Abstract

Unmanned aircraft systems (GlossaryTerm

UAS

s) have drawn increasing attention recently, owing to advancements in related research, technology, and applications. While having been deployed successfully in military scenarios for decades, civil use cases have lately been tackled by the robotics research community.This chapter overviews the core elements of this highly interdisciplinary field; the reader is guided through the design process of aerial robots for various applications starting with a qualitative characterization of different types of UAS. Design and modeling are closely related, forming a typically iterative process of drafting and analyzing the related properties. Therefore, we overview aerodynamics and dynamics, as well as their application to fixed-wing, rotary-wing, and flapping-wing UAS, including related analytical tools and practical guidelines. Respecting use-case-specific requirements and core autonomous robot demands, we finally provide guidelines to related system integration challenges.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

- Aerial Robots

- Unmanned Aerial Systems (UAS)

- Blade Element Momentum Theory (BEMT)

- Rotorcraft

- Reconnaissance, Surveillance, And Target Acquisition (RSTA)

These keywords were added by machine and not by the authors. This process is experimental and the keywords may be updated as the learning algorithm improves.

1 Background and History

The field of aerial robotics encompasses a very broad class of flying machines that nowadays often possess the perception capabilities and decisional autonomy to accomplish complex tasks without the need for any direct human interventioning. Historically and within the aerospace jargon, robotic flying machines are commonly referred to as unmanned aerial vehicles (GlossaryTerm

UAV

s), while the entire infrastructures, systems and human–machine interfaces required for autonomous operation are often called unmanned aerial systems (UAS). Aerial robotic technologies are currently on the cutting edge of aerospace and robotic research. Breakthrough contributions take place in various fields such as design, estimation [26.1], perception [26.2], control [26.3], and planning [26.4], paving the way for a historical change on how flying systems are operated and what application challenges they fulfill.As a class of systems, aerial robots have their roots in the first guided missiles; however, nowadays they refer to a wide variety of advanced intelligent systems. According to the American Institute of Aeronautics and Astronautics (GlossaryTerm

AIAA

) [26.5], a UAV is defined asan aircraft which is designed or modified, not to carry a human pilot and is operated through electronic input initiated by the flight controller or by an onboard autonomous flight management control system that does not require flight controller intervention.

As is generally the case in robotics, aerial robots tend to become more and more complex systems as a result of the effort to achieve advanced decision making and planning capabilities based on its on-board perception of the environment and a set of relatively abstract mission goals.

Aerial robots posses the unique capability to gently fly over terrain that other robots struggle to roll or crawl over. The price to be paid is related with the advanced challenges in terms of system design, propulsion, perception, control, and navigation. Autonomous flight requires handling of all six degrees of freedom and advanced cognition capabilities within challenging environments. In that sense, perception and navigation complexity drastically increase, while payload and available power consumption for processing tends to be limited, especially as scale decreases. Essentially, the design of aerial robots requires increased attention and thorough selection, or even combination, of one or more existing or new flying concepts, electronic components and algorithms. The design engineer has to assess specific optimization challenges and trade-offs as important desired goals like decreased weight and modularity typically contradict each other.

1.1 A Glimpse of History

Aerial robotics is a field of active research and promising perspectives, yet it already accumulates more than a century of developments. Figure 26.1 depicts some historical as well as recent examples of UAVs in the military and civilian sector. Starting as conceptual designs in the context of the human efforts to develop flying machines, aerial robots soon proved their extensive potential and have already created their own legacy. As was also the case for manned aviation, aerial robotic technologies accelerated within the framework of the 20th century world conflicts. Within World War I, Hewitt–Sperry developed an automatic plane that acted as a flying torpedo, carrying onboard intelligence to autonomously sustain flight over long periods of time. This page-turning success was achieved through the integration of (Sperry’s self-made) gyroscopes which were then mechanically connected to the control surfaces and therefore established the necessary feedback control loop. During World War II, the German armed forces deployed one of the first successful cruise missiles, the V–1. Despite the fact that V–1 had limited success rate it did incorporate most of the elementary components, estimation algorithms and control loops that can allow autonomous navigation and reference tracking. Military applications kept being, and still are, the main driving force of aerial robotics research and the newest developments in the area change and shape the modern warfare. With the introduction of global positioning systems (GlossaryTerm

GPS

s), aerial robots managed to achieve the first completely autonomous surveillance missions. As information and intelligence gathering became one of the most important aspects of the world’s open or silent conflicts, military research around the 1970s led to systems equipped with cameras and other sensory systems, giving birth to the UAV prototype the way we know it today. However, civil applications are currently emerging at a very fast pace and the majority of market predictions converge to the conclusion that this area will take dominant characteristics, and most importantly, will become an equally important – if not more – innovation drive.Within this framework, the advancements in the field of microprocessors, miniaturized sensing, as well as actuator efficiency and downscaling greatly accelerated the field of aerial robots and paved the way for the great achievements we observe today. Aerial robots have advanced to a state in which sophisticated sensor modules for onboard state estimation and environmental perception, powerful embedded processors running sophisticated navigation algorithms, potentially several communication interfaces, as well as high-end-mission-oriented payloads that enable the execution of challenging tasks, can be tightly integrated.

2 Characteristics of Aerial Robotics

This section aims to provide an overview of the key characteristic features and properties of different aerial robotic configurations as well as a classification based on the key advantages and limitations of some of the most common flying concepts found in unmanned aviation.

2.1 Aerial Robots Classification

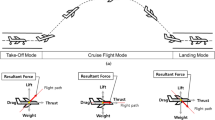

Compared to the categorization of manned aviation, aerial robots classification is more complex, as the term currently refers to a very wide variety of systems of different scale, mechanical configuration, and actuation principles. In their vast majority, aerial robots correspond, in one way or another, to miniaturized versions of manned aircraft designs. Relatively classical fixed-wing unmanned aerial systems (FW-UAS) designs and rotary-wing unmanned aerial systems (RW-UAS) such as those shown in Fig. 26.2 are common vehicle configurations one may encounter in most applications, including those of surveillance, monitoring, inspection, mapping, or payload transportation. However, even within these relatively traditional concepts, several design aspects differ from those chosen for manned systems. This reflects the fact that for different scales, the variation of the physical properties behavior, along with the search for optimized designs, will naturally lead to modified and novel design considerations. This is further triggered by the fact that the absence of a pilot on-board unlocks a wide set of engineering choices, typically out of question or even forbidden in manned aviation. As expected for a multitude of engineering reasons, large UAS tend to follow design concepts closer to – while at smaller scale to classical designs while as scale decreases innovation – at the level of the flying principle – becomes more and more intense.

Apart from lighter-than-air systems (GlossaryTerm

LtA-UAS

), FW-UAS tend to be the most power efficient flying principle, while RW-UAS are tailored to increased maneuverability as well as the ability of stationary vertical flight (hovering). This general classification (also valid for manned aviation) is then further complicated with the relatively large class of convertible designs (such as tilt-rotors or cruise-flight-enabled ducted fans). This first attempt for aerial robots classification has then to be further augmented to account for the biologically inspired concepts, and especially the emerging field of flapping-wing UAS (GlossaryTermFl-UAS

). Figure 26.2 provides an abstract – yet incomplete – overview of the vehicle classes one may encounter in most of the application fields. As shown, a large diversity is observed as a result of the engineering efforts to propose designs with optimized endurance, agility, controllability, or even simplicity in a very wide scale range. In the following subsections, a brief overview on how the main aerodynamic forces and effects depend on the design scale of an aerial vehicle are provided.2.2 The Effect of Scale

The understanding of how aerial vehicles manage to remain airborne, provides a useful insight into the effect of scale, and how different dimensioning has a huge impact on the efficiency of every flying machine. Table 26.1 provides an overview of the formulas expressing the lift force, as well as the drag forces that govern the flight of the most common UAS configurations. More detailed definitions on the aerodynamic forces can be found on the subsequent sections.

Within these equations, ρ is the density of the air while the remaining parameters are specific to the vehicle configuration. For FW-UAS, cL and cD represent the wing lift and drag coefficients, respectively, A is the wing area, and Vt denotes the airspeed. For the case of RW-UAS, cT and cQ denote the rotor thrust and drag coefficients, is the rotor disk area, Ω is the angular velocity of the rotor, and R is the rotor disk radius. Finally, for LtA-UAS, VLtA is the volume of the blimp, is the drag coefficient depending on the blimp shape, Vt is the blimp’s airspeed, ALtA is the blimp surface in the direction of motion and ρgas is the filling gas density. Figure 26.3 illustrates these forces on the body of the relevant aerial vehicle configurations.

Main aerodynamic forces applied on (a) fixed-wing, (b) rotary-wing, and (c) lighter-than-air systems. (a) AtlantikSolar is a solar-powered FW-UAS developed by the Autonomous Systems Lab at ETH Zurich, (b) Firefly is developed by Ascending Technologies GMBH, while (c) Skye is developed by students of ETH Zurich

Derivation of scaling laws starts with the observation of the lift and drag forces and how these are functions of scale-dependent parameters such as the area of the wing or the rotor radius. Proper dimensioning is essentially a very complex procedure where a multitude of factors has to be taken into account. Among others, one has to account for the issues of aerodynamics efficiency, availability of propulsion systems at a given scale, the technologies they employ (e. g., electric motors, jet engines) as well as the simplicity and robustness of the corresponding mechanical configuration. In the following, scaling laws and relevant design guidelines for fixed-wing, rotary-wing, and lighter-than-air systems are provided. Only a brief overview is provided for the case of flapping-wing systems, as the effect of scale on such UAS configurations is separately discussed within Sect. 26.6.

2.2.1 FW-UAS

Scaling laws express the dominant role of size and scale for a given vehicle configuration. In the case of fixed-wing systems, the wing loading, defined as the ratio of the weight (W) versus the wing area A, is the key parameter one has to focus to get some first insight on the role of scale. The Tennekes diagram shown in Fig. 26.4 provides a visual interpretation of this fact [26.6]. Working around the point that the lift force exactly counteracts the weight, the indicated trend line was derived using the following formulas [26.7]

where Vt is the airspeed, W is the weight, A is the wing area, bw is the wing span, and cw is the wing chord. These equations express the role of the lifting properties of the airfoil and airspeed against the ratio of the weight of the flying body and its wing area. For this analysis, a fixed aspect ratio is assumed for all sizes of aircraft. Although such a simple analysis does not account for the details of the fluid dynamics environment between the different aircraft sizes, it is known that smaller aircrafts are typically built with lower aspect ratios, and that the difference in aspect ratio over existing aircraft within the size range of interest is significant.

2.2.2 RW-UAS

For the case of rotorcraft configurations, similar scaling laws regarding the vehicle efficiency may be derived. It is important to highlight however that especially for rotorcrafts, working with scaling laws demands that one has to simultaneously focus on both efficiency and dynamic response in order to avoid undesired effects in the vehicle flight dynamics such as unstable oscillations. Regarding the power efficiency, let power loading (GlossaryTerm

PL

) be defined as T ∕ P, where P corresponds to the ideal power. As the induced ideal power to hover is given by , the ideal power loading will be inversely proportional to the induced velocity at the rotor disk υiObserving Fig. 26.5, it is shown that the ratio T ∕ P decreases quickly with increasing disk loading. Therefore, configurations with proportionally smaller rotors against their mass will tend to be less efficient in hovering flight; that is, the rotor will require proportionally more power to generate the required amount of thrust. It is also to be noted, however, that calculation of the actual power loading and rotor efficiency requires the consideration of viscous losses.

From the above brief analysis, we concluded that in general the tendency to increase the rotor dimension favors efficiency. However, this is not the only scaling law one has to consider. Rotorcrafts are particularly complex dynamic systems and scaling considerations also have to focus on dynamic aspects of their flight. A more concrete analysis may take place using Froude or Mach scaling models. Let N denote the length scale between two vehicles, Rm the rotor radius of the model vehicle, and Rp the rotor radius of the prototype vehicle: thus, a scale factor N denotes a helicopter times the size of its prototype. Table 26.2 summarizes the Froude and Mach scaling laws that account for the role of scale in a set of significant parameters namely the length of the model and the prototype Lm, Lp, the dominant time constants tm, tp of the inner-loop characteristic response, the characteristic velocities Vm, Vp, the weight values Wm, Wp, the expected moments of inertia Im, Ip, and the response-dominant frequencies ωm, ωp.

These, slightly more advanced scaling laws, further provide the opportunity to assess the aspects of main rotor performance, and more specifically the expected thrust margin. Traditional manned helicopters have small thrust margins in hover, typically 5–10 % while miniaturized vehicles often present very high values. Mach models predict in general faster rotor speeds as compared to Froude scaled models, which consequently leads to a lower expected thrust coefficient. The thrust coefficient reflects the lift loading of the rotor. For a given, single rotor configuration, the maximum thrust is provided by the following expression

where σ represents the blade solidity (Sect. 26.3.4 ). This relation gives a maximum thrust that scales as for a Froude model and as for a Mach model. Once divided by the vehicle weight which scales as , it is deduced that Froude models present a similar thrust-to-weight ratio. On the contrary, for a Mach model, there is an increasing expected maximum thrust-to-weight: . Using these formulas, researchers in [26.8] calculated the scaling parameters for several conventional helicopters that provide intuitive insight on how scaling laws work.

2.2.3 LtA-UAS

For the case of lighter-than-air vehicles simple scaling laws regarding the efficiency of the system hold. Considering the example of a spherical blimp, it is directly deduced that the lift force scales with the cubic power of the radius. On the other hand, its mass, which depends on the surface, scales with the square power of the radius and also does the drag force. This essentially indicates that larger blimps will tend to have a higher maximum lift to weight and lift-against-drag force ratios.

2.2.4 Fl-UAS

Analysis of the scaling laws for flapping wing systems requires a different treatment, as the flight modality changes while the robot operates in hover mode or navigates in forward flight. Furthermore, the lift and drag coefficients are dependent on the airfoil characteristics of the wing and also on the flapping frequency, a fact that further increases the complexity of the analysis on the effect of scale. Section 26.6 provides insight on how to deal with this challenging issue so that proper flapping wing systems design is achieved.

3 Basics of Aerodynamics and Flight Mechanics

Assembling an analytic representation of a UAS involves the derivation of approximative expressions for the aerodynamic forces, accounting for the actuator dynamics and appending the resulting effect to the vehicle body equations of motion. The goal of this section is to provide the necessary insight and understanding of the underlying mechanisms and physical phenomena along with the derivation of the formulae for the most dominant effects one has to account for with any UAS configuration.

3.1 Properties of the Atmosphere

Assessing flow properties forms the basis for any further qualitative or quantitative aerodynamic analysis relevant for aircraft design, modeling and control. The international standard atmosphere (GlossaryTerm

ISA

) [26.9] provides a reference for the average main air characteristics as a function of altitude. Figure 26.6 shows the evolution of air temperature Tair, pressure p, and density ρ. These parameters largely affect the Reynolds number Re, which can be interpreted as the influence of inertial forces as compared to viscous forces of a flow, as well as the Mach number Ma representing the ratio of airspeed versus speed of sound.Variation of (a) air temperature, (b) pressure, and (c) density with altitude in the lower part of the International Standard Atmosphere.The tropopause, above which the temperature is not further decreasing, corresponds to the red dashed line. It constitutes the upper limit of common weather phenomena

It is noteworthy that the above parameters may be brought into relationship by the ideal gas law

with denoting the ideal gas constant of air.

In contrast to aerodynamics, where forces, first and foremost lift, is generated by motion of an object through the air, the aerostatic lift force is formed solely by static properties of an object. It forms the basis of operation for a balloon or blimp.

According to Archimedes’ principle, the aerostatic lift Lstat pointing upward, amounts to

where g stands for the Earth gravitational acceleration, V for the volume of the object, and m for its mass. To state an example, consider a helium balloon of spherical shape with a diameter amounting to 1 m in the lower atmosphere. Neglecting its hull weight (thus with ), it will generate an aerostatic lift force of 5.4 N, representing an upper bound for any kind of total design mass including payload. Increasing the diameter of said sphere to 1.5 m has the huge effect of increasing lift to 18.1 N.

3.2 General Fluid Dynamics and 2-D Flow around Airfoils

A general airflow around an aircraft is three-dimensional, unsteady, and may be turbulent, even interacting with a nonrigid structure. In this setting, computations are almost intractable. We will thus rely on certain simplifications in order to allow simpler calculations and notably enhancing the understanding of a flow field together with resulting forces and moments. In both airplane and rotorcraft aerodynamics, the assumption of a locally two-dimensional (GlossaryTerm

2-D

) flow can be very helpful to serve as a starting point for more advanced computation.Before diving into a formal treatment, the example in Fig. 26.7 depicts some characteristic elements of 2-D flow around an airfoil.

Notice that the pressure distribution on the airfoil contour is induced by the flow field, making the most significant contribution to the aerodynamic force and moment. However, also viscous effects yield a typically unwanted share in the overall force (and moment) in the form of shear stress transmitted to the surface. The elements overviewed in Fig. 26.7 will now be explained in the following paragraphs.

3.2.1 Finite Control Volume Analysis: Mass and Momentum Conservation

Consider a finite control volume B bounded by the surface S with normal n, which may contain a body or airfoil, depending on the context. For convenience, parts of the boundaries are often chosen to be streamlines (in 2-D) or stream surfaces (in GlossaryTerm

3-D

). For this volume, the conservation of mass must be fulfilledwhere n denotes the fluid velocity vector.

From classical Newtonian mechanics, we can furthermore postulate the applicability of conservation of linear and angular momentum

where r denotes the position vector.

3.2.2 Differential Volume Analysis: Euler and Bernoulli Equations

When applied to a differential volume and assuming inviscid flow, (26.7) can be used to derive Euler’s equation

This equation forms the basis of many finite-element-based numerical tools neglecting viscous effects outside the boundary layer. Such methods employ potential flow theory along with some boundary layer analysis module; free example tools are JavaFoil [26.10] and xfoil [26.11] for 2-D flow computation as well as XFLR [26.12] allowing also 3-D flow extensions.

When applying (26.9) along a streamline and under the assumption that the flow is incompressible (a fair assumption for low-speed aerodynamics up to ), Bernoulli’s equation relating speed (Vt) and pressure can be formulated

where g denotes gravitational acceleration and h the elevation – the aerostatic pressure component can often be neglected due to small elevation changes along a streamline.

3.2.3 Viscous Effects and the Boundary Layer

While it is often a valid approximation to neglect viscous effects far enough from the body surfaces, they have to be considered within the boundary layer, where the fluid is slowed down to meet the speed of the surface. The friction shear stress τw transmitted to the surface is characterized by the gradient of the flow speed perpendicular to the surface

where μ denotes the dynamic viscosity of the fluid, U stands for the airspeed parallel to the surface, and n for the coordinate along the surface normal n. This tangential fluid velocity gradient in the boundary layer is visualized qualitatively in Fig. 26.7.

The boundary layer will be laminar around the nose, with the fluid moving parallel to the surface. At some point (at a critical local Reynolds number), however, influenced by disturbances such as surface roughness, a transition to a turbulent boundary layer will occur: it is characterized by stochastic fluctuations, significantly thicker and producing substantially more friction than before the transition.

3.2.4 Section Lift, Drag, and Moment Representation with Dimensionless Coefficients

Historically and for practical reasons, the aerodynamic force is split into a component perpendicular to the inflow direction called lift, and a second one parallel to the inflow called drag. We write 2-D lift, drag, and moment as infinitesimal quantities , , and , respectively, as opposed to L, D, and M designating physical forces of a whole airplane. Figure 26.8 visualizes these quantities. Furthermore, we define the angle of attack α as the angle between inflow direction and the chord line of length c connecting airfoil leading edge and trailing edge. Note that force and moment are reduced to the point at , i. e., one quarter of the chord behind the leading edge.

Dimension analysis suggests the formulation of aerodynamic forces and moments in terms of section lift, drag, and moment coefficients cl, cd, and cm

where Vt stands for the inflow speed and denotes an infinitesimal length element perpendicular to the 2-D flow (which can be interpreted as a length element into span-wise direction of an infinitely long wing).

These coefficients largely depend on the angle of attack α; but furthermore, the Reynolds and Mach numbers significantly influence them as well. The angle of attack dependences are typically given in the form of section lift, drag and moment polars, an example of which is provided in Fig. 26.9. Note that the drag component is originating both from viscous skin friction as well as form drag, caused by an asymmetric pressure distribution due to boundary layer development and separation. The lift curve shows its characteristic linear increase with increasing α for small angles of attack. The maximum and minimum lift values beyond which stall is entered are clearly visible in the lift polar. Note that the aerodynamic performance of the airfoil generally decreases with smaller Reynolds numbers as expected. The choice of reference point at typically leads to a mostly constant moment coefficient when varying α, cl, respectively, as can be seen in Fig. 26.9 as well.

3.2.5 Separation and Stall

At the upper side of the airfoil, the fluid is moving from the under-pressure region toward a higher pressure at the trailing edge; the slower moving fluid in the boundary layer will at some point not be able to follow this adverse pressure gradient, leading to flow separation. As the angle of attack is increased, the separation point suddenly moves far toward the leading edge: this condition is referred to as stall, with the catastrophic consequence of significant loss of lift and increase of drag. Figure 26.10 illustrates the changes in the flow and pressure distribution when varying the angle of attack. Note that the maximum lift and stall conditions are highly influenced by the choice of airfoil, Reynolds number, and Mach number.

3.3 Wing Aerodynamics

So far the 2-D flow characteristics around airfoils were treated. This will form the basis for the understanding and computation of lift and thrust forces generated on any type of aircraft; the following treatment of a finite wing serves as an important example of how to include three-dimensional (GlossaryTerm

3-D

) flow effects.Recording lift and drag polars for a finite wing rather than just for its airfoil reveals less lift increase per angle of attack increase, less maximum lift, and higher drag at raised angles of attack. These observations are related to the concept of induced flow to be treated in the following.

3.3.1 Vortex System of a Wing

As a direct consequence of lift, we observe a downward flow deflection across an airfoil. This is intuitively explained with conservation of linear momentum as stated in (26.7). Assuming an inviscid and incompressible fluid, the flow may be modeled with potential field theory [26.13], where the velocity vector field is defined as the gradient of a scalar function. This concept allows for the insertion of singularities into a free stream, such as sources, sinks, and vortices. Figure 26.11 shows a first approximation using a single vortex – conceptually illustrating the flow characteristics around a simplified wing. The vortex system consists of the bound vortex and tip vortices; note that the vortex will in theory have to be closed to a ring by a starting vortex. In practice, i. e., in the presence of friction, the vortices will of course decay over time. Figure 26.12 illustrates the existence of tip vortices trailing an airplane wing.

The vortices induce a downwash area behind the wing; nevertheless, the trailing vortices will also induce some downward flow at the wing.

3.3.2 Induced Drag

With the simplified concept of the vortices around a wing in mind, we conclude that the wing lift induces downward flow, thus reducing the effective angle of attack when looking at the 2-D-flow of a wing cross-section. Figure 26.13 illustrates this reduction of the angle of attack from αf (free stream) to αe (effective) by the induced angle αi that is caused by the induced flow component wi. Note that this reduction of angle of attack is typically resulting in a smaller lift. Furthermore, when decomposing the lift into components parallel and perpendicular to the free stream velocity, it becomes apparent that a part of the lift results parallel to the effective inflow, thus will contribute to the overall drag of the wing. The integral of these components is referred to as induced drag. The actual amount of induced drag largely depends on the wing geometry; a variety of approaches have been employed in order to minimize induced drag, the most popular of which are winglets. For an approximately elliptical lift distribution, the induced drag coefficient can be roughly calculated as

with the aspect ratio Λ and the Oswald efficiency e (deviation from the truly elliptic distribution) amounting from 0.7 to 0.85 for typical configuration.

3.3.3 Lifting Line Method

In the following, we present one example of how to numerically approximate the lift and drag distribution of a wing including induced drag. The lifting line method is a GlossaryTerm

2.5-D

(two-and-a-half-dimensional) approach in which the induced flow is viewed as generated by several discrete horseshoe vortices rather than just one as introduced qualitatively earlier. Figure 26.14 depicts the geometry and variables involved. Note that the method only provides reliable results, if the assumption holds that spanwise flow is negligible; in particular, spanwise variation of parameters such as chord length and twist is supposed to be rather small. The Kutta–Joukowsky theorem relates circulation and lift; applied to a discrete wing segment, we obtainwith the segment (index k) circulation Γk, the local chord length ck, and the local airfoil lift coefficient . The lift coefficient depends on the effective angle of attack: . The induced downwash at position mk is obtained by adding the induced speeds of all the individual vortices according to Biot–Savart

where eV stands for the (unit) direction of flight. At mk, the induced angle of attack is calculated as

Together with the respective 2-D polar data, the above relations allow calculating the lift, drag, and moment distribution (with respect to the free inflow direction eV) from a known circulation distribution, and can be summed and reduced to, e. g., the center of mass of a whole airplane. Note that the section lift coefficient is often approximated linearly as , which allows for a direct solution when applying (26.16) and (26.17). More accurate results, in particular in the domain near maximum lift, however, are obtained by using the nonlinear lift polar. In this case, a standard iterative numeric solver may be used. Furthermore, airfoil data with deflected control surfaces can be included, allowing to calculate control moments (and forces).

Note that the above method is just one example of numerically solving for the wing characteristics knowing the 2-D airfoil properties (polars) – well-suited for low-speed medium to high aspect ratio wings. For an overview on alternatives, the reader is referred to, e. g., [26.13].

3.4 Performance of Rotors and Propellers

The propulsion mechanism found on many robotic aerial vehicles is commonly a specific configuration of propellers or rotors. In the case of a robotic airplane, forward facing propellers produce thrust forces compensating drag in forward flight. In case of a tail sitter or multicopter UAV, the propellers may be facing up (or down) and produce the main lift component compensating the vehicle’s weight allowing it to hover in the air. Similarly, the more classic helicopter-type configurations (single rotor with tail rotor, coaxial rotor, tandem rotor, etc.), use rotors to generate the required thrust force to fly.

In order to decide on a suitable rotor or propeller geometry and to define requirements for the UAV motor drives, models must be available which allow for an assessment of the thrust and torque characteristics of a particular rotor or propeller. For this purpose, the blade element momentum theory (GlossaryTerm

BEMT

) has found widespread use, as it often provides a prediction accuracy which is acceptable for the UAV design process (despite its simplicity).3.4.1 Blade Element Momentum Theory

One of the basic difficulties in aerodynamic rotor and propeller studies is the prediction of the induced inflow velocities discussed in Sect. 26.3.3. BEMT addresses this problem by combining two simple modeling approaches, namely momentum theory (GlossaryTerm

MT

) and blade element theory (GlossaryTermBET

) which individually cannot directly resolve this issue in an accurate manner [26.14].The basic idea of momentum theory is to consider the revolving propeller or rotor as a propulsion disk which produces a thrust force by accelerating the surrounding (incompressible) air mass passing through it. A boundary volume is defined encapsulating the propulsion disc. Subsequently, the laws of mass, momentum and power conservation are formulated across the boundaries of the defined control volume. The concept of this propulsion disk as well as the corresponding control volume are visualized in Fig. 26.15.

From this simplistic model, two main conclusions may be drawn. First and foremost, it is possible to establish a relation between the induced velocity vi at the propulsion disk and the produced thrust force T. In normalized form, it can be expressed as

To simplify notation, the external airflow velocity as well as the induced velocity vi have been normalized with the rotor or propeller tip speed

and the nondimensional thrust coefficient cT is defined as

The parameter ρ corresponds to the density of air, R to the rotor or propeller radius, and Ω to the rotor or propeller angular speed.

In case of a robotic airplane, the velocity at the start of the control volume corresponds to the body forward flight velocity Vt and in case of a rotorcraft configuration to the body climb respectively descent rate w.

Similarly, an incremental expression for the thrust coefficient may be found from MT by evaluating the mass, moment, and power conservation laws over an annular ring of the defined control volume only. The corresponding expression can be found as

where and are the normalized radial location and the radial increment of the propulsion disk annulus.

Another relevant conclusion that may be drawn from MT is that ideally, the induced component vi of the slipstream velocity at the propulsion disk will accelerate to two times its initial value before leaving the control volume. In consequence to this acceleration of the flow field, the radial slipstream boundary will (in the ideal case) contract to half the propulsion disk area at the end of the control volume.

For the BET approach, the modeling process starts by investigating the aerodynamic lift and drag forces and on an individual rotor or propeller blade revolving around its shaft. These lift and drag forces produced by each airfoil segment depicted in Fig. 26.16, contribute to the total thrust and torque increments and of the respective rotor or propeller annular section. The corresponding relation can be established as

In this context, Nb represents the number of rotor or propeller blades and Φ corresponds to the local inflow angle which is assumed to remain small. Under this assumption, the inflow angle Φ can be directly derived as the ratio between the local perpendicular inflow velocity and the tangential velocity visualized in Fig. 26.16b. Additionally, the assumption introduced in (26.23) is justified by the fact that at low angles of attack α, the drag forces are at least one order of magnitude smaller than the corresponding lift forces .

Based on (26.23) and the definition of the lift increment (26.12), the local thrust coefficient at each radial blade station r may be derived as

The parameter c corresponds to the local blade chord and σ is the so-called rotor or propeller solidity. The solidity is a rough metric representing how much of a propulsion disk is covered by rotor or propeller blades. The aerodynamic parameter corresponds to the airfoil lift coefficient in function of the local angle of attack α and the local Reynolds and Mach numbers Re and Ma.

Accordingly, as established in (26.25), the thrust produced by a rotor or propeller strongly depends on the angle of attack α, which itself is a function of the local airfoil pitch angle θ and the inflow angle Φ

In conclusion, MT as well as BET are capable of establishing a meaningful relation between the induced velocities vi and the resulting thrust force T. However, none of the two theories are capable of accurately predicting rotor or propeller performance as either the radial distribution of the induced velocity or the radial distribution of the thrust coefficient must be known to compute the other.

The basic idea behind BEMT is to combine the thrust expression (26.22) resulting from MT with the thrust expression (26.25) from BET to compute the induced inflow velocity independently of the thrust force. Different BEMT implementations are possible depending on how willing one may be to introduce further assumptions for the section lift coefficient cl.

Reference [26.14] presents a straightforward approach tailored toward helicopter rotors operating bellow stall by introducing a linear model for cl in function of the angle of attack

The parameters and can be computed from the lift polars of a particular airfoil geometry for a given range of angles of attack, Reynolds, and Mach numbers. This linear approximation may have limited validity for very low Reynolds numbers and strongly cambered airfoils but is in general acceptable for many typical airfoil geometries found on UAV rotors and propellers. Assembling (26.22) and (26.25) under the assumption (26.27), an algebraic expression of the radial induced inflow distribution can be derived as

Note that the lift-curve offset has been absorbed in the virtual pitch angle

to simplify the notation.

Once the approximate radial distribution of inflow velocities has been found, the local rotor or propeller thrust increments (26.25) can be computed. Similarly, the rotor or propeller torque increments derived from BET as

can be evaluated based on the inflow distribution given in (26.28). For clarity, the total torque coefficient increment has been separated into its induced component originating from the lift forces and its profile component due the drag forces. The aerodynamic drag coefficient can be approximated using a quadratic function in dependency of the angle of attack [26.14]

The parameters , , and can be computed from the drag polars of the modeled airfoil.

Consequently, the thrust and torque increments may be integrated along the radial direction of the rotor or propeller disk to compute the total thrust and torque coefficients

These thrust and torque integrals are usually evaluated numerically, as the blade pitch as well as the blade chord may be nonlinear functions of the radial direction r (blade twist and taper).

Finally, note that the presented theory may be extended to provide performance estimates under lateral inflow velocities such as in case of a rotorcraft in forward flight and may also be used to asses other types of rotor or propeller configurations such as, e. g., the coaxial rotor. Also note that the prediction accuracy of BEMT tools can be further improved by accounting for tip-loss effects and the nonlift producing rotor or propeller hub, e. g., using the Prandtl tip-loss function also presented in [26.14] and incorporating a root cutout radius R0.

The resulting predictions are generally in good agreement with experimental data – nevertheless, an experimental verification is strongly recommended.

3.5 Drag

The sources of drag on aircraft are manifold: historically, the distinction between the lift-dependent induced drag and parasite drag is made. The latter is further subdivided into skin friction drag due to viscous shear stress at the surface, and form drag, generated by pressure loss along bodies (i. e., due to boundary layer development or even flow separation). Both these components contribute to the airfoil profile drag, i. e., the section drag coefficient cd introduced before.

On a whole aircraft, many more drag sources are distinguished. For an exhaustive overview, the interested reader is referred to [26.13]. In the following, we will present an overview of drag generated by different typical shapes; note that when simply summing drag of different shapes associated with aircraft parts, the result may be a helpful initial estimate, but can be inaccurate, because of neglecting the interaction of flows resulting in interference drag. Depending on the stage of the design process or the desired modeling accuracy, 2.5-D computations or even full 3-D computational fluid dynamics (GlossaryTerm

CFD

) simulations might be necessary to satisfy the needs of aerodynamics calculations.3.5.1 Skin Friction

The simple but important example of a flat plate of length l in parallel flow is well studied. As introduced in the airfoil theory Sect. 26.3.2, the boundary that develops will be laminar near the leading edge and transitions into a turbulent one, generating more drag, at some point downstream. The friction coefficient is defined as

with the wetted surface Sw and the friction drag force Df. According to [26.13], the coefficients can be approximated by

Note that the point of transition is depending on the local Reynolds number , where x denotes the coordinate along the flow from the leading edge of the plate. Depending on the surface roughness and ambient turbulence, the critical (transition) Reynolds number varies; as an average guess for a flat plate, it will be in the order of .

3.5.2 Drag Coefficients for Selected Bodies

In the following, drag coefficients for a selection of 2-D and 3-D bodies of rotation are given, obtained from [26.13]. Table 26.3 overviews a category of bodies, the drag coefficients of which are largely indifferent to the Reynolds number, owing to their geometrically defined (sharp edge) flow separation point.

Rounder bodies, most prominently the cylinder in cross-flow or the sphere, however, show a distinctively different behavior quantified in Table 26.4: below a critical Reynolds number , the drag coefficient is significantly higher, where separation occurs before boundary layer transition. In contrast, above the critical Reynolds number, the turbulent, more energetic boundary layer separates only further downstream, reducing the wake and thus the amount of form drag.

A third important object category is formed by streamlined and fuselage-like bodies: due to their comparably high skin friction part, the fineness ratio largely influences the drag coefficient (along with the Reynolds number). The fineness is defined as body length divided by body diameter. We introduce a volumetric drag coefficient as with the body volume Vm. Interestingly, this is minimal and approximately constant at fineness ratios between 4 and 10, which provides a range for optimal sizing of such a body when a certain volume needs to be fitted. The values are given in Table 26.5.

3.6 Aircraft Dynamics and Flight Performance Analysis

Sections 26.3.1–26.3.5 shortly presented the basic theory of wings, rotors, and propellers as well as a few tools to assess their respective aerodynamic performance. To develop fully functional UAV platforms, merely evaluating the individual flight mechanisms is a good starting point but generally not sufficient.

Designing high-performance aircraft systems requires a fundamental understanding of how the respective design parameters affect the full flight dynamic response and application-specific capabilities. In order to comprehend how design changes affect an aerial robotic system, representative models of its flight dynamics are required. Such models must be capable of capturing the dominant system dynamics within the relevant part of the flight envelope. Furthermore, especially in an interdisciplinary field such as robotics, these models must be accessible to the nonaerodynamic expert (the roboticist) and thus need to be simple enough to provide the required insight for the aircraft design process.

As many other types of robots, robotic flight platforms may be treated as a multibody system where a set of interlinked bodies exchanges kinetic and potential energy under the influence of external forces and moments. For aircraft systems it is common to treat the entire aircraft as a single rigid body first, with related body coordinate frame attached, as visualized in Fig. 26.17. Additional dynamics such as for example rotor flapping (as in case of a helicopter system) may be appended to these body dynamics in a subsequent step.

The modeling process thus starts by treating the aircraft system as a rigid body affected by external forces F and external moments . Using the Newton–Euler formalism to derive the aircraft body dynamics, one can directly write down the linear and angular momentum balance for a single rigid body

For simplicity’s sake, (26.39) is usually expressed with respect to a body fixed frame B located in the center of gravity of the aircraft. The velocity vectors and thus represent the aircraft linear and angular velocities with respect to B. The inertial properties of the above body dynamics are defined by the aircraft’s total mass m and its second mass moment of inertia also expressed with respect to B and its origin.

The most relevant contribution to the forces and the moments originates from the aerodynamic flight components such as wings, propellers and rotors. By integrating (26.39) over time one may compute a prediction of the aircraft’s dynamic response to these external forces and moments and thus the evolution of its absolute pose. This pose is commonly represented by the position of the vehicle’s center of gravity as well as the vehicle’s orientation relative to an earth fixed world frame W which is considered inertial. The aircraft orientation is commonly represented using rotation matrices or quaternions. In the case of the rotation matrix representation, the aircraft orientation may be parameterized in three dimensional space by three consecutive rotations with the roll, pitch, and yaw angles , and as

In this case, relations between the body frame velocities and and the world frame pose can be expressed as

where corresponds to the skew-symmetric matrix of the vector .

In a minimal form, the orientation dynamics can be expressed in terms of roll, pitch, and yaw angles

Note that the Jacobian Jr becomes singular at the boundaries of .

As a singularity-free, but still compact representation of orientation, quaternions may be used. Using the representation with real part qw, the rotational kinematics become

with the matrix defined as

In summary (using quaternions), we thus have the equations of motion

Note that the external forces and moments are related to the system’s actuator inputs u, the vehicle’s orientation with respect to W and they typically are also functions of the linear and angular body motion as well as additional dynamics terms, represented here by the vector

The additional dynamics may account for structural dynamics such as rotor flapping in case of a robotic helicopter or relevant actuator dynamics.

The resulting nonlinear system dynamics can usually be cast into state-space form and represented as

where the nonlinear functions f define the rate of change of the aircraft body states xb as well as the additional states xr affected by the set of N actuator inputs u1 to uN.

In order to gain a deeper understanding of how (26.48) is affected by changes of the flight system’s geometric, structural, inertial, and aerodynamic parameters, three main problems are commonly of relevance [26.15]:

-

The trim problem deals with the computation of the set of actuator inputs under which the nonlinear dynamic system presented in (26.48) remains in a desired trim point and thus . The most simple example of such a trim point is the hover condition for a rotorcraft system where one may want to find the required rotor speed Ω0 to hover or the steady forward flight condition for a fixed-wing UAV at a forward velocity Vt.

-

The topic of stability deals with the question of how easily the system (26.48 ) will deteriorate from a specific trim condition under the influence of small disturbances and . This investigation commonly involves the linearization of (26.48) according to

(26.49)where the eigenvalues and vectors of A will provide deeper insight into the motion characteristics and stability properties of an aircraft.

-

Analyzing the System Response

(26.50)to characteristic inputs such as steps, pulses or specific input frequencies will provide additional information about the flight characteristics of a specific aircraft configuration.

These modeling and analysis concepts commonly find wide applicability for various types of robotic flight configurations and will be discussed in more detail for the specific UAV types presented hereafter.

3.6.1 Actuator Dynamics

Deriving the aerodynamic forces is combined with the dynamic equations of motion in order to assemble a complete model of the flying vehicle. However, as the employed actuators are of naturally limited bandwidth, accurate modeling furthermore requires the integration of the relevant motor or servo dynamics.

Nowadays, motors utilized in small size unmanned systems often belong to the category of brushless direct-current (GlossaryTerm

DC

) electric motors (BLDC). BLDCs are synchronous motors powered by a DC electric source via an integrated switching power supply. The equations of motion for a such a system are essentially nonlinear and rather complex. However, working with small UAS, we may solely focus on the input–output dynamics which can be described with the following transfer functionwhere , correspond to the Laplace expressions of the linearized angular velocity and input torque, Km is the mechanical gain, τm represents the mechanical time constant, is the rotor gain, is the rotor time constant, K depends on electromagnetic properties of the motor and denotes the stator current linearization point [26.16]. Often, a satisfactory speed controller and BLDC dynamics description is obtained as the relation between a reference angular velocity and the actual output taking the even simpler first-order form

with the time constant τmc of the controlled motor.

Accounting for motor dynamics is essential for high-bandwidth control of agile vehicles that highly depend on such actuators (i. e., multirotors). However, in several other UAS configurations such as fixed-wing vehicles or conventional helicopters may, if needed, rather account for servo dynamics acting on control surfaces or a swashplate. Again, the relevant servo angle dynamics can be captured by an identified first-order transfer function of the form , with the servo time constant τs.

4 Airplane Modeling and Design

Ever since the beginning of aviation, a broad spectrum of airplanes has been built and operated successfully: size, speed, and maneuverability vary widely and as a function of application. Since design and modeling are strongly related, we want to first give an overview of the physical principles common to all such configurations, and provide analysis tools for characterizing static and dynamic properties of an airplane. The design problem somewhat constitutes the inverse problem: for specified target characteristics, the engineer needs to find a suitable configuration; we therefore provide a summary of design guidelines aimed at fast convergence to a suitable design. Finally, a simple and classical autopilot scheme is presented underlining the need for models also at that stage.

4.1 Forces and Moments

Consider Fig. 26.18 for the introduction of airplane geometry definitions and main forces. Forces and moments are reduced to the airplane center of gravity (GlossaryTerm

COG

). Note that the angle of attack (GlossaryTermAOA

) α is defined as the angle between the x-axis and the true airspeed vector vt projected into the body x–z-plane, β denotes the sideslip angle, causing a typically unwanted sideslip force Y, L, and D denote lift and drag, W stands for the weight and T for thrust, which may act into a direction different from x (at a thrust angle ϵT). We furthermore write the aerodynamic moment vector as . Also note the introduction of the main control surfaces that are designed to mainly influence the aerodynamic moment: with ailerons, elevator, and rudder, the roll , pitch , and yaw moments are controlled. The indicated flaps, if available, are used for increasing lift for take-off and landing, in order to achieve a slower minimum speed.4.1.1 Aerodynamic Forces and Moments

The aerodynamic forces and moments can be modeled to various accuracy using full 3-D CFD or with 2.5-D tools: Sect. 26.3.3 overviews such an approach which can be used to model the aerodynamic surfaces in incompressible flow. For enhanced accuracy, fuselages may be considered using again a combination of potential flow (placing singularities) and boundary layer theory. Respective ready-to-use software such as AVL [26.17] and XFLR [26.12] is available for free.

The forces and moments may again be written with dimensionless coefficients as

with the wing area A, the mean chord length , and the true airspeed . The moments LA and NA are made dimension-less with the wingspan b rather than the chord length.

4.1.2 Static Performance Considerations

Having characterized lift and drag of an airplane, three operating points are of particular interest.

First, stall is occurring at . This condition can be directly translated into constant-speed level-flight stall speed by applying the lift balance L = mg.

Second, the maximum ratio, or the glide ratio characterizes the maximum aerodynamic efficiency, i. e., the operating point for maximum range (assuming constant propulsive efficiency).

Finally, the maximum ratio, or the climb factor describes the condition at which power consumption is minimized, thus maximizing flight time (again assuming constant propulsion unit efficiency).

The latter two conditions have direct interpretation in gliding (or propulsion shut-off), in terms of maximum distance reached per altitude lost and minimum sink rate, respectively. Again, corresponding velocities can be found using the lift balance.

4.1.3 Thrust

For detailed insight into the variety of propulsion systems and respective models, the interested reader is referred to [26.13, 26.18]. As an approximation for the important case of a propeller, the BEMT method as described in Sect. 26.3.4.1 is suggested. For many applications, choosing the propeller speed as the system input and neglecting motor dynamics is sufficient.

4.2 Static Stability

Various forms of stability constitute central characteristics of an airplane related to whether or not it can be flown by a human pilot or flight controller. Simple stability criteria can be derived by requiring reaction forces and moments to be opposing a disturbance. We assume stationary conditions in the sense of constant linear and angular speeds: the respective force and moment balance is typically straightforward to apply in order to determine the starting point of the stability analysis.

4.2.1 Longitudinal Static Stability

We will take a close look at the example of longitudinal static stability playing a central role in airplane analysis and design. Leaving aside possible influence of the propulsion unit, the respective directional stability criterion is stated as

at the equilibrium condition . Figure 26.19 illustrates an exemplary moment coefficient as a function of AOA. Note that elevator actuation will move this curve up and down, and with it the equilibrium point (2) toward higher or lower angles of attack (i. e., lower or higher trimmed speeds). Figure 26.20 illustrates the forces and moments in the stable equilibrium with a simplified airplane side-view as compared to the points (1) and (3), i. e., zero-lift and high-lift, respectively. The stability criterion can be equivalently stated as: the airplane COG needs to be in front of the airplane aerodynamic center. Note the main parameters that influence the stability are tail lever arm, tail area, the longitudinal dihedral (Fig. 26.20 for its geometric definition), and the COG location along the x-axis.

Forces and moments at the main wing and tail for zero lift (1), the stable equilibrium AOA (2), and for high lift (3). The forces and moments are drawn into the individual surfaces’ aerodynamic centers. Note the tilted inflow at the tail due to downwash. The green filled circle denotes the overall airplane aerodynamic center (AC )

4.3 Dynamic Model

While some core characteristics such as static stability and performance measures may already be established using aerodynamics coefficients only, we now turn to analyze the dynamics, since they provides a much richer insight into airplane characteristics.

For application of the GlossaryTerm

6-D

(six-dimensional) rigid body dynamics (26.45), the forces and moments from the various sources need to be assembled and represented in the body framewith the weight in body coordinates , and where the T-subscript indicates (possible) moment components from thrust. Note that the system inputs u are hidden inside these forces and moments. Also be aware of α and β containing parts of the state vector

where the true airspeed components are used

with the wind vector .

Furthermore, due to the airplane symmetry plane, the inertia matrix becomes

4.3.1 Parametric Force and Moment Models

Let us consider the example of a simple airplane configuration with ailerons, a rudder and an elevator plus a propeller, driven by an electric motor at rotation speed ωp.

We define the system input vector as normalized aileron, rudder, and elevator action, as well as (normalized) thrust .

The fully parametric nonlinear model provided below largely follows [26.19]. We approximate the lift, drag as well as sideslip coefficients with polynomials in α and β

For many applications except slow flying airplanes, the second-order and third-order term of cL can be omitted.

As far as the torques are concerned, we introduce also dependencies on normalized angular rates

A suitable approximation of the moment coefficients is now made as

Finally, the propeller thrust force needs to be modeled. Using the advance ratio , with propeller diameter d, we can approximate the thrust coefficient

The thrust is then obtained as

4.3.2 Linearized Dynamics

As common throughout literature, the linearized airplane dynamics are written using Euler angles, which is why we will follow the same approach. But conceptually, they could be written in a singularity-free form using a minimal quaternion perturbation.

Typically, a separation into longitudinal and lateral dynamics is made, in order to assess related characteristics separately. Furthermore, the state is transformed to contain α, β, and Vt rather than .

The linear dynamics around a reference state and input vector takes the form

and

The following formulation follows [26.19] to a large extent.

Figure 26.21 describes the separation in terms of inputs and states for the linearized system.

The longitudinal nonlinear equations are given as

and the lateral nonlinear equations amount to

where the following terms were used

The linearizations of (26.68) and (26.69) are straightforward to obtain and not provided here due to space constraints. For a specific operating point, typically stationary (, , and ), the standard tools of linear systems analysis can be employed. Most importantly, the pole locations in the imaginary plane will tell the characteristic modes and their dynamic stability. Figure 26.22 shows a pole location plot for an example RC airplane and introduces the related mode names.

In the case of a real pole πi, it has the time constant . In the case of a complex conjugate pole pair, it is associated with a damping ratio and with an eigenfrequency .

Figure 26.23 illustrates and characterizes the main modes.

4.4 Design Guidelines

Airplane design typically consists of the three stages conceptual design, preliminary design, and detail design. Here, we focus on the first two phases; due to space constraints, details of airplane structural design and analysis are not covered here. The reader is referred to respective literature, e. g., [26.20], or [26.21], the latter covering RC-type aircraft. In the following, we provide a quick overview of practical guidelines for the typically iterative design process related to achieving characteristics as described above. The guidelines follow largely [26.22] and [26.18], with focus on slow-flying small-scale UAS.

4.4.1 Sizing and Geometry of Main Components

In the following, we provide some rules of thumb as initial guess for the design process in terms of sizing the wing, tail, control surfaces, and the propulsion unit. As a first and very general advice, the engineer is encouraged to minimize wetted area and cross section, as well as any kind of nacelles for increased aerodynamic efficiency.

4.4.1.1 Wing

First, an existing airfoil shall be chosen with characteristics meeting the requirements in the target flow regime (Re and Ma). When it comes to determining the overall wing size, a first estimate of design weight including structure, avionics, payload, propulsion unit, and energy storage is of crucial importance (26.2). With the target speed Vr and design lift coefficient cl, a rough guess can be made for the wing area

Concerning wing shape, clearly highest efficiency is reached with high aspect ratios (plus no multiple lifting surfaces), and, at low Ma, no sweep-back – as long as still implementable with a structural concept and staying at reasonably high Re numbers. For high efficiency, it is advisable to achieve an elliptic lift distribution to some extent by geometry. For benign stalling characteristics, it is furthermore highly advisable to twist the wing leading edge downward with increased spanwise distance (which also influences the lift distribution).

Finally, some dihedral should be considered for roll stability.

4.4.1.2 Tail

Various types of tails and even exotic configurations like the canard have been suggested; here, we want to simply point out the importance of the so-called tail volume coefficient, cVT and cHT concerning vertical and horizontal tail, respectively,

with the wing to vertical tail lever arm lVT and the wing to horizontal tail lHT (these are referenced to the individual mean 1/4-chord points). Typical values for small-size slow airplanes are cVT=0.02–0.04 and –0.7. Furthermore, care should be taken that control surfaces are not completely blanketed in the case of stall (for stall/spin recovery).

4.4.1.3 Control Surfaces

Ailerons typically extend from around 50 % in span direction to 90 %; in this setting, 20–30 % of wing chord is suggested as aileron depth. Tail control surface depth is typically chosen around 40 % of the respective chord.

4.4.1.4 Propulsion

Finally, some advice is given concerning the propulsion unit. Some UAVs are required to be handlaunched: note that this imposes limits on the overall maximum take-off mass and minimum/stall airspeed. Experience shows that reasonable limits are <9 m/s minimum/stall speed and 7 kg airplane mass. For such small UAVs, a static thrust to weight ratio of at least 50 % is highly recommended. In general, the propulsion unit must be sized to meet the specifications in terms of climb rates, maximum level flight speed and service ceiling. For the highest efficiency, the propulsion unit should be designed such as to provide highest efficiency at the design operating point (subscript r) . For a hobbyist brushless DC outrunner type motor, the maximum power per motor mass ratio of 3.4 kW/kg can be used for estimation of the propulsion unit weight [26.23] (gearbox and propeller mass not included).

4.4.2 Handling Qualities

Manned aviation introduced the notion of handling qualities, assessing how well an aircraft can be flown by a human pilot as a basis for certification of both civil and military airplanes. Since UAS typically rely on autopilot systems enabling a certain degree of autonomy, these concepts may not be directly applied, but are still extremely relevant. Most importantly, the handling qualities concerning static and dynamic stability, as well as controllability determine the success of a UAS design.

While an autopilot can handle more and faster instabilities than a pilot, it can certainly not compensate for missing actuation authority. As detailed in Sect. 26.7, it is advisable to implement de facto manual operation mode as a testing, backup, or even standard operation mode, in which the airplane is either steered manually or through some stability augmentation system (GlossaryTerm

SAS

). Therefore, it is highly advisable that the resulting system complies with the following core requirements (simplified from [26.18]):-

Static longitudinal stability: most aft COG at least 5 % of in front of aerodynamic center (static margin, GlossaryTerm

SM

). -

Phugoid damping .

-

Short-period oscillation , .

-

Spiral mode may be unstable, if .

-

Roll acceleration at maximum aileron deflection , roll subsidence time constant .

-

Dutch roll damping .

-

Spins shall not be entered abruptly and must always be recoverable.

4.5 A Simple Autopilot

As shown earlier, airplane dynamics are nonlinear multiple-input-multiple-output (GlossaryTerm

MIMO

) systems with a significant amount of cross-coupling, thus they are inherently challenging to control. While a plethora of control strategies have been suggested as autopilots, we will provide a simple yet functional approach here that employs the popular concept of cascaded control loops as well as simple linear single-input–single-output (GlossaryTermSISO

) PID controllers acting on subparts of the dynamics. This approach is still widely deployed and well-understood, despite the fact that more advanced controllers, such as model-based linear quadratic regulators (GlossaryTermLQR

) with gain scheduling or nonlinear dynamic inversion (GlossaryTermNDI

) may achieve significantly better performance. Reference [26.24] constitutes an eccelent reference for in-depth treatment of small UAS guidance and control with cascaded control loops.4.5.1 Cascaded Control Architecture

Figure 26.24 introduces the overall controller architecture. It presents the (typical) separation of per-axis rate controllers at the innermost loop, followed by an attitude controller and a combined altitude and speed controller GlossaryTerm

TECS

(total energy control system), as well as by a lateral guidance. In general, care must be taken to separate successively closed loops by around a decade in terms of bandwidth.Assuming little cross-axis sensitivity, the rate controllers may be implemented with simple individual P-controllers, optionally with gain scaling. Also the attitude controllers can be as simple as P and PI-controllers for roll and pitch, respectively. Note that the desired roll and pitch angle derivatives need to be transformed in the static block Tr into angular reference rates: this can be achieved by applying the inverse Jacobian Jr from (26.42) – where the missing yaw angle time derivative can be computed from the coordinated turn constraint β = 0, in (26.69)

The combined altitude and speed controller (TECS) inspired from [26.25] uses the difference to the reference altitude to compute a desired climb rate of the form , with the given trajectory rate of climb and a P-gain . Knowing the speed and corresponding angle of attack, can be simply converted into a desired pitch angle θd – to be saturated according to maximum thrust (climb) and drag (sink). Since climb rate must be provided via additional thrust, the respective power component is computed as . Concerning the speed control, the second thrust component is computed with the P-gain as .

As a last autopilot component, the lateral guidance [26.26] proceeds as follows (illustrated in Fig. 26.25): a reference circular path of radius R is calculated that intersects the reference path given by the waypoint sequence at look-ahead distance L1. In order to track this reference, a centripetal acceleration of is needed, which can now be directly translated into a desired roll angle corresponding to a coordinated (level) turn – saturated with maximum bank angles.

Note that the suggested scheme should be enhanced by stall prevention and recovery (AOA monitoring and control), as well as by preventing sideslip for safer (and more efficient) operation.

5 Rotorcraft Modeling and Design

Various types of rotorcraft UAS configurations have been developed in the past (some examples are shown in Fig. 26.26), from helicopter-type UAVs such as [26.27, 26.28], over a vast selection of multicopter configurations such as [26.29, 26.30] and tail-sitter vehicles such as [26.31, 26.32] up to completely new types of flight mechanisms [26.33, 26.34]. The design, modeling, and system analysis process for all these RW-UAS types is essentially very similar and is largely based on the methodologies originally developed within the aerospace community for full-scale rotorcraft design and evaluation [26.15, 26.35]. In this context, it is important to realize that the rotorcraft design process goes beyond mere efficiency and payload considerations focused on the propulsion components (e. g., using BEMT). Designing an effective RW-UAS should in principle also include flight dynamics assessments of the entire robotic flight platform.

Flight performance assessment is commonly based on one of two types of modeling approaches referred to as quasi-steady and hybrid [26.36]. The quasi-steady modeling method employs a single rigid body representation of the aircraft affected by the steady-state forces and moments originating from the propulsion subsystem. Hybrid models treat the rotorcraft as a multibody system where the dynamics of the aircraft body are coupled with additional dynamics of the rotor or propeller blades (e. g., blade flapping dynamics). For propeller-based RW-UAS like multicopter and tail-sitter vehicles using the quasi-steady approach to, e. g., model attitude dynamics is most widespread. This may be related to the fact that for these vehicle configurations, properly accounting for motor dynamics may be more relevant than accounting for high-order effects related to structural deformations of the propeller blades. For helicopter-type UAVs the hybrid approach is more common as some dynamic modes of the rotor system are likely to couple with the attitude dynamics of the main rotorcraft body. Note that a proper application of the hybrid approach is considerably more involved than using quasi-steady models and should only be resorted to if justified.

A detailed treatment of the specific modeling and design procedures for every robotic rotorcraft configuration is beyond the scope of this chapter and thus the presented considerations focus on helicopter-type and multicopter UAVs. Based on the extensive theoretical aerospace-related background available in [26.14, 26.15, 26.35] amongst others, models for the most relevant rotor respectively propeller forces and moments are presented and subsequently appended to the rotorcraft body dynamics discussed in Sect. 26.3.6. A simplified hybrid modeling approach is introduced and reductions to quasi-steady models are discussed where applicable. Finally, a few metrics meaningful for rotorcraft design and control purposes are discussed and summarized shortly.

5.1 Mechanical Design of Rotors and Propellers

The main control mechanism for any RW-UAS is its rotors or propellers. Accordingly, to understand the working principles and the dynamics of the rotorcraft type of aircraft, it is worth investigating a few of the main design characteristics found in these flying mechanisms.

The following discussion focuses on the operation principles of helicopter rotors and will be expanded to propellers subsequently. Figure 26.27 visualizes the typical rotor degrees of freedom realized via the flap, lead-lag and feathering (also referred to as pitch) hinges. The flap hinge allows the rotor blade to flap due to aerodynamic and inertial loads affecting the blade body during flight. The lead-lag hinge responds to lateral rotor blade moments due to Coriolis forces related to flapping. Where the flap and the lead-lag hinges are usually passive, possibly augmented with spring or damper elements, the pitch hinge is active in order to adjust the blade angle of attack and thus the generated aerodynamic forces.

Three types of rotor hubs are typically found in modern helicopters referred to as teetering, articulated, and hingeless depending on the mechanical realization of the flap hinge (Fig. 26.28). In the case of teetering rotor, a single hub flap hinge is located directly on the rotorshaft axis, rigidly connecting a set of two rotor blades. For the articulated rotor, the blades and the rotor hub are connected via mechanical hinges at a specific offset e from the rotor shaft axis, thus allowing each blade to flap individually. The hingeless rotor flaps through the deformation of elastic elements connecting the hub with each individual rotor blade or directly through structural deformation of the blades themselves. In this case, a virtual hinge offset can be defined at the intersection of the rotor hub plane and the tangent to the deflecting blade body at 75 % of the rotor radius [26.14]. The specific characteristics of the flap hinge (offset from rotor shaft, stiffness, and damping) are fundamental for rotor blade flapping and in consequence for the rotorcraft pitch and roll dynamics as discussed later.

In the case of most propeller-based rotary-wing (GlossaryTerm

RW

) UAVs (e. g., multicopter systems) the feathering and lead-lag degrees of freedom do not exist. Nevertheless, propeller-based RW-UAVs may exert blade flapping by deformation of the propeller blades.5.2 Rotorcraft Dynamics

As discussed in Sect. 26.3.6, the main rotorcraft body dynamics can be directly described by the simplified differential (26.45) which for most rotorcraft systems maintain the presented mathematical structure. For helicopter-type and multicopter UAV configurations the dominant set of external forces and moments affecting these dynamics can be summarized as

The vector FG represents the weight force and is the thrust force of the i-th rotor or propeller out of the total set of Nr rotors or propellers (Fig. 26.29). These forces are related to the body heave dynamics but due to the underactuation of most rotorcraft are also responsible for the lateral rotorcraft acceleration.

The additional in-plane hub forces represent drag-related effects that may be neglected near hover but become more dominant for higher lateral flight velocities [26.15]. The vector FD represents the drag force associated with the rotorcraft main body. For simplicity’s sake, it is assumed that the center of pressure of the rotorcraft body is collocated with its center of gravity which is not necessarily the case.

The relevant set of external moments is defined by the torques affecting the vehicle yaw dynamics, the thrust-induced moments , the moments introduced by the hub forces and the flapping moments related to the rotor hub stiffness .

More explicit expressions for the respective force and moment terms may be found in Tables 26.6 and 26.7 , where Ti is the averaged thrust force magnitude, and are the hub force components along the rotorcraft body frame x- and y-axes, and Qi is the torque generated by the i-th propeller or rotor. The aerodynamic drag of the main rotorcraft body, represented by the components Dx, Dy, and Dz, has been discussed in some detail in Sect. 26.3.5.

The vector corresponds to the displacement of the i-th rotor or propeller hub from the rotorcraft body frame origin and is the tip-path plane normal of the i-th propeller or rotor disk as explained in [26.37].

The coefficients and represent the longitudinal and lateral flapping coefficients [26.15] describing the tilting of the rotor or propeller disk as elaborated in more detail later in this section. Finally, the parameter corresponds to the flapping spring stiffness of the i-th rotor or propeller hub. In the case of articulated or teetering hubs this torsional spring stiffness represents potential flap hinge springs and in case of hingeless hubs approximates the structural bending stiffness of a particular rotor or propeller.

In the case of a helicopter tail rotor, flapping is usually neglected and the thrust direction is modeled as, e. g.,