Abstract

Mixtures of silica and titania, beginning with those containing mostly silica to those where the titania precipitates out of the mixture, have been investigated for the production of thin films on a variety of substrates. The primary interest in silica-titania thin films is for antireflection coatings. Besides this application, silica-titania films are considered for rare earth hosts and photocatalysts. The precursors and the methods to prepare silica-titania films are surveyed for their ease of formation and their suitability for the applications.

Access provided by CONRICYT-eBooks. Download reference work entry PDF

Similar content being viewed by others

Introduction

Sol-gel films in the SiO2–TiO2 system exhibit a huge potential for numerous application fields. Provided that the TiO2 content and/or processing temperature are low enough, such films do not undergo any phase separation between the SiO2 and TiO2 components. Thus, they benefit from the high optical quality of silica glasses. On the other hand, TiO2-rich films that undergo phase separation can, however, be endowed with good optical characteristics when processing temperatures are adapted to the synthesis of amorphous or nanocrystallized TiO2 particles. A specific control of the TiO2 content allows continuous tailoring of the film refractive index, from 1.45 at 632 nm for pure silica films to around 2.20 or more for pure titania films (in this latter case, the refractive index strongly depends on the heat-treatment temperature). Therefore, sol-gel films in the SiO2–TiO2 system have been studied extensively for optical applications, e.g., low, medium, or high-refractive index single-layer components of antireflective or highly reflective multilayer coatings. Because it is possible to precisely control the film refractive index with respect to the substrate index, such films have also been studied for integrated optics applications, e.g., integrated channel waveguides. In particular, numerous studies have been devoted to the sol-gel fabrication of SiO2–TiO2 films doped with rare earth ions for applications in active optics, including all-optics amplifiers and integrated display or lighting devices.

In many cases, sufficient chemical stability and mechanical resistance are required in order to avoid damage occurring during coated support handling or use. Such criteria are generally met by performing a postdeposition thermal treatment at temperatures in the range (400–600 °C). Heat treatment completes the densification and polycondensation or oxidation degrees of as-deposited sol-gel films, and enhances mechanical and chemical stability. Because densification proceeds during heat treatment, this latter also yields a film refractive index optimization. When sufficiently high TiO2 contents and heat-treatment temperatures are used, phase separation between SiO2 and TiO2 components and subsequent crystallization of the TiO2 component occur, and the films can benefit from the semiconducting properties of titanium oxide. A crystalline TiO2 phase promotes an efficient generation and separation of charge carriers, which guarantee excellent semiconducting properties. Crystalline TiO2 sol-gel films are generally obtained after posttreatment above 350 °C, and the presence of SiO2 shifts amorphous/crystalline state transition toward higher temperatures. On the other hand, the mechanical properties of titania crystalline films can be enhanced by a SiO2 component, because the silica network acts as a binder between titanium oxide crystallites. Semiconducting properties of TiO2-derived sol-gel films, for instance, have been studied extensively for applications, such as solar cells, gas sensors, or photocatalysts.

Sol-gel films can be deposited at room temperature on many kinds of substrates. OH bonds that are naturally present at the surface of ceramic or glass substrates favor good liquid wetting behaviors, which guarantee good film uniformity. These groups also form oxygen-bridging bonds with OH groups present in the film, which in turn favors good film adhesion. In some cases, a specific preparation of the substrate is required to enhance its surface properties. For instance, caustic etching, cleaning with a basic soap, or oxygen plasma treatment are commonly used to tailor the surface of hydrophobic polymer supports. Since the sol-gel transformation takes place at room temperature, it offers opportunity to process films on thermally sensitive substrates. However, when the films are posttreated at low temperature they are traditionally affected by some limitations, which have often restrained applications of SiO2–TiO2 sol-gel films on thermally sensitive supports. The films primarily suffer from insufficient densification and hydrolysis/polycondensation degrees. Thus, their chemical stability and mechanical resistance are quite poor. Owing to incomplete hydrolysis/polycondensation, alkoxy groups are still present in the films. These groups act as structural impurities that inhibit low-temperature crystallization of titania films and cancel their semiconducting properties. OH groups are also known to severely quench the photoluminescence of rare earth ions in optically active films. The presence of OH groups in sol-gel films processed at low temperature ensues either from incomplete polycondensation of hydrolyzed alkoxide precursors, or from nonelimination of adsorbed water issued from polycondensation of hydrolyzed precursors. Finally, owing to insufficient densification, the porosity of sol-gel films processed at low temperatures yields rather low-refractive indices. This limitation is particularly prevalent in the case of TiO2-rich films, because it restrains their use as high-refractive index single-layer component in multilayer interference films.

Since the early 1990s, numerous studies have been performed to overcome the limitations of SiO2–TiO2 sol-gel films processed at low temperatures. In this chapter, we present experimental procedures that were proposed for three application fields, namely antireflective films (section “Antireflective Films”), rare earth doped optically active films (section “Rare Earth Doped Films”), and photocatalytic films (section “Photocatalytic Films”). We primarily focus on the film functionality, i.e., properties related to the intended application. Attention is also paid to the film optical quality, because for many applications it is required that the film does not modify the optical transparency of the substrate, even when no optical applications are intended. The mechanical quality of the films is considered as well, which is an important criterion that often determines the final usefulness of the films. For the three selected fields, the application potential of SiO2–TiO2 sol-gel films is outlined. Recent trends in research on SiO2–TiO2 sol-gel films processed at low temperature are then reviewed. To illustrate these trends, results obtained in our department are also described and discussed with respect to existing literature.

Antireflective Films

Context and Applications

At the air–substrate interface, transparent materials such as glasses or plastics suffer from reflection losses. For this reason, antireflective (AR) coatings are often necessary to reduce reflectance of the substrates and/or increase the optical efficiency of optical devices such as cameras, microscopes, binoculars, or telescopes. In this context, sol-gel AR films have been extensively studied, e.g., for automotive applications or for cathode ray tubes (CRT) used in TV screens or computer display terminals (Derks 1999; Morimoto et al. 2001). Nowadays, more than 85% of CRTs are coated by wet chemical methods (Abe et al. 2003).

Under light incidence perpendicular to the surface of a dielectric coating of thickness d and refractive index n, a zero reflectance can theoretically be obtained at a single wavelength value (A) when (i) the product n × d is an odd integer multiple of λ/4, and (ii) n = (n1n2)1/2, where n1 and n2 are the refractive index of the substrate and of the surrounding medium, respectively (Cox and Hass 1964). If we take the example of an AR film deposited on a fused silica substrate (n1 = 1.46) in the air (n2 = 1), a very low refractive index of 1.22 is necessary. This requirement makes it practically impossible to design a dense single-layer AR film. Indeed, the desired refractive index value is much lower than the index of any bulk mineral compound. For instance, traditional low refractive index mineral compounds such as MgF2 and Na3AlF6 exhibit an index value of 1.38 and 1.36, respectively. To fulfil the low refractive index criterion, the deposition of a highly porous coating is therefore required. For instance, a porosity of 53 vol% would be necessary to deposit a silica AR coating on silica substrate (Vong and Sermon 1999).

Many applications require wide-spectrum AR coatings, which cannot be produced from aforementioned single-layer deposition conditions. Broadband AR coatings may be accomplished using a coating whose refractive index closely matches that of the substrate at the contact interface, and gradually decreases outward, ideally approaching the index of the surrounding medium (Yoldas and Partlow 1984). This new criterion requires in turn a single-layer coating of both high and graded porosity. Pioneering sol-gel studies performed in the 1980s by Yoldas and Partlow (1984, 1985) were devoted to such a target. Graded porosity and pore size tailoring were performed on silica sol-gel films using mild etching or specific heat-treatment procedures. Because such a porosity control is very hard to achieve, a less straightforward but more controllable and versatile alternative has generally been used to deposit sol-gel AR coatings. This approach is based on the deposition of multilayer films that consist of stacked single layers of tailored high, medium, and low refractive index (Cox and Hass 1964). Through destructive interference mechanisms, reflectance can be reduced to a value near zero in a wide spectral range. Since a very large range of refractive indices can be covered with SiO2–TiO2 binary compositions, multilayer interference sol-gel films deposited in this system have extensively been studied for the last 25 years. Stacks of quarter- or half-wavelength SiO2–TiO2 sol-gel films of tailored refractive indices allowed to cover a wide variety of optical properties that ranged from AR coatings on glass or silicon (see pioneering works performed by Yoldas and O’Keeffe 1979 and Brinker and Harrington 1981) to, e.g., highly reflective films (Floch and Priotton 1989) or highly selective optical filters (Partlow and O’Keeffe 1990).

Nowadays, specialty coatings are essential value-added products that actively participate to the development of glass industry. Indeed, coating technology is superior to in-bulk glass modification techniques with respect to nonexpensive production and easy tailoring of performance. Among the very large variety of on-glass specialty coatings, which include, e.g., electrochromic, conductive, semiconducting, catalytic, or surface functionalization coatings, AR coatings are the object of a continuously increasing demand, which often associates AR properties with one or several of the aforementioned properties (Allendorf 2001). Furthermore, AR coatings are not restrained only to glass industry and they cover numerous application fields ranging from household articles to high technology devices. For instance, in the frame of the Nova Laser program developed at Lawrence Livermore National Laboratory for high-power laser fusion, numerous studies were performed to coat potassium dihydrogen phosphate (KDP) converter crystals, fused silica, and BK-7 glass substrates with sol-gel AR coatings (Yoldas and Partlow 1984, 1985; Thomas 1986, 1988, 1992).

The need for value-added coatings, such as AR films, has recently extended to modern polymers used in many application fields. Indeed, low weight, great break resistance, reduced cost, and ease of complex shape manufacturing have promoted the development of polymers products, which are now commonly replacing glass articles. For instance, organic lenses are now highly demanded in ophthalmic industry and require in turn AR coatings to enhance their optical performance (Samson 1996). Another well-known example concerns automotive industry where a plastic foil is embedded in a laminated glass windshield. The plastic foil is coated with a multilayer interference coating that provides high reflectance in the near-infrared range for solar energy and heat protection, together with high transmittance in the visible range (Mennig et al. 1999). Polymers are a typical case of thermally sensitive substrates that require low-temperature processing. Ophthalmic organic lenses are a well-representative illustration of such a need. In that case, raising the processing temperature to near the limit of plastic lenses, in order to improve coatings properties, can definitely alter the final functionality of the product (Samson 1996). For instance, flat polycarbonate (PC) substrates of sufficient thickness (2 mm or more) support a maximal processing temperature of 130 °C, which has to be reduced to 80 °C when thinner or shaped articles are envisaged (Oliveira et al. 1997). Furthermore, the need of low-temperature processing is not restrained to organic substrates. For instance, for CRT applications, coatings are preferentially deposited on finished tubes, which require a maximum processing temperature of c.a. 160 °C in order to prevent tube damages (Derks 1999; Morimoto et al. 2001).

Low-temperature PVD methods, such as ion beam–assisted deposition techniques, are traditionally used to coat thermally sensitive organic substrates and to produce AR coatings. Sol-gel procedures have often been proposed as a low-cost alternative. However, as-deposited sol-gel coatings are generally fragile, and a postdeposition treatment is always needed to strengthen their mechanical resistance. In the case of thermally sensitive substrates, the need of a low-temperature posttreatment often limits the scratch resistance of the films. Scratches induce in turn dramatic losses of optical quality and esthetic aspect. For instance, transparent polymers coated with AR films that are not endowed with antiscratch properties can only be used for restricted applications or low-value articles. This is particularly true in the case of household applications, where products are submitted to repeated handling or wiping that can rapidly cause abrasion damages. Thus, for thermally sensitive substrates, AR and antiscratch (AS) properties are often nondissociated, which has introduced the need of antireflective and antiscratch (ARAS) coatings. In the following parts, we will more particularly focus on ARAS sol-gel coatings deposited on thermally sensitive substrates.

Colloidal Routes

Many works have been devoted to the preparation of silica colloids using a sol-gel method developed by Stober et al. (1968). These authors first reported on the possibility to process liquid suspension of monodisperse silica colloids from sol-gel reactions in basic conditions. Since then, these liquid suspensions have been studied for many purposes, including the deposition of sol-gel AR coatings. Thomas (1986) reported on the deposition of narrow-bandwidth AR films on fused silica or KDP crystals from colloidal suspensions. When this suspension was applied to the substrate, a porous coating was obtained after solvent evaporation, which consisted of stacked submicron size silica particles. A refractive index of 1.22 was measured, which exactly matched the zero-reflectance conditions for the intended substrates. Because these studies were carried out in the frame of the Nova Laser program, another requirement for AR coatings was the necessity to present a high-laser damage threshold. This criterion was met from colloid suspensions, because sol-gel particles processed in basic conditions are substantially mineral, i.e., in basic medium hydrolysis preferentially occurs over polycondensation and particles free of organic entities are produced (Brinker and Scherer 1990).

However, the highly porous films exhibited extremely poor abrasion resistance because of weak binding between silica particles. Though abrasion resistance was not essential for the intended applications (Nova Laser), poor abrasion resistance considerably reduced practical interest of these AR coatings for alternative applications. Thomas also studied mixed colloidal/polymeric sol-gel approaches to enhance the abrasion resistance of AR silica films (Thomas 1992). Silica coatings of refractive index that varied between 1.22 and 1.44 were deposited from the combinations of colloidal suspensions and polysiloxane solutions or polymeric sols. Such composite films were posttreated at 80 °C. The polysiloxane acted both as a binder and filler for the deposited colloidal silica particles. Increasing the polysiloxane to colloid ratios produced coatings of lower porosity, which exhibited therefore better abrasion resistance but higher refractive index. As a result of this approach, AR coatings with improved abrasion resistance were obtained but only for high-refractive index substrates, i.e., most of the common transparent supports were not concerned. Floch and Belleville (1992) drew similar conclusions from their studies on AR coatings deposited from inorganic colloidal/polysiloxane mixed sols. Alternative low-temperature AR procedures were also proposed by Thomas for KDP crystals in the frame of the Nova Laser program (Thomas 1991). AR films consisted of silica colloids embedded in a low-refractive index fluorinated polymer matrix (AF 2400 polymer produced by DuPont Company; n = 1.29). This dense composite film exhibited good laser damage threshold and provided good environmental protection to the KDP support. The extremely low-refractive index of the polymer matrix promoted excellent AR properties as well. No antiscratch performance was however reported.

In the frame of the Mega Joule Laser program developed at Commissariat à l’Energie Atomique (the French homologue of the US Nova Laser project), Belleville and Floch (1994) have proposed a posttreatment for strengthening porous sol-gel AR silica coatings deposited at room temperature. The authors showed that the adhesion and mechanical strength of their films could significantly be enhanced by exposition to ammonia vapors. After exposition for 5 h, AR properties (0.1% reflectance) of the strengthened films were retained, despite 20% shrinkage of the original coating that induced blue shift of the maximum transmission wavelength. The authors explained the beneficial effect of this posttreatment according to a base-catalyzed mechanism formerly proposed by Iler (Brinker and Scherer 1990), which involved surface silanol condensation and hydrogen bonding of neighbor silica particles. The narrow-band AR coating exhibited excellent laser damage threshold and withstood standard drag-wiping procedures without showing any microscopic damage. However, the authors mentioned that the resulting strengthened coating could not as far be considered as scratch-resistant. It must be noted that all previously cited studies only concerned narrow-band AR coatings, i.e., single-layer porous coatings. More recent studies performed on porous AR silica coatings dealt with the incorporation of organic species (polyethylene glycol) in the sol in order to tailor the film porosity (Wongcharee et al. 2002). Good broadband AR coatings have been deposited, but no improvement concerning antiabrasion properties is reported. It has also been shown that, due to their high porosity and surface area, such coatings undergo water adsorption–desorption mechanisms when exposed to humid atmospheres, which can significantly alter their AR properties (Vong and Sermon 1999).

Inorganic Polymeric Routes

Since in multilayer interference systems, denser layers can be deposited, improved abrasion resistance is expected compared to porous coatings. Multilayer AR films can readily be deposited from traditional polymeric sols, and low-temperature posttreatments allow processing such films on polymer substrates. For instance, multicomponent AR coatings have been applied on PC and acrylate substrates by hydrolysis and condensation of silanes and various metal alkoxides (Ashley and Reed 1986). However, it seems that low-temperature sol-gel routes devoted to the deposition of ARAS coatings from traditional polymeric sols have not been extensively investigated. Such a route was recently proposed to process ARAS coatings at low temperature from SiO2 and Ta2O5 polymeric sols (Prene et al. 2000). AR bilayer coatings cured at 150 °C exhibited a broadband AR spectrum and excellent abrasion properties. This curing temperature is, however, too high for processing many kinds of polymer substrates.

Polymeric sols in the SiO2–TiO2 system were explored in our department for the low-temperature processing of multilayer AR films. As previously mentioned, enhanced densification and polycondensation degrees are necessary to obtain films of good mechanical resistance and tailored refractive index. Polymeric sols were, therefore, formulated to meet such criteria through low-temperature posttreatments. The sol formulation was performed with regard to a low-temperature postdeposition densification/polycondensation competitive mechanism, which has extensively been studied by Brinker et al. (1994) and Logan et al. (1994). On the one hand, the formation of highly cross-linked species, i.e., highly polycondensed particles, in too reactive sols inhibits the deposition of dense films, because such particles are not able to pack suitably during postdeposition liquid film drying. Thus, sols with moderate reactivity are preferable. On the other hand, at low temperature (c.a. 100 °C for applications on polymer substrates), densification and polycondensation mechanisms are poorly thermally activated. Densification essentially takes place under the effects of capillary forces related to the postdeposition evaporation of liquid (water and alcoholic dilution solvent). Moreover, densification is accompanied by the development of a stiff oxide network (polycondensation), which rapidly counteracts the capillary force-induced densification. Thus, porous and mechanically fragile films deposited from polymeric sols are traditionally obtained after a low-temperature posttreatment.

To overcome such features, specific sol preparation procedures were set up. A multistep preparation was implemented for SiO2 sols, which allowed precisely tailoring the cross-linking degree and chemical functionality of reactive species (Vautey et al. 1999). Sols were processed from ethanolic solutions of tetraethoxysilane (TEOS) through several successive adjustments of the pH, water to TEOS molar ratio, and TEOS concentration. SiO2-derived films heat treated at 110 °C exhibited a refractive index of 1.45 in the visible range and excellent chemical stability (hot water and saline tests), adhesion, and abrasion resistance properties in compliance with severe standard tests (MIL C 48497A, MIL C 675C, ASTM D 3330–96). In the case of TiO2 films, sols were processed from tetraisopropoxide (TIPT). Because titanium alkoxides are highly reactive to hydrolysis/polycondensation reactions, fast particle cross-linking and oxide network development rapidly inhibit film densification during postdeposition drying. Accordingly, TiO2 films heat treated at low temperature are traditionally much more porous than SiO2 films. They are therefore particularly fragile and exhibit low-refractive indices. Thus, our efforts were focused toward a minimization of the sol reactivity through a precise adjustment of the pH, water to TIPT molar ratio, and TIPT concentration in the sol (Bekiari et al. 1999). However, films heat treated at 110 °C could still not densify properly, owing to the fast development of a dense surface layer that inhibited liquid evaporation from the deeper layers and related densification. We have shown that an additional aging treatment at 60 °C favors complementary liquid evaporation and film densification (Langlet et al. 2001a). The aging duration could be reduced to about 4 h when the final step was performed under a hot dry air flux (60 °C, 2001/min). So-obtained films exhibited a rather high-refractive index value around 2.00 in the visible range. Their chemical stability and mechanical properties were comparable to that of optimized SiO2 films.

SiO2/TiO2 bilayer ABAS coatings were then deposited on glass substrates and processed at 110 °C. The ideal thickness of each single-layer was determined on the basis of an optical simulation, which aimed at optimizing AR properties together with minimizing angular dependence of the reflectance (Burgos 2001). Thicknesses of the TiO2 inner layer (n = 2.01 at 560 nm) and SiO2 outer layer (n = 1.45 at 560 nm) were finally adjusted at 110 and 80 nm, respectively. The final coating exhibits the typical V-shape broadband AR spectrum of a bilayer coating (Cox and Hass 1964), with a minimum reflectance of 0.2% at 560 nm (4.3% for the bare glass substrate) (Fig. 1). This result shows that our procedure could be adapted to a low-temperature processing of ARAS coatings on CRTs. We also developed a low-temperature heat-treatment procedure (110 °C) under water atmosphere that allowed preventing cracks in films deposited on polymer substrates (Burgos and Langlet 1999). Indeed, densified TiO2 films are particularly sensitive to the high thermal expansion of polymer substrates during heat treatment at 110 °C and tend to crack. Heat treatment under humid atmosphere allowed a precise adjustment of the film densification and substrate expansion kinetics, which yielded crack-free films. Such a procedure could so far be considered for ARAS coatings on polymer supports, e.g., ophthalmic organic lenses.

Reflectance spectra of (a) a bare glass substrate, and (b) a substrate coated with a SiO2/TiO2 bilayer ARAS coating SiO2 and TiO2 single-layers were deposited using the Aerosol-gel process (see Chap.16, “Ultrasonic Pulverization of an Aerosol: A Versatile Tool for the Deposition of Sol-Gel Thin Films” of this book) and heat treated at 110 °C

Most recent trends in low-temperature processing of ARAS coatings deposited from polymeric sols rely on approaches that combine composite films with multilayer interference systems. Such approaches are, for instance, commonly applied to CRTs (Abe et al. 2001, 2003; Morimoto et al. 2001). Bilayer AR coatings are composed of a high-refractive index inner layer and a low-refractive index outer layer. The outer layer consists of a SiO2 film deposited from polymeric sol. The inner layer consists of commercially available titanium-derived particles (TiOxNy) dispersed in a SiO2 matrix processed from polymeric sol. The advantages of this method are twofold. Because TiOxNy particles are separately synthesized, deposition of the high-refractive index inner layer does not require a delicate and critical low-temperature densification treatment. Moreover, the composite inner layer can be made of different kinds of particles. For instance, modern CRTs require antistatic properties to prevent users from electric shock when touching the screen. Antireflective and antistatic composite coatings are produced through the deposition of an inner layer composed of TiOxNy and antimony-doped tin oxide (ATO) particles. Surface negative charges of the ATO–TiOxNy particles favor their intimate dispersion within the SiO2 matrix, which promotes in turn the deposition of high optical quality films.

Furthermore, because SiO2 polymeric sols are rather weakly reactive, the aforementioned densification/polycondensation competitive mechanism can readily be managed to promote an efficient low-temperature densification of the inner SiO2 matrix and outer low-refractive SiO2 layer. Antiscratch coatings on CRTs are thus produced after curing at a maximum temperature of 160 °C. Philips Company has also developed a so-called skin-heating process to optimize the optical and mechanical properties of sol-gel AR coatings deposited on CRTs (Derks 1999). This high-throughput speed and in-line method involves blowing the coating with a very hot gas (e.g., air flux heated at temperatures up to 800 °C). The heat needed for curing the coating is only applied at the outermost “skin” of the screen including the coating, and does not propagate toward the inner surface of the tube. Finished tubes already provided with deflection coil can therefore be processed without exceeding the maximum tolerable temperature of 160 °C.

Hybrid Organic/Inorganic Routes

Since pioneering works performed in the early 1980s (Schmidt et al. 1982; Avnir et al. 1984), the sol-gel fabrication of hybrid organic/inorganic materials has attracted a continuously growing interest both from industrial and academic point of view. Works were mainly focused on hybrid organic/inorganic silicates. These hybrid silicates are also mentioned in the literature as ormosils (organically modified silicates), ormocers® (organically modified ceramics), ceramers (ceramic polymers), or other denominations. Hybrid silica films are deposited from silicon alkoxide precursors partially substituted with nonhydrolyzable organic ligands, which lead to the stabilization of an organic component within the mineral silica network. Then, the film can be heat treated in order to enhance its mechanical or physical properties, provided that the temperature is low enough to avoid the organic component decomposition. Thus, the sol-gel processing of hybrid films involves low-temperature approaches, which are well suited for coating applications on thermally sensitive substrates (Seddon 1998). The main interest of hybrid silicates arises from their ability to combine the assets of mineral silica glasses (optical quality, mechanical robustness, and chemical and thermal inertness) with additional properties induced by the organic component. New or enhanced properties can therefore be obtained, which could not be possible using a traditional inorganic sol-gel route. For this reason, hybrid organic/inorganic silica films have extensively been studied in numerous application fields including optics, electronics, ionics, mechanics, membranes, protective coatings, catalysis, sensors, and biology (see reviews in Seddon 1998; Loy 2001; Sanchez and Lebeau 2001).

Among specific features induced by the organic component of hybrid silica films, the first one relies on the possibility to develop an organic polymeric network together with the inorganic network issued from sol-gel reactions. Depending on the hybrid precursor nature, the polymeric network develops at low temperature under the effects of a thermal or radiative (UV) curing treatment. The organic component of hybrid films generates a mechanically flexible network, which plays a beneficial role in the sol-gel deposition of thick films. The flexible network is able to accommodate capillary stresses related to the postdeposition solvent evaporation, which usually promote cracks for too thick sol-gel films. In the case of hybrid matrices, crack-free films of several tens of microns in thickness can readily be deposited in a single deposition process (Krug and Schmidt 1994). This feature reduces therefore the need of a time-consumable multilayer deposition procedure when micron-scale films are required. The organic polymeric network can also efficiently strengthen the mechanical resistance of the inorganic sol-gel network. Several modified silica alkoxide precursors have been proposed for the low-temperature processing of scratch-resistant sol-gel films on plastic substrates: epoxy-based (e.g., 3-glyciloxypropyl trimethoxysilane: GPTS) (Kron et al. 1994), vinyl-based (e.g., vinyltriethoxysilane: VTES) (Iwamoto and Mackenzie 1995), or methacrylate-based precursors (e.g., 3-methacryloxypropyl trimethoxysilane: MPTS) (Greiwe et al. 1992). Furthermore, scratch resistance of hybrid silica films deposited on plastic substrates can be reinforced by the use of an additive inorganic component (e.g., hybrid Zr-, Ti-, or Al-silica films) (Greiwe et al. 1992; Iwamoto and Mackenzie 1995; Sepeur et al. 1999).

Thick hard coats are particularly important in the case of ABAS applications on polymer substrates because, due to the thinness of the AR film (wavelength thick film), this coating cannot induce an efficient protection on the mechanically soft organic surface. Two hard-coat procedures can be used on polymer substrates. A hard coat of sufficient thickness (2–3 μm) can directly be applied at the surface of the polymer. In that case, the AR film deposited on the top surface should present antiscratch properties comparable to that of the hard coat in order to promote optimum mechanical resistance. The hard coat can also be deposited at the surface of the AR coating, which reduces in that case the need of ARAS function. In any cases, the hard-coat refractive index has to closely match those of the substrate and single-layers constituting the AR film, in order to prevent reduction of the AR properties and appearance of undesirable colored reflections due to optical interference effects. AlOOH-modified GPTS (Mennig et al. 1999) or MPTS hybrid silica coatings (Sepeur et al. 1999) were, for instance, proposed as interfacial or top hard-coats for ARAS applications on polycarbonate or polymethylmethacrylate (PMMA) plastic substrates used in household, ophthalmic, or automotive industry.

In inorganic SiO2–TiO2 sol-gel films, the refractive index usually increases linearly with the TiO2 amount, from the value measured for pure silica up to the value measured for pure titania. For instance, a refractive index increase from 1.45 up to around 2.20 has been reported for sol-gel films heat treated in the range (400–600 °C) (Brinker and Harrington 1981; Langlet et al. 1995). The same effect is also observed in hybrid organic/inorganic SiO2–TiO2 films but the refractive index increase (Δn) is much weaker. For instance, it was reported that up to 50 mol% TiO2 could be incorporated in hybrid silica matrices, which yielded a Δn of only 0.07 (Schmidt and Popall 1990), to be compared to Δn ≈ 0.35 for inorganic films with the same TiO2 amount. Thus, it seems that traditional hybrid routes are not well adapted to the sol-gel deposition of high-refractive index films in the SiO2–TiO2 system, which could be used for interference AR coating applications. Accordingly, hybrid organic/inorganic approaches have widely been proposed for scratch-resistant coating applications on thermally sensitive substrates, but did not aim at ARAS applications. On the other hand, mixed hybrid/colloidal and hybrid/composite approaches have been developed for ARAS applications on thermally sensitive substrates, which combine the potential of hybrid silica precursors with advantages of silica colloids or high-refractive index particles.

In the frame of the Mega Joule Laser project, Floch and Belleville have proposed improved silica colloid approaches (Floch and Belleville 1992, 1994), which were inspired by the former works of Thomas (1986, 1991, 1992). Their narrow- and broadband AR coatings exhibited a high laser damage threshold. Besides, significant improvements based on the use of hybrid silica precursors allowed envisaging extensions of the coatings to household ARAS applications on plastic supports. The authors particularly pointed out the necessity of hybrid silica coupling agents and adhesion promoters to improve antiscratch properties of their films. A multistep deposition procedure was thus proposed for the deposition of a composite quarter wavelength ARAS coating, which was called Fluosil-coating process. The Fluosil-coating process includes (i) deposition of silica colloids that yield a porous coating; (ii) impregnation of the porous coating with a siloxane sol that bonds together silica colloids but is deposited in sufficiently weak amount in order to prevent unwanted increase of the composite film refractive index; (iii) postimpregnation with a low-refractive index polymer filler (AF 2400) that yields a dense composite coating; and (iv) final impregnation with different hybrid silica precursors that act as adhesion promoters and coupling agents.

Assets of the Fluosil-coating process rely on the specific composition of hybrid silica precursors, which comprise hydrolyzable groups (typically alkoxy groups) that link with inorganic components of the composite coatings and with inorganic substrates through sol-gel reactions, and nonhydrolyzable organic radicals that can chemically bond with organic resins and polymeric substrates. These hybrid precursors promote, therefore, adhesion of the composite film to the substrate and chemical coupling between organic and inorganic components of the composite film. Three-aminopropyl triethoxysilane, 3-glycidoxypropyl trimethoxysilane, and hexamethyldisilazane were used for composite film coupling with plastics substrates and glass-like substrates, as well as for organic/inorganic component coupling, respectively. AR composite films were heat-treated at a maximum temperature of 120 °C that was shown to be compatible with numerous organic substrates. Owing to a strong multicomponent bonding, AR films deposited using the Fluosil-coating process exhibited excellent hot water and saline test stability, as well as very good adhesion and scratch resistance performances, which allowed envisaging ARAS applications for ophthalmic components, computer displays, or others on thermally sensitive substrates.

Hybrid/composite mixed approaches were also developed to produce high-refractive index layers, for highly reflective or AR multilayer film applications on PC (Oliveira et al. 1997; Mennig et al. 1999). TiO2 nanoparticles (4 nm diameter) were preliminary synthesized through sol-gel reactions and subsequently diluted in a GPTS sol. Oliveira et al. showed that the refractive index of composite films deposited from the resulting sol could flexibly be adjusted from 1.505 to 1.93 by varying the TiO2–GPTS composition (Oliveira et al. 1997). These authors have proposed a complete procedure for the fabrication of AR multilayer films from hybrid-derived sols. A low-refractive index (n = 1.483) single-layer, constituted of silica colloids (10 nm diameter) diluted in a GPTS silica matrix, was deposited on the top of a high-refractive index (n = 1.93) TiO2–GPTS single layer. Like Floch and Belleville, the authors pointed out the necessity to optimize multicomponent binding to improve abrasion resistance of the AR coating. Organic polymerization of the hybrid GPTS precursor promoted an efficient covalent bonding with nanoparticles. Furthermore, an MPTS–GPTS adhesion primer, whose index closely matched that of the low-refractive single layer, was inserted between the TiO2- and SiO2-derived layers in order to optimize interfacial adhesion. For the three single-layer components (low- and high-refractive index layers and primer), photoinitiators were used in order to promote polymerization of the MPTS and GPTS organic components during a postdeposition UV curing. The final multilayer coating was finally heat treated at 80 °C.

Oliveira et al. mentioned a rather good scratch resistance of their AR film (Eraser and Taber tests), i.e., despite a small overall thickness of the AR coating (around 200 nm), the scratch resistance of the coated polymer substrate was improved by 25% compared to the bare substrate. Scratch resistance was significantly enhanced in the presence of a 3 μm thick hybrid silica hard-coat containing AlOOH particles. The refractive index of this hard coat was adjusted by varying the AlOOH content in the silica matrix. The authors showed that a refractive index of 1.586 allowed total cancellation of colored reflections induced by the hard coat. Besides excellent antiscratch properties, this strengthened AR coating deposited on PC did not show any delamination or defects after boiling, ultrasonic, and NaCl tests, and excellent adhesion was proved in the cross hatch and tape test. The final multilayer coating exhibited a typical V-shape broadband AR spectrum, with a minimum reflectivity of 0.5% (instead of 5.2% for the bare PC substrate) at the 550 nm wavelength. Since the overall fabrication procedure implied a maximum temperature of 80 °C, the ARAS coating appeared to be compatible with the major part of usual technological plastic supports.

Rare Earth Doped Films

Context and Applications

Since the development of the erbium-doped fiber amplifier (EDFA) in the 1980s, the fast evolution of the optical telecommunication network has generated an increasing demand for optically active devices. This need has motivated particular efforts concerning the fabrication of compounds and devices doped with erbium, since the photoluminescence emission of this element is situated at 1.53 μm, in the center of the third telecommunication window, which nearly matches the minimum absorption region of optical fibers. More recently, this interest has increased again when the advantages of system integration, i.e., compactness and easiness of multifunction integration on a same chip, have promoted the need of erbium-doped thin films. Optical quality and easiness of film doping are two major assets of the sol-gel process, which have motivated extensive studies for applications in rare earth–based active optics. Erbium-doped sol-gel films have particularly been studied. However, the application field of rare earth–doped films is not limited to telecommunication devices. The initial research focused on erbium-doped sol-gel films has progressively been extended to many other rare earth elements, in the view to meet needs for integrated devices active in the visible or infrared range, i.e., integrated laser sources, sensors, displays, lighting devices, or integrated devices for medical applications. A review concerning rare earth–doped sol-gel films can be found in Jenouvrier et al. (2003).

Applications of rare earth–doped films in active optics primarily require a high light-emission efficiency. Furthermore, many applications (e.g., light amplification) necessitate long lifetimes of the emitting metastable states, which guarantee the necessary population inversion of energy levels. More generally, a long lifetime is an important criterion, which depicts that photoluminescence is not affected by any nonradiative parasitic mechanisms. These features rely on several issues. The first one is related to the use of low phonon energy host matrices, in order to prevent active ions from nonradiative recombination via matrix phonons, which can efficiently quench the luminescence. For sol-gel films, recombination via hydroxyl groups is a particular problem. For instance, two hydroxyl groups (phonon energy around 3300 cm−1) are sufficient to quench the luminescence of a single erbium ion (luminescence at 1.53 μm, i.e., 6500 cm−1). To prevent luminescence quenching via OH species, postdeposition heat treatments at high temperature are generally necessary, which promote the oxidation of remnant hydroxyl groups and the elimination of adsorbed water. Another important issue relies on size effects related to integration scaling. To achieve luminescence intensities comparable to what is obtained with existing devices, for instance rare earth–doped fibers or monolithic glasses, heavily doped films are required. This criterion implies that host matrices showing high solubility for rare earth ions have to be chosen. Indeed, when rare earth ions are not efficiently diluted, they tend to form clusters that promote a nearly total luminescence quenching, i.e., “concentration quenching,” due to detrimental short-range interactions between active ions.

Owing to their excellent optical quality, mechanical resistance, and thermal and chemical stability, sol-gel silica derived films were extensively studied for integrated amplifier applications. In that field, works performed by Orignac et al. on erbium or neodymium doped SiO2–TiO2 sol-gel films are particularly relevant (Orignac et al. 1996a, b, 1999; Orignac and Barbier 1997). However, doping levels remained rather weak because the erbium and neodymium ions have no particular affinity for the silica matrix and tend to share free oxygen available in the matrix and to easily form clusters. Clustering occurs all the more easily as high-temperature heat treatments (900 °C or more) are performed to eliminate hydroxyl groups. Furthermore, other parasitic ion-ion interactions such as cooperative upconversion or energy transfer are very likely to occur at high rare earth ion concentrations. Consequently, it has generally been considered that spectroscopic performances of rare earth–doped SiO2–TiO2 sol-gel films are too limited to envisage short-term applications as optical amplifiers (Ameida 1999; Yeatman et al. 1999). But these matrices remain of strategic interest for several other applications in active optics. Besides, limitations observed for SiO2–TiO2 matrices have motivated prospective studies of alternative sol-gel approaches, including silica matrices codoping, new silicate glassy matrix compositions, or nonsilicate matrix compositions, which broadens the application fields of rare earth doped sol-gel films (Jenouvrier et al. 2003). However, all these approaches implied rather high-temperature sintering of the films and were of no concern for applications on thermally sensitive substrates.

A low-temperature approach has recently been proposed by Que et al., which is based on the preliminary synthesis of crystalline rare earth compounds, followed by their dilution in a precursor sol that can be used for composite film deposition. Er2O3 (Que et al. 2001a, b) and Nd2O3 crystallites (Que et al. 2001c, d) were synthesized by a microemulsion method and subsequently embedded in a GPTS–SiO2–TiO2 organic/inorganic hybrid film. Interesting photoluminescence properties of such films were reported after heat treatment in a rather low temperature range of 100–300 °C. Besides the fact that this composite approach involves a low-temperature procedure, it benefits from two assets. Firstly, as rare earth ions are included in a crystalline environment, they are efficiently protected against interaction with phonons and hydroxyl impurities of the surrounding host matrix. Secondly, rare earth ions are located on well-defined crystallographic sites of the crystalline lattice, which prevents any aggregation effects that are usually observed in glassy host matrices. However, detrimental short-range distance interactions can still occur within the crystallites, because interatomic distances in the crystalline lattice are very short (Langlet et al. 2001b). Actually, it is very difficult to infer on the actual advantages of this composite film approach because Que et al. did not compare the spectroscopic performances of their films to that of reference samples. Furthermore, the authors mentioned crystallite sizes in the range of 5–60 nm. Biggest crystallites are very likely to cause optical losses in the film. This limitation appears particularly damning when waveguiding applications are intended. Crystallites are all the more susceptible to promote Raleigh scattering as the refractive mismatch between rare earth compounds and the silica-derived host matrix is important. In order to limit this effect, crystallite size has to be in the order of few nanometers (Fick et al. 2000). In that case, the benefit of the crystalline structure on the rare earth luminescence is partially lost, because a very important fraction of rare earth ions are located at the crystallite surface and can therefore interact with the surrounding matrix. In the present state, it seems therefore that low-temperature approaches involving rare earth doping at the molecular scale remain preferable. Following sections are devoted to such an approach.

Organic Encapsulation Approach

It is well established that rare earth elements readily undergo complexation with organic ligands (Sinha 1966). Numerous studies showed that such complexes exhibited very good luminescence properties, which were attributed to the intramolecular transfer between the organic ligand and the chelated rare earth ion. However, those complexes were excluded from practical applications, owing to their poor stability for moisture and heating as well as low-mechanical strength. By the end of the 1990s, the incorporation of rare earth complexes in sol-gel-derived matrices has been the object of extensive studies in order to overcome the limitations of pure complexes and to envisage applications such as phosphors or laser sources. These studies particularly dealt with the synthesis of bulk silica-derived gels processed at low temperature. Gels were heat treated at various temperatures below 300 °C depending on the thermal stability of the complex. Complexation was generally performed from rare earth nitrate or chloride precursors.

Several approaches were proposed, which led to the molecular scale dilution of the complexes into the gel matrix. A first approach consisted of preparing complexes separately, and then adding them to the solution containing the matrix precursor to form the final sol (Jin et al. 1995, 1997; Yan et al. 1998). In some cases, silica gels were doped by impregnation, i.e., they were immersed in liquid solutions containing the rare earth precursor and a complexing agent (Bekiari et al. 1999). However, the most commonly used approach consisted of an in situ complexation. In that case, the rare earth and organic ligand precursors are added separately to the matrix precursor solution and complexation takes place within the sol or during gel formation. This in situ method was proposed both for the fabrication of inorganic and hybrid organic/inorganic silica doped gels, and numerous rare earth/complexing ligand systems were studied. For instance, terbium salts were in situ complexed using salicylic acid (Fu et al. 1999), sulfosalicylic acid (Fan et al. 1999; Jenouvrier et al. 2001), bipyridyl (Guodong et al. 1997), phenanthroline (Zhang et al. 1999), or phtalic acid (Zhang et al. 1996). Photoluminescence measurements performed on so-doped gels generally demonstrated excellent spectroscopic properties. Yan et al. mentioned that the luminescence lifetime of silica gels doped with europium or terbium complexes were longer than those of pure complexes (Yan et al. 1998). This was due to the fact that the excitation energy of rare earth ions can be absorbed by vibrations of the ligand, while the rigid structure of the silica host limits such vibrations. On the other hand, the emission intensity of silica gels doped with terbium complexes was compared to that of gels doped without complex (Guodong et al. 1997; Jin et al. 1997; Fu et al. 1999). The photoluminescence intensity appeared to be about one order of magnitude greater in the presence of chelating ligand.

Two mechanisms account for the excellent photoluminescence properties of silica gels doped with rare earth complexes. Firstly, owing to the strong absorption of organic species in the UV range, the ligand acts as an antenna under near UV pumping. Under UV light irradiation, most organic compounds are excited into the S1 singlet state, and then decay through intersystem crossing to a T triplet state. If the energy level of state T is higher than the emission energy level of the rare earth ion, the energy absorbed by the organic compound is transferred to the chelated active ion. Thus, necessary conditions for an efficient photoluminescence emission are twofold. The excited level of the rare earth should be below the lowest triplet level of the organic ligand, and the lifetime of the triplet level should not be too short to achieve an energy transfer and not too long to effectively populate the rare earth excited level. This indirect excitation scheme is of great interest since absorption cross sections of organic ligands are much higher than that of rare earth ions. Indeed, the low pump absorption cross section of rare earth ions under direct pumping is another factor that usually limits their spectroscopic efficiency for active optics applications.

A second asset of the organic complexation method relies on encapsulation effects. Depending on the ligand nature, and provided that the complex is not decomposed by thermal treatment, rare earth ions are encapsulated into an organic cage and shielded from interactions with the host matrix. Thus nonradiative recombination via matrix phonons or hydroxyl groups can efficiently be prevented. Protection against hydroxyl groups is particularly relevant in the case of sol-gel compounds processed at low temperature where the amount of such groups is very important. Another beneficial effect of the organic encapsulation ensues from steric hindrance promoted by the chelating ligand. Encapsulated ions are thus efficiently protected from short-range distance interactions that usually quench the rare earth ion luminescence. To sum up, in silica gels doped with rare earth complexes, cage effects inhibit parasitic mechanisms that traditionally affect the photoluminescence of rare earth doped silica glasses.

Despite a promising potential, this doping method that is particularly well adapted to low-temperature processing has not yet been largely extended to thin films. The main raison probably arises from the film elaboration conditions that are often hardly compatible with the chemical stability of the complexes. In particular, pH effects significantly reduce the possibility to dope thin films with organic complexes, because acidic conditions promote the complex decomposition. Indeed, while silica gels can be processed in wide pH conditions ranging from acidic to basic pH, sol-gel films are preferentially deposited from acidic solutions. Such conditions promote the formation of short and linear species in the solution, which are more prone to compact during the liquid to solid transformation and promote the formation of denser films. Denser films present in turn better mechanical resistance, which is often an essential prerequisite for many applications. Besides, denser films exhibit weaker scattering losses induced by pores, which favors a better optical quality. Hence, studies concerned with the low-temperature processing of thin films doped with rare earth complexes are very recent and were restrained to punctual complexing ligands of suitable chemical stability. Precursor sols were generally processed in moderate acidic conditions, i.e., pH in the range of 2.0–4.0.

Sol-gel films have essentially been doped with europium and, to a lower extent, terbium complexes. Such a feature is not only due to the novelty of this film doping method but also to the fact that it presents some limitations. For instance, to our knowledge only one study reports on photoluminescence emission from sol-gel thin films doped with an erbium complex (Etienne et al. 2000). In that study, thin film samples containing erbium pentanedionate complex were heat treated at 120 °C and characterized from a spectroscopic point of view. It can be noted that rather noisy photoluminescence spectra were presented under 980 nm excitation. In this study, no antenna effect was expected because the active ion was directly pumped at its current IR excitation wavelength, without benefiting from the UV absorption of the organic ligand, which means that the functionality of the organic encapsulation was only to shield the erbium ion from the matrix. These data illustrate limitations of the rare earth complexation method for an element like erbium. Because the energy involved in the erbium infrared emission is very close to the vibration mode energy of hydroxyl groups, photoluminescence quenching resulting from resonant coupling is more likely to occur. The quantity of residual hydroxyl groups after a low-temperature heat treatment is too high, and screening by the organic cage is not efficient enough to prevent photoluminescence quenching. Furthermore, most organic ligands contain hydroxyl groups, which can influence the rare earth emission. Finally, the most efficient erbium ion absorption and emission lines are situated in the near-infrared range. The energy transfer between the organic ligand and the erbium ion is, therefore, less efficient than for e.g. terbium or europium ions that emit in the visible range, nearer to the UV ligand emission wavelengths. However, first studies performed on silica-derived films doped with europium or terbium complex illustrate the great potential of this doping method and open the door to further promising optimizations.

Low-Temperature Processing of Thin Films Doped with Europium Complexes

Europium ions complexed with bipyridyl (bipy) (Meng et al. 2000), phenanthroline (phen) (Li et al. 2001), dibenzylplymethane (DBM) (Meng et al. 2001), or thenoyltrifluoroacetone (TTFAH) (Hao et al. 1999), or cocomplexed with phen and DBM (Meng et al. 2001), were incorporated in silica-derived films and studied from a spectroscopic point of view All these works were primarily focused on the effects of a heat treatment on the luminescence properties. The red emission of europium complexes (5D0 → 7F2 transition of Eu3+ ions at λ = 613 nm) was reported to continuously increase in intensity with an increase in temperature up to a threshold value ranging from 80 °C to 150 °C, which depended on the ligand nature. Hao et al. have postulated that, because the sol is processed in acidic condition, only partially complexed species can be formed in the as-deposited films (Hao et al. 1999). When increasing the heat-treatment temperature, some H+ ions are progressively eliminated with the evaporation of residual water present in the film. The acidity of the gel gradually decreases and enhanced complexation occurs in the film. The other authors explained the thermally induced enhancement of the emission intensity by the elimination of solvated water, whose presence in the film inhibits the energy transfer from π–π* transition of the ligand to the central Eu3+ ion. In any case, it appears that the efficiency of the organic encapsulation is not optimum in the as-deposited film and requires heat treatment for optimization.

However, all the authors mentioned a rapid decrease of the luminescence intensity with further heating above the threshold temperature, which was attributed to the thermal decomposition of the complex. Among the different tested complexes, it seems that phenanthroline exhibited best thermal stability because no luminescence intensity decrease was observed up to 150 °C, which allowed more efficient water elimination. Accordingly, the best lifetime values measured on films doped with europium complex were reported by Li et al. for complexation with phenanthroline (Li et al. 2001). The lifetime characterized as the first e-folding decay time was measured to be 1.40 ms. However, these authors also mentioned a biexponential luminescence decay, which indicated that Eu3+ ions occupy two kinds of spectroscopic sites. This feature probably indicates that all Eu3+ ions were not similarly encapsulated in the phenanthroline cage.

The different authors have also investigated the influence of the host matrix. Meng et al. showed that a SiO2 sol-gel matrix provides a much efficient environment to europium ions than a purely organic one (Meng et al. 2000, 2001), which confirmed aforementioned results obtained for bulk gels. Not only the inorganic matrix restrains ligand vibrations, which are less prone to absorb the excitation and emission energies of europium ions, but it also confers an enhanced thermal stability to the complex. Accordingly, SiO2 films doped with bipy/Eu or phen/Eu complex exhibited much greater luminescence intensities and longer lifetimes than polymer films doped with the same complexes. Hybrid organic/inorganic silica host matrices were also studied (Hao et al. 1999; Li et al. 2001). Besides the advantages of hybrid films already cited in “Hybrid Organic/Inorganic Routes” of this chapter, such films exhibit particular features that make them of particular interest for active optics applications. Indeed, the organic component of hybrid films does not participate in hydrolysis/polycondensation reactions. Such films elaborated at low temperature present, therefore, a smaller content in hydroxyl groups or residual water, when compared to traditional sol-gel silica films elaborated at the same temperature. For this reason, hybrid films have often been considered as a host matrix for rare earth ions (Sanchez and Lebeau 2001).

Furthermore, we mentioned in “Hybrid Organic/Inorganic Routes” of this chapter that in the case of hybrid matrices, crack-free thick films of 1 μm or more in thickness can readily be deposited in a single deposition process. This feature reduces, therefore, the need of a time-consumable multilayer deposition procedure when micron-scale active films are required, e.g., for active planar waveguide applications. Li et al. also claimed that the vibrations of the organic ligand around europium ions were inhibited in the case of a hybrid matrix, which favored enhanced spectroscopic properties of hybrid films doped with europium complex (Li et al. 2001). Accordingly, these authors showed that an MPTS hybrid film doped with phen/Eu complex exhibited higher quantum efficiency and longer lifetime than silica films doped with the same complex.

Hao et al. also reported excellent spectroscopic properties of GPTS hybrid films doped with TTFA/Eu complex (Hao et al. 1999). They showed that the luminescence intensity was strongly enhanced when increasing the film thickness up to a threshold value of c.a. 8 μm, which illustrates the interest of hybrid organic/inorganic materials for the preparation of thick films. However, no enhancement of the luminescence intensity was observed with further thickness increase, because the whole excitation signal was completely absorbed by the complex within the surface layers and the deeper layers of the film were not excited. The authors also showed that the shape of the excitation spectrum evolved with increasing film thickness, from that measured on the precursor sol, for films of 1 μm or less in thickness, to that measured on bulk gels, when the film thickness reached the optimum threshold value. A similar spectrum evolution was also observed with increasing heat treatment temperature up to 130 °C, for which maximum emission intensity was measured. Excitation spectrum modifications and emission intensity increases were attributed to enhanced complexation of europium within the gel films.

Low-Temperature Processing of Thin Films Doped with Terbium Complexes

Some studies performed on silica derived films doped with terbium complexes confirmed results obtained for europium complexes. It was reported that green emission (5D4 → 7F5 transition of Tb3+ ions at λ = 545 nm) of terbium complexed with phenanthroline (Meng et al. 2000) or sulfosalicylic acid (Jenouvrier et al. 2001; Trejo-Valdez et al. 2003) was optimum when the film was heat treated at moderate temperature around 120–150 °C, after what the luminescence intensity dramatically decreased with further temperature increase. Meng et al. also confirmed good complexation effects in the case of phenanthroline (Meng et al. 2000). A lifetime of 1.23 ms was measured for a SiO2 film doped with phen/Tb complex, which had to be compared to 0.67 ms for a SiO2 film doped with bipy/Tb complex. The same comparison was made between silica and polymer hosts thin films doped with phen/Tb complex. The PL lifetime was measured to be only 0.12 ms for the doped polymer film.

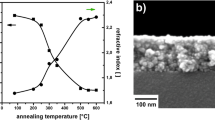

Inorganic SiO2–TiO2 and hybrid MPTS–SiO2–TiO2 films doped with terbium complexes were investigated in our department (Jenouvrier et al. 2001; Trejo-Valdez et al. 2003). The ability of thin films to guide light is very important for several integrated optics applications. In particular, when guiding properties on silica support are envisaged, a significant refractive index mismatch between the guiding layer and silica support is required to favor optimum planar light confinement. Such a refractive index control is readily achieved by TiO2 incorporation into silica-based films. For a 20SiO2–80TiO2 molar composition, a refractive index of 1.55 was measured at 633 nm wavelength both for inorganic and hybrid films doped with SSA/Tb complex. For multilayer inorganic films and single-layer hybrid films of 0.7 μm thickness, standard m-lines spectroscopy showed that two propagation modes (one TE and one TM) were supported at 633 nm, which evidenced the ability of our active films to guide light. Furthermore, we showed that MPTS–SiO2–TiO2 hybrid films doped with SSA/Tb complex could be UV imprinted, owing to the high photosensitivity of the MPTS component under UV exposure (Trejo-Valdez et al. 2003). This is another functionality that can be induced by the organic component in hybrid films. This result allows envisaging direct writing of channel waveguides or other integrated devices for active optics without etching and use of photoresist.

We studied the luminescence properties of inorganic SiO2–TiO2 and hybrid MPTS–SiO2–TiO2 films doped with SSA/Tb complex. Spectroscopic properties were compared to those of a silica bulk gel doped with the same complex. The luminescence emission spectrum of the terbium-doped films is composed of narrow lines at 490 nm (5D4 → 7F6), 545 nm(5D4 → 7F5), 580 nm (5D4 → 7F4), and 620 nm (5D4 → 7F3) (Fig. 3), which exactly match the emission lines measured on the bulk gel (Jenouvrier et al. 2001). However, the PL decay appears to be biexponential with a fast (FDC) and a slow decay component (SDC) (Fig. 3a). Time constants were determined to be c.a. 10 and 400 μs for the FDC and SDC, respectively. The corresponding photoluminescence decay in pure SiO2 bulk gels was single exponential with a lifetime of 450 μs (Jenouvrier et al. 2001), which fitted fairly well the SDC time constant measured on SiO2–TiO2 films. The biexponential luminescence decay measured on the films can be explained by less efficient screening or higher impurity concentration in the SiO2–TiO2 thin film samples than in pure SiO2. It is also possible that the TiO2 component detrimentally interacts with the rare earth complex. As our films are rather thin (0.7 μm thick), it is not excluded either that their luminescence properties undergo thickness effects similar to those reported by Hao et al. for hybrid films doped with TTFA/Eu complex (Hao et al. 1999).

More recently, we studied MPTS–SiO2–TiO2 hybrid films doped with alternative terbium complexes. Compared to films doped with SSA/Tb complex, the luminescence intensity is enhanced by a factor 4–5 in the presence of bipy/Tb or phen/Tb complex (Fig. 2b and c). Luminescence decay curves show that, in presence of these complexes, the FDC is much less pronounced than for SSA/Tb complex and it is characterized by much longer lifetimes of 0.090 and 0.230 ms for phen/Tb and bipy/Tb, respectively (Fig. 3b and c). The SDC time constant is similar to that measured on SSA/Tb doped films. Slowest decays were observed for bipy/Tb doped films, which might suggest that this complex is even more efficient than phen/Tb. This is a reverse trend from that reported by Meng et al. (2000). These authors also mentioned much longer lifetimes than those measured on our films and did not report any FDC. Such differences in the results are possibly due to the different matrices used. However, Meng et al. did not precisely detail their experimental conditions, e.g., film thickness, excitation wavelength, and time resolution for decay curve measurement. Direct comparison is therefore difficult. In particular, in a previous paper, we have pointed out the importance to measure decay curves with various time resolutions, in order to evidence possible FDC, and to precisely quantify FDC and SDC lifetimes (Langlet et al. 2002a). FDC was clearly influenced by the complex nature in our hybrid films when using a time resolution of 1 μs (Fig. 3). On the other hand, decay curves did not evidence any significant difference when using a time resolution of 20 μs. It might, therefore, be possible that in their experimental conditions, Meng et al. could not detect an eventual FDC.

Photoluminescence spectra of MPTS-SiO2–TiO2 hybrid films doped with (a) SSA/Tb, (b) bipy/Tb, and (c) phen/Tb complex. The Tb concentration and complex/Tb molar ratios are 2 and 1 mol%, respectively. Films were deposited using the aerosol–gel process (see Chap. 13, “Sol-Gel Processing of Fluoride and Oxyfluoride Materials” of this book) and heat treated at 150 °C. Spectra were collected under XeCl excimer laser excitation (λ = 308 nm). The spectral resolution is 0.4 nm

Photoluminescence decay curves (λ = 545 nm) of films illustrated in Fig. 2 doped with (a) SSA/Tb, (b) bipy/Tb, and (c) phen/Tb complex. Decays were measured under XeCl excimer laser excitation (λ = 308 nm). The time resolution is 1 μs

Photocatalystic Films

Context and Applications

The discovery by Fujishima and Honda that a TiO2 electrode promotes the photocatalytic splitting of water (Fujishima and Honda 1972), i.e., TiO2 electrode decomposes water to hydrogen and oxygen under photoillumination, has driven the photocatalysis field in the center of a worldwide attention. Since then, Bard et al. reported on the possibility of using TiO2 to photocatalytically decompose cyanide in water (Frank and Bard 1977). This new discovery considerably broadened the field of photocatalytic applications and promoted tremendous research efforts that aimed at understanding fundamental processes and enhancing the photocatalytic efficiency of semiconductor catalysts. So far it has been well established that titanium dioxide is the best candidate for photocatalytic applications (Serpone and Pelizetti 1989; Hoffmann et al. 1995; Herrmann 1999). Under UV-irradiation of photon energy greater than or equal to TiO2 band gap energy (e.g. hv > 3.2 eV for anatase, i.e., λ < 380 nm), electron–hole pairs are formed, which once dissociated, generate free photoelectrons and holes able to interact with organic matter present at a TiO2 particle surface. Thus, through a complex multistep heterogeneous photocatalytic process, an oxidative decomposition of organic molecules can be induced. Photocatalytic TiO2 films are specialty-coatings that are now commonly produced in glass industry (Saitou et al. 1997). Such films have been proposed for self-cleaning applications on architectural or lamp glasses. They are also considered for indoor environment atmospheres, as an odor-causing organic matter or toxic carbonyl products can be decomposed through a photocatalytic process. Furthermore, photocatalytic TiO2 films deposited on various kinds of supports have been proposed for the removal of aqueous pollutants, i.e., for water purification.

Since pioneering works performed in the early 1990s (for instance see Tunesi and Anderson 1991), sol-gel processing of TiO2 photocatalysts has been the subject of a continuously growing interest in several application fields. In particular, the sol-gel process is a versatile method for the preparation of optical quality photocatalytic TiO2 films, which has been reported in many articles. Good photocatalytic activities of such films require (i) an efficient photoinduced electron–hole pair generation, and (ii) an efficient charge separation, which necessitates a well-crystallized titanium dioxide phase and preferably the anatase polymorphic form (Herrmann 1999). Usually, well-crystallized sol-gel TiO2 films are obtained after a postdeposition thermal treatment at c.a. 350 °C or above. Over the past 10 years, numerous studies have been devoted to photocatalytic properties of sol-gel TiO2 films deposited on mineral substrates able to withstand such a heat treatment, including mineral glasses and fused silica (Doushita and Kawahara 2001; Hattori et al. 2001; Negishi and Takeuchi 2001; Smirnova et al. 2001; Yu et al. 2002; Sonawane et al. 2002). Such films have been proposed for indoor environment atmosphere (Romeas et al. 1999), self-cleaning glass (Romeas et al. 1999; Paz et al. 1995), and water purification applications (Fernandez et al. 1995; Wang et al. 1998).

As mentioned in “Antireflective Films,” polymer supports are now commonly replacing glasses in many application fields. To exploit photocatalytic properties of sol-gel derived titania films deposited on thermally sensitive substrates such as polymer supports, a crystallization occurring at low temperature is required. At the end of the 1990s, this target has become a major challenge subject in photocatalysis. In the following sections, procedures intended to meet such a purpose are described. The optical quality and mechanical resistance of films are also considered because they are needed in several application fields. For instance, self-cleaning transparent articles are a typical example of an application where it is required that the film does not modify the optical transparency of the substrate, even when no optical applications are intended. Besides, self-cleaning products do not exclude the necessity of occasional wiping, which can damage or even erase the coating when its abrasion resistance and adhesion to the substrate are not sufficient.

Treatments Under Water Exposure

Because sol-gel films processed at low temperature usually exhibit a significant amount of nonhydrolyzed alkoxy groups, which act as structural impurities and inhibit titanium oxide crystallization, several studies were devoted to low-temperature crystallization procedures under water exposure. Imai et al. reported on the possibility to crystallize sol-gel TiO2 and SiO2–TiO2 films at low temperature by film autoclaving under water pressure (Imai et al. 1997, 1999; Imai and Hirashima 1999). They mentioned a nanocrystallization for films autoclaved in the 60–180 °C thermal range. However, only results concerning films autoclaved at 180 °C were described, which is by far too high to envisage applications on thermally sensitive supports such as polymers. To explain the low-temperature crystallization of their films, Imai et al. proposed a mechanism based on three points: (i) presence of fragile Ti–O–Ti or Si–O–Ti bonds due to the initial strained state of the as-deposited xerogel network; (ii) cleavage of fragile bonds under water vapor effects with formation of Ti–OH bonds, and complementary hydrolysis of residual alkoxy groups; and (iii) structural rearrangements and polycondensation of so-formed Ti–OH bonds into a stable state leading to anatase nanocrystallites. These authors also mentioned that autoclaved films were brittle and easily removed from the substrates. The photocatalytic properties of their films were not studied.

Iketani et al. recently reported on the low-temperature crystallization of anatase/poly (dimethylsiloxane) (anatase/PDMS) hybrid films of good optical quality (Iketani et al. 2003). Films with PDMS concentrations ranging from 0 to 100 wt% were deposited on PMMA organic supports and subsequently heat treated at 100 °C for 1 h under a relative humidity of 60%. These authors did not mention how the films were heated and how they controlled the relative humidity. They did not either discuss the low-temperature crystallization mechanism, but it may be supposed that crystallization followed the same water-induced scheme as that proposed by Imai et al. Iketani et al. reported on a well-crystallized anatase phase for films with a PDMS content lower than 40 wt%. They also mentioned good photocatalytic activities of such films for the decomposition of methylene blue and acetaldehyde. However, because no comparison was done with relevant references, e.g., commercial anatase pigments or sol-gel anatase films crystallized at high temperature, it is difficult to infer the actual photocatalytic efficiency. These authors also pointed out the beneficial influence of the PDMS component for protecting the PMMA substrate from photocatalytic degradation induced by anatase crystallites.

More recently, new low-temperature autoclaving experiments were performed in our department (Langlet et al. 2002b). Sol-gel TiO2 films were autoclaved in the 90–140 °C thermal range under various water/ethanol atmospheres, in such a way that the whole pressure within autoclave could be controlled independently of the water partial pressure. The crystallization appeared to be thermally activated and favored by a higher water vapor pressure in the autoclave. However, too high water pressures led to a partial film delamination, which confirmed the brittleness mentioned by Imai et al. On the other hand, we found that optimal crystallization could be obtained for low water pressures in the range of 0.6–1.5 bars. Such water pressures could be reached for temperatures as low as 90–100 °C, which was compatible with processing of thermally sensitive polymer substrates. Furthermore, no film delamination occurred under low water pressures. Consequently, photocatalytic TiO2 films of excellent optical quality could successfully be deposited on mineral substrates (silicon wafers) but also on PMMA and PC organic supports. However, we also showed that crystallization in the autoclave was accompanied by a noticeable increase in the porosity, which reduced abrasion resistance of the films. The photocatalytic activities of films deposited on silicon wafers, evaluated by malic acid decomposition tests, appeared to be comparable to that measured on sol-gel anatase films crystallized at high temperature (Langlet et al. 2002b). The photoactivity of films deposited on polymers was about 40% lower than the activity measured for films deposited on silicon and autoclaved in similar conditions. However, this lower activity could not be correlated with any sample degradation. In particular, no photocatalytic decomposition of the organic support could be evidenced. Consequently, the lower activity observed on organic supports was attributed to multireflections of the UV radiation occurring within films deposited on silicon, which favored the creation of additional photoinduced electrons and holes.