doped carbon nanotubes to form graphitic nanoribbons using metal clusters as nanoscalpels. Nano Lett 10:366–372

Feng SY, Ma JJ, Lin XY et al (2012) Covalent functionalization of graphene oxide by 9-(4-aminophenyl) acridine and its derivatives. Chinese Chem Lett 23:1411–1414

Ferreira FV, Francisco W, Menezes BRC et al (2015) Carbon nanotube functionalized with dodecylamine for the effective dispersion in solvents. Appl Surf Sci 357:2154–2159

Frank O, Kalbac M (2014) Chemical vapor deposition (CVD) growth of graphene films. Woodhead Publishing Limited, pp 27–49

Geim AK, Novoselov KS (2007) The rise of graphene. Nat Mater 6:183–191

Georgakilas V, Otyepka M, Bourlinos AB et al (2012) Functionalization of graphene: covalent and non-covalent approaches, derivates and applications. Chem Rev 112:6156–6214

Goenka S, Sant V, Sant S (2014) Graphene-based nanomaterials for drug delivery and tissue engineering. J Controlled Release 173:75–88

Grachova Y, Vollebregt S, Lacaita AL et al (2014) High quality wafer-scale CVD graphene on molybdenum thin film for sensing application. Procedia Eng 87:1501–1504

Green AA, Hersam MC (2009) Graphene and its derivatives for cell biotechnology. Analyst 9:4031–4036

Haldar S, Bhandary S, Bhattacharjee S et al (2012) Functionalization of edge reconstructed graphene nanoribbons by H and Fe: a density functional study. Solid State Commun 152:1719–1724

Han MY, Özyilmaz B, Zhang Y et al (2007) Energy band-gap engineering of graphene nanoribbons. Phys Rev Lett 98:206805

Hassan HMA, Abdelsayed V, Khder AERS et al (2015) Microwave synthesis of graphene sheets supporting metal nanocrystals in aqueous and organic media. J Mater Chem 19:3832–3837

Hirsch A (2009) Unzipping carbon nanotubes: a peeling method for the formation of graphene nanoribbons. Angew Chem Int 6594–6596

Ho CY, Wang HW (2015) Characteristics of thermally reduced graphene oxide and applied for dye-sensitized solar cell counter electrode. Appl Surf 357:147–154

Hossain MZ, Johns JE, Bevan KH et al (2012) Chemically homogeneous and thermally reversible oxidation of epitaxial graphene. Nat Chem 4:305–309

Huang Z, Zhang H, Chen Y et al (2013) Microwave-assisted synthesis of functionalized graphene on Ni foam as electrodes for supercapacitor application. Electroc Acta 108:421–428

Hummers WS, Offeman RE (1958) Preparation of graphitic oxide. J Am Chem Soc 80:1339

Jayasena B, Melkote SN (2015) An investigation of PDMS stamp assisted mechanical exfoliation of large area graphene. Procedia Manuf 1:840–853

Ji Liangliang, Yanhong Wu, Ma Lijun et al (2015) Noncovalent functionalization of graphene with pyrene-terminated liquid crystalline polymer. Compos Part A Appl 72:32–39

Jiao L, Zhang L, Wang X et al (2009) Narrow graphene nanoribbons from carbon nanotubes. Nature 458:877

Jo S, Park YH, Ha SG et al (2015) Simple noncovalent hybridization of polyaniline with graphene and its application for pseudocapacitor. Synthetic Met 209:60–67

Karamat S, Sonuşen S, Çelikd U et al (2015) Synthesis of few layer single crystal graphene grains on platinum by chemical vapour deposition. Prog Nat Sci Mater Inter 25:291–299

Kaur P, Shin MS, Sharma S et al (2015) Non-covalent functionalization of graphene with poly (diallyl dimethylammonium) chloride: effect of a non-ionic surfactant. Int J Hydrogen Energ 40:1541–1547

Kim JY, Grossman JC (2015) High-efficiency thermoelectrics with functionalized graphene. Nano Lett 15:2830–2835

Kim H, Abdala AA, Macosko CW (2010) Graphene/polymer nanocomposites. Macromolecules 43:6515–6530

Kim JY, Lee JH, Grossman (2012) Thermal transport in functionalized graphene. ACS Nano 6:9050–9057

Konios D, Stylianakis MM, Stratakis E et al (2014) Dispersion behaviour of graphene oxide and reduced graphene oxide. J Colloid Interf Sci 430:108–112

Kosynkin DV, Higginbotham AL, Sinitskii A et al (2009) Longitudinal unzipping of carbon nanotubes to form graphene nanoribbons. Nature 458:872

Kudin KN, Ozbas B, Schniepp HC et al (2007) Raman spectra of graphite oxide and functionalized graphene sheets. Nano Lett 8:36–41

Kuila T, Bose S, Mishra AK et al (2012) Chemical functionalization of graphene and its applications. Prog Mat Sci 57:1061–1105

Kumar B, Baraket M, Paillet M et al (2016) Growth protocols and characterization of epitaxial graphene on SiC elaborated in a graphite enclosure. Phys E (Amsterdam, Neth.) 75: 7–14

Layek RK, Nandi AK (2013) A review on synthesis and properties of polymer functionalized graphene. Polymer 54:5087–5103

Li L, Qin R, Li H et al (2011) Functionalized graphene for high-performance two-dimensional spintronics devices. ACS Nano 5:2601–2610

Li Y, Peng Z, Larios E et al (2015) Rebar graphene from functionalized boron nitride nanotubes. ACS Nano 9:532–538

Lian M, Fan J, Shi Z et al (2014) Kevlar®-functionalized graphene nanoribbon for polymer reinforcement. Polymer (United Kingdom) 55:2478–2587

Liao L, Peng H, Liu Z (2014) Chemistry makes graphene beyond graphene. J Am Chem Soc 136:12194–12200

Lim T, Su C, Song M et al (2015) Organic solar cells with surface-treated graphene thin fi lm as interfacial layer. Synthet Metals 205:1–5

Lin Z, Liu Y, Yao Y et al (2011) Superior capacitance of functionalized graphene. J Phys Chem 115:7120–7125

Lin YH, Yang CY, Lin SF et al (2015) Triturating versatile carbon materials as saturable absorptive nano powders for ultrafast pulsating of erbium-doped fiber lasers. Opt Mat Expr 5:236–253

Liu Z, Liu Q, Huang Y et al (2008) Organic photovoltaic devices based on a novel acceptor material: Graphene. Adv Mat 20:3924–3930

Liu H, Ryu S, Chen Z et al (2009) Photochemical reactivity of graphene. J Am Chem Soc 131:17099–17101

Liu M, Duan Y, Wang Y et al (2014) Diazonium functionalization of graphene nanosheets and impact response of aniline modified graphene/bismaleimide nanocomposites. Mater Design 53:466–474

Liu H, Kishi N, Soga T (2015a) Synthesis of thiolated few-layered graphene by thermal chemical vapor deposition using solid precursor. Mat Lett 159:114–117

Liu J, Liu Z, Barrow CJ et al (2015b) Molecularly engineered graphene surfaces for sensing applications: a review. Anal Chim Acta 859:1–19

Liu D, Zhao W. Liu S et al (2015c) Comparative tribological and corrosion resistance properties of epoxy composite coatings reinforced with functionalized fullerene C60 and graphene. Surf Coat Technol 286:354–364

Liu L, Qing M, Wang Y et al (2015d) Defects in graphene: generation, healing, and their effects on the properties of graphene: a review. J Mater Sci Technol 31:599–606

Liu X, Han Y, Evans JW et al (2015e) Growth morphology and properties of metals on graphene. Prog Surf Sci 90:397–443

Lu X, Li L, Song B et al (2015) Mechanistic investigation of the graphene functionalization using p-phenylenediamine and its application for supercapacitors. Nano Energy 17:160–170

Lv W, Li Z, Deng Y et al (2015) Graphene-based materials for electrochemical energy storage devices: opportunities and challenges. Energy Storage Mater (in press)

Maktedar SS, Mehetre SS, Singh M et al (2014) Ultrasound irradiation: a robust approach for direct functionalization of graphene oxide with thermal and antimicrobial aspects. Ultrason Sonochem 21:1407–1416

Malard LM, Pimenta MA, Dresselhaus G et al (2009) Raman spectroscopy in graphene. Phys Rep 473:51–87

Mao HY, Lu YH, Lin JD et al (2013) Manipulating the electronic and chemical properties of graphene via molecular functionalization. Prog Surf Sci 88:132–159

Marcano DC, Kosynkin DV, Berlin JM et al (2010) Improved synthesis of graphene oxide. ASCNANO 4:4806–4814

Márquez AGC, Macías FJR, Delgado JC et al (2009) Ex-MWCNTs: graphene sheets and ribbons produced by lithium intercalation and exfoliation of carbon nanotubes. Nano Lett 9:1527–1533

Mhamane D, Ramadan W, Fawzy M et al (2011) From graphite oxide to highly water dispersible functionalized graphene by single step plant extract-induced deoxygenation. Green Chem 13:1990–1996

Mittal G, Dhand V, Rhee KY et al (2015) A review on carbon nanotubes and graphene as fillers in reinforced polymer nanocomposites. J Ind Eng Chem 21:11–25

Mo M, Zhao W, Chen Z et al (2015) Excellent tribological and anti-corrosion performance of polyurethane composite coatings reinforced with functionalized graphene and graphene oxide nanosheets. RSC Adv 5:56486–56497

Mohanty N, Berry V (2008) Graphene-based single-bacterium resolution biodevice and DNA transistor: interfacing graphene derivatives with nanoscale and microscale biocomponents. Nano Lett 8:4469–4476

Naebe M, Wang J, Amini A et al (2014) Mechanical property and structure of covalent functionalised graphene/epoxy nanocomposites. Sci Rep 4:1–7

Naeimi H, Golestanzadeh M, Zahraie Z et al (2016) Synthesis of potential antioxidants by synergy of ultrasound and acidic graphene nanosheets as catalyst in water. Int J Biol Macromol 83:345–357

Niyogi S, Bekyarova E, Itkis ME et al (2010) Spectroscopy of covalently functionalized graphene. Nano Lett 10:4061–4066

Novoselov KS, Geim AK, Morozov SV et al (2004) Electric field effect in atomically thin carbon films. Science 306:666–669

Oh J, Lee JH, Koo JC et al (2010) Graphene oxide porous paper from amine-functionalized poly(glycidyl methacrylate)/graphene oxide core-shell microspheres. J Mater Chem 20:9200–9204

Oznuluer T, Pince E, Polat OA et al (2011) Synthesis of graphene on gold. Appl Phys Lett 98:183101

Park MS, Lee YS (2016) Functionalization of graphene oxide by fluorination and its characteristics. J Fluorine Chem 182:91–97

Parvez K, Yang S, Feng X et al (2015) Exfoliation of graphene via wet chemical routes. Synth Met (in press)

Pinto AM, Gonçalves IC, Magalhães FD (2013) Graphene-based materials biocompatibility: a review. Colloids Surf B 111:188–202

Qian X, Song L, Yu B et al (2014) One-pot surface functionalization and reduction of graphene oxide with long-chain molecules: preparation and its enhancement on the thermal and mechanical properties of polyuria. Chem Eng J 236:233–241

Ren X, Hu Z, Hu H et al (2015) Noncovalently-functionalized reduced graphene oxide sheets by water-soluble methyl green for supercapacitor application. Mat Resear Bull 70:215–221

Renteria J, Legedza S, Salgado R et al (2015) Magnetically-functionalized self-aligning graphene fillers for high-efficiency thermal management applications. Mater Des 88:214–221

Rohini R, Katti P, Bose S (2015) Tailoring the interface in graphene/thermoset polymer composites: a critical review. Polymer 70:A17–A34

Sanchez VC, Jachak A, Hurt RH et al (2012) Biological interactions of graphene-family nanomaterials: an interdisciplinary review. Chem Res Toxicol 25:15–34

Sayin CS, Toffoli D, Ustunel H (2015) Covalent and noncovalent functionalization of pristine and defective graphene by cyclohexane and dehydrogenated derivatives. App Surf Sci 351:344–352

Shen G, Zhang X, Shen Y et al (2015) Immobilization of antibodies on aldehyde-functionalized polymer/graphene films for the fabrication of a label-free electrochemical immunosensor. J Electroanal Chem 759:67–71

Shin HJ, Kim KK, Benayad A et al (2009) Efficient reduction of graphite oxide by sodium borohydride and its effect on electrical conductance. Adv Funct Mater 19:1987–1992

Singh V, Joung D, Zhai L et al (2011) Graphene based materials: past, present and future. Prog Mater Sci 56:1178–1271

Somani PR, Somani SP, Umeno M (2006) Planer nano-graphenes from camphor by CVD. Chem Phys Lett 430:56–59

Song Y, He Z, Hou H et al (2012) Architecture of Fe3O4–graphene oxide nanocomposite and its application as a platform for amino acid biosensing. Electrochim Acta 71:58–65

Stankovich S, Dikin DA, Piner RD et al (2007) Synthesis of graphene-based nanosheets via chemical reduction of exfoliated graphite oxide. Carbon 45:1558–1565

Su Z, Wang H, Tian K et al (2016) Simultaneous reduction and surface functionalization of graphene oxide with wrinkled structure by diethylenetriamine (DETA) and their reinforcing effects in the flexible poly (2-ethylhexyl acrylate) (P2EHA) films. Compos Part A-Appl S 84:64–75

Suggs K, Reuven D, Wang XQ (2011) Electronic properties of cycloaddition-functionalized graphene. J Phys Chem 115:3313–3317

Terrones M, Mendez ARB, Delgado JC et al (2010) Graphene and graphite nanoribbons: morphology, properties, synthesis, defects and applications. Nano Today 5:351–372

Toda K, Furue R, Hayami S (2015) Recent progress in applications of graphene oxide for gas sensing: a review. Anal Chim Acta 878:43–53

Wallace PR (1947) The band theory of graphite. Phys Rev 71:622–634

Wan X, Long G, Huang L et al (2011) Graphene - A promising material for organic photovoltaic cells. Adv Mat 23:5342–5358

Wang H, Maiyalagan T, Wang X (2012a) Review on recent progress in nitrogen-doped graphene: synthesis, characterization, and its potential applications. ACS Catal 25:781–794

Wang X, Dong X, Wen Y et al (2012b) A graphene–cobalt oxide based needle electrode for non-enzymatic glucose detection in microdroplets. Chem Commun 48:6490–6492

Wang L, Liu W, Zhang Y et al (2015a) Graphene-based transparent conductive electrodes for GaN-based light emitting diodes: challenges and countermeasures. Nano Energy 12:419–436

Wang Y, Xie Y, Sun H et al (2015b) 2D/2D nano-hybrids of γ-MnO2 on reduced graphene oxide for catalytic ozonation and coupling peroxymonosulfate activation. J Hazard Mater (in press)

Wu ZS, Yang S, Sun Y et al (2012) 3D nitrogen-doped graphene aerogel-supported Fe3O4 nanoparticles as efficient electrocatalysts for the oxygen reduction reaction. J Am Chem Soc 134:9082–9085

Xia F, Farmer DB, Lin Y et al (2010) Graphene field-effect transistors with high on/off current ratio and large transport band gap at room temperature. Nano Lett 10:715–718

Xue B, Zhu J, Liu N et al (2015) Facile functionalization of graphene oxide with ethylenediamine as a solid base catalyst for Knoevenagel condensation reaction. Catal Commun 64:105–109

Yadav SK, Cho JW (2013) Functionalized graphene nanoplatelets for enhanced mechanical and thermal properties of polyurethane nanocomposites. App Surf Sci 266:360–367

Yang M, Yao J, Duan Y (2013) Graphene and its derivatives for cell biotechnology. Analyst 138:72–86

Yang Y, Gao F, Cai X et al (2015) β-Cyclodextrin functionalized graphene as a highly conductive and multi-site platform for DNA immobilization and ultrasensitive sensing detection. Biosens Bioelect 74:447–453

Yu D, Park K, Durstock M et al (2011) Fullerene-grafted graphene for efficient bulk heterojunction polymer photovoltaic devices. J Phys Chem Lett 26:1113–1118

Yu Z, McInnis M, Calderon J et al (2014) Functionalized graphene aerogel composites for high-performance asymmetric supercapacitors. Nano Energy 11:611–620

Yu P, Lowe SE, Simon GP et al (2015) Electrochemical exfoliation of graphite and production of functional graphene. Curr Opin Colloid Interface Sci (in press)

Yuan B, Shi Y, Mu X et al (2016) A facile method to prepare reduced graphene oxide with a large pore volume. Mat Lett 162:154–156

Zarotti F, Gupta B, Iacopi F et al (2016) Time evolution of graphene growth on SiC as a function of annealing temperature. Carbon 98:307–312

Zhang N, Zhang Y, Xu YJ (2012a) Recent progress on graphene-based photocatalysts: current status and future perspectives. Nanoscale 4:5792–5813

Zhang Y, Zhang L, Zhou C (2013) Review of chemical vapor deposition of graphene and related applications. Acc Chem Res 46:2329–2339

Zhang R, Li H, Zhang ZD et al (2015a) Graphene synthesis on SiC: reduced graphitization temperature by C-cluster and Ar-ion implantation. Nucl Instrum Methods Phys Res Sect B 356–357:99–102

Zhang L, Li Y, Wang H et al (2015b) Strong and ductile poly(lactic acid) nanocomposite films reinforced with alkylated graphene nanosheets. Chem Eng J 264:538–546

Zhang Y, Ma HL, Zhang Q et al (2012b) Facile synthesis of well-dispersed graphene by γ-ray induced reduction of graphene oxide. J Mater Chem 22:13064–13069

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Copyright information

© 2016 The Author(s)

About this chapter

Cite this chapter

Ferreira, F.V. et al. (2016). Functionalization of Graphene and Applications. In: Functionalizing Graphene and Carbon Nanotubes. SpringerBriefs in Applied Sciences and Technology. Springer, Cham. https://doi.org/10.1007/978-3-319-35110-0_1

Download citation

DOI: https://doi.org/10.1007/978-3-319-35110-0_1

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-35109-4

Online ISBN: 978-3-319-35110-0

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)