Abstract

This chapter focuses on nuclear magnetic resonance relaxation, pulsed field gradients NMR, and magnetic resonance imaging applied to the characterization of dairy products and dairy processes. This chapter is an updated version of a previously published review (Mariette F. Nuclear magnetic resonance: principles. In: Fuquay JW, Fox PF, Mc Sweeney PLH, editors. Encyclopedia of dairy sciences. 2nd ed. San Diego: Academic Press; 2010). This chapter is organized in several parts. The first part provides an overview on the interpretation of water NMR relaxation and its application in dairy systems. It starts with diluted models where the diffusion exchange is fast and only chemical exchange and molecular mobility are considered. Next, the regime of slow diffusion exchange is considered and applications to concentrated and complex systems are discussed. The second part of this chapter focuses on the special case of fat relaxation in the liquid and solid states. The third part includes all the aspects related to the use of the pulsed field gradient NMR technique for water diffusion and molecular probe diffusion. The fourth part provides some insights into applications of magnetic resonance imaging.

This chapter is dedicated to Brian Hills for his impressive contribution to NMR science and its application in food.

Access provided by CONRICYT-eBooks. Download reference work entry PDF

Similar content being viewed by others

Keywords

- Casein micelle

- Sodium caseinate

- Whey protein

- Cheese

- Fat

- Gel

- Ice cream

- Cream

- Draining

- Curd

- High pressure

- Powder

- Ripening

- Solid fat

- Syneresis

- Rennet

- Water diffusion

- Probe diffusion

- Acidification

- Rennet

Introduction

Dairy systems are fascinating because they offer food scientists a large space of investigation to design new food products and/or ingredients for many applications [1]. To profit from these opportunities, several experimental techniques are used as standard methods, including the most sophisticated. Surprisingly, among all the techniques, NMR relaxation, NMR diffusion, and magnetic nuclear imaging are still only used by a few teams. The subject of this chapter is to illustrate the potential of these techniques. The first part of this chapter focuses on the interpretation of NMR relaxation and provides different examples of NMR relaxation used to model systems up to complex and real dairy products such as cheese or ice cream. The second part is dedicated to pulse field NMR for diffusion coefficient measurements, and the last part deals with MRI applied to dairy systems.

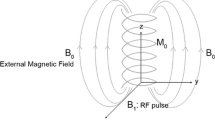

NMR Relaxation

H1 Relaxation in Dairy Protein System and Skimmed Milk

In diluted fat-free dairy systems, NMR relaxation is generally described as including two relaxing components [2, 3]: the component comprising nonexchangeable protons and the component including all exchangeable protons. The first component corresponds to protons from the CH2, CH3, and NH2 groups in dairy protein and lactose. The second group includes exchangeable protons from protein, lactose (OH and SH), and water.

In nonexchangeable proton relaxation, changes in T2 or T1 relaxation can be directly related to a change in the mobility of the molecule (rotational and segmental motion), explained either by composition or by a structural modification. In casein suspensions with different concentrations of casein, whey protein, and lactose, the nonexchangeable proton component was mainly explained by casein protons. More recently, Bouchoux et al. [2] compared the relaxation time of nonexchangeable casein protons for casein micelle and for sodium caseinate systems with concentrations ranging from 20 to 150 g/L. In the case of casein micelle dispersions, a high 1/T2 value of between 35 and 45 ms−1 was observed, which did not vary much with the concentration of casein up to 180 g L-1. Above this concentration, a slight increase was observed (Fig. 1). Conversely, below 80 g/L, the sodium caseinate T2 relaxation rate was low, between 5 and 10 ms−1, while for the 80–100 g/L range, a marked increase was observed. At concentrations above 100 g/L-1, the relaxation rates of casein micelle and sodium caseinate protons were similar. These results were related to the average compactness of the casein chains. Sodium caseinate is comprised of highly deformable small aggregates, whereas casein micelles are large aggregates with strong associative internal organization based on clusters of calcium phosphate. At low concentrations, the relaxation rate of sodium caseinate is slower than that of casein micelle because of the difference in the local mobility of the casein chain. When the casein concentration increases and approaches the close packing limit, the deformation and interpenetration of the casein chain explains the increase in the relaxation rate of sodium caseinate. In very concentrated systems, casein micelle and sodium caseinate had the same relaxation rate [2].

NMR relaxation of nonexchangeable protein protons. The relaxation rate 1/T2ne is plotted as a function of casein concentration for both casein micelle (squares) and sodium caseinate (circles) dispersions (From Ref. [2], reprinted with permission)

Differences between the nonexchangeable protein protons T2 depending on the state of the protein have also been reported in whey protein systems. For example, a biexponential relaxation T2 curve for a CPMG was measured in whey suspensions [4]. A component with a T2 which decreased from 3.9 to 1.28 ms when the concentration of whey protein increased from 1.79 to 44.66 g/100 g of water was attributed to nonexchangeable protein protons. After thermal aggregation, this component was no longer detected in the CPMG. The relaxation time was strongly reduced by thermal aggregation and only an FID would have enabled the detection of short T2 component.

The interpretation of the relaxation of exchangeable protons is more difficult since this parameter includes protons from different molecules (water, protein, and lactose) but also involves different NMR mechanisms. Several studies have been undertaken to understand the mechanisms which govern the variations in T2exch relaxation in food systems in general, and a general model has been proposed [5,6,7]. According to the pioneer paper by Hills et al. [5], this model considered bulk relaxation (or free water), hydration water relaxation, and exchangeable protons from protein and lactose. A fast chemical exchange occurs between the two water fractions and also between the hydration water proton and the exchangeable protons from nonaqueous molecules. For protein dispersion, this model is characterized by a linear relationship between relaxation and protein relaxation expressed through:

where a, b, and c refer to bulk water, hydration water, and exchangeable protein protons. T2i is the relaxation time of different proton states, Pi is their relative population, and kc is the rate of proton exchange. One of the main conclusions of this model is that T2exch measured experimentally is not a true measurement of water mobility, as was often assumed, and should not be interpreted in terms of less mobile or more mobile water [8]. Indeed, this term also includes information on macromolecule mobility [2, 9]. The relative importance of the water hydration relaxation term and the chemical exchange term between water and nonwater molecule has been discussed [5, 6]. In casein systems, the hydration term has a significant effect on the relaxation time T2exch. This was demonstrated by comparing the T2 variation in the dairy system with pH measured by 17O and 1H [3, 6]. Compared to 1H relaxation, NMR 17O relaxation only reflects changes in the molecular motion of water. The relaxation is thus given by the simple two-site model with free and hydration water in fast exchange. So, any change in 17O T2 could be interpreted either as a change in water mobility or as a change in the hydration water fraction, or both. Several authors observed a decrease in 17O relaxation time of water in skim milk when the pH decreased from 6.6 to around 5.3 [3, 6]. The same behavior was observed for 1H T2 relaxation, which confirms that hydration water has to be considered in casein systems. This result also highlighted the sensitivity of NMR relaxation time to casein micelle structure, which is discussed in Fig. 2.

NMR relaxation of both exchangeable protein protons and water protons plotted in a log − log scale and as a function of casein concentration in grams per gram of water. Casein micelle solution (squares) and sodium caseinate solution (circles). The dashed lines are guides for the eye (From Ref. [2], reprinted with permission)

A strong linear relationship has been observed between 1/T2 and the casein concentration by several authors [10, 11] and was confirmed in a wide range of casein concentrations [2]. The comparison of the 1/T2 linear relationships with protein concentration in different proteins showed that the same relationship exists, but there is a clear distinction between the absolute T2 value in casein micelle, sodium caseinate, and globular proteins such as whey protein or bovine serum albumin [2] (Fig. 2). These results show that a change in the amount of hydrating water cannot explain the data because it is known that hydration of sodium caseinate in gwater/gprotein is higher than the hydration of casein micelle, which is inconsistent with the T2 value measured. So, only a change in the relaxation time of hydration water or a change in the chemical exchange term kc and the relaxation time of exchangeable proton T2c could explain such differences. To explain the difference between the caseinate and micellar casein relaxation rate and the linear relationship between 1/T2 (which means that Pb, T2C, and Kc remain constant with concentration), Bouchoux et al. [2]. suggested that the parameters T2c and kc mainly depend on the loss of molecular mobility induced by direct casein-casein and casein-CaP interaction, as observed during protein aggregation, but remain constant despite a change in casein concentration. This is in agreement with the key role of the calcium phosphate cluster in the relaxation. The role of the calcium phosphate cluster in the chemical exchange mechanism was first demonstrated by investigating the effect of pH, the addition of a chelating agent to milk, or the addition of calcium and phosphorus to sodium caseinate [6, 12]. The calcium phosphate complex appears to locally affect the mobility of the casein chain and plays the role of a strong relaxing agent for the surrounding water molecules. Conversely, if casein micelles are coagulated by adding rennet, which does not modify the casein-casein interaction due to the calcium phosphate complex, no variation in the relaxation time of water and exchangeable proton is observed [12, 13]. Note that the slight variation reported by [12] is probably explained by an artifact of the fitting method. Indeed, two relaxation times with values of around 90 and 120 ms are extracted with a discrete multiexponential fitting method. Such close T2 values show that the water relaxation cannot be described by a Dirac function but needs to be interpreted as a continuous distribution [14]. Thus, the slight variation in the relative amplitude observed after 105 min of coagulation rather reflects the beginning of the shrinkage of the gel, than the change in casein micelle caused by renneting.

The sensitivity of 1/T2exch to the structure and the state of aggregation of whey protein was demonstrated by Indrawati on β lactoglobulin solutions [15]. By comparing the relaxation time T2 measured for β lactoglobulin gel and concentrated unfolded β lactoglobulin at the same concentration, Indrawati et al. showed that the change in T2 was directly related to the aggregation of the β lactoglobulin. The T2 decreased with an increase in the hydrodynamic radius, which is consistent with a decrease in the exchangeable protein proton T2. Thermal aggregation induced protein-protein interactions which consequently reduced the overall mobility of the protein as a function of the increase in the hydrodynamic radius. The same observations have been made for a milk concentrate solution at pH 5.3 processed by high-pressure homogenization at 300 MPA [16]. Samples with 4.2 g/100 g of casein exhibited particle sizes of 4–300 μm compared with 0.01–1 μm for sample with the same casein concentration with 3% added salt. The sample with the larger aggregates was also characterized by a short T2 < 80 ms (and a T1 of around 600 ms) compared with a T2 = 160 ms (T1 around 1 s) for the smaller aggregates.

Thanks to the sensitivity of the NMR relaxation time to casein structure, this technique has been extensively used during gel formation induced by thermal, high-pressure [16], enzymatic processes [12] or by a change in pH [3, 17]. The advantage of the NMR technique is the ability to monitor changes continuously to investigate kinetic effects.

Interactions between dairy protein and polysaccharides have also been investigated using T2 relaxation measurements. For example, Burgardt et al. [18] studied microstructural modifications of gelified caseinomacropeptide (CMP) with the addition of carboxymethylcellulose (CMC). Whatever the concentration of CMP, addition of CMC resulted in changes in the monoexponential T2. The modifications depended on the CMP:CMC ratio. At low CMP concentrations, a slight decrease in T2 was observed with an increase in the CMC, as expected. But at a concentration of 0.6 g.Kg−1, the T2 increased when CMC was added at a concentration of 0.025 g.Kg−1. In that case, the CMC had a plasticizing effect which weakened the CMP network [18].

Applications of NMR are not limited to casein systems and several studies have been performed on whey systems. The sensitivity of the T2exch to protein structure has also been used to investigate thermal denaturation of whey proteins [19], the effect of pH on gel structure [20], whey-polysaccharide interactions [21], and protein-protein interactions [22]. These changes have been reported in pure protein solutions as well as in complex formulation concentrates [8]. The formation of gel under high pressure has been investigated in a mixture of α-lactalbumin and β lactoglobulin [23]. The T2 relaxation curve was fitted using a three-exponential decay model, but the effect of gel formation was observed on the two major relaxation components. A significant decrease was observed for both T2 and their relative amplitude after high-pressure treatment, which could be attributed to a decrease in protein mobility and a change in the homogeneity of the sample, because the difference between the two T2 values decreased significantly (T2a = 12.6 ± 0.6 ms and T2b = 42.9 ± 0.7 ms in the solution and T2a = 17.5 ± 0.9 ms and T2b = 24.3 ± 1.9 ms in the gel).

T2 Relaxation Mechanism in a Diffusion-Limited System

The relaxation mechanism described above is only valid when the fast diffusive exchange limit has been confirmed. If the diffusion coefficient is slow compared to the relaxation rate, then the water molecule will not be exchanged and the NMR signals will be characterized by several components of water relaxation, each with its own relaxation time. The NMR signal is therefore given by Eq. (2)

In this case, each exponential term will be an NMR signature of the two local environments. The limit between the fast and slow diffusion regimes is given by \( \frac{a^2\Delta \left(\frac{1}{T_2}\right)}{D}\ll 1 \).

The change from a fast to slow diffusion regime is therefore a very sensitive way to detect slight modifications in the distribution of water in a sample. This change from single exponential was first reported in rennet gel [13]. Indeed, rennet gels are unstable and because of the gel shrinkage, a release of the whey, called syneresis, is observed. A soon as syneresis starts, the relaxation become biexponential and each component can be attributed to each water fraction, the water fraction expelled from the gel, and the water fraction confined in the gel shrunk [13]. The NMR method has been used to study the effects of chemical factors on syneresis such as ionic strength and pH, or physical factors such as temperature [1] and to simultaneously monitor the kinetic effects of lactic fermentation on casein destabilization and its consequences for the water retention properties of yoghurts [24], or to investigate the effect of the addition of polysaccharide on the water retention properties of milk drinks [14]. For example, Solomonsen et al. [14]. studied the effect of pectin on whey separation in acidified milk drinks. A narrow monoexponential T2 distribution was observed in samples with more that 0.3% of pectin, which corresponded to stable samples with no whey separation. Conversely, broad monoexponential T2 distribution was observed in samples with low or no added pectin but with clear whey separation. This change in the T2 distribution is clearly a signature of the heterogeneity of the gel sample related to the stability of the sample against whey release. This was illustrated by the influence of temperature on T2 relaxation. The samples were heated from 5 °C to 25 °C and then cooled to 5 °C. A reversible T2 variation was observed in samples with pectin, but a new T2 component with a T2 value above 1000 ms was detected in samples with a low concentration of pectin, due to expelled whey.

The sensitivity of water relaxation time to water distribution in porous samples was used to propose a new NMR method to characterize the water-binding capacity (WBC) of protein microparticles. WBC is commonly calculated from the dry matter of the protein suspension hydrated in excess water and the weight of a pellet after centrifugation to remove the surplus water [25]. This method assumes that the amount of water confined between the particles can be disregarded. Recently, Peters et al. [25] demonstrated that water relaxation in a pellet of whey protein microparticles can be described by two water relaxation times. The first T2 (10 ms) was attributed to the water inside the microparticles, and the second one (T2 = 100 ms) was attributed to the water between the microparticles. The authors then demonstrated that some variation in WBC determined by centrifugation can be explained by a change in the amount of the water confined between the particles and not by a change in the water inside the microparticles. The NMR method is consequently more accurate because it allows the quantification of the two water fractions separately.

Water-holding capacity can also be measured using a method based on washing out water using heavy water [26]. T2-experiments were performed before and after washing with D20. The reduction in the NMR signal is therefore proportional to the amount of water replaced and related to the water-holding capacity of the sample, assuming that the NMR signal for liquid fat protons is negligible.

Finally, the NMR method has also been proposed to monitor powder rehydration [27]. The advantage of the NMR method is that measurements are performed under stirring at a controlled temperature. As a consequence, the NMR method provides complete kinetics of the rehydration process and can be used whatever the composition of the powder. Moreover, due to the sensitivity of T2 to protein structure, the method also enables to discriminate the powder according to the denaturation of the protein induced by the preparation of the concentrate before drying and by the drying process itself.

Complex and Fatty Dairy Products

Analysis of the NMR relaxation time in concentrated dairy products such as cheese is very difficult to interpret because of the multiexponential relaxation behavior. This nonexponential behavior can have different origins: first, the composition of the cheese, so that the contribution of protons from different molecules, fat, protein, and water, has to be taken into account; second, the diffusion limited process, which, as mentioned above, can induce multiexponential behavior of the water phase; third, the experimental conditions of the measurement. For example, the choice of the number of points and the interecho spacing in the CPMG can considerably modify the number of components. For example, it was found two relaxing components in mozzarella cheese, one with a T2 of around 7 ms and a second one with a T2 of around 20 ms at 5 °C from a CPMG decay curve acquired up to 70 ms [28]. Conversely, in another study on the same system, four relaxation components were found from a CPMG curve acquired up to 4.8 s at 8 °C, the shorter one around 7.2 ms, the second one around 16 ms, the third one around 69 ms, and the longest around 488 ms [29]. Finally, the choice of the fitting method should also been considered. Care should be taken when using a nonlinear discrete method to process the relaxation curve. For example, in cream cheese with 6% fat content, around 79% moisture content, 0.4% salt content, and a pH at 4.4, a biexponential fitting was used with a first T2 at 54.3 ms and a second one at 126.7 ms with a relative intensity of 23.7% for the first component [30]. Conversely, when a continuous distribution method was used to fit the CPMG curve of a similar cream cheese with very similar composition (4% fat, 78.5% water, pH 4.17, and 0.17% salt), three relaxation times were obtained, T21 = 2.8 ms, T22 = 11.1, and T23 = 82.3 ms, with a relative intensity of 1.3%, 0.9%, and 96.1%, respectively [31]. The difference between the two results highlights the sensitivity of the results to the processing method and to the acquisition parameters, which, in turn, influence the interpretation of the data.

In cheese, the first attribution of the different relaxing component to the fat, protein, and water protons was proposed by [32]. The full range of relaxation was measured from a combination of free induction decay and a CPMG curve from 11 μs up to 4 s and fitted by the following equation:

To validate the attribution of the relaxation parameters to a specific proton molecule fraction, an approach was used based on the comparison of two cheeses, a soft cheese versus a hard cheese, the effect of changing the measurement temperature from 6 °C to 12 °C in order to change the solid/liquid fat ratio, and including measurements of the anhydrous fat extract from the same cheese. The conclusions were that the T2 at 17 μs mainly explained the solid fat fraction and partly explained the nonexchangeable protein protons, and the T2 at 100 μs was explained both by a fraction of the semisolid fat and protein proton. From the CPMG, the T2 of 13 ms for hard cheese and of 30 ms for soft cheese was mainly explained by the water phase, and the second component with a T2 of 13 ms for hard cheese and of 7 ms for soft cheese was attributed to liquid fat. The analysis of the relaxation distribution of the extracted fat in the liquid state showed a wide distribution of T2 from 7 to 30 ms at 6 °C. The complexity of the fat relaxation has also been reported in a cheese model [33, 34] and from D-T2 measurements of numerous dairy products [11]. From these studies, it appears that the water relaxation and the liquid fat relaxation are often superimposed and the different components cannot be attributed to fat or water separately. This observation was confirmed by T1-T2 or T2-D experiments [11] and also by water and fat saturation CPMG sequences [35]. Finally, a contribution of the protein proton to the CPMG signal could not be excluded [32]. It should be mentioned that the work reported by Chaland et al. [32] did not consider possible multiexponential behavior of the water protons, which introduced a higher level of complexity in the interpretation of the data. This multiexponential behavior has been reported in sheep cheese measured at 20 °C by using a CPMG with an echo time of 7.9 ms and including a fat suppression scheme measured at 300 MHz [35]. A bimodal T2 water distribution was observed with a first peak centered at approximately 9 ms and a second peak at 35 ms. A single peak characterized by a broader distribution between 20 and 100 ms attributed to fat was observed from a water-suppressed CPMG sequence curve. Biexponential behavior was also reported for water relaxation in cream cheese and in mozzarella cheese [29, 30]. The fast relaxation component with a T2 = 7.2 ± 0.8 ms was attributed to water molecules trapped in the casein. The relaxation component with T2 = 16.2 ± 0.1 ms was attributed to the water inside the mesh of the gel network, this value being controlled by diffusive exchange [29]. In nonfat cream cheese, a first T2 at 61.7 ms and a second one at 149 ms were obtained with a relative intensity of 57% for the first component. Changing the pH from 4.4 to 5.0 or changing the salt content from 0.4 to 0.9 resulted not only in a change in the T2 value but also in marked variation in relative intensity [30]. Such variations are a clear sign that in such a cream cheese, water relaxation should be considered as a wide T2 distribution reflecting a water diffusion regime induced by local heterogeneity in the water distribution, and should not be interpreted as being caused by different water mobility regimes.

Finally, when interpreting their results, several authors failed to mention a possible contribution of protein protons. It is known that the contribution of the exchangeable protein proton have to be taken into account and the changes in water T2 cannot be discussed in terms of bound or free water or water mobility as it was still previously reported.

Despite the difficulty in attributing the relaxation component, several investigations of cheese microstructure have been performed using NMR which demonstrated the high sensitivity of the technique. For example, NMR relaxation time measurements have been used to investigate the effect of pH on the casein gel structure of cream cheese [30, 31], the addition of emulsifying salt in processed cheese [36], changes occurring during heating [37], the effect of freezing [38], the effect of the different processing stages in the manufacture of imitation cheese, and the effect of starch in such processed cheeses [39]. Ripening has been also investigated by NMR. During ripening, the variation in T2 can be related to a change in protein mobility and hydration induced by pH and hydrolysis, and the migration of salt [35]. Changes in water distribution have been investigated in mozzarella cheese. For example, three water relaxation components have been identified in mozzarella cheese [29], one for serum water, the water accumulated in the large open channels of the protein network, one for the water inside the meshes of the casein gel-like network, and one for water trapped in the casein matrix. A decrease in the T2 from the serum was observed during aging, and was attributed to a change in the microstructure of the cheese induced by the rearrangement of the protein network. The effects of the composition of the surface of the fat globule on water-holding capacity have been studied in rennet-derived retentates [33]. Reconstituted fatty retentates were prepared from a fat-free retentate mixed with different fat-in-water emulsions stabilized with native phosphocaseinate (NPC) or sodium caseinate. The coagulation of retentate reconstituted with native fat globules (fresh cream) and industrial fatty retentate was also investigated. The results showed that fatty products reconstituted from fresh cream and the industrial retentate had less water-holding capacity than that obtained with native phosphocaseinate (NPC) or sodium caseinate emulsions. The high sensitivity of water relaxation to any change in the structure of the protein network has been also used to propose an NMR method to distinguish Sardinian sheep cheese made from heat-treated or raw milk [40]. Cheese made from heat-treated milk showed a significant difference in the relative intensity between the two water relaxation times. In heat-treated cheese, a high relative fraction (70–80%) for the water T2 around 9 ms was obtained compared to the raw milk cheese, for which the opposite was observed.

Dairy Powder

Only few studies have been performed on dairy powder [41]. In such systems, the complete relaxation decay curve should be measured with a combination of a free induction decay (FID) and the CPMG sequence [41]. The signal was described by a Gaussian exponential equation with a sinc function and an exponential equation:

where b is a constant, A1 is the proton of the solid fraction, A2 is the proton fraction of the mobile component mostly from water, and T21 and T22 are the corresponding relaxation times. The sinc term is used for systems with a highly structured solid phase which show a sinusoidal oscillation at the end of the Gaussian phase in the echoes. The second moment can be calculated according to:

The transversal relaxation time T21 of the immobile component as a function of the temperature difference from the glass transition temperature Tg remained relatively constant independently of the physical state (Fig. 3). Conversely, the T22 was very low for powder in the glassy state and increased considerably beyond the glass transition temperature (Fig. 4). Thus, the physical state has a major impact on the transversal relaxation time T22 of the mobile component. Moreover, crystallization led to a step increase of the second moment. From the second moment, the crystalline state can be distinguished from amorphous powders, i.e., glassy or rubbery in the case of model dairy powders. The power of NMR to characterize the chemical stability of dairy powders and to complement the stability concept based on the physical state was demonstrated [41].

Transversal relaxation time T2,1 of the immobile component as a function of the temperature difference from the glass transition temperature after heating the model dairy powder (From Ref. [41], reprinted with permission)

Transversal relaxation time T2,2 of the mobile component as a function of the temperature difference from the glass transition temperature after heating the model dairy powder (From Ref. [41], reprinted with permission)

Fat Relaxation

Measurement of Solid Fat Content

Among the NMR-based techniques used for quality control in the food industry, the solid fat content method is the most widespread. The technique can be used for quality control as well as for more exhaustive studies of the interactions (compatibility/incompatibility) that occur in fat mixtures containing vegetable oil and anhydrous milk fat to improve the formulations of butyric-based shortening and butter-like spreads [42]. Many improvements have been made since the first implementation of this basic method. It has been demonstrated that greater accuracy in the measurement of the solid fat content could be achieved by combining FID and CPMG acquisition. This method also takes the α and β polymorphic forms of the fat crystal into account. It simultaneously provides the solid fat content and the ratio of the α and β polymorphic forms in the crystal phase. An extension of the method has also been proposed to adapt it to emulsions [43, 44]. For such complex products, the solid fat content can be deduced after a full deconvolution of the NMR relaxation curves and by converting the mass fraction of each ingredient into a proton fraction using the proton density of each ingredient. Another extension of this method based on the rheo-NMR method has been proposed, with which the SFC content of anhydrous fat can be measured directly under shear, and the impact of the shear rate can be analyzed [45].

Polymorphism and Crystal Organization

Parallel to the development of these T2-based approaches, changes in T1 relaxation of the solid phase have been investigated [46]. For example, changes in T1 were observed during the storage of a model mixture consisting of a liquid and a solid triacylglycerol. Changes in T1 with storage time followed a power-law model which was related to the Ostwald ripening phenomenon, which corresponds to the melting of smaller crystals to form larger ones. An increase in the thickness of the crystals was suggested to explain the increase in T1.

The sensitivity of the T1 relaxation time of the organization of fat crystals has also been observed in fat mixtures with added surfactant and in food emulsions. For example, marked variations in T1 were observed as a function of the cooling rate of milk fat. A shorter T1 was observed for a faster cooling rate, and the T1 was reduced when surfactants were added, compared to the T1 from the dairy fat with no surfactant. In dairy emulsions, a change in T1 relaxation time of the fat crystal was observed depending on the maturation temperature of the emulsion. A narrow range of T1 was obtained with a maturation temperature of 4 °C, whereas a bimodal distribution was obtained with a maturation temperature of 12 °C. Changes in the T1 relaxation time of the crystallized fat phase have also been reported in ice cream mixes and in ice cream [47]. The T1 of the crystalline phase thus seems to be a very interesting parameter to investigate the behavior of food containing significant amounts of fat, since the fat crystal network gives food its physical properties.

Liquid Fat Phase and Crystal Network

The relaxation time of a mixture of lipids in the liquid state is characterized by a wide continuous distribution of relaxation times, in both T2 and T1, and is influenced by the length of the carbon chain and also by the amount of unsaturation, which complicates the interpretation of the relaxation times of the lipid phase [48]. Nevertheless, despite this wide distribution, a mean T2 value can be calculated which makes it possible to explain the expected relationship between the molecular mobility (reflected by T2) and the viscosity and chain length of the triacylglycerol. It should be pointed out that this relationship is only valid in a nonconstrained system, in other words in the absence of a crystal network. Indeed, in porous media, the spin-lattice relaxation time (T1) and the spin-spin relaxation time (T2) depend on interactions with the surface of the pores [48]. The T1 and T2 relaxation times at the surface are reduced by dipole-dipole interactions, cross relaxation, and chemical exchanges. Due to the surface relaxation mechanism, the relaxation times are shorter in pores with a high surface-to-volume ratio. This phenomenon was used to explain the behavior of the mean T2 value of a tricaprin in the liquid state in a tristearin crystal network during storage. In this situation, the amount of liquid phase remained constant and the change only depended on modifications to the specific surface area developed by the crystals. In dairy cream, the behavior of the T2 distribution of the relaxation as a function of the temperature has been reported [34]. The results revealed different behavior according to the low or high content of long-chain fatty acids in fat as function of temperature. The effect of the size of fat droplets was also considered to significantly contribute to the difference observed in the two fat samples at 31 °C. In that case, a surface relaxation mechanism explained by the droplet membrane was considered to explain the effect of the droplet size on fat relaxation. Of course, at 4 °C, the difference was smaller because the fat is partially crystallized.

NMR Diffusion

Water Diffusion in Dairy Suspensions and Gels

In addition to relaxation, water diffusion experiments are a unique way to investigate changes in water mobility. Many authors have reported monoexponential water diffusion decay in different dairy systems such as casein, caseinate, and whey protein suspensions [2, 4, 7, 49, 50]. All these results demonstrated a high degree of universality plus the fact that the casein structure had no effect on the water diffusion coefficient in a wide range of casein concentrations up to 500 g/l, and that water diffusion is not related to the rheological properties of the dispersion [2]. The slight differences between water diffusion in casein and in globular proteins such as whey protein can be explained by difference in hydrophobicity, since casein is an open structure and hence less hydrophobic than globular proteins. Moreover, no difference in water diffusion was observed regardless of the method used to prepare the gel, i.e., acid or rennet gel [3, 49]. However, heat treatment of the whey protein solution caused a slight reduction in water diffusion, which was explained by a change in the accessibility of the whey protein aggregates to water [4]. In the case of casein, overall accessibility to water was not significantly affected by the formation of a gel. It was concluded that water diffusion in protein systems follows a general trend whatever the protein system studied [2] (Fig. 5).

Concentration dependence of water self-diffusion: casein micelle solutions (squares), sodium caseinate solutions (circles), whey protein solutions (stars) (From Ref. [2], reprinted with permission)

The specific effects of casein and fat content on water diffusion have been described in a cheese model [33]. The experiments demonstrated that water diffusion was not only explained by the water content of the cheese model, as had been expected. The obstruction effects induced by the casein and the fat globules on the water diffusion differed. The reduction in the water diffusion coefficient was less with fat than with casein. This was explained by the internal diffusion of water molecules in the casein, which significantly reduced diffusion. A model describing the effects of water content on water self-diffusion was proposed. This model includes the effects of the composition of the aqueous phase, the obstruction effects of casein, and the effect of fat droplets on water diffusion. It requires no structural information on the gel network since no effect of the network structure has been observed, except when the water distribution inside the gel becomes heterogeneous and when the serum phase starts to release. This model was validated using information obtained from industrial cheese.

Thanks to the development of new algorithm for two-dimensional Laplace inversion, two-dimensional spectra-based T2-D acquisition spectra have been performed to improve the assignment of multiexponential relaxation behavior. The D-T2 distribution functions improved separation of the water and fat features because of the marked difference between the water diffusion and fat diffusion coefficients [11]. This separation was independent of the chemical composition. Such methods offer many opportunities for sample characterization [11, 51].

Diffusion has been often measured at a constant value of diffusion time, Δ, for the whole range of protein concentrations. For casein system, no variation has been reported in the diffusion coefficient for Δ between 20 and 200 ms up to a casein concentration of 0.19 g/g [49]. The same results have also been reported at higher concentrations [2], which confirms the presence of a free diffusion water regime in casein systems. Contradictory results were obtained in cheddar and mozzarella cheeses [37]. For such sample, a large variation has been reported for the water diffusion according to the diffusion time. This variation was explained by tortuosity effect of the porous matrix. In this study, relaxation measurements were done with a 300-MHz MRI scanner, and the relaxation of water was measured selectively with a CPMG based on the water frequency values. A biexponential fit was used and each T2 was assigned to different water fractions. A short component with a T21 between 9 and 14 ms was associated with the fraction of water, while the longer T22 with a value around 100 ms was associated to the water in a free state. This component contributed significantly to the diffusion experiment as the echo time for diffusion measurement was 3.8 ms. The attribution of the second component to water is questionable since no variation was reported between the cheese samples despite their different water content. Moreover, a strong linear T22 variation during heating was reported. The T2 value range is compatible with fat relaxation and the temperature dependency was the same for the cheddar and mozzarella cheeses which is expected for fat relaxation. Moreover, this component represented a larger fraction in cheddar cheese which is surprising since the amount of water is less for this sample compared to the mozzarella cheese. Therefore, pollution from the fat signal cannot be underestimated. So, we assumed that this component can be attributed to a residual fat signal as observed previously [40] and contributed to the time diffusion experiment which should not be related to tortuosity effect.

In gels with 15% whey protein concentrate prepared from commercial whey protein isolate, biexponential decays were observed for the ratio of the stimulated echo amplitude with and without applied field as a function of the diffusion distance Δ [52]. Two diffusion coefficients were computed, a free water self-diffusion coefficient and a restricted water diffusion, and changes in the measurement temperature were discussed in terms of changes in the porosity of the gel systems and changes in the composition of the solvent phase.

Probe Diffusion in Dairy Systems

From the works cited above, water diffusion experiments do not appear to be a very sensitive way to obtain microstructural information about dairy products. This explains why the majority of the diffusion studies on dairy products have been based on measuring the diffusion of polymer probe molecules of different molecular weights. One of the most commonly used probe molecules is polyethylene glycol (PEG). A first group of studies was performed on whey protein systems and casein systems [53]. The main findings of these studies showed that diffusion of the probe was affected by (i) the protein concentration, PEG diffusion decreases with increasing protein concentration, (ii) PEG diffusion decreases with increasing polymer size (Fig. 6), and (iii) the state of the matrix (solution or gel), PEG diffusion increases after coagulation.

Plot of the normalized PEG self-diffusion coefficient in casein suspensions versus casein concentrations for different PEG molecular mass. Full lines are only guides for the eyes (From Ref. [53], reprinted with permission)

Other studies showed that the PEG diffusion coefficient for PEG molecular weights above 8440 g/mol in a casein gel was strongly dependent on the structure of the casein network [54]. Marked variations in PEG diffusion were obtained between rennet gel, acidic gel, and the gel obtained by a combination of both processes. A kinetic NMR probe diffusion approach was proposed to investigate changes in the microstructure of the sample, which provided a way to distinguish between the change in the casein aggregate size and the change in the network porosity [55]. The effect of casein microstructure was extensively investigated by comparing the reduced diffusion coefficient of PEG in casein micelle and sodium caseinate [56]. The biggest reduction was observed in a sodium caseinate suspension, because of the difference in the size of the casein particles and the entanglement of the systems. The deformability of the probe was also investigated in casein and caseinate systems by comparing PEG diffusion and a nondeformable dendrimer probe with the same hydrodynamic radius (Fig. 7) [57]. The results showed that the deformability of the probe has to be taken into account above a casein critical interaction concentration C*. Above C*, the diffusion coefficient of the nondeformable probe is significantly reduced compared to that of the deformable probe. When the critical casein concentration limit is reached, NMR probe diffusion can be used to investigate the porosity of the casein particle itself.

Comparison of reduced self-diffusion coefficients of 0.1% w/w of PEG3.16 (▲)/PEG7 (•) and G2.84 (○); G3.51 (Δ)/G6.27 (◊) dendrimers in relation to casein concentrations in NPC suspensions measured at T = 20 °C (From Ref. [57], reprinted with permission)

Finally, a combined experimental approach including the simultaneous measurement of the translational mobility of the probe from diffusion experiments and the rotational or local mobility measurement from T2 experiments was proposed [58]. Different relaxation behavior was observed in casein and sodium caseinate systems and a delay in T2 relaxation time was highlighted in rennet and acid casein gels. These results were interpreted in terms of changes in the local mobility of the matrix itself.

Pulsed field gradient NMR has been also used to investigate casein diffusion in a casein system [49, 59]. For example, the diffusion of casein particles was monitored during the renneting of a concentrated casein micelle suspension [59]. This study showed that the self-diffusion of both casein particles and soluble caseins can be determined simultaneously, and that changes can be linked to the key stages of coagulation process. Two diffusion coefficients were also measured in sodium caseinate and attributed to soluble casein compounds and casein particles [56]. The sizes of the casein particles estimated by the Stokes Einstein relation were consistent with the casein size distribution determined by dynamic light scattering in both casein micelle and sodium caseinate systems. The variation in the normalized diffusion coefficient as a function of the casein concentration was investigated in the two casein systems and discussed assuming a noninteracting hard sphere diffusion model. Below the critical interaction concentration limit, the results were consistent in the two systems. Above this concentration of casein, the noninteraction hard sphere model failed and entanglement and interpenetration had to be taken into account.

Magnetic Resonance Imaging

Among all the NMR-based methods, magnetic resonance imaging has been poorly developed in dairy science despite the fact that the technique has a wide range of possible applications.

The first group of applications focuses on the development of MRI protocols to obtain water and fat distribution in dairy products or for the determination of casein concentration in dairy products in unopened packages [60]. Several NMR parameters are used to determine water content, e.g., proton density and spin-spin relaxation time T2, since both depend on water content. The T2- or the T1-based approach is usually preferred over gray level-based methods, since these methods are less sensitive to variations in gray level caused by the nonuniformity of the coil used for excitation and acquisition of the MRI signal. Other methods based on the differences in resonance frequency between fat and water protons have been proposed to provide water- or fat-suppressed images. However, the accuracy of their absolute quantification remains to be evaluated. These methods have been used for the determination of water distribution during the draining of curd [1], to simultaneously monitor the release of calcium and the swelling of sodium caseinate isolate suspended in the aqueous solution [20, 21], and to monitor changes in feta cheese during brining [61].

The second group of applications focuses on the determination of the macroscopic structure or organization of cheese. This approach was first used to quantify the morphology of holes by MRI. More recently, a 3D MRI method combined with an image processing algorithm was proposed for the characterization of individual eyes in semihard cheeses [62]. It was successfully used to evaluate the number, volume, and spatial distribution of eyes. Investigation of individual eye characteristics during ripening allowed differentiation of eye behavior. The MRI method made it possible to highlight the effects of a salt gradient and of a water gradient on the spatial heterogeneity of eye growth [63]. A dedicated setup was developed for the simultaneous measurement of pressure and volume in a single eye of semihard cheese [64]. Finally, criteria computed from texture analysis methods were also used for the classification of soft cheese as a function of the processing conditions, and to predict the sensory textural properties of the cheese. Other examples focused on the determination of rind thickness and analysis of the structure of blue-veined cheeses.

The third group of applications exploits the sensitivity of T2 water relaxation to changes in the molecular dynamics of protein. For example, this property has been exploited for the study of cheese ripening [35] and the effects of freezing-thawing on dairy gels. As explained previously in the NMR section, a change in T2 can be related to a change in the structure of the protein network caused pH or by heat treatment of milk. For example, a method combining MRI measurement with multiexponential analysis of water proton magnetization decay was able to differentiate cheese made from heat-treated milk cheese from cheese made from raw milk [40]. Other MRI applications focus on the effect of temperature on cheese. For example, differences between unfrozen pasta filata and non-pasta filata were noted in the T2 histogram. After a freezing-thawing process, the T2 histogram was modified and this effect depended on the original structure of the cheese and also on the storage time, the differences being explained by the microstructure of the gel, and by the damage to the protein structure caused by the freezing-thawing process. The structural changes that occurred during heating of mozzarella and cheddar cheeses were also investigated using T2-MRI map images. The images showed large areas of fat aggregations within the cheddar structure after being heated at 65 °C and cooled back to 20 °C, but no macroscopic fat clusters were visible in the T2-MRI map image of the mozzarella sample [37]. Finally, other applications used the specific effect of paramagnetic ions such as manganese on water relaxation to investigate the uptake of divalent ions in whey protein gel immersed in a water solution [65].

Future Trends

The NMR and MRI applications described in this chapter confirm the potential for noninvasive characterization of the effects of dairy processing and how information about composition, internal structure at different scales, and molecular mobility can improve our understanding of the mechanisms involved in dairy formulation and engineering. Whatever the NMR or MRI protocol used, the relaxation mechanism should always be taken into consideration. This a crucial step in dairy production not only because of the high sensitivity of water relaxation to the concentration and structure of casein, as well as the structure of the casein network, but also because dairy products contain often a significant amount of fat which complicates the interpretation of relaxation data and is therefore often a source of complication that results in errors. However, because dairy products and dairy ingredients offer a wide range of applications, and because NMR and MRI are always the subject of new developments, the combination of the two will provide fascinating new results in the near future.

References

Mariette F. Nuclear magnetic resonance: principles. In: Fuquay JW, Fox PF, Mc Sweeney PLH, editors. Encyclopedia of dairy sciences. 2nd ed. San Diego: Academic Press; 2010.

Bouchoux A, Schorr D, Daffe A, Cambert M, Gesan-Guiziou G, Mariette F. Molecular mobility in dense protein systems: an investigation through 1H NMR relaxometry and diffusometry. J Phys Chem B. 2012;116(38):11744–53.

Moller SM, Whittaker AK, Stokes JR, Gidley MJ, Andersen U, Bertram HC. Molecular water motions of skim milk powder solutions during acidification studied by 17O and 1H nuclear magnetic resonance and rheology. J Agric Food Chem. 2011;59(18):10097–103.

Colsenet R, Mariette F, Cambert M. NMR relaxation and water self-diffusion studies in whey protein solutions and gels. J Agric Food Chem. 2005;53(17):6784–90.

Hills BP, Takacs SF, Belton PS. A new interpretation of proton NMR relaxation time measurements of water in food. Food Chem. 1990;37:95–111.

Mariette F, Tellier C, Brule G, Marchal P. Multinuclear NMR study of the pH dependent water state in skim milk and caseinate solutions. J Dairy Res. 1993;60(2):175–88.

Gottwald A, Creamer LK, Hubbard PL, Callaghan PT. Diffusion, relaxation, and chemical exchange in casein gels: a nuclear magnetic resonance study. J Chem Phys. 2005;122(3):034506.

Hinrichs R, Gotz J, Noll M, Wolfschoon A, Eibel H, Weisser H. Characterisation of different treated whey protein concentrates by means of low-resolution nuclear magnetic resonance. Int Dairy J. 2004;14(9):817–27.

Le Dean A, Mariette F, Marin M. (1)H nuclear magnetic resonance relaxometry study of water state in milk protein mixtures. J Agric Food Chem. 2004;52(17):5449–55.

Mariette F. NMR relaxometry and MRI for food quality control application to dairy products and processes. In: Belton PS, Gil AM, Webb GA, Rutledge D, editors. Magnetic resonance in food science: latest developments. Cambridge: Royal Society of Chemistry Special Publications; 2003. p. 209–22.

Hurlimann MD, Burcaw L, Song YQ. Quantitative characterization of food products by two-dimensional D-T2 and T1-T2 distribution functions in a static gradient. J Colloid Interface Sci. 2006;297(1):303–11.

Hinrichs R, Bulca S, Kulozik U. Water mobility during renneting and acid coagulation of casein solutions: a differentiated low-resolution nuclear magnetic resonance analysis. Int J Dairy Technol. 2007;60(1):37–43.

Tellier C, Mariette F, Guillement JP, Marchal P. Evolution of water proton nuclear magnetic relaxation during milk coagulation and syneresis – structural implications. J Agric Food Chem. 1993;41(12):2259–66.

Salomonsen T, Sejersen MT, Viereck N, Ipsen R, Engelsen SB. Water mobility in acidified milk drinks studied by low-field H-1 NMR. Int Dairy J. 2007;17(4):294–301.

Indrawati L, Stroshine RL, Narsimhan G. Low-field NMR: a tool for studying protein aggregation. J Sci Food Agric. 2007;87(12):2207–16.

Sorensen H, Mortensen K, Sorland GH, Larsen FH, Paulsson M, Ipsen R. Dynamic ultra-high pressure homogenisation of whey protein-depleted milk concentrate. Int Dairy J. 2015;46:12–21.

Mok C, Qi J, Chen P, Ruan R. NMR relaxometry of water in set yogurt during fermentation. Food Sci Biotechnol. 2008;17(5):895–8.

Burgardt VDD, de Oliveira DF, Evseev IG, Haminiuk CWI, Waszczynskyj N. Addition of carboxymethylcellulose in gelified caseinomacropeptide systems: NMR, X-ray diffraction and rheology. J Food Nutr Res. 2012;51(4):207–16.

Goetz J, Koehler P. Study of the thermal denaturation of selected proteins of whey and egg by low resolution NMR. LWT Food Sci Technol. 2005;38(5):501–12.

Oztop MH, Rosenberg M, Rosenberg Y, McCarthy KL, McCarthy MJ. Magnetic Resonance Imaging (MRI) and relaxation spectrum analysis as methods to investigate swelling in whey protein gels. J Food Sci. 2010;75(8):E508–E15.

Wichchukit S, Oztop MH, McCarthy MJ, McCarthy KL. Whey protein/alginate beads as carriers of a bioactive component. Food Hydrocoll. 2013;33(1):66–73.

Celebioglu HY, Gudjonsdottir M, Meier S, Duus JO, Lee S, Chronakis IS. Spectroscopic studies of the interactions between beta-lactoglobulin and bovine submaxillary mucin. Food Hydrocoll. 2015;50:203–10.

He JS, Mu TH, Guo XS, Zhu SM, Azuma N, Kanno C. Comparison of the gel-forming ability and gel properties of alpha-lactalbumin, lysozyme and myoglobin in the presence of beta-lactoglobulin under high pressure. Food Hydrocoll. 2013;33(2):415–24.

Hansen CL, Rinnan A, Engelsen SB, Janhoj T, Micklander E, Andersen U, et al. Effect of gel firmness at cutting time, pH, and temperature on rennet coagulation and syneresis: an in situ H-1 NMR relaxation study. J Agric Food Chem. 2010;58(1):513–9.

Peters J, Vergeldt FJ, Van As H, Luyten H, Boom RM, Van der Goot AJ. Time domain nuclear magnetic resonance as a method to determine and characterize the water-binding capacity of whey protein microparticles. Food Hydrocoll. 2016;54:170–8.

Hinrichs R, Gotz J, Noll M, Wolfschoon A, Eibel H, Weisser H. Characterisation of the water-holding capacity of fresh cheese samples by means of low resolution nuclear magnetic resonance. Food Res Int. 2004;37(7):667–76.

Davenel A, Schuck P, Mariette F, Brule G. NMR relaxometry as a non-invasive tool to characterize milk powders. Lait. 2002;82(4):465–73.

Kuo MI, Gunasekaran S, Johnson M, Chen C. Nuclear magnetic resonance study of water mobility in pasta filata and non-pasta filata Mozzarella. J Dairy Sci. 2001;84(9):1950–8.

Gianferri R, D’Aiuto V, Curini R, Delfini M, Brosio E. Proton NMR transverse relaxation measurements to study water dynamic states and age-related changes in Mozzarella di Bufala Campana cheese. Food Chem. 2007;105(2):720–6.

Andersen CM, Frost MB, Viereck N. Spectroscopic characterization of low- and non-fat cream cheeses. Int Dairy J. 2010;20(1):32–9.

Moller SM, Hansen TB, Andersen U, Lillevang SK, Rasmussen A, Bertram HC. Water properties in cream cheeses with variations in pH, fat, and salt content and correlation to microbial survival. J Agric Food Chem. 2012;60(7):1635–44.

Chaland B, Mariette F, Marchal P, De Certaines J. H1 nuclear magnetic resonance relaxometric characterization of fat and water states in soft and hard cheese. J Dairy Res. 2000;67(4):609–18.

Metais A, Cambert M, Riaublanc A, Mariette F. Influence of fat globule membrane composition on water holding capacity and water mobility in casein rennet gel: a nuclear magnetic resonance self-diffusion and relaxation study. Int Dairy J. 2006;16(4):344–53.

Bertram HC, Wiking L, Nielsen JH, Andersen HJ. Direct measurement of phase transitions in milk fat during cooling of cream – a low-field NMR approach. Int Dairy J. 2005;15(10):1056–63.

Mulas G, Anedda R, Longo DL, Roggio T, Uzzau S. An MRI method for monitoring the ripening of Grana Padano cheese. Int Dairy J. 2016;52:19–25.

Chen L, Liu H. Effect of emulsifying salts on the physicochemical properties of processed cheese made from Mozzarella. J Dairy Sci. 2012;95(9):4823–30.

Vogt SJ, Smith JR, Seymour JD, Carr AJ, Golding MD, Codd SL. Assessment of the changes in the structure and component mobility of Mozzarella and Cheddar cheese during heating. J Food Eng. 2015;150:35–43.

Kuo MI, Anderson ME, Gunasekaran S. Determining effects of freezing on pasta filata and non-pasta filata Mozzarella cheeses by nuclear magnetic resonance Imaging. J Dairy Sci. 2003;86(8):2525–36.

Noronha N, Duggan E, Ziegler GR, O’Riordan ED, O’Sullivan M. Inclusion of starch in imitation cheese: its influence on water mobility and cheese functionality. Food Hydrocoll. 2008;22(8):1612–21.

Mulas G, Roggio T, Uzzau S, Anedda R. A new magnetic resonance imaging approach for discriminating Sardinian sheep milk cheese made from heat-treated or raw milk. J Dairy Sci. 2013;96(12):7393–403.

Schmitz-Schug I, Gianfrancesco A, Kulozik U, Foerst P. Physical state, molecular mobility and chemical stability of powdered dairy formulations. Food Res Int. 2013;53(1):268–77.

Danthine S. Physicochemical and structural properties of compound dairy fat blends. Food Res Int. 2012;48(1):187–95.

Duval FP, van Duynhoven JPM, Bot A. Practical implications of the phase-compositional assessment of lipid-based food products by time-domain NMR. J Am Oil Chem Soc. 2006;83(11):905–12.

Mariette F, Lucas T. NMR signal analysis to attribute the components to the solid/liquid phases present in mixes and ice creams. J Agric Food Chem. 2005;53(5):1317–27.

Mazzanti G, Li MY, Marangoni AG, Idziak SHJ. Effects of shear rate variation on the nanostructure of crystallizing triglycerides. Cryst Growth Des. 2011;11(10):4544–50.

Adam-Berret M, Riaublanc A, Mariette F. Effects of crystal growth and polymorphism of triacylglycerols on NMR relaxation parameters. 2. Study of a tricaprin-tristearin mixture. Cryst Growth Des. 2009;9(10):4281–8.

Lucas T, Le Ray D, Barey P, Mariette F. NMR assessment of ice cream: effect of formulation on liquid and solid fat. Int Dairy J. 2005;15(12):1225–33.

Adam-Berret M, Boulard M, Riaublanc A, Mariette F. Evolution of fat crystal network microstructure followed by NMR. J Agric Food Chem. 2011;59(5):1767–73.

Mariette F, Topgaard D, Jonsson B, Soderman O. H-1 NMR diffusometry study of water in casein dispersions and gels. J Agric Food Chem. 2002;50(15):4295–302.

Maruyama Y, Numamoto Y, Saito H, Kita R, Shinyashiki N, Yagihara S, et al. Complementary analyses of fractal and dynamic water structures in protein-water mixtures and cheeses. Colloids Surf A. 2014;440:42–8.

Castell-Palou A, Rossello C, Femenia A, Simal S. Simultaneous quantification of fat and water content in Cheese by TD-NMR. Food Bioproc Tech. 2013;6(10):2685–94.

Gotz J, Zick K, Hinrichs R, Weisser H. Characterisation of carrageenan and whey protein gels using NMR PGSTE diffusion experiments. Eur Food Res Technol. 2004;218(4):323–32.

Colsenet R, Soderman O, Mariette F. Effect of casein concentration in suspensions and gels on poly(ethylene glycol)s NMR self-diffusion measurements. Macromolecules. 2005;38(22):9171–9.

Le Feunteun S, Mariette F. Impact of casein gel microstructure on self-diffusion coefficient of molecular probes measured by 1H PFG-NMR. J Agric Food Chem. 2007;55:10764–72.

Le Feunteun S, Mariette F. Effects of Acidification with and without rennet on a concentrated casein system: a kinetic NMR probe diffusion study. Macromolecules. 2008;41(6):2079–86.

Salami S, Rondeau-Mouro C, van Duynhoven J, Mariette F. PFG-NMR self-diffusion in casein dispersions: effects of probe size and protein aggregate size. Food Hydrocoll. 2013;31(2):248–55.

Salami S, Rondeau-Mouro C, van Duynhoven J, Mariette F. Probe mobility in native phosphocaseinate suspensions and in a concentrated rennet gel: effects of probe flexibility and size. J Agric Food Chem. 2013;61(24):5870–9.

Salami S, Rondeau-Mouro C, Barhoum M, van Duynhoven J, Mariette F. Translational and rotational diffusion of flexible PEG and rigid dendrimer probes in sodium caseinate dispersions and acid gels. Biopolymers. 2014;101(9):959–65.

Le Feunteun S, Ouethrani M, Mariette F. The rennet coagulation mechanisms of a concentrated casein suspension as observed by PFG-NMR diffusion measurements. Food Hydrocoll. 2012;27(2):456–63.

Alekseev GV, Khripov AA. Method of rapid remote control of casein concentration in dairy products in unopened packages. J Food Process Eng. 2015;38(1):11–8.

Altan A, Oztop MH, McCarthy KL, McCarthy MJ. Monitoring changes in feta cheese during brining by magnetic resonance imaging and NMR relaxometry. J Food Eng. 2011;107(2):200–7.

Musse M, Challois S, Huc D, Quellec S, Mariette F. MRI method for investigation of eye growth in semi-hard cheese. J Food Eng. 2014;121:152–8.

Huc D, Roland N, Grenier D, Challois S, Michon C, Mariette F. Influence of salt content on eye growth in semi-hard cheeses studied using magnetic resonance imaging and CO2 production measurements. Int Dairy J. 2014;35(2):157–65.

Grenier D, Laridon Y, Le Ray D, Challois S, Lucas T. Monitoring of single eye growth under known gas pressure: magnetic resonance imaging measurements and insights into the mechanical behaviour of a semi-hard cheese. J Food Eng. 2016;171:119–28.

Oztop MH, McCarthy KL, McCarthy MJ, Rosenberg M. Monitoring the effects of divalent ions (Mn+2 and Ca+2) in heat-set whey protein gels. LWT Food Sci Technol. 2014;56(1):93–100.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2018 Springer International Publishing AG, part of Springer Nature

About this entry

Cite this entry

Mariette, F. (2018). NMR Relaxometry and Imaging of Dairy Products. In: Webb, G. (eds) Modern Magnetic Resonance. Springer, Cham. https://doi.org/10.1007/978-3-319-28388-3_38

Download citation

DOI: https://doi.org/10.1007/978-3-319-28388-3_38

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-28387-6

Online ISBN: 978-3-319-28388-3

eBook Packages: Chemistry and Materials ScienceReference Module Physical and Materials ScienceReference Module Chemistry, Materials and Physics